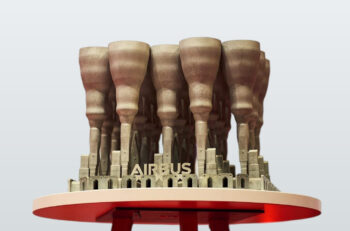

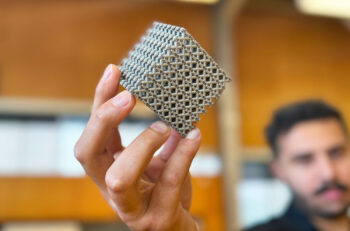

Researchers at RMIT University in Melbourne, Australia, developed a new 3D-printed metamaterial (an artificial material with unique properties not observed in nature) from a common titanium alloy. The metamaterial is said to achieve a level of strength to weight that is not available in current manufacturing. It is expected to be used in a wide […]