Latest

-

Alumtek Minerals (AM), based in Australia, recently completed research and development on bauxite residue waste, commonly known as red mud, which has resulted in the development of a technology to extract critical raw materials. Following a collaboration with Cement Australia, AM developed a supplementary cementitious material (SCM) that meets the stringent Australian Standard AS3582.4 and has […]

-

Profilglass S.p.A. started up production its new 6-high cold rolling mill and high bay coil storage system at its plant in Fano, Italy. The new mill will enable the production of AA1xxx, AA2xxx, AA3xxx, AA4xxx, AA5xxx and AA6xxx alloy strip to serve demanding industrial sectors, including the automotive, construction, and shipyard industries. Supplied by MINO, […]

-

Hydro Extrusions recently expanded its extrusion operation in Rackwitz, Germany, with the installation of a third extrusion press line, which was officially put into operation at the end of 2023. The €11 million project includes a 22 MN, 8 inch upcycled extrusion press, along with an energy efficient aging oven—representing a solid investment in the […]

-

Alumobility, the global association committed to advancing the adoption of aluminum in the automotive industry, partnered with Porsche to complete a new joint study, entitled “Aluminum Lightweight Study: A Conversion of the Porsche Taycan Top Hat from Mixed Material to an Aluminum Design.” “For us at Porsche it is a great benefit to get state-of-the-art […]

-

Aluminum extrusion is at the core of several furniture designs — including lamps, vases, chairs, coat stands, shelving systems, and room partitions — presented at Milan Design Week, going on this week (April 16–21) in Italy. These beautiful, anodized designs were part of a challenge that Hydro presented to seven world renowned designers. Each of […]

-

Posted in:

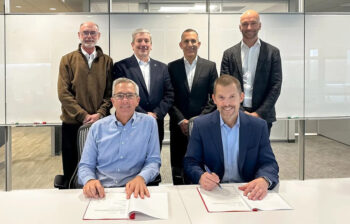

Constellium and PyroGenesis to Jointly Develop Plasma Torch Technology for Aluminum Melting

Constellium signed a partnership agreement with PyroGenesis Canada Inc. to test the use of plasma torch technology at one of Constellium’s casthouses. This will support the company’s decarbonization goals. “As part of our decarbonization roadmap, Constellium has been evaluating various solutions to support the decarbonization efforts within our aluminum casthouses. The plasma torch technology has the […]

-

Jupiter Aluminium Industries (JUPALCO), a newly established aluminum factory within the Jupiter Group, ordered three furnaces for annealing aluminum coils for its new rolling mill in India. The new rolling mill will provide the highest production of aluminum coil in India’s history, as well as create an ecosystem of comprehensive aluminum-based solutions that are Made […]

-

Hydro entered a multi-year agreement with Sims Alumisource to purchase processed aluminum scrap for its North American extrusion business. Hydro is the largest producer of aluminum billets in North America, with 12 recycling facilities in the U.S. and Canada. Hydro and Sims Alumisource have previously worked together to refine the processing of post-consumer aluminum scrap […]

-

Vista Metals, located in Adairsville, Georgia, introduced the largest forging ingot in the western world. This billet was developed to supply aluminum forging applications serving the needs of the aerospace, industrial, and power generation sectors. The new forging ingot — cast at a 52-inch (1,321 mm) diameter with a weight of approximately 50,000 lbs (22,680 […]