By Andrew Halonen, Mayflower Consulting, LLC.

Vehicle construction has always been a multi-material story. Instrument panels are comprised of plastic, foam, and metal, while seats are made from leather or fabric covering foam on a steel structure. Looking under the hood, the engine block is often made of cast iron with cylinder heads made of cast aluminum mounted to the top. In the body structure, there tends to be monolithic materials, with either steel or aluminum sheet in form of stamped or rolled components to form the inner and outer panels of the vehicle, typically referred to as the body-in-white (BIW).

As manufacturing and material innovations progress, engineers are challenging the status quo to achieve advancements in performance and cost efficiency. A recent example is the Ford Mustang Mach-E, an electric vehicle with a steel body combined with extruded aluminum front and rear crash management systems.

In parallel to finding the optimal material for each function within the vehicle, the timeline to develop and produce the new models, particularly electric vehicles, has been greatly reduced from five years to less than two years. With such a short development timeline, how are OEMs able to quickly manufacture a great car with new multi-material construction? Often, they will either stick to what they know or will work with suppliers who are able to provide expertise on how to join the materials in a quick, automated, and reliable process.

The automotive aluminum extruders in Europe and North America are hearing a common demand from vehicle OEMs — either provide the means to join extrusions to mating materials at assembly line speeds or risk having the OEMs choose another solution for their vehicles. Assembly line speeds vary, but for the number one selling vehicle in America, Ford is able to manufacture and have a new F-150 pickup come off the production line every 53 seconds.1

Methods of Joining Extrusions

Aluminum extrusions are the epitome of efficiency, providing easy to integrate features to satisfy a specific performance requirement, such as hollows for stiffness or energy absorption. They also ensure low density, consistent thin walls, and leak-free chambers, while being easy to machine. Despite the value of extrusions they rarely exist in isolation on a vehicle, which means they need to be joined to and integrated with adjacent components to form an assembly. The extrusion may be joined to another aluminum extrusion, sheet panel, or casting, or it could be joined to other materials, such as magnesium, steel, polymer, or composite.

“For aluminum extrusions, sheet, and castings, the success of the joint is highly dependent on the alloy, the joint design, and the joint strength needed,” said Marc Auger of Coherent, a laser welding company. “We have welded these combinations and have many examples in production.”

Similarly, during projects at 3M Automotive, a major focus was to make sure that the bond area of the joint was prepared for a successful application. Many times, developing a proper joint was further complicated by the production process and the fact that the automotive line seldom stops.

There are many methods to join extrusions and one way to distinguish them is by temperature, whether they are a cold or hot process. Cold joining methods are those applied with no heat input, while hot methods require heat to be effective.

Hot Joining Technologies

Hot joining methods are those in which either external heat is applied or heat is generated during the process to form the bond. In regards to processes that require external heat, metal inert gas (MIG) welding is a popular and very common method for joining extrusions. Welding material companies understand what base materials are best for a joint and can provide expertise in joint preparation, as well as weld filler material selection.

Magna, who is one of the world’s largest Tier 1 suppliers, is credited in commercializing cold metal transfer (CMT) welding, a process developed by Fronius (Figure 1).2 CMT is able to weld faster and with less energy. It is also capable of bonding steel to aluminum in order to maximize the performance benefits of each material. Meanwhile, Lincoln Electric commercialized a low heat-input process called AC Precision Pulse™, which advertises a speed increase of 40% over standard DC pulse MIG welding.3 In addition to providing increased speeds, both of these new welding methods are designed to address the burn-through issue, a common problem with high heat welding methods, particularly as the walls of the extrusions become thinner. Limiting the heat also limits distortion, a critical need on the kinds of long, straight extrusions needed for EV battery boxes.

Resistance spot welding (RSW), also known as spot welding, has been the high-volume joining method of choice for steel construction for about 100 years. With the growth in aluminum body structures comes the need to develop equally fast joining techniques. RSW for aluminum is used today to join aluminum sheet panels, as well as to join aluminum panels to steel sheet panels.

