By Alton Tabereaux, Contributing Editor.

Spent potlining (SPL) disposal is one of the largest environmental waste management challenges confronting worldwide primary aluminum smelters due to its toxicity. The International Aluminium Institute (IAI) asserts that 1.6 million tons of SPL were generated from primary aluminum production in 2019,1 making it the second largest waste volume produced after bauxite residue. Furthermore, as the world’s aluminum production continues to increase annually, the quantity of SPL waste connected with the industry increases.

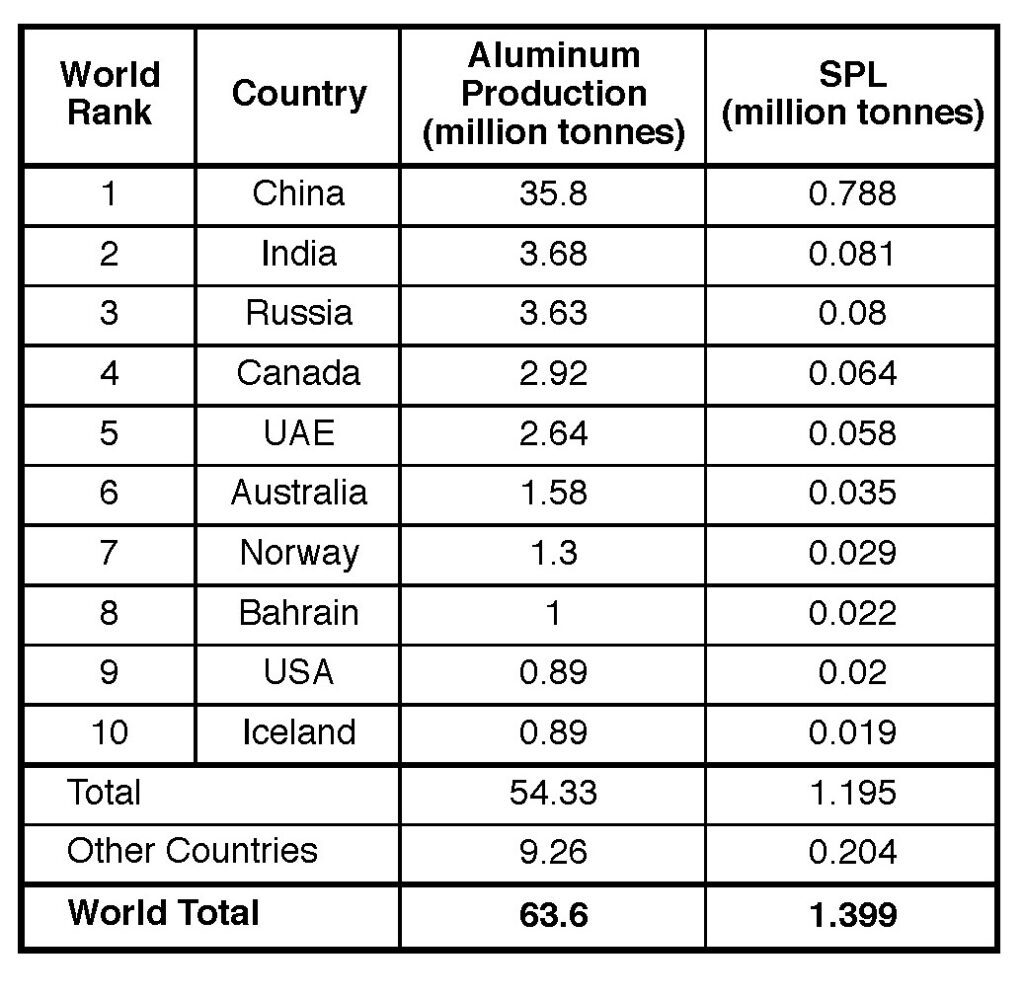

According to Hollywell,2 the rate of SPL generation for prebake cells in aluminum smelters is typically 22 kg SPL/t Al. Based on this value, it is estimated that 1.4 million tonnes of SPL hazardous waste was generated from the production of 63.6 million tonnes of primary aluminum in 2018 (Table I). According to the U.S. Geological Survey report from 2018-2019, the top ten global aluminum producing countries in the world in 2018 produced 85.4% of the total aluminum and generated an estimated 1.2 million tonnes of SPL.3

SPL Management

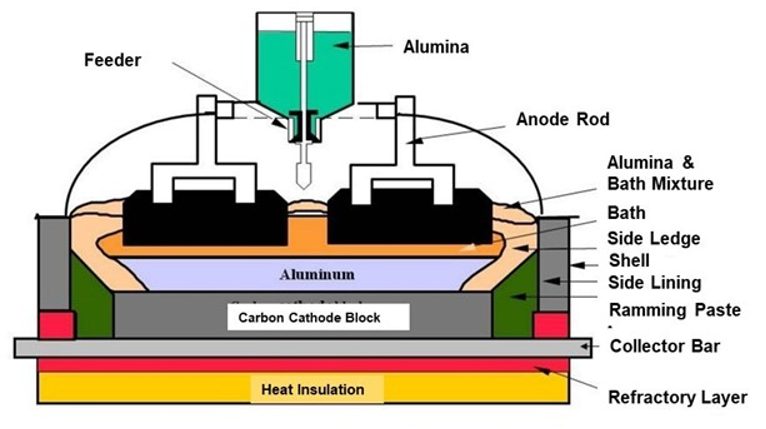

SPL is generally a mix of all cell lining materials left in the cathode, including the bath impregnated carbon blocks and carbon binder paste, sidewall carbon and silicon carbide blocks, bottom refractory, and insulation (Figure 1).

Cathode Lifetime

The average operating lifetime of the cathode lining in industrial aluminum cells is typically four to seven years depending on the cell lining design, materials, construction, and operating irregularities. The cathode lining deteriorates over time influencing cell production and increasing energy consumption and iron and silicon impurity levels, therefore requiring the need to replace the lining.

The cathode lifetime can be significantly shorter than average if an unexpected cathode lining failure occurs. Linings fail early due to unexpected cracks in the cathode blocks, allowing liquid aluminum and molten cryolite to penetrate through the gaps, dissolve the steel collector bars, and result in leakage of liquid aluminum and molten electrolyte out of the cathode, or pot tap-out. In general, cracks are one of the main reasons for early cathode failures.

Cathode Lining Dismantling Procedures

Pots are stopped for relining by installing shunts in the potroom busbar system that bypass electric current around cells. After removing as much bath and aluminum metal as possible, the carbon layer is demolished, and the steel collector bars are removed (Figure 2).

The cathode lining is then demolished and removed in two separate cuts: the industrial names for the waste parts are “first cut” (carbon lining) and “second cut” (refractory lining). Depending on the solutions considered for SPL treatment, the first cut is usually separated from the second layer of refractory. Typically, SPL comprises approximately 55% of the first cut carbon fraction and 45% of the refractory second cut. The first cut is almost fully graphitized carbon; it’s hard and dense with a high specific gravity and has low volatiles and sulfur content.

SPL Composition

During electrolysis, molten cryolite and alumina salts penetrate and fully impregnate the carbon cathodes. Sodium from the bath is absorbed by the carbon cathode, forming intercalation compounds that cause changes in the wetting behavior of carbon material towards the electrolyte, allowing the electrolyte to penetrate the carbon cathode through the pores and cracks of the cathode. Electrolyte penetration continues until the solidus temperature zone in the carbon refractory lining is reached and the melt starts to solidify.

