By Andrea Svendsen, Managing Editor.

With a growing worldwide focus on sustainability, the automotive industry has been shifting its designs towards more environmentally friendly models. The initial focus was on lightweighting using aluminum, magnesium, higher strength steels, and other materials in order to improve fuel economy.

Much of the current attention is now focused on expanding the availability of electric vehicles (EVs), which have near zero emissions during their use phase. One of the main challenges for automakers regarding EVs, however, is the aspect that makes them environmentally friendly — the batteries themselves.

Lithium-ion batteries, which represent the current standard in available technology, provide a number of challenges. EV batteries are heavy, high cost, and can take a long time to charge. Putting more batteries into an EV can improve the driving range — but it also significantly increases the cost and weight of the vehicle.

This is an area in which aluminum is seeing an increase in demand, since the metal is able to provide a particularly high strength-to-weight ratio, while also providing benefits such as increased stiffness and thermal management within the battery casing. As a result, the use of aluminum is able to help offset the cost and weight of the batteries — allowing automakers to optimize their EVs based on desired range and price point.

Nevertheless, automakers and other manufactures are actively seeking to address the challenges surrounding lithium-ion batteries by targeting lower costs and improving their performance in order to decrease their weight and increase their charging speeds.

Engineers in the automotive and other industries are not limiting their research and development to lithium-ion batteries. They are also looking into alternative battery designs, searching for improved performance for use in the automotive industry and beyond.

One of the areas of ongoing research is in the implementation of aluminum- and magnesium-based batteries. Over the last decade, a number of such research projects have been put forward, such as:

- Scientists at the Toyota Research Institute of North America (TRINA) noted a breakthrough involving magnesium as an anode material for batteries.

- Engineers from Stanford University developed a nonflammable, low-cost, high-performance aluminum-ion battery that could provide an inexpensive storage solution for solar power or other forms of renewable energy.

- Under the “Horizon 2020” program, the European Commission began funding new research and innovation projects, including the European Magnesium Interactive Battery Community (E-MAGIC) project, which was working on the development of rechargeable magnesium battery (RMB) technology.

Research into new forms of batteries is ongoing. As recent announcements involving aluminum-based batteries attest, the desired implementation of alternative materials and improved battery designs continues to garner interest.

Cornell Develops Aluminum Anode Batteries

Looking to address challenges involved in of energy storage related to generating electricity via solar power, researchers from Cornell University have been exploring the use of low-cost materials, such as aluminum, in batteries as an alternative to lithium-ion. The team led by Lynden Archer, a professor of Engineering at Cornell, aims to create rechargeable batteries that will make energy storage safer and more affordable.

The research has led to the development of an aluminum-based anode for battery storage. “A very interesting feature of this battery is that only two elements are used for the anode and the cathode – aluminum and carbon – both of which are inexpensive and environmentally friendly,” said Jingxu (Kent) Zheng, Ph.D., one of the members of the research team.

Historically, aluminum has been difficult to integrate into battery electrodes. Batteries use a glass fiber separator between the anode and cathode, which acts as a catalyst in order to promote the necessary electrical charge. However, aluminum tends to chemically react with the glass fiber, causing the battery to short circuit and fail.

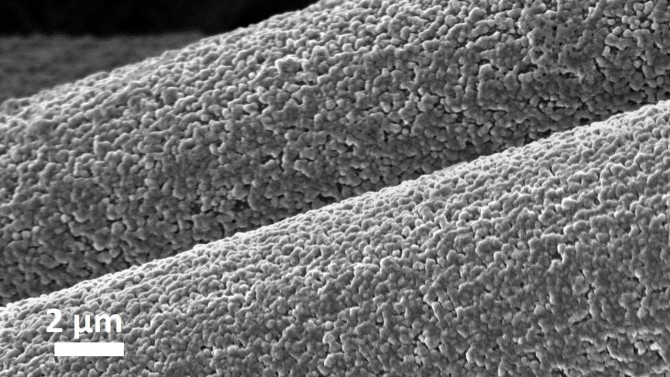

The Cornell researchers addressed this challenge by designing a substrate of interwoven carbon fibers that form a strong chemical bond with aluminum when the battery is charged. This method is able to provide a deeper, more consistent, and carefully controlled layering of aluminum.