Friction stir welding (FSW) has gained significant ground as a method of joining extrusions (Figure 2). Although it is achieved with no external heat source, once the insert begins to spin and the metal flows, it becomes very hot. FSW can be performed on long sections. It can also be performed on a single point, which is called a friction spot weld.

Laser welding is a newer method, which has recently reached production. It can be used to join aluminum extrusions to aluminum sheet or castings, or can also be used to join steel to aluminum. Coherent Inc. has demonstrated the application of laser welding, achieving the joining of aluminum extrusions to stampings (both being 6000 series alloys).4 The company has also welded 7000 series aluminum to 6000 and 5000 series aluminum sheet.

A challenge with the welding processes is when materials change during product development, such as when switching from steel to aluminum, as this will change the welding parameters, which can alter the speed of assembling the vehicle. Even when changing from a soft aluminum alloy to a hard aluminum alloy, the welding parameters need to be adjusted. These kinds of changes are not quickly realized.

Raheel Kahn of Lincoln Electric also mentioned that even different filler alloys have different electrical conductivities based on their chemistries, requiring unique ideal operating parameters. Therefore, a great working relationship with a welding materials company is invaluable during product development and launch.

Cold Joining Technologies

Cold joining methods are those that can be implemented without heat and include flow drills, flow drill screws (FDS), self-piercing rivets (SPR), and structural adhesives, among others. Some of these methods can be applied without access to the back of the substrate, while others require an anvil to support the joint and to enable the formation of the fastener.

SPR is a common joining method in aluminum-intensive body structures. This is a high speed process, in which the metal is secured against an anvil and the semi-tubular rivet is driven into the materials, which are joined between a punch and die in a press tool (Figure 3). Alumobility recently released a study that compares SPR in an aluminum-intensive vehicle to RSW in a steel body-in-white.5 The report notes the improvements in SPR. It also points to a 2006 SAE study, which found SPR to be greater than four times the cost of RSW. As of 2022, SPR only has a slightly higher cost than RSW, from an operational expense perspective.