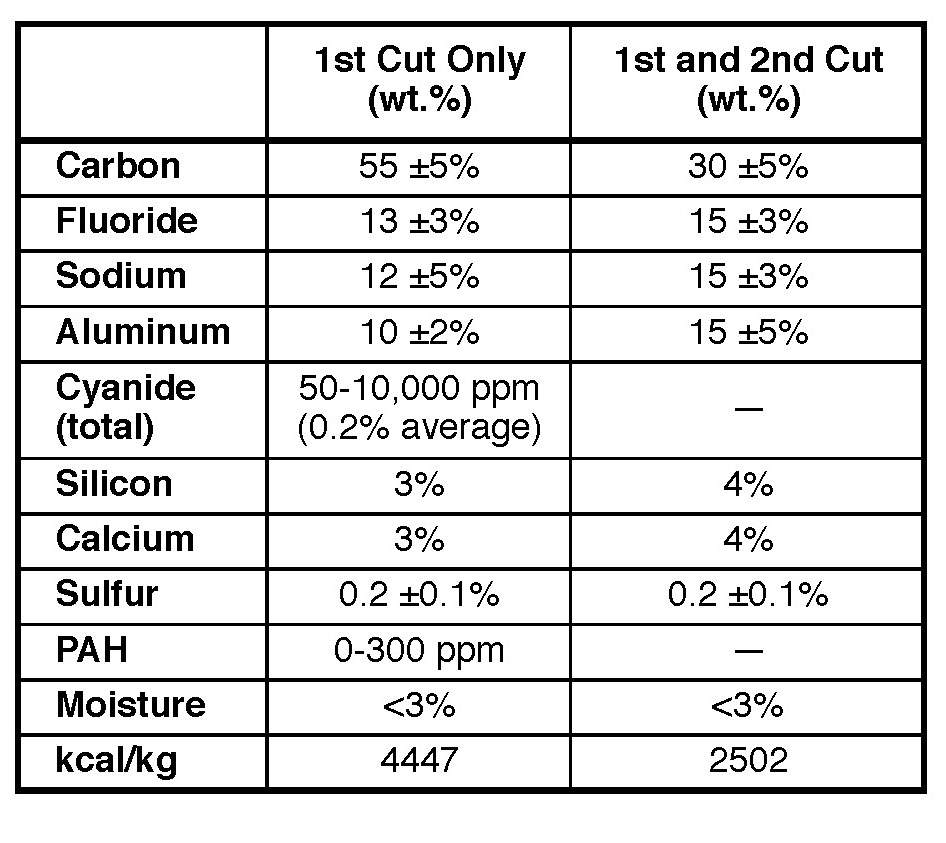

The composition of SPL depends on how long the pot operated, as sodium and NaF will have diffused deeper inside the lining for pots that have operated longer, increasing the sodium and fluoride content. Table II shows the range of chemical composition of the first cut SPL and the combined first and second cuts of SPL waste.4

Smelters may or may not separate the first and second cuts, depending on the treatment processes. The average carbon content in the first cut of prebake cells is 55% of the whole sample, compared with 30% in combined first and second cuts. By comparison, Søderberg cells have a higher rate of SPL generation (35 kg SPL/t Al) due to their thick rammed carbon sidewalls and end walls.2

The average fluoride concentration of SPL is 12-13%. The SPL is impregnated with cell bath salts, with the major fluoride components being cryolite (Na3AlF6), sodium fluoride (NaF), and calcium fluoride (CaF2). The average sodium concentration is 12–15% in the SPL. The major components that contain 10–15% aluminum are cryolite (Na3AlF6) and alumina (Al2O3).

Hazardous Waste Classification of SPL

The average total cyanide concentration in the first cut SPL samples is 50–10,000 ppm (0.2% average). The average polycyclic aromatic hydrocarbon (PAH) is 0–300 ppm. The concentration of cyanide in the form of sodium cyanide (NaCN) and sodium ferrocyanide (Na4Fe(CN)6) is typically more than 1%. Cyanides are formed by the ingress of air through openings in the potshell and subsequent reaction of nitrogen with the carbon lining. Cyanide is concentrated around the perimeter of the cathode, predominantly in the rammed end walls and sidewalls of the carbon lining.

Leachable cyanide and fluoride compounds present the major problem in SPL disposal. In most countries, the first cut of SPL is always classified as hazardous material due to its leachable and toxic content of fluorides and cyanides and its reactivity with water, which can produce explosive gases. The U.S. Environmental Protection Agency classified SPL as hazardous in 1988 due to its high fluoride and cyanide content. The second cut of SPL is generally classified as a regulated or controlled waste.

Usually, governmental agencies regulate transboundary movements of hazardous waste and control movements of wastes within jurisdictions. The Basel Convention for the Control of Transboundary Movements of Hazardous Wastes and their Disposal, adopted in 1995 in Basel, Switzerland, provides stringent protocols and prohibition of exports of all hazardous wastes covered by the convention that are intended for final disposal, reuse, recycling and recovery from countries.

Disposal Options for SPL

Prof. H.A. Øye reported that more than 50% of the smelter produced SPL is currently landfilled without any special treatment.5 Current SPL disposal options in the aluminum industry include: landfilling or sea water disposal; securing the SPL in temporary storage buildings until treatment; various SPL treatment processes; detoxifying, refining, and landfilling the non-hazardous residue; using the SPL as a fuel feedstock for other industries (e.g. cement, steelmaking, and mineral wool); and recovering of alkaline salts from the SPL as a feedstock for alumina refineries.

“Many smelters have been putting off SPL treatment for 30 years in the hope that this stuff will become valuable enough for someone to pay them for it,” noted Phil Black, an aluminum industry consultant.6 “This is just wishful thinking. Even by optimizing the value in the mineral components, there is just not enough commercial value in SPL. However, with continuous improvements in technology the costs to a smelter of recycling SPL are now less than the liabilities associated with landfilling.”

The following sections of this article highlight how the top ten aluminum producing countries are addressing the environmental challenge of SPL. The sections are organized from the largest producers to the smallest.

China

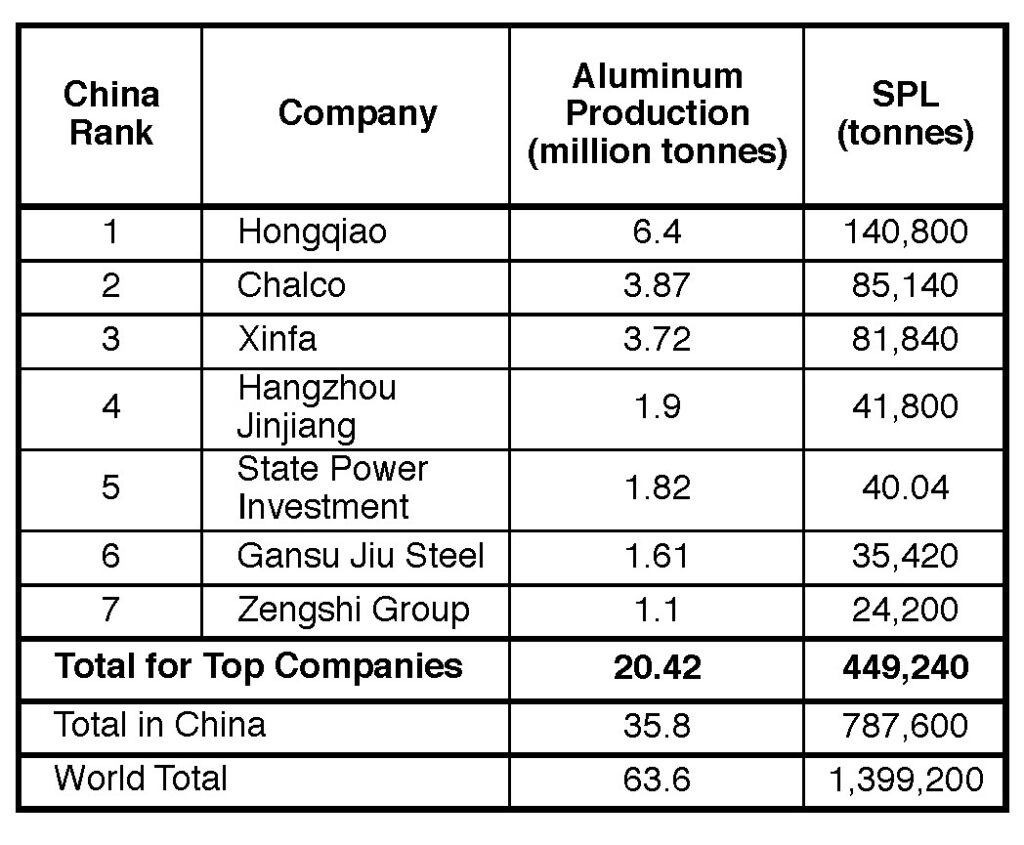

The worldwide production of primary aluminum was 63.6 million tonnes in 2018.3 With more than 60 aluminum smelters, China was the largest producer of primary aluminum in the world, producing 35.8 million tonnes and accounting for approximately 56.3% of global production. The top seven aluminum companies in China produced 20.42 million tonnes of primary aluminum, which accounted for 57% of the total aluminum produced in China, according to 2018 company annual reports. There were 12 electrolytic aluminum enterprises in China at the time, operating with an annual capacity of over 1 million tonnes each, and with a combined capacity that accounted for over 70% of the aluminum production in the country.