“Basically we use a chemical driving force to promote a uniform deposition of aluminum into the pores of the architecture,” noted Zheng. “The electrode is much thicker and it has much faster kinetics.”

The aluminum-anode batteries have a notably longer cycle life and are able to be recharged up to 10,000 times. “When we calculate the cost of energy storage, we need to amortize it over the overall energy throughput, meaning that the battery is rechargeable, so we can use it many, many times,” explained Zheng. “So if we have a longer service life, then this cost will be further reduced.”

The aluminum-ion battery is discussed in the paper, “Regulating Electrodeposition Morphology in High-Capacity Aluminium and Zinc Battery Anodes Using Interfacial Metal–Substrate Bonding,” published by the Cornell research team in Nature Energy.

Phinergy Expands Aluminum Air Battery Implementation

Phinergy introduced its aluminum air battery development in 2014, which was introduced as part of a demonstrator car designed in cooperation with Alcoa. Instead of being in competition with lithium-ion batteries, the aluminum air battery was developed to compliment them. It essentially enables car makers to reduce the size of the lithium-ion battery pack by installing the aluminum air system in their EVs as a range extender, providing up to around 1,600 km of additional driving range with zero CO2 emissions.

The air battery uses the energy released by the reaction of aluminum with oxygen to generate electric power. The aluminum anode acts as the fuel, breathing oxygen, which breaks the water into hydroxide. The outside layer is slowly dissolved back into alumina hydroxide. Once the aluminum is depleted, the aluminum air battery has to be entirely replaced.

Since introducing the battery in 2014, Phinergy has continued to refine the technology and introduce it into the wider EV market. This year, the company has signed several collaborations with Indian companies.

In March, Phinergy formed a cooperation with Mahindra Electric, India’s leading company in the electric vehicle sector, through which the companies will introduce an electric rickshaw prototype, which will be tested in India. The aluminum-air battery is expected to increase the rickshaw’s travel range from 130 km to 400 km.

Also in March, IOP, a company jointly owned by Phinergy and Indian Oil Corporation, signed letters of intent with two major Indian automakers — including Maruti Suzuki, a subsidiary of Suzuki Motor Corporation, and Ashok Leyland, the second largest manufacturer of commercial vehicles in India. The automakers will collaborate with IOP to test Phinergy’s aluminum-air battery in prototype EVs for buses and passenger cars.

“Collaborations with leading vehicle manufacturers cement Phinergy’s position and vision in the field of electric vehicles in general and in the Indian market in particular,” said David Mayer, CEO of Phinergy. “We hope that the first demo vehicles will drive on Indian roads in the near future, and will subsequently drive millions of passengers in India in an environmental, pollution-free way, with longer driving range compared with lithium batteries of similar size and weight, [while providing] fast recharging without electric grid dependency at a competitive price.”

GM Testing Batteries with Aluminum-Based Cathodes

General Motors (GM) announced plans to develop and test a variety of technologies and manufacturing processes in order to extend the range and reduce the cost of batteries for EVs. This includes exploring various chemistries for its next-generation Ultium battery platform, which are being developed as part of Ultium Cells LLC, a joint venture with LG Energy Solution.

“Affordability and range are two major barriers to mass EV adoption,” said Mark Reuss, president of GM. “With this next-generation Ultium chemistry, we believe we’re on the cusp of a once-in-a-generation improvement in energy density and cost. There’s even more room to improve in both categories, and we intend to innovate faster than any other company in this space.”

The Ultium battery is currently being designed with nickel-cobalt-manganese-aluminum (NCMA) cathodes, along with graphite-based anodes and liquid electrolyte. The batteries are expected to have a range up to 450 miles and will be used in new GM electric models, such as the Cadillac Lyriq and Hummer EV.

The joint venture company is currently constructing a $2.3 billion, 2.8 million sq ft facility in Spring Hill, Tennessee. This will be the second facility capable of producing the new Ultium batteries.