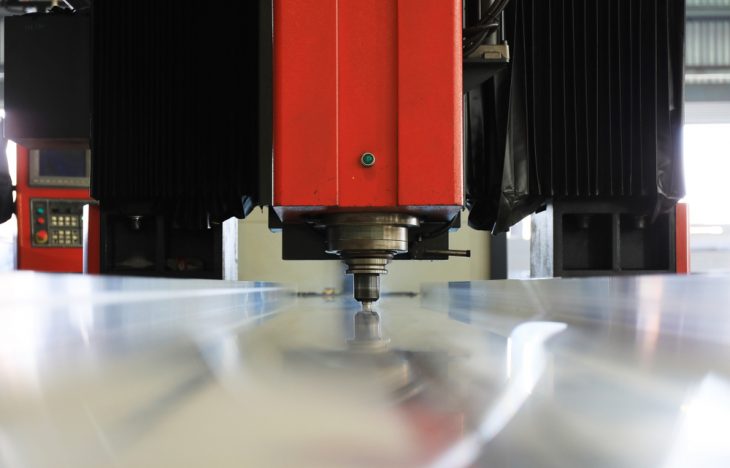

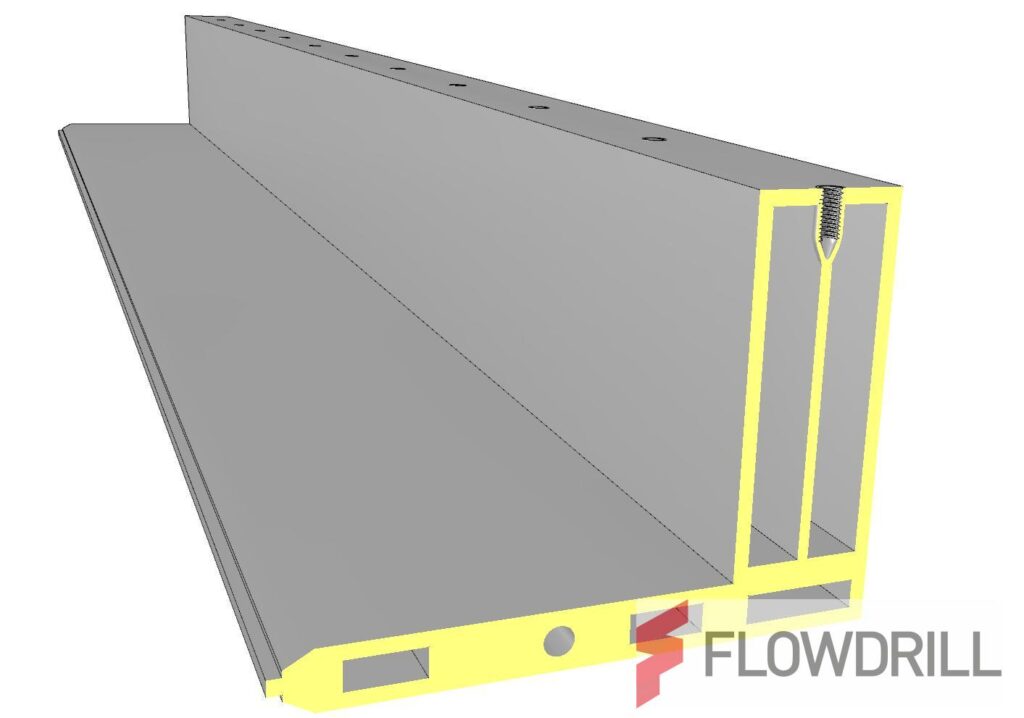

FDS and flow drills are two other fastening techniques that don’t require heat. The methods are similar in that the tool spins to generate heat, which makes the substrate flow to form the thread attachment material. In addition, both of these methods can be applied without access to any surface beyond the application surface.

With FDS, the screw acts as the drill and a tap, all in one step. The use of FDS is popular on shock tower attachments, in which the tower is joined to adjacent sheet metal. These joints are generally limited to size M8 or smaller (based on typical measurements for nuts and bolts).

The flow drill method is a two-step process (Figure 4), in which the machine tool drills and flows and then a separate fastener is inserted to complete the joint. An advantage of a flow drill over FDS is that it creates about three times the wall thickness for thread engagement, with the max size being up to 2 inch NPT (National Pipe Tapered) threads. In addition, the screw can be removed multiple times.6 The creation of thread engagement material, and the fact that flow drill does not ever require a nut, makes for attractive cost and weight reductions.

Multi-Material Assemblies

When addressing steel-to-aluminum joining, galvanic corrosion is a significant concern. There are a number of means to mitigate corrosion between joints, even when one is welded to the other. In the case of steel welded to aluminum, it is important to avoid situations where corrosion is likely to occur. For example, a vertical joint cannot pool liquid like a horizontal joint. Another example is the fact that a joint high off the ground will have less exposure of water or road salt.

For the popular Ford F-150, the aluminum body sits on a steel frame. Therefore, it was necessary to apply a barrier material. One solution is isolation tape,7 which is delivered to the assembly plant in die cut shapes on a roll, making it easy to apply prior to the electro-coating oven. In the oven, the isolation tape cures and bonds well, providing a tough barrier layer.

At the ET ’22 event in Orlando, FL, in May 2022, the AEC displayed automotive extrusions, one of which was the rocker and battery support for the new GMC Hummer EV pickup truck (Figure 5). In this assembly, an adhesive layer was applied between a steel bracket and the extrusion. The adhesive was cured and hardened in the electro-coating oven, providing both a strong bond and a galvanic corrosion barrier between the dissimilar metals. Note that both the adhesive and the screws are holding the bracket to the rocker. This “belt and suspenders” approach is common with adhesives, even though the adhesive creates a very effective bond between the substrates.