It is estimated that 787,000 tonnes of SPL were generated in China in 2018 (Table III), based on its 35.8 million tonnes of aluminum production and the widely accepted SPL generation rate of 22 kg SPL/t Al.2 The top seven aluminum companies in China generated 449,240 tonnes of SPL in 2018, which was 57% of the SPL generated in China. The largest company, China Hongqiao Group, generated 140,800 tonnes of SPL that year, which represented 17.8% of the total amount produced in China.

“China has the largest aluminum production capacity in the world and, thus, it also has the largest amount of waste from failed cathodes,” noted Prof. Gao Bingliang.7 “SPL contains compounds that are toxic, hazardous, and environmentally undesirable, so it is becoming one of the aluminum industry’s major environmental concerns.”

According to Wang Zhaowen, et al.,8 “The National Hazardous Waste Inventory classifies the wastes from the aluminum electrolysis industry (code: 321-023-48) as hazardous waste with toxicity (T). Even though many new technologies for treatment of solid wastes have been developed in China, very few of them have been put into industrial practice. Companies like to use mature technologies for treatment of solid wastes at low cost and do not like to develop new technology and conduct industrial tests, which slows down the industrialization of emerging technology.”

Analysis of Hazardous SPL Materials in Cathodes

In a study,9 the spent cathode carbon blocks, waste silicon carbide side blocks, and waste refractory material taken from a demolished cathode lining of a cell, which had been in service for 2,163 days in a smelter in western China, was analyzed for hazardous material content. The results of the SPL sample after leaching toxicity analysis showed that the cyanide content in the spent cathode carbon block was 10–20 mg/L and the soluble fluoride content was about 3,000–6,000 mg/L, far exceeding the national standard of 100 mg/L for hazardous waste.

Another study looked at the distribution of fluorides and cyanide in a 350 kA cell that operated for 2,396 days.10 It found that the fluorides were mainly concentrated in the cathode carbon block and the layer of dry barrier under the cathodes. Cyanide has a low concentration in the cell center and a high concentration in the sidewall, which is related to the amount of air entering these areas in the cells.

Flotation Process

Froth flotation is a low-cost and lucrative method that has been applied by several aluminum refineries in China for the comprehensive recycling of first cut SPL. This approach enriches carbon in a flotation concentrate via its eminent hydrophobicity, while other insoluble components — mostly cryolite, alumina, and sodium aluminate — are collected in the flotation tailing. The first cut sample of SPL was provided by an aluminum smelter situated in Yunnan province, China. The effects of types, dosing times, dosage, and emulsification of collecting agent on the flotation index were determined. The carbon content of concentrate and carbon recovery have been increased by 9.2% and 13.2%.11

A flotation process was developed in 1989 by Prof. Qiu Zhuxian and Dr. Zhai Xiujing to separate electrolyte from carbon in SPL. The purity of electrolyte was approximately 90%, containing about 5% carbon.12 Industrial tests of the flotation process for treating SPL were conducted in 1993 at the Fushun, Qingtongxia, and Guangxi Pingguo aluminum smelters. From 2007 to 2010, Northeastern University cooperated with Yichuan Electric Power Co. Ltd. to commercialize the flotation process. A pilot plant was built with a processing capacity of 3,000 tpy.

Alkaline-Acid Leaching Process

An alkaline-acid leaching (AAL) process to recycle SPL was developed at Northeastern University. After alkaline leaching, the carbon content in carbon block increases from 65 to 73%. The main impurities (β-alumina and CaF2) can be further removed by acid leaching according to reactions. The purity of recycled carbon powder can reach up to 97%, which can be used as raw material for anode production.13-14

Pyro-Processing Technology

In 2003, CHALCO developed a high temperature sintering process for treatment of SPL. Mixture of SPL, lime, and coal fly ash is baked in a rotary furnace at 900–1,100°C. The fluoride vapor is absorbed by alumina in the dry scrubbing system to recycle fluorides; the solids, mainly CaF2, are sent to a cement factory as raw materials. In 2017, two industrial SPL treatment lines based on CHALCO’s pyro-processing technology were put into operation. The latest line has a treatment capacity of 10,000 tpy and produces raw materials for cement manufacture.15

Recycling of Spent Electrolyte

At present, aluminum electrolytes containing 3% LiF and 2% KF are common in most Chinese smelters that use alumina with a high content of Li2O and K2O. These additives may benefit the electrolysis process by lowering the liquidus temperature of the electrolyte, but cause several operation problems for the reduction cell at the same time. In the worst case, the bath contains 7% LiF and 4% KF, which cause poor dissolution behavior of the alumina in the aluminum bath and unstable electrolysis cells. In China, the spent electrolyte with high content of LiF and KF must be removed from the bath recycling and stored without treatment in smelters. It is estimated that China produces about 500,000 tonnes of spent electrolyte per year. Two methods have been developed to recycle the spent electrolyte, including acid leaching and aluminum salt leaching. Large-scale pilot tests have been conducted with good results.16

India

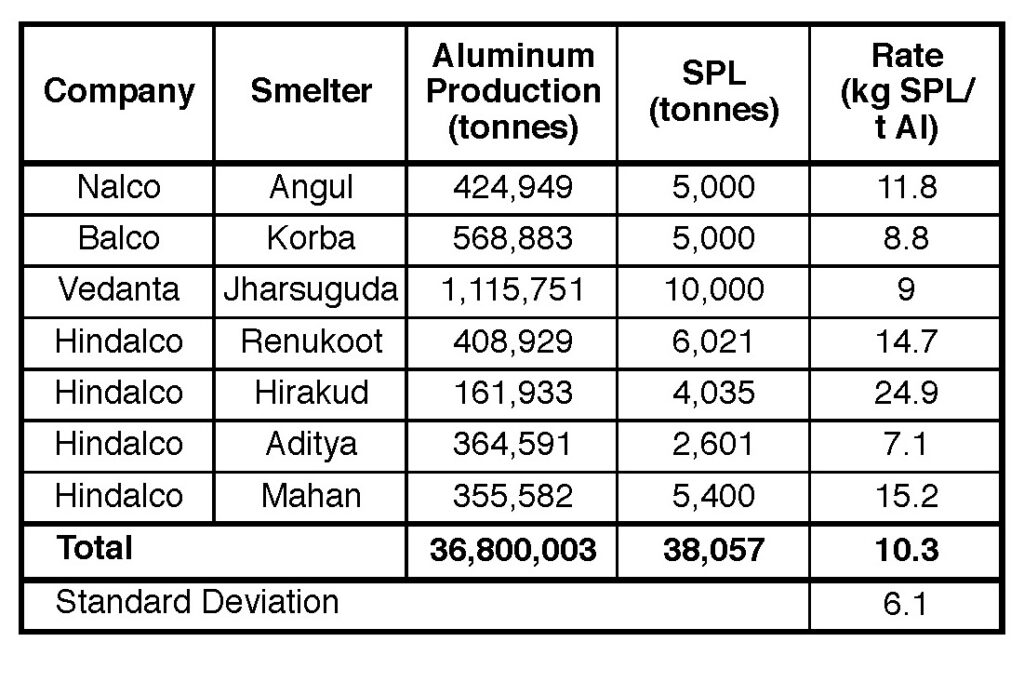

India was the second highest producer of primary aluminum in the world in 2018, with 3.68 million tonnes, which represented 5.8% of the total global aluminum production. Aluminum is produced by three major companies: Vedanta, Hindalco, and National Aluminium Company (NALCO).17

All together, the seven aluminum smelters in India generated 38,057 tonnes of SPL.18 The amount of SPL generated for each aluminum smelter in India (Table IV) is based on total plant measurements per year of SPL. The overall average rate of SPL generation for the seven smelters is low, at 10.3±6 kg SPL/t Al. Only the Hindalco Hirakud smelter reached a normal SPL generation rate of 24.9 kg SPL/t Al. Care must be taken when interpreting SPL generation figures as they depend on the lining life achieved (which affects the number of cells relined) and aluminum production. The abnormally low rates for SPL generation in the smelters in India may be due to the startup of new potlines or restart of potlines, which causes an irregularity in the number of pots relined for each four to seven year relining cycle.

SPL Management

With India poised for substantial growth, industries within the country should work together to reuse, recycle, and reduce the use of natural resources. SPL usage can be a promising proposal for both the cement and aluminum industries to optimize their cost and be competitive. Storage of SPL is not a viable solution due to the threat of land and water contamination. Advocacy from government authorities is very much essential to promote recycling and reuse of SPL as an alternate fuel. Currently, a number of SPL management practices have been put into place at aluminum smelters in India:19

- A secured landfill practice as per Central Pollution Control Board (CPCB) guidelines is commonly adopted by aluminum plants.

