By Kevin Widlic, Contributing Editor.

Aluminum has been used in various sectors for years, and most in the industry are accustomed to seeing aluminum in assorted everyday products. But what many may not be aware of is that aluminum can advantageously replace other materials in bridge constructions with regard to ease of construction and cost over the lifetime of the bridge, among other benefits.

Aluminum has been used in bridges for some 80 years, so it does have a history. But truth be told, its story has been spotty and relatively short. With increasing international collaboration, however, better solutions are being developed. New projects in Canada and Norway are creating excitement for the aluminum industry — and extruders in particular. Additional projects are looking at standardizing bridge design using aluminum, developing new pedestrian and vehicular bridges, and replacing aging infrastructure. Today, industry experts from across the world are working diligently to show the value of aluminum and expand its use in bridge design.

Background

The Smithfield Street Bridge in Pittsburgh, PA, was built in 1933 with aluminum railings and an aluminum deck. This was the first reported use of structural aluminum in a bridge.

Since then, the number of reference bridges has been small. Probably the best known is the Arvida Bridge in Canada, around 120 miles north of Québec City, which has been described as a masterpiece in civil engineering. It also became the first highway bridge in the world to be built completely of aluminum, upon its completion in 1950. The 153 m long arch bridge still stands today, and its repairs have been limited to the replacement of the concrete deck and several aluminum components due to corrosion. The bridge has not required any maintenance of its main aluminum components.1

It took another 65 years, however, for the next aluminum-made vehicular transport bridge to be built. The Saint-Ambroise Bridge in Québec, consisting of an aluminum deck on steel beams, was installed in 2015. Despite so few representative examples, there is incredible potential for the use of aluminum in bridges.

Utilizing Aluminum

Why will future bridges contain more aluminum? Dr. Mario Fafard, a consultant for AluQuébec, who has a PhD in numerical modelling and is a former professor at Laval University in Québec, lists several points. Aluminum is ideal for accelerated construction and installation, offers a lower carbon footprint than other materials (when made using renewable energy), and lowers maintenance costs compared to concrete, steel, and wood designs, due to its high resistance to atmospheric corrosion. But the light weight of aluminum is the key element. For equal rigidity, an aluminum bridge will be twice as light as a steel bridge and four times as light as a concrete bridge. Lightweight bridge decks reduce the dead load on the superstructure, which frees up load-carrying capacity. This is particularly important on long-span bridges.2

Another vital element is that aluminum is fully recyclable. This is especially important in respect to the global push toward more sustainable solutions and lowering the carbon footprint as an environmental concern. Fortunately, the aluminum industry has been adding recycling capacity worldwide at a fairly rapid pace, making recycled aluminum more available.3

Aluminum extrusions, in particular, are well-suited to the design of pedestrian and vehicular bridges. Designers point out that other building materials, such as steel and composites, do not have the same potential for creativity as aluminum extrusions because they have more limits.4

Combining the flexibility and creativity that extrusions offer, with the ability to utilize friction stir welding for joining the extrusions together to make the bridge deck, provides bridge owners with the most cost-efficient solution on the market. “Friction stir welding is extremely affordable,” said Benoît Cusson, a structural designer for WSP, a consulting firm in Canada. “Not only does it perform well, but it is also very cost effective. I don’t think we say that enough.”

Bridges need large extrusions. These are not always easy to find. It can still be a challenge to find the capacities and the lengths that bridge-builders need. But Thomas B. Svendsen, an engineer working in business development for Hydro, noted that things are improving. “Extrusions are necessary components for both pedestrian bridges and highway bridges,” he explained.

New Projects in Norway and Canada

Hydro is the leader in Norwegian aluminum production and is keen to promote the material’s possibilities in a variety of sectors, including bridges. Svendsen said that the properties of aluminum lend themselves well to bridge construction, adding that a recent shift has sparked interest in new materials. “There are other perspectives and arguments today,” he said. “These include the climate, environmental savings, value chains, and more focus on sustainability. A new element that has entered the picture is emission reduction, in addition to cost.”

Svendsen spoke about the advantages of using more aluminum in larger, more comprehensive projects, including in transport infrastructure. When it comes to bridges in particular, several new projects in Norway are showing that aluminum indeed has a place.

