By Rose Eaton, Light Metal Age.

In a village in Norway called Sunndalsøra, nestled between a crystal blue fjord and two massive mountain ranges, lies Hydro Sunndal, the largest primary aluminum plant in Europe and one of the most modern. Overabundant water flowing down the mountains and the deep-sea fjord have provided the area with great potential for industry to thrive due to the capacity for hydroelectric power and easy access for cargo ships.

In 1913, construction of the power plant to supply the aluminum smelter began, and in 1954, the smelter began production with a capacity of 40,000 tonnes and 474 employees. The town has evolved alongside the plant. Most of the surrounding industry and all who live there are linked to the Hydro plant in one way or another. In fact, the locality is so integrated with Hydro, that more than 90% of all the municipal and a considerable amount of private buildings, swimming pools, and sports facilities in the town are heated through pipes carrying thermal energy produced from the smelting process.

The Hydro Aluminium AS Research and Development (R&D) center and Hycast AS, the casthouse technology company, are located just adjacent to the Sunndal primary production. These three branches of Hydro work together and form an interdependent feedback loop of aluminum science, innovation and production (Figure 1). ”The cooperation between these companies is the key to innovation and to bringing good equipment or technology to the market,” said Ola Furu, head of Projects and Sales, Hycast. “In what we call a competence triangle, we have been able to do things that really affect the whole of Hydro.”

Hycast uses a full-scale testing casthouse to test their new technology at the R&D center, which is steps away. Once their innovations are ready, they are installed in the Sunndal primary production area, where Hydro operators first pilot the technology in real time before it enters the external market.

Sunndal Statistics

The original Søderberg plant with 300 electrolytic cells was operational until 2002. In 1969, production capacity was doubled to 120,000 tonnes, when a modern prebake plant (SU3) with 168 cells became operational. Between 2000 and 2004, the Hydro Sunndal plant was modernized and production expanded. The Søderberg plant was phased out and a new prebake plant (SU4) phased in, with 340 cells based on Hydro’s own HAL250 prebake carbon anode technology, which made significant environmental emission improvements, even considering the almost double increase in production.1

At the same time, the capacity of the casthouse was increased through the establishment of new casting production lines. Support facilities were also upgraded to meet new environmental and quality requirements. In 2021, the total production of primary aluminum at Hydro Sunndal was 423,000 tpy and 66,000 tpy of anodes. Additionally, in the finished goods category, it produced 144,000 tpy primary foundry alloy and 315,000 tpy of extrusion ingot. Today, there are 675 employees in the plant itself and a total of 850 overall, including the R&D center, Hycast AS, and the other Hydro offices on the property.

Research and Development

The R&D center at Sunndal houses 40 employees, who work with extrusion ingots, foundry alloys, and various other projects that focus on product development and optimizing operations at Hydro casthouses. The R&D center also carries out quality control for Hydro casthouses, such as taking samples of billet to verify a stable process and consistent quality. If there are trends in certain negative directions, the R&D team can suggest actions to be taken by the casthouses.

The R&D center has a well-equipped metallographic and material testing laboratory to also support customers with technical service and troubleshooting. “For example, with the scanning electron microscopes, you can analyze defects of a product in detail,” said Stig Brusethaug, R&D manager at the research center. “Is it an impurity or an inclusion? If it’s an inclusion, you can analyze what kind of elements are in it and where that might come from. Our electron scanning microscopes are key instruments in our technical support work.”

The role of the R&D center is extremely varied. For the development of new alloys for the market, they often work on different types of projects together with the customers or end users. This can be either small tasks or larger projects over several years aimed at finding solutions and optimizing the use of aluminum in different applications. “As for casthouse technology development, there is a very close cooperation between Hycast and the R&D center, where Hycast utilizes our capabilities to also do development, prototype testing, and evaluation of equipment and its performance,” said Brusethaug. “The dynamics between Hycast and R&D through our facilities form an integrative new way to develop technology.”

Casthouse Technology

Hycast was formed in 1990 as a spinoff from Hydro’s R&D center. The casthouse solution company provides safe, cost-effective, and innovative technologies to improve casthouse processes. Before Hycast was formed, the R&D center would have ideas for products and technologies, but didn’t have the people to take it from the drawing board and transform it into a workable and marketable technology. When Hycast was formed, its main purpose at first was to only supply cutting edge technology to Hydro. While supplying Hydro with melt refining and casting technology is still Hycast’s main goal, now they additionally market to other companies.