- An SPL co-processing trial was completed at the ACL Bhatapara cement plant completed in 2016 as per an MOU signed between Holcim and Bharat Aluminium Company Ltd. (BALCO), part of Vedanta. ACL received permission to process 3,200 tpy of SPL.

- Ultratech Hirmi Cement got permission to co-process 2,880 tpy of SPL from BALCO for five years in 2016, with execution starting soon after.

- At the Hindalco Renukoot plant, SPL is being reprocessed in a cryolite recovery plant.

- A quantity of SPL is being converted to mineral fuel by Green Energy Sambalpur and Subhra Chemicals, who are authorized reprocessors at a smelter in Odisha.

- Some aluminum smelters in India are also finalizing agreements with treatment, storage, and disposal facilities (TSDF).

Hindalco’s Hirakud smelter has a goal to reduce the SPL generation by reconfiguring its pot lining design and materials along with Cu-insert collector bar to improve the cell thermal balance and improve the pot performance with respect to the energy efficiency. It will also improve the pot life, which is estimated to decrease the rate of SPL generation in the smelter by 23.8%, from 20.41 kg SPL/t Al to about 15.55 kg SPL/t Al. According to Mahesh Sahoo, et al.,20 the new design pots have been running efficiently for the last five and a half years. Measurements indicate that the erosion rate of the cathode surface is much smaller than in the old pot design. The average pot life is expected to exceed 2,200 days, providing an expected further reduction in SPL generation.

SPL Disposal in Cement Plants

Recycling SPL is an attractive and proven option, perhaps best for the cement and steel industries. Opportunities and availability of cement kilns for SPL disposal through co-processing is not a constraint in India. First and second cut SPL can be used as a fuel supplement, as it contains ~60–70% carbon, with calorific value ranges of 3,200–3,400 kCal. As of 2019, India is the second largest cement producer in the world after China, with a production of around 480 million tonnes, representing 8% of the global installed capacity. A total of 210 large cement plants account for a combined installed capacity of 410 tonnes in the country, whereas 350 mini cement plants make up for the rest. Of the total capacity, 188 large cement plants (98%) are in the private sector with the top 20 companies accounting for about 70% of the total production.21

SPL Disposal in Steelmaking

In 2019, India became the second largest steel producer in the world after China and the largest producer of steel iron in the world. The industry produced 82.68 million tons of total finished steel and 9.7 million tons of raw iron. Coal, which is used for coke-making and pulverized coal injection (PCI), is the most expensive raw material for primary iron production. Due to high costs, ironmaking plants are constantly searching for alternative carbonaceous materials. SPL is a carbonaceous waste from primary aluminum production, which could potentially be used in ironmaking. Considering SPL first cut properties and the processes available in the ironmaking industry, without beneficiation, SPL appears promising as an auxiliary fuel for blast furnaces.22

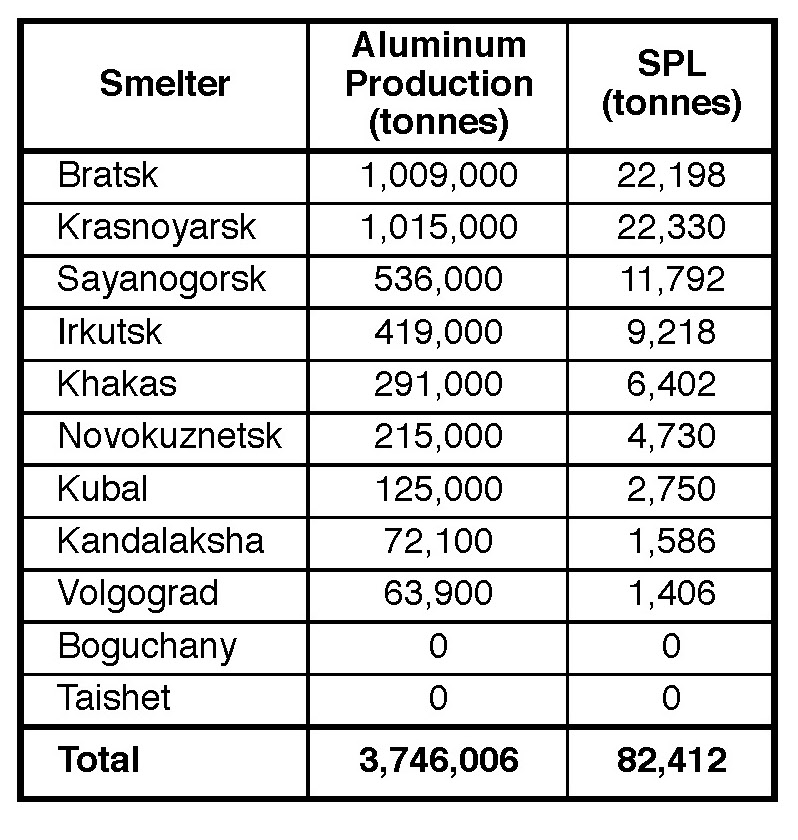

Russia

Russia was the third largest producer of primary aluminum in the world in 2018, with 3.75 million tonnes, representing 5.9% of global aluminum production. UC Rusal operated eight aluminum smelters in Russia, as well as its Kubal smelter in Sweden (Table V). The startup of the Boguchansky smelter with an aluminum production capacity of 592,000 tonnes per year occurred in 2019 and the startup of the Taishet smelter had been delayed.

The environmental policy of Rusal (approved by Act NRGM-11-P029 in 2011) involves all of the company’s divisions. As per this policy, the company aims to consistently improve its environmental parameters by engaging the best available techniques and methods to increase waste recycling and recovery of waste materials, as well as their safe storage.23

It is estimated that 82,412 tonnes of SPL were generated by Rusal smelters in 2018 (Table V), of which the company processed more than 60%. Overall, the amount of recycled waste from carbon potlining increased by 20% by the end of 2018 as compared to 2009. Rusal has demonstrated its commitment towards sustainability by processing and selling over 50% of the waste generated by its smelters in the last ten years. Rusal processed about 10% of red and nepheline mud at its alumina refineries, making it a leader in alumina mud processing among the global aluminum companies. Rusal’s Sayanogorsk industrial site already processes or sells over 90% of waste produced.24

Re-Processing Technology for SPL

Rusal proposed a process that uses highly dispersed shapeless lining materials, which can be recycled. The company currently has over 100 reduction cells in operation that have been lined with recycled materials using this method. Secondary cryolite production from a potlining production facility in Russia was designed and put into operation in 1972 at Achinsk alumina refinery. The technology and the project were developed by the Irkutsk branch of VAMI to extract fluorides as cryolite. In 1989, VAMI together with the Ural Scientific-Research Institute of Ferrous Metallurgy conducted the research program, Fluoride Carbon Waste of Aluminium Cell Application in Steelmaking. Based on the developed technology the smelters introduced grinding of first cut spent lining (carbon only), grading and delivery to ZapSib (West-Siberian Metallurgical Plant) starting from 1993.25

