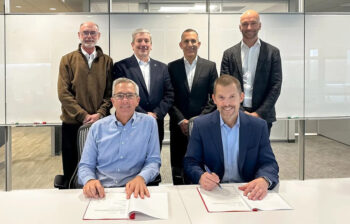

Hydro entered a multi-year agreement with Sims Alumisource to purchase processed aluminum scrap for its North American extrusion business. Hydro is the largest producer of aluminum billets in North America, with 12 recycling facilities in the U.S. and Canada. Hydro and Sims Alumisource have previously worked together to refine the processing of post-consumer aluminum scrap […]