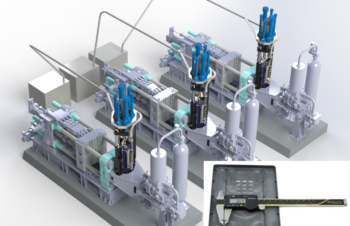

Hydro Extrusions recently expanded its extrusion operation in Rackwitz, Germany, with the installation of a third extrusion press line, which was officially put into operation at the end of 2023. The €11 million project includes a 22 MN, 8 inch upcycled extrusion press, along with an energy efficient aging oven—representing a solid investment in the […]