“We decided we would like to expose our products to the world to see whether we are actually competitive, and the best test is if other companies also like it,” said Furu. “Ever since 2009, we have been working hard on trying to gain market share, and we have seen tremendous growth. We would not be the same company without being exposed to the external market. It has been important to learn and to gain more experience from a wide variety of customers to help improve our products and technologies. Of course, we have a special link to Hydro, and we will always be its technology and development partner.”

Hycast strongly believes that open innovation by being exposed to the global market is the best way of keeping innovation moving forward. “If you are a closed company sitting in your basement trying to impress the world, you might do it,” said Furu, “but it’s more likely that you will succeed if you communicate your theories and technologies to others.”

Hycast has 60 employees, headed by Ola Ulvund who was raised in the town. “Growing up here in Sunndal in some way you have to relate to aluminum because it’s so important in this local society that working in this industry is extremely natural for me,” Ulvund explained. “Life here has always depended on the fluctuations in the aluminum industry, and in that way we are a global city.”

Hycast has been expanding. In 2019, Hycast established a standalone entity in China where Ulvund is also head of the board. “China produces 50% of the aluminum in the world, and to be a serious player in China, we needed to have feet on the ground,” he said, “it will be an important market.”

The next step was to establish a sales office and representative in the U.S., especially due to the new Hydro Cassopolis plant in Michigan. Moreover, the company has customers in the aluminum valley in Quebec, Canada, and are looking into India, where they established a first contract with Vedanta in 2021. India is a place where the company sees aluminum growth taking off.

Together with Hydro Sunndal and the R&D center, Hycast innovates, plans, project manages, installs, and commissions complete DC casting lines (Figure 2). However, for the construction of Hycast’s equipment, the company works with a number of local suppliers that are able to provide steel welding and fabrication services. Since Hycast is nearby, they can drop in at any time to oversee the progress of their equipment as it is being built at the nearby supplier companies.

Complete and Safe

Instead of focusing on only one part of the casting process, Hycast provides turnkey solutions from the exit of the furnace through to the casting machine, so their equipment can integrate seamlessly in the casthouse. The company already has an outstanding safety record, with no recorded fatalities at producers using their equipment since its inception. Fully automating their equipment will bring them closer to the goal of zero injuries accrued. From their headquarters’ close proximity to Hydro, and working closely with the R&D center, Hycast has the tools at their disposal to build complete, safe casting lines using knowledge gained from real time experience.

“Together with Hydro, we are working very hard to remove all personnel in hazard zones. Getting operators away from all the metal or other dangerous places in the casthouse is key,” said Furu. “For instance, we designed the launder system well, so you don’t need personnel running around paddling the liquid metal at the end of the cast anymore.”

Billet Casting Technology

Hycast’s original gas cushioning billet casting technology has been used in Hydro casthouses for over 30 years. It provides great flexibility with module-based casting tables, wide diameter and alloy ranges, outstanding pit recovery, and excellent and consistent surface quality. The company’s more recent low pressure casting (LPC) system offers an even higher standard in surface quality.

During the LPC process casting unit lids close and seal over the mold table. Once the lids are closed, the mold height is adjusted until it is even with the level of aluminum in the trough. Aluminum is then siphoned from the launders into the casting system, ensuring accurate metal level control in the molds with one control dam and one laser. Since the metallostatic pressure is kept close to zero, the melt remains stable throughout the casting process, preventing segregation of the alloying elements and minimizing oxide formation. The process provides full control of the temperature, water, and other parameters, which makes it possible to reduce cooling intensity within the mold, resulting in a shallow shell zone, as well as aiding in lowering the segregation zone and achieving the smooth billet surface.2

Capable of producing forging stock in several diameters, the LPC technology has been installed in several casthouses around the world, where it has been proven to provide excellent surface quality for all alloys and dimensions of extrusion billets. Rio Tinto’s Arvida casthouse in Quebec, Canada, was the first to introduce Hycast’s LPC technology in North America.