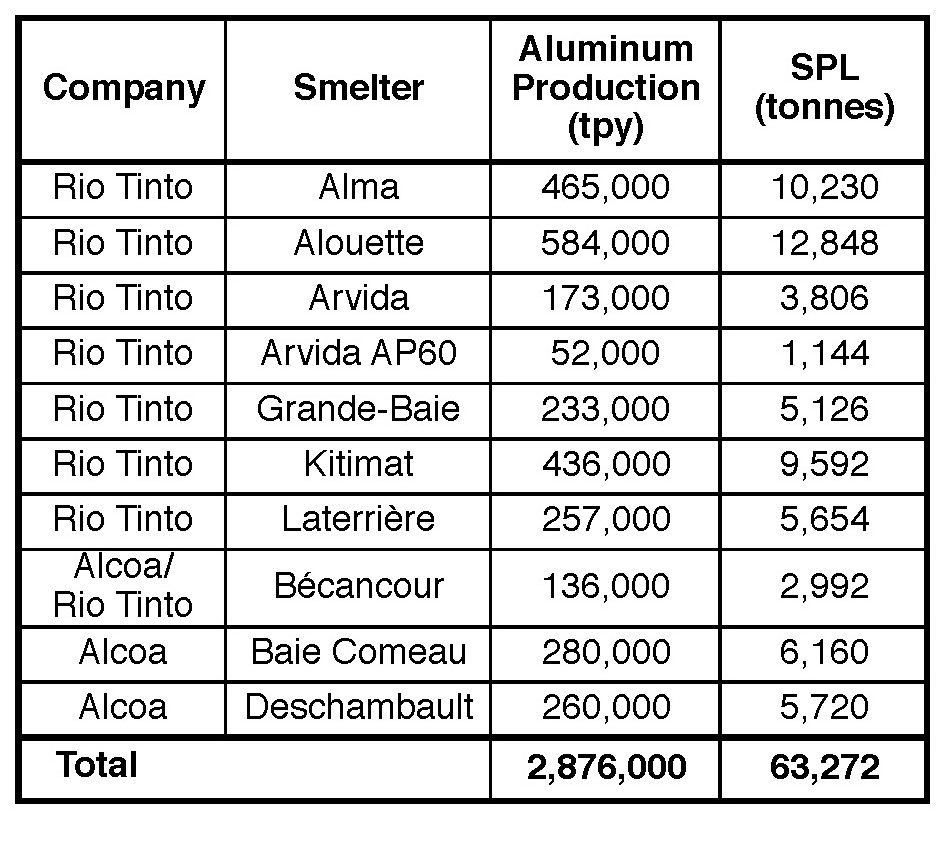

Canada

Canada was the fourth largest aluminum producer in the world in 2018 with 2.9 million tonnes produced by seven Rio Tinto smelters and three Alcoa smelters. Together they generated an estimated 63,000 tonnes of SPL (Table VI). An estimated 39,000 tonnes of SPL was generated from aluminum electrolysis cells in 2018 by the seven Rio Tinto smelters in Quebec.

According to Rio Tinto’s 2019 Environmental BC Works Report, 7,365 tonnes of SPL was generated in 2019 at the Kitimat BC smelter (at a rate of 16.9 kg SPL/t Al). All the SPL material was sent to the Rio Tinto SPL recycling plant located in Saguenay, Quebec, where the material was treated and recycled. The SPL generated originated from the replacement campaign of the AP4X pots.

In 2008, Rio Tinto started treatment and recycling of SPL based on the low-caustic leaching and liming (LCLL) process at its new plant in Jonquière, Quebec, Canada. The plant treats 80,000 tonnes of SPL annually and has treated 700,000 tons of SPL since 2008. The plant produces mainly chemicals (NaOH, CaF2, and NaF) and pure carbon materials.26 After treatment with the LCLL process, the refractory part of SPL (second cut) becomes an inert non-hazardous material. On average 10,000 tonnes per year of LCLL ash are produced in this plant. Studies show that LCLL ash behaves as a mineral retarder in cement hydration with the potential to reduce the heat of hydration. It also behaves like a standard fly ash and has the potential to be used as a reactive supplementary cementitious material in concrete.27

Rio Tinto, Lafarge Canada, and its subsidiary Geocycle Canada created a new SPL product, dubbed Alextra, following several years of research and development.28 At its facility in Bath, Ontario, Lafarge Canada will ultimately produce about 1 million tonnes of cement each year using Alextra as an ingredient in place of alumina and silica, which are commonly refined or mined for use in the manufacturing of cement. In addition, the companies are exploring options to further expand the supply of Alextra from Rio Tinto’s Potlining Treatment Plant in Saguenay-Lac-Saint Jean. The expanded supply will be shipped to Lafarge Canada’s network of cement plants across Canada.

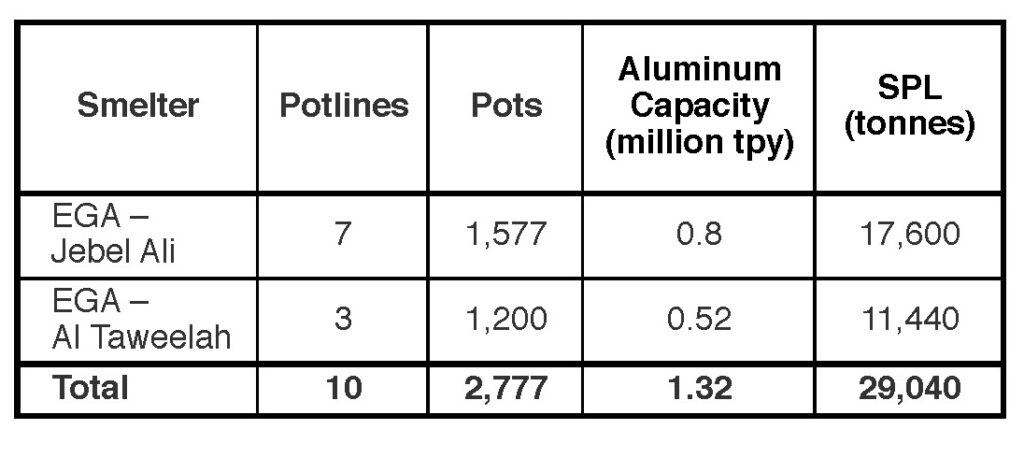

UAE

The United Arab Emirates (UAE) was the fifth largest producer of primary aluminum in 2018. The combined aluminum production in 2018 of Emirates Global Aluminium’s (EGA’s) two operating smelters in Jebel Ali in Dubai and Al Taweelah in Abu Dhabi was 2.64 million tonnes in 2018. Together, the two smelters generated an estimated 29,040 tonnes of SPL, at a rate of 11 kg SPL/t Al (Table VII). According to EGA’s 2018 Sustainability Report, the company recycled a record 41,323 tonnes of SPL, including all of its SPL generation in 2018 as well as some previously stockpiled material. The SPL is distributed to the UAE cement industry for use as a feedstock and alternative fuel.

EGA has developed strategic partnerships and agreements with eight UAE cement producers to create a new market and opportunities for recycling SPL and thereby turn it from an unwanted waste into a valuable feedstock. In June 2019, EGA started a $4 million pre-treatment and crusher facility for SPL in Al Taweelah. The EGA facility will pre-treat SPL, which will be delivered to UAE cement companies to be used as substitute feedstock to boost the recycling and reuse of industrial waste.

At a cement plant located in Ras Al Khaimah, UAE, assessed the environmental benefits of SPL utilization in cement manufacturing. The cement plant produces around 8,000–8,500 tonnes of clinker per day (347 tonnes/h), with an annual capacity of around 2.8 million tonnes. It has been using 0.6% SPL as part of its raw feed stock for several years. The study showed that the toxic materials (cyanides and fluorides) are destroyed or transformed in the cement process, and that SPL utilization reduced CO2 and NOx emissions in addition to providing monetary benefits that include savings in the form of fuel and raw material.29

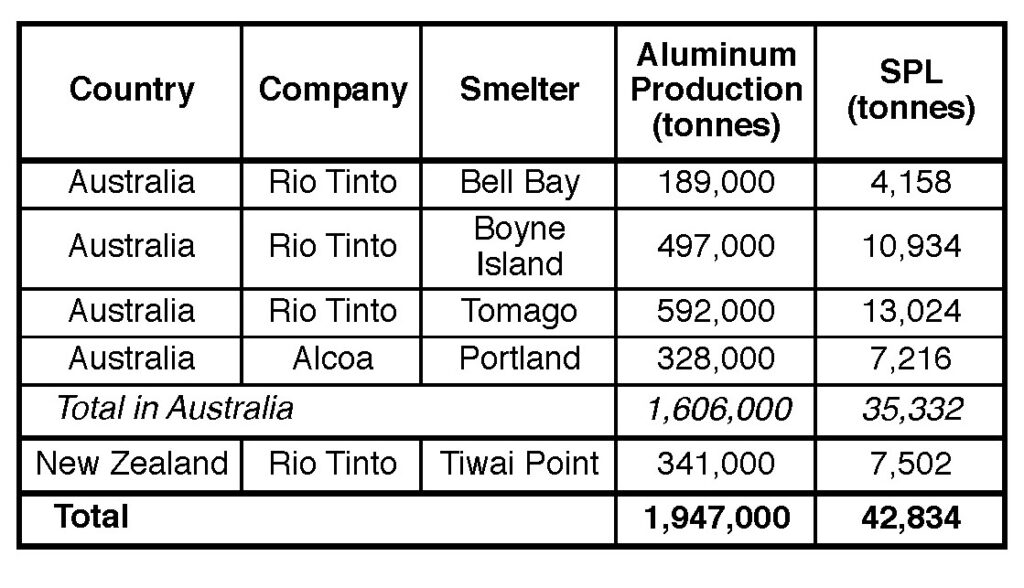

Australia

Australia (including New Zealand) was the sixth highest producer of primary aluminum in the world in 2018. In Australia, Rio Tinto (operating the Tomago, Boyne, and Bell Bay smelters) and Alcoa (operating the Portland smelter) produced a combined 1.6 million tonnes of aluminum from four smelters, and generated a combined estimated 35,332 tonnes of SPL (Table VIII).30 In New Zealand, the Tiwai Point smelter (owned by Rio Tinto and Sumitomo Corporation) produced 341,000 tonnes of aluminum in 2018, generating an estimated 7,502 tonnes of SPL. Hazardous SPL wastes produced by Australian aluminum smelters were reported in 2016 to be stockpiled in Queensland, New South Wales, Victoria, and Tasmania.31

The Tomago smelter has never landfilled SPL on-site. The smelter exported approximately 118,000 tonnes of SPL before the 1990s to Italy and Spain for cement kilns and for carbon in steel manufacturing. Tomago has utilized the Regain process to treat the smelter generated SPL on-site. It has also sent some SPL to Weston Aluminium, which is processing Tomago’s aluminum dross.

