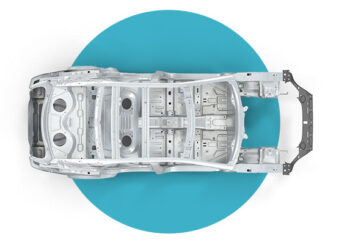

Constellium SE is leading a new consortium of automakers and their suppliers to develop lower carbon, lower cost aluminum extrusion alloys. The Circular and Constant Aluminium (CirConAl) project aims to improve how industry manages scrap aluminum in order to maximize the use of post-consumer scrap in a new generation of high-strength alloys that emit less than […]