At Hydro’s casthouse in Husnes, Norway, the LPC technology was further developed to produce smaller diameter forging stock. Since the surface quality is very smooth and the surface segregation is close to zero, the cast forging stock may be forged without requiring any scalping of the surface. It also eliminates the need for homogenization prior to forging. As a result, material costs for a forged part can be reduced by about 20%, making forged aluminum suspension parts less costly to produce.3

New Pit-Monitoring System

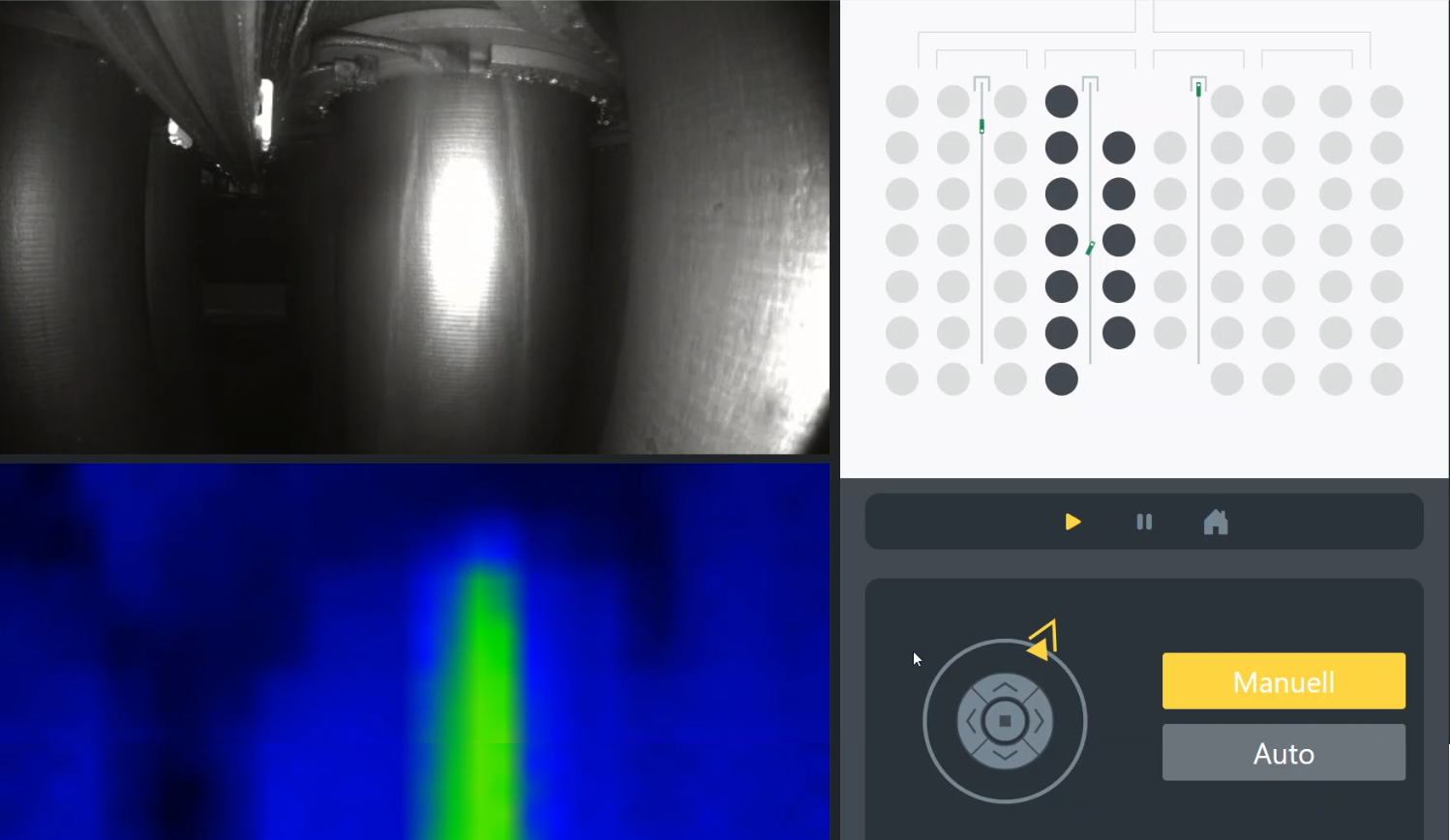

To increase safety and process control at Hydro’s new state-of-the-art recycling plant in Cassopolis, MI, Hycast is introducing a pilot of its new pit-monitoring system. The company believes the system will be a “game changer.” Operating automatically and wirelessly, it will provide personnel with a live overview of billets being cast. This will be accomplished with a torch light camera that will travel a course along the inside tracks of the logs to see if there are oxides or defects forming on any parts of the billet (Figure 3). This will eliminate the need for manual inspection at the pit, removing operators from dealing directly with molten metal, and therefore increasing safety.