Addressing Competition

It takes considerable expertise and resources to be a successful Tier 1 supplier. Some extruders view this level of support as the value that they want to deliver to automotive companies. Others find the Tier 2 level, which requires less fabrication and assembly, to be their sweet spot, as it allows them to focus on delivering innovative extrusions. The message from automotive OEMs seems to be that they want more assembly smarts from extruders, which could turn some Tier 2 extruders into Tier 1s.

As extruders track the automotive market and work to grow their market share and maintain value, it is important that they observe both their peers and customers and target OEMs. However, it’s also important to check out possible competition from other kinds of aluminum product types, as well as other materials.

As the market evolves, Tier 1 suppliers that previously sold to automotive companies producing internal combustion engine components are moving into the EV market. Case in point, Nemak is one of the world’s largest engine component producers of cast heads and blocks, yet they have expanded their capabilities. They recently supplied the battery housing for the Ford Mustang Mach-E.8 The news release speaks to the use of extrusions and sheet, but does not mention castings. Another indication of Nemak’s move away from traditional cast parts is their recent job posting. The posting notes that the company is looking for a senior joining specialist, with a background in a variety of joining technologies, including, but not limited to: SPR, RSW, FDS, adhesives, and laser welding.

Another area of competition is from other materials and forms. The steel market is innovating with more versatile materials and process techniques. In addition, metal castings are now in the automotive news daily, with Tesla and now Volvo moving to large castings to replace stampings.

The Future of Joining Extrusions

Like many manufacturing industries, automakers are challenged by worker shortages. This, combined with faster development cycles for EVs, drives the need for increased automation in manufacturing, allowing for rapid manufacturing processes that require few people to run them. This includes the development of fast welding, quick tack time adhesives (if such a thing is possible), and new fasteners. Assembly time on the automaker’s manufacturing line is critical, yet another way to increase speed is for subsystems like cross car beams, battery boxes, and subframes to be produced elsewhere and quickly integrated in final assembly.

In the mission of increasing the speed and capabilities for the OEM, it’s important for material producers to bring their own integration expertise to the table. This is no time to be complacent, rather it is time for extruders to look for integration innovations that their customers will need in the future. Alternatively, extruders should seek out integration partners to combine complementary capabilities. Companies like EJOT proactively list their integration partners on their website to further support this kind of cooperation.9 Don’t give the OEM reasons to look for solutions that are easier to integrate than extrusions.

References

- “F150 Factory Tour—How Ford Builds an F-150 Every 53 Seconds – The Haul” (video), AmericanTrucks Ford.

- Trommer, Gerd, “Cold Joining: Automotive Industry Supplier Magna Develops Technology for Joining Steel and Aluminum Using the CMT Welding Process,” Welding Productivity.

- “AC Aluminum Pulse Weld Process Overview,” Lincoln Electric.

- “How to Advance Aluminum Laser Welding in Automotive Structures” (video), Coherent Inc.

- Rudlaff, Thomas and Julien Laye, “Spot joining technologies for light-weight materials in body structure assembly,” Alumobility, May 31, 2022.

- Flowdrill website, www.flowdrill.com.

- “3M™ Structural Isolation Tape SIT2010,” 3M Science, August 2021.

- “Nemak to supply battery housings for the Mustang Mach-E,” Nemak, January 21, 2020.

- “FDS® Specifications,” EJOT.

Andrew Halonen is president of Mayflower Consulting, LLC, a lightweighting consultancy that provides strategic marketing, market research, and business development for high tech clients. Halonen works with castings, extrusions, brakes, and new material development programs. Contact him at: www.lightweighting.co.

Andrew Halonen is president of Mayflower Consulting, LLC, a lightweighting consultancy that provides strategic marketing, market research, and business development for high tech clients. Halonen works with castings, extrusions, brakes, and new material development programs. Contact him at: www.lightweighting.co.