One is the Langenuen Bridge, which might be the most exciting project under development in the country today. It is part of Norway’s ambitious ferry-free E39 project, designed to provide a smoother and more efficient travel route along the country’s west coast. The bridge over Langenuen Sound, south of Bergen, is to be built using aluminum.

According to Svendsen, Hydro has been working on the Langenuen project since 2016. “The developer of the E39 project wanted to look at the entire cost picture, and whether technology from other industries could help. They wanted to look at materials, the supply chain, and construction, and they wanted to gain experience from, among other things, the oil industry. However, they had not considered aluminum,” he explained. “When we started the study, we first had to conclude that it was technically possible to build a bridge of this size with aluminum. We also considered the costs of using aluminum versus steel. Aluminum is normally more expensive than steel, but you get many synergy effects. As an example, the weight savings you get with aluminum can help reduce the use of concrete.”

The need for less concrete also means that carbon dioxide emissions are reduced. Concrete is the world’s most-used building material and accounts for 5–8% of the world’s greenhouse gas emissions. The production of cement, which is the actual binder in concrete, accounts for 80–90% of the emissions from concrete.

Another major bridge project is taking place this year at Laval University in northern Quebec, Canada, where climate conditions are harsh. The transport vehicular bridge will be comprised of an extruded aluminum deck on steel beams. The extrusions will be joined together using gas metal arc welding (GMAW). Trucks carrying wood will travel across the bridge.

Fafard said that the bridge will be monitored by researchers from the university. “We have estimated that over the life cycle of the bridge, the total cost of ownership will be lower for this bridge than for a concrete or steel bridge, due to the low maintenance cost of the aluminum structure,” he noted.