Additionally, the system will continuously monitor the billet throughout the casting process, allowing any potential defects to be discovered early. The units will be equipped with thermal sensors, allowing for potential early bleed out detection based on metal surface temperature. The control software, which was built from the ground up for the system, has many functions. It allows users to control each unit individually, get an overview of particular sections of the casting table during production, turn lights on or off, mark hot billets, take a photo for records at any point in the cast, and show thermal and position data, etc. “Should the system be proven in operation at Cassopolis, the possibilities are endless in regards to software functions, defect predictability, and machine learning,” said Arild Hakonsen, head of Technology, Hycast.

Environmental Development Agenda

Besides their focus on safety and health, Hydro’s main focus is to take the leading position on sustainability in the aluminum market. The company has the goal of net zero carbon by 2050 or earlier and 70% of Hydro’s primary production is already based on renewable energy. Hydro wholly or partially owns and operates 17% of the hydroelectrical power production in Norway, producing electricity for many of its own aluminum plants. Combined, they produce about 9 TW hours of electricity per year.3 The overall strategy involves investing and growing in other renewable energy systems—not only hydroelectric power, but wind farms, solar power, and hydrogen production. Most recently, Hydro is expanding its global network of recycling plants to help meet its goal of a zero carbon footprint.

“We have a broad technology development agenda to meet the decarbonization target, including carbon capture, zero emission primary production (HALZero), advancing post consumer scrap recycling, etc. A key technology development for recycling is sensor-based scrap sorting, enabling the separation of various alloys,” said Stig Tjøtta, head of technology, Hydro. “Today, we are able to be above 75% and we have the ambition towards 100% post-consumer scrap recycled content in our aluminum.”

Electrification of heavy vehicles within its smelter and casthouse is one of the top priorities at Sunndal, which currently has 36 operational vehicles (Figure 4) with an annual diesel consumption of 1.3 million liters. The first step of the program includes exchanging eight vehicles, which will result in a reduction in diesel consumption of approximately 200,000 liters annually. This will not only improve the carbon footprint, but will also affect the work environment through reduced noise levels from the vehicles, and less emissions within the buildings. In addition, Hydro has begun using AGVs and digital twin technology, automating many of their operations in the process using digital predictive maintenance.

Part of Hydro’s plan for the future is the collaboration with local high schools and universities, helping students learn about aluminum and learning from the new generation. They partner with leading universities, including the nearby university of Trondheim that has a department exclusively devoted to aluminum. Hydro is happy to have students come experience and learn at the plant, and even have interns during the summer. The local vocational education and training school also is a funnel for students into the company. By keeping the younger generation in the aluminum loop, the industry will be sure to have fresh ideas and minds for years to come.

Feedback Loop

Several times a year, the top technology experts from Sunndal primary production sit with the researchers from R&D and Hycast at a workshop, where they review the future needs of the plant and what the teams should be focusing on. With discussions back and forth, they take a list of dozens of items and prioritize the most important amongst them into a shorter list. The companies work together so that the list not only makes sense for Hydro, but also for Hycast.

In this competence triangle, Hydro operators can voice their needs, and Hycast can take it to the drawing board. After the equipment is built, R&D can test it and make suggestions to improve it, and then Hydro can pilot the technologies in a reactive and functional feedback loop. This level of collaboration creates a rare kind of harmonious synergy that keeps aluminum innovation in the forefront at Hydro Sunndal.

References

- Benedyk, Joseph C., “Phase 1: Sunndal Smelter Commissioned Ahead of Schedule,” Light Metal Age, February 2003, p. 46.

- Svendsen, Andrea, “Arvida Casthouse Upgrades with Revolutionary Billet Casting Technology,” Light Metal Age, April 2018, pp. 16-21.

- Tundal, Ulf, Knut Omdal Tveito, Sigrun Sofie Berg, Lars Moen, Magne Boge, Arild Håkonsen, and Rune Ledal, “Low-Pressure Casting Technology Represents Step Change in Producing High Quality Forging Stock,” Light Metal Age, December 2020, pp. 24-29.

Editor’s Note: This article first appeared in the February 2023 issue of Light Metal Age. To receive the current issue, please subscribe.