The Boyne smelter also never landfilled SPL on-site. The smelter utilizes the COMTOR method for processing SPL, which involves a three-stage process of crushing, thermal destruction of cyanide by calcination, and wet digestion that consists of adding lime and water. The final crushed and dried product output is exported to Spain.

The Bell Bay smelter has been stockpiling SPL in above-ground sheds since the late 1990s. In 2010, the smelter began processing SPL at the Cement Australia Railton (CAR) site. Bell Bay reports processing around 4,000 tonnes of SPL per year at CAR since 2014.

Alcoa’s Portland Smelter has never landfilled SPL. However, dedicated SPL storage areas, at the smelter and at an off-site storage facility are used. Treatment of smelter generated SPL occurred at the smelter’s on-site Ausmelt plant between 1995 to 2007. After 2007, Portland transported SPL to the Point Henry Regain facility for processing.

Regain SPL Processing Technology in Australia

Regain developed a process technology to detoxify and refine SPL. The patented detoxification and refinement process recycles reaction off-gases to provide heat. No residual material is left over, and a bag house recycles particulates. Cyanide destruction is achieved by thermal oxidation, heating the material in the presence of oxygen. Neutralization of the reactive compounds is achieved by using water to carry out the reactions that generate the explosive gases in a controlled environment using special apparatus, making it so that no more gas can be generated. Mineral products with fluxing and mineralizing properties are manufactured by processing the detoxified SPL material and other ingredients. The Regain process does not destroy the fluoride hazard in SPL, which has some benefit for clinkering in downstream cement manufacturing markets.

Regain has treated over 370,000 tonnes of SPL from smelters across Australia since 2002. The company has exported processed SPL to cement kilns overseas as cement clinker mineralizing products used to improve cement production. Regain’s Point Henry plant processes SPL and operates under the umbrella of the Alcoa site license. The license does not specify an annual processing capacity limit for the plant. However, it does limit storage of the waste materials to 3,000 tonnes. The company’s Tomago site also processes SPL and the site has a licensed capacity to process 20,000 tpy. More than 250,000 tonnes of SPL has been processed since 2002 using Regain technology.32

Befesa

Befesa recycles aluminum dross salt slags and other residues from secondary aluminum producers and uses SPL to reduce energy input requirements. The current export options for SPL management include mineral wool (Rockwool) manufacture in Germany and Spain. However, mineral wool manufacture is only suited to blocks of first cut SPL processing.

Weston Aluminium

Historically, Weston Aluminium in New South Wales operated as a salt dross processing company to recover aluminum from primary and secondary aluminum dross. Weston has developed a proprietary process in which it converts SPL to a non-hazardous and non-dangerous material. The process involves the thermal destruction of cyanide and off-gases using a furnace at 1,000°C. The manufactured product from SPL, named Nepheflux, is ideal as a flux and mineralizer for the brick and cement industry. The company has demonstrated that bricks made with as little as 3% Nepheflux fire at a reduced temperature and subsequently save on fuel and greenhouse gases. These bricks have increased strength and are less water absorbent. Currently, the company is only licensed for second cut SPL. This limits the company’s processing capacity to a combined total of 40,000 tpy for SPL and aluminum dross, and limits storage on-site to 5,000 tonnes.

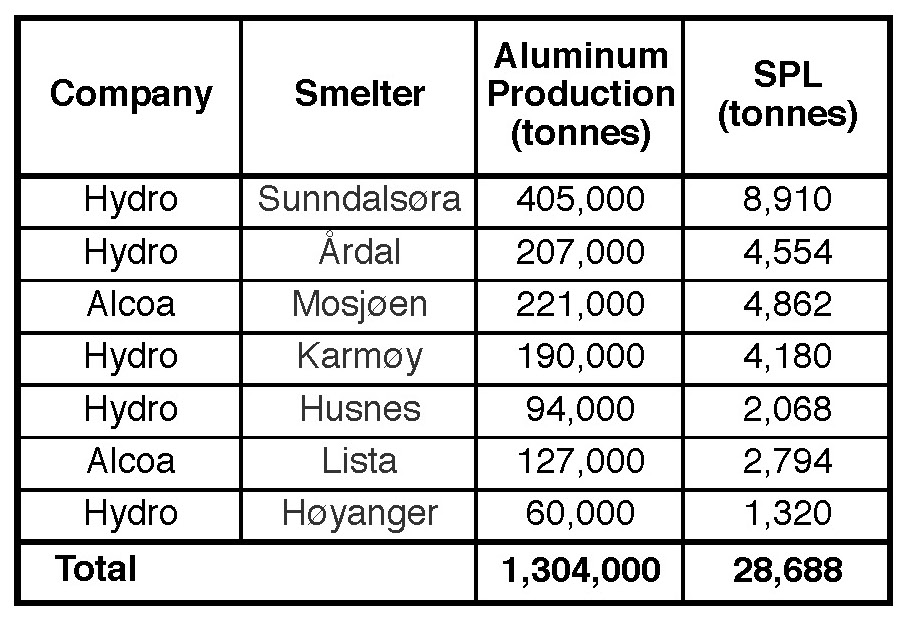

Norway

Norway was the seventh largest aluminum producer in the world in 2018, producing an estimated 1.3 million tonnes of primary aluminum from its five Norsk Hydro aluminum smelters and two Alcoa smelters. This resulted in the generation of an estimated 28,688 tonnes of SPL (Table IX).

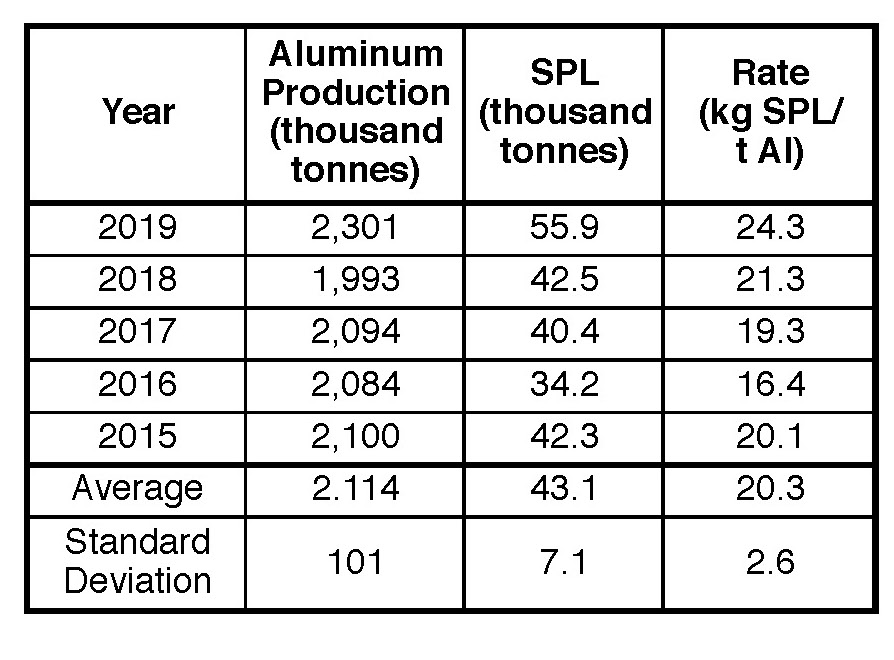

The total projected aluminum produced by Hydro’s five smelters in Norway in 2018 was 1,013,000 tonnes. Together, they generated an estimated 22,286 tonnes of spent potlining. According to Hydro’s 2018 Annual Report, the total aluminum production from Hydro domestic and international smelters in 2018 was 1,993,000 tonnes aluminum, which altogether generated an estimated a reported 42,500 tonnes of SPL. The average rate of SPL generation at the company’s worldwide smelters was 20.3 kg SPL/t Al, as determined from actual plant measurement of SPL over a five-year period (Table X). This shows reasonably good agreement with the acknowledged SPL generation rate of 22 kg/t Al, except for in 2016 when the rate dropped significantly lower.