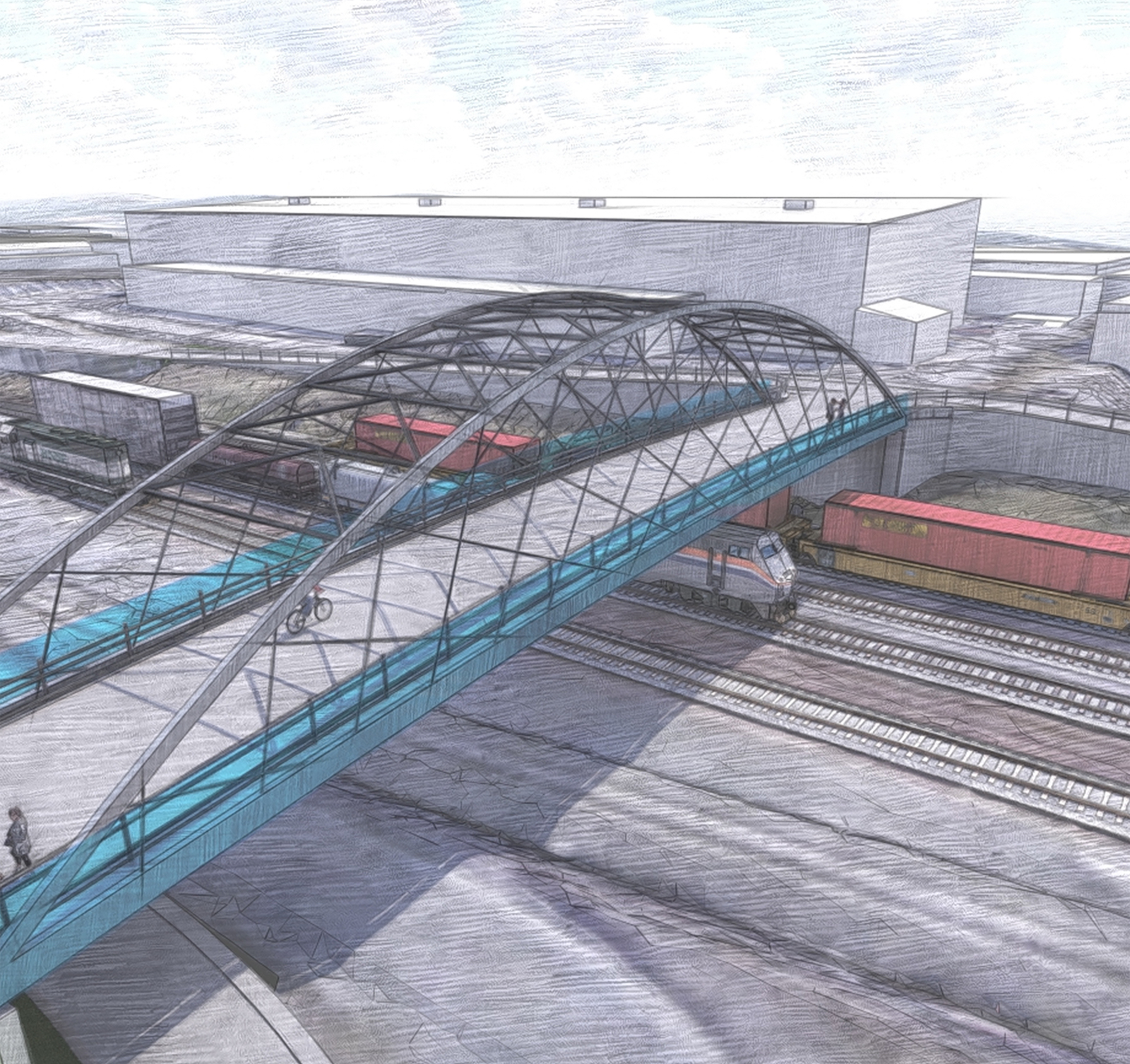

Svendsen agreed, adding that a master’s thesis recently completed at the Norwegian University of Science and Technology (NTNU) shows that the maintenance element of a traditional bridge often exceeds the construction costs. He also noted that in addition to cost, carbon footprint has become a requisite for new designs. Another of the new projects being developed in Norway — a pedestrian bridge crossing railroad lines in Trondheim (Figure 1) — is considering the use of 100% recycled aluminum for the bridge.

Standardization and Collaboration

The province of Québec has more than 50 aluminum-made pedestrian bridges. The truss is the main system in the construction of these bridges. These trusses and bridge designs have become optimized, almost standardized, and are growing more popular for the application, compared to steel solutions. Recently, the Canadian Standards Association (CSA) published new documentation, entitled “Pedestrian, cycling, and multiuse bridge design guideline (CSA S7:23),” which includes aluminum as a material for those bridges.

“Whenever you have an existing structure and you’re trying to add a new pedestrian bridge or an annex to an existing bridge, these are the types of projects we have seen in recent months that show aluminum structures are more cost-efficient and durable,” said Cusson. “They also ease the construction. [Because the] cranes will be smaller, there are fewer and smaller disruptions to traffic.”

In addition to his work at WSP, Cusson is part of a working group in Quebec, comprising bridge designers, fabricators, and bridge owners. He is optimistic about what he has been experiencing in the last year alone. “Our membership in the working group has increased enormously,” he said. “We have seen a lot more motivation, and delegates from every main engineering firm have joined this working group.”

This momentum has carried over to his work with adapting the Canadian Highway Bridge Design Codes CSA S6:19 in the Aluminum Structures chapter, where he served as vice-chair. Cusson explained that the group made many modifications to aluminum structure provisions during its recent code cycle (to be published in 2025) partly because there are many more participants at the table. “We focused on ease, simplification and efficiency,” he said. “For example, we will have a new section on aluminum decks, with recommendations to designers. We are moving faster.”

In October 2023, Cusson presented a keynote speech at the International Aluminium Conference (INALCO) in Quebec City, which was organized by the aluminum cluster AluQuébec and the aluminum research center REGAL.5 In his speech, he pointed to the momentum in Canada, where a growing number of projects are being developed with aluminum in pedestrian and vehicular bridges. In addition to the mega-project in northern Quebec, these developments include two architectural pony-truss pedestrian bridges and a pedestrian bridge where an 80 m long truss connects to a curved girder structure. In addition, AluQuébec is working with engineering firms and manufacturers to develop a bridge entirely made of aluminum — consisting of a deck connected to aluminum beams — within the next three years.

