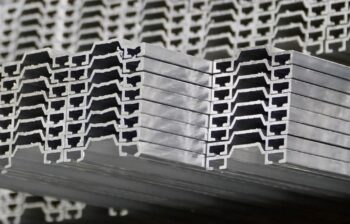

Matalco Inc. completed the construction and startup of its seventh remelt facility, located in Franklin, KY, which will operate under the name Matalco Kentucky LLC. The $65 million investment represents the company’s third new plant project in the last eight years. The new plant will focus on the production of rolling ingot — affirming the […]