In Norway, the total projected aluminum produced by Hydro’s five smelters in 2018 was 956,000 tonnes, generating an estimated 21,032 tonnes of SPL. Aluminum production (and SPL generation) was impacted by the idled B-Line at the Hydro Husnes smelter in western Norway since 2009, which had been shut down due to a financial crisis. The B-Line capacity resumed operation on November 24, 2020, which will increase production to 195,000 tpy (and SPL generation to 4,290 tpy), once the 200 electrolysis cells in B-Line restart operation.

Since 2012, anode waste from Hydro has been used as an alternative fuel at the Norcem cement plant in Brevik, Norway (part of Heidelberg Cement), where high temperature incineration ensures safe treatment of hazardous components. Hydro has an agreement with a refractory supplier to recycle part of the bricks coming from relining its anode baking furnace. In 2013, Hydro entered into a contractual agreement with Rockwool International in Germany to process their first cut SPL. Because it is high in carbon, it has been used as a substitute for coke in the thermal process of insulation material production.

Regain is evaluating its thermal vacuum treatment process for the purification of first cut SPL waste in Norway.33 The process involves the purification of graphite from sodium and fluorides. Samples of 1,000 g first cut SPL achieved a purity of 91% graphite, with 1.2% CaF2, and 0.9% Al2O3. The value of the graphite product will depend on achieved purity, which will be the most essential parameter for the business case of the process.

Bahrain

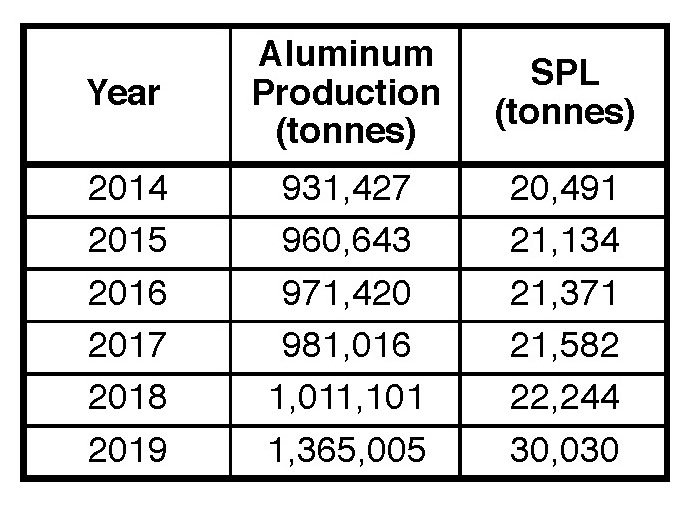

Aluminium Bahrain (Alba) was the eighth largest producer of primary aluminum in the world in 2018. The Alba smelter produced 1,011,101 tonnes of primary aluminum and generated an estimated 22,244 tonnes of SPL in 2018. The increase in the estimated SPL generated at the Alba aluminum smelter from 2014 to 2019 (Table XI) is a result of the increase in aluminum production.

At Alba, 60,000 m3 of SPL waste that had been generated over the past several years was subjected to physical segregation into four fractions namely steel, carbon blocks, refractory and insulation bricks, and fine fractions, which cannot be segregated. All the steel was sold to a steel recycling furnace adjacent to Alba.

Alba began construction of a US$44 million SPL treatment plant in 2019.34 Regain was selected to support the development and construction of the 26,000 sq m plant, which will use the supplier’s proprietary technology to recycle and repurpose SPL that would typically be warehoused off-site or sent off to landfills. The SPL treatment plant will have an annual capacity of 35,000 tonnes of SPL when it starts up in the first quarter of 2021.

U.S.

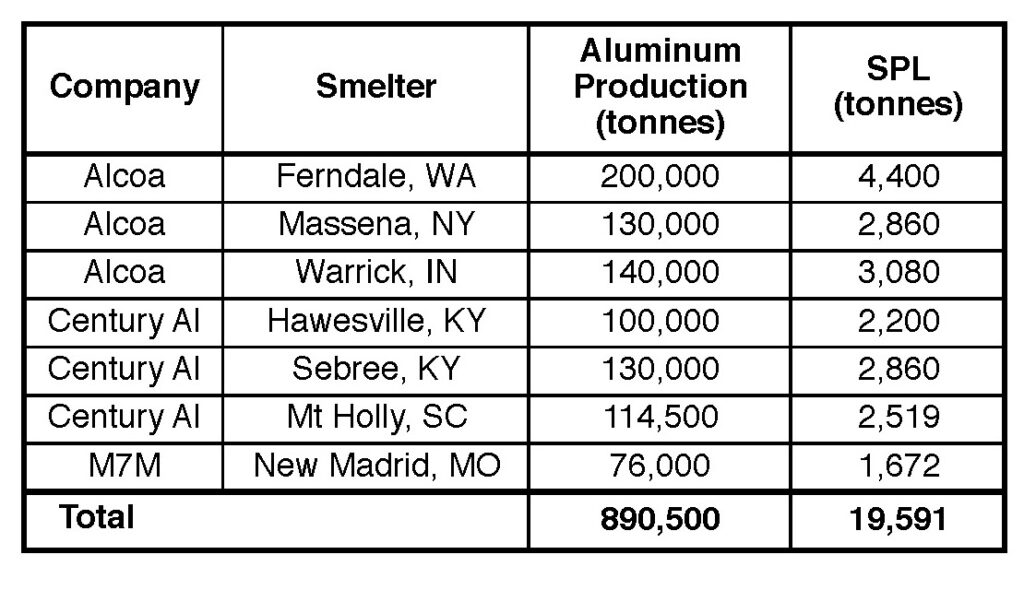

The U.S. was the ninth largest producer of primary aluminum in the world in 2018. The three aluminum companies, Alcoa, Century Aluminum, and Magnitude 7 Metals (M7M), operate seven smelters, which produced a combined 890,500 tonnes of aluminum in 2018, generating an estimated 19,591 tonnes of SPL (Table XII). The demand for SPL treatment in the U.S. has declined significantly with the decrease of aluminum smelting activities in North America.

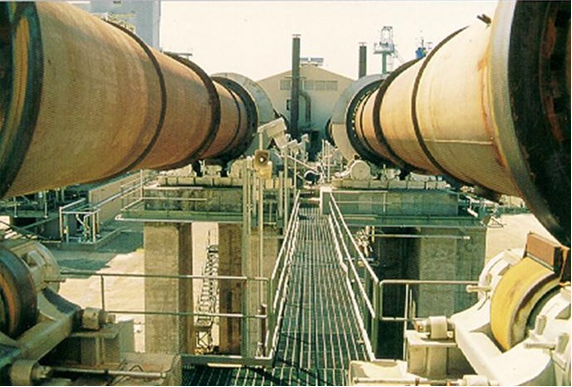

Alcoa treats the SPL produced from its U.S. smelters at the Gum Springs, AR, hazardous waste treatment facility (Figure 3), which uses a thermal treatment process to de-toxify SPL in a rotary kiln.35 The plant started operation in 1993 and was one of the first large-scale SPL processing plants in the world, with a capacity to process 110,000 tonnes of SPL per year. Alcoa acquired the SPL hazardous treatment facility from Reynolds in 2000, and it was operated by Elemental Environmental Solutions, a wholly owned Alcoa subsidiary. During Q1 2020, Alcoa sold the Gum Springs facility to Illinois-based waste management firm Veolia ES Technical Solutions for US$200 million. While remaining a key service provider to Alcoa through a multi-year dedicated agreement, the facility will also be expanding its services to customers throughout North America.

At the Gum Springs site, a mixture of pre-grinded SPL, lime, and anti-caking agent (calcium silicate) is loaded into a rotary kiln. Limestone is added to combine and react with fluorides, while cyanides are destroyed at 650–815°C. The main goal of this process is the detoxification of SPL with the aim of producing a non-hazardous byproduct that is suitable to be stored in a landfill.

Century Aluminum states that it manages its impact on the environment through the responsible and efficient management of any hazardous and non-hazardous waste. When Century Aluminum closed the Ravenswood, WV, smelter in 2009, the remediation was completed with the removal of the final SPL at the former plant.