The INALCO conference also provided a lot of new ideas aimed toward generating more aluminum in new bridges. This includes a development project for making highway bridges easier to fabricate. According to Cusson, this project could grow into an international collaboration, since the conference attracted representatives from Sweden, Germany, Norway, the Netherlands, Italy, Canada and the U.S. — establishing a global scientific community for the first time since the 1990s. One goal for this group could be standardizing the design codes between North America and Europe, another might aim toward bringing the transportation departments of relevant countries closer together.

Sharing costs related to the development of new solutions will also be a target. “Developing solutions together would be beneficial for everyone,” said Cusson. “I feel this is a momentum that will not end.”

Aiming for Highway Bridges

Highway vehicular bridges remain the pot at the end of the rainbow for the aluminum industry, simply due to the mass volume of aluminum needed to build such bridges. “With aluminum decks and the use of friction stir welding, we are seeing new ideas emerging, including modern details and applications,” noted Cusson. “We can actually envision new types of solutions for highway vehicular bridges.”

Fafard concurs, adding that the game-changer for the use of aluminum in highway bridges may not come until transportation authorities include aluminum material as a standard material. It also requires that bridge owners allow for aluminum to be included among the choice of materials for construction and take into account the total cost of ownership and the environmental footprint of materials. The industry must now follow up. “We have the standards and the design rules. Now it is about using those design rules and applying new solutions,” he said. “There are no more main obstacles in the way.”

Yet, smaller obstacles still remain. Around the world, civil engineering programs generally do not include aluminum as a material for use in the design of structures. As an example, Canada has only three civil engineering programs that include aluminum design as an optional course.

Another point is that engineers in transportation departments and private engineering firms tend to be unfamiliar with the material, according to Fafard, and so they tend to prefer to design bridges using steel. Even if aluminum is prescribed, engineers sometimes try to replace the aluminum with steel.

The Bridges to Come

Around 660,000 public roadway bridges were built in the U.S. and Canada between the 1950s and 1970s.4 According to the 2021 National Bridge Inventory, compiled by the U.S. Federal Highway Administration, more than 43,000 bridges in the U.S. are in poor condition.6

The Bipartisan Infrastructure Law, introduced in 2023, is investing $40 billion to repair and rebuild the nation’s bridges.7 This represents a great opportunity for aluminum. Through this new law, the Biden Administration initiated a plan to improve about 15,000 highway bridges, as well as bridges that are not part of the federal highway system. The bridge improvement program is expected to cost more than $40 billion to repair and rebuild the nation’s bridges, making it the “largest dedicated investment in bridges since the construction of the Eisenhower-era Interstate Highway System.”7

Meanwhile, last month, the Aluminium Association of Russia announced the opening of the country’s first aluminum road bridge. The bridge is 72 m long and is located on the Tolokontsevo–Mogiltsy motorway. Both the spans and the orthotropic plates are made of aluminum alloys. According to the association, the bridge structure comprises four aluminum spans of 18 m each and that friction stir welding was used to join the spans.8

Indeed, the future for aluminum use in bridges appears bright. “I feel that these next few years will be exciting for us,” concluded Cusson.

References

- “Designing a Traffic Barrier Anchorage System for Aluminum Bridge Decking,” Light Metal Age, October 2019, pp. 12-13.

- “Opportunities for Extruded Aluminum Alloy Shapes in Restoration of Aging Bridge Decks,” Light Metal Age, June 2008, pp. 12-17.

- “Deploy-Ready Aluminum Bridge Decking,” Light Metal Age, August 2019, pp. 30-33.

- “An Aluminum Extruded Bridge is Born,” Light Metal Age, April 2018, pp. 32-33.

- Cusson, Benoit, “Modern Applications and Construction Details for Aluminium Bridges,” Presented at INALCO, Quebec, Canada, October 11–13, 2023.

- “Bridges: 2021 Infrastructure Report Card,” American Society of Civil Engineers, 2021.

- “Fact Sheet: President Biden, Vice President Harris, Senior Administration Officials Kick Off 2023 Implementing Bipartisan Infrastructure Law,” The White House, January 4, 2023.

- “The First Aluminium Road Bridge in Russia Opens for Traffic,” Aluminium Association of Russia, December 28, 2023.

Editor’s Note: This article first appeared in the February 2024 issue of Light Metal Age. To receive the current issue, please subscribe.