A team of researchers successfully developed a means of using aluminum as reinforcement in concrete structures, presenting a new bench design as a demonstration of the technology’s capabilities.

Traditionally steel, rather than aluminum, has been used as reinforcement in concrete. The reason is that the high basic pH of ordinary concrete causes aluminum to corrode. A researcher at SINTEF (one of Europe’s largest independent research organizations) in Trondheim, wanted to answer the question, “What if it wasn’t aluminum’s ‘fault,’ but rather the cement?” As a result, Prof. Harald Justnes worked with a team over two years to invent a new concrete that is not so alkaline, making it possible to reinforce concrete with aluminum instead of with steel.

Aluminum Concrete Reinforcement

The research project, DARE2C (Durable Aluminum Reinforced Environmentally-friendly Concrete Construction) was a collaboration between Justnes, a team of experts, and the Norwegian University of Science and Technology (NTNU) and SINTEF. Hydro acted as the project manager, and they were also supported by cement producer Norcem, contractors Veidekke and Overhalla Betongbyg, and the Norwegian Research Council.

The new concrete recipe has been fine-tuned and tested with aluminum reinforcement – with such promising results that already, halfway through the research project, it is assumed that the new concrete will actually become a reality. In addition to being suitable for aluminum reinforcement, the new concrete has many and surprisingly significant benefits related to environment and quality, which can revolutionize the concrete industry:

- The new concrete requires far less energy and CO2 emissions to produce

- It enables slimmer concrete structures (smaller volumes of concrete)

- The concrete becomes maintenance-free

- It can absorb and store CO2 from its surroundings during the use phase

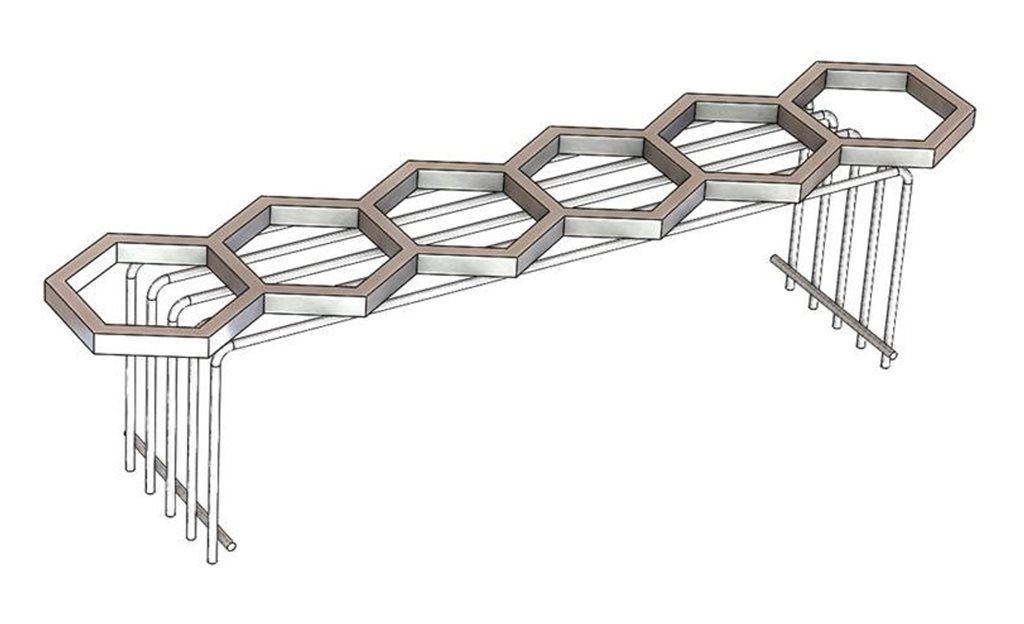

The research team designed a bench using the new concrete, along with aluminum reinforcements as a living example of the invention. The aluminum-reinforced concrete bench was cast by Overhalla Betongbygg and first exhibited at the AquaNOR fair in Trondheim in August 2019.

Aluminum vs. Steel

Why benefits can reinforcement with aluminum instead of steel provide? The fact that steel is strong makes it intuitive choice for reinforcement — however, steel also has some inherent weaknesses. Steel corrodes when in contact with seawater and CO2 from the air. In fact, steel reinforcement must be covered by denser and thicker concrete in order to protect the reinforcement itself from contact with air and water to prevent the concrete from cracking. Therefore, today’s common concrete structures only last as long as the concrete can shield the steel from external influences.

Aluminum is different since it has a “membrane” of oxide that protects the metal against corrosion, which enables it to naturally resist and enduring air and seawater far better than steel. Because of this traditionally denser concrete is not needed to protect the reinforcement structure, nor any kind of thick covering. With aluminum, concrete structures can be lighter weight, have a longer life, and require less maintenance, as well allowing for a wider variety of aesthetically pleasing design possibilities.

Aluminum reinforcement also allows the use of binders (which steel cannot withstand) that result in far less CO2 emissions compared with traditional cement clinker. A lot of the cement (about 55%) is replaced by ordinary clay and other binders that do not decompose CO2 the way the cement clinker does, and is burned (produced) at lower temperatures (850°C instead of 1,450°C). This, of course, saves huge amounts of energy and emissions.

Sustainably Speaking

Although the bench was made of primary aluminum, an important goal with the research project is to enable use of recycled aluminum – and preferably aluminum that has been reused so many times in various consumer products, and so mixed with other metals, that it no longer has so many suitable alternative applications. The ability to use recycled aluminum is one of the major advantages of the DARE2C concept.

For example, aluminum engine blocks for cars is one application that is able to use recycled aluminum that has been “contaminated” with many other metals. But since the world will need fewer engine blocks — as cars switch from internal combustion engines to electric motors in the future — aluminum-reinforced concrete can be seen as a potential application for this contaminated aluminum scrap. It may even further improve the climate footprint of new concrete structures.