Iceland

Iceland was the tenth largest producer of primary aluminum in the world in 2018. The three aluminum smelters — Fjardaál (owned by Alcoa), ISAL (owned by Rio Tinto), and Norðurál (owned by Century Aluminum) — produced 875,000 tonnes of aluminum and generated 16,745 tonnes of SPL in 2018 (Table XIII).36 The average rate of SPL generation for the three smelters is 20 ±3 kg SPL/t Al, based on actual annual plant measurements. By comparison, the estimated rate of SPL generation for the three smelters (based on the production of 875,000 million tonnes of aluminum in 2018) is 19,243 kg SPL/tonne Al.

Iceland and Norway have stored SPL from aluminum smelters in basins on the seashore, allowing sea leaching and neutralization of soluble components. The leachable fluorides present in SPL will react with the calcium ions in seawater to form a stable calcium fluoride. An extensive investigation of marine organisms around a cathode dumping site by Svavarsson and Ingólfsson, University of Iceland, did not indicate that the dumping pits had detrimental effects on shore communities.37

Alcoa

The Fjardaál smelter started in 2008 in Reyðarfjörður and has environmental goals aimed at recycling waste, with a non-landfill policy (Figure 4). SPL is transported in containers to the on-site port and shipped overseas. This waste goes through a recycling process in England, where the first cut is used as a fuel for energy intensive industries and the second cut is used for cement and brick production. Alcoa does not dispose of SPL onsite at its smelter in Iceland.

Century Aluminum

The Norðurál smelter started in 1998 in Grundartangi and is using a flood pit disposal method, where the SPL is mixed with shell sand. The purpose of the sand is to neutralize fluoride and cyanide and to dilute the material before being placed in the flood pit. The flood pit method is currently the best practice for treating SPL in Iceland and complies with the operational license approved by the Icelandic Environmental Agency. The seawater acts to neutralize the SPL prior to deposition in landfill. Adding layers of limestone in the basin can promote the neutralization process. Chemical samplings are conducted by the seashore next to the repository to evaluate landfill effects on the nearby environment.

Rio Tinto

The ISAL smelter started in 1969 in Hafnarfjörður and has an on-site landfill, which is a seawater repository. The seashore deposit is located where the tide flows at the bottom of the landfill. This creates a chemical reaction and hazardous substances are neutralized over time.

Other Regions

Additional projects for the processing of SPL are being carried out in countries other than the top ten producing, as noted previously. These are noted hereafter.

Brazil

Hydro’s smelter, Albras Alumínio Brasileiro S.A., has a significant stock of SPL. This is being reduced through deliveries to the local cement industry, thus substituting fuel or raw materials, while reducing landfill and saving landfill costs. The appropriate treatment of SPL is a part of the planned rehabilitation work at Hydro’s former aluminum plant in Kurri Kurri, Australia.

France

Ultromex signed a major multi-million euro contract with Rio Tinto to excavate, process, and reinstate a recycling plant in France. The facility will treat 65,000 tonnes of salt slag and dross from primary and secondary aluminum furnaces. A pilot trial validated and demonstrated the effectiveness of the Ultromex’s Saltromex process for remediating slag. The plant will be built during 2021.

Ultromex also developed the Carbomex process for downsizing either first or second cut fractions into a form suitable for chemical treatment to remove contaminants (mainly cyanide and fluoride). The Carbomex chemical process for treating SPL is unique and is highly effective in removing the contaminants, leaving the cleaned residuals — carbon from the cathode and aluminum oxides from the refractory — as potentially valuable secondary resources. The Carbomex SPL treatment process was initially developed and rigorously tested at lab scale and is now in the process of building a pilot plant (~500 kg batch size) to demonstrate the effectiveness of the technology.

Qatar

Qatalum, a joint venture between Hydro and Qatar Petroleum, delivers all first cut SPL to its neighbor Qatar Steel, which uses it in production. In addition, Qatalum and Hydro have cooperated with local cement plants in the development of a solution for co-processing of second-cut SPL.

References

- “Sustainable Spent Pot Lining Management Guidance,” International Aluminium Institute (IAI), February 2020.

- Holywell, J.G., and R. Breault, “An Overview of Useful Methods to Treat, Recover or Recycle Spent Potlining.” JOM, Vol. 65, 2013, pp. 1,441–1,451.

- U.S. Geological Survey, Mineral Commodity Summaries, 2018-2019.

- Tabereaux, A., Reynolds Metals Gum Springs Internal Report, 2000.

- Øye, H.A., “Discussion of Industrial Spent Pot Lining Treatment,” Proceedings of 35th Intl. ICSOBA Conference, Hamburg, Germany, October 2–5, 2017, pp. 1081–1087.

- Black, Phil, “Innovation in SPL Transformation – The Industrial Ecology Way,” Light Metal Age, Vol. 73, No. 1, 2015, pp. 84–85.

- Gao, B.L., “Innovations in Aluminum Production Technology at Northeastern University, Shenyang, China,” Light Metal Age, Vol. 74, No. 1, 2016, pp. 29–33.

- Wang, Zhaowen, et al., “Recycling of Solid Wastes in Aluminum Electrolysis in China,” ICSOBA Conference, Krasnoyarsk, Russia, September 2019, pp. 16–20.

- Xie, Mingzhuang, et al., “Characteristic Analysis of Hazardous Waste from Aluminum Reduction Industry,” Light Metals 2020, TMS, pp. 1,261–1,266.

- Liu, Feng Qin, et al., “Footprint of harmful substances in spent pot lining of aluminum reduction cell,” Transactions of Nonferrous Metals Society of China, Vol. 30, Issue 7, July 2020, pp. 1,956–1,963.

- Li, Nan, Lei Gao, and Kinnor Chattopadhyay, “Experimental Study on the Collecting Agent for Spent Potlining Flotation Index Optimization,” Light Metals 2020, TMS, pp. 1,243–1,250.

- Huxian Flotation, Flotation Process for SPL Innocuous Treatment, developed by Prof. Qiu Zhuxian and Dr. Zhai Xiujing in 1989.

- Shi, Zhongning, et al., “Recovery of carbon and cryolite from spent pot lining of aluminum reduction cells by chemical leaching,” Transactions of Nonferrous Metals Society of China, No. 22, 2012, pp. 222–227.

- Patent CN104894600A, September 9, 2015.

- Wang, Yaowu, Jianping Peng, and Yuezhong Di, “Separation and recycling of spent carbon cathode blocks in the aluminum industry by the vacuum distillation process,” JOM, Vol. 70, No. 9, 2018, pp. 1,877–1,882

- Hou, Jian-feng, et al., “Elimination of lithium from aluminum electrolyte by acid leaching method,” Light Metals 2016, TMS, pp. 353–357.

- Tabereaux, A., “India – An Aluminum Giant Awakens” Light Metal Age, Vol. 76, No. 1, 2018, pp. 42-49.

- Tiwari, N.K., “Waste Mapping and Forecasting for Alternate Fuel Usage in Cement Plants,” Confederation of Indian Industry (CII), New Delhi, India, March 2, 2017.

- Tiwari, N.K., “Spent Pot Liner Utilization in Cement Industry Steel Industry,” Vedanta, March 7, 2019.

- Sahoo, M., Amit Gupta, and S.K. Badajena, “Minimizing SPL Generation via Redesigning Pot and Life Enhancement,” ICSOBA Virtual Conference, November 16-18, 2020.

- “Cement Industry in India,” India Brand Equity Foundation (IBEF).

- “Steel Manufacturing Companies in India,” IBEF.

- Kulikov, B.P., and S.P. Istomin, Aluminium Smelting Wastes Treatment and Recovery, 2nd Edition, MANEB, St Petersburg, Russia, 2004, p. 480.

- Mann, V., et al., “UC Rusal advances new technology in improving environmental standards,” Light Metal Age, Vol. 74, No. 1, 2016, pp. 34–36.

- Mann, V. et al., “SPL Recycling and Re-processing,” Light Metals 2017, pp. 571–578.

- Birry, Laurent, and Stephane Poirier, “The LCL&L Process: A Sustainable Solution for the Treatment and Recycling of Spent Pot Lining,” Light Metals 2020, pp. 1,237–1,242.

- Ouellet-Plamondon, C., et al., “Valorization of Treated Spent Pot Lining By-Product in Concrete,” TRAVAUX 49, Proceedings of the 38th International ICSOBA Conference, November 16-18, 2020.

- “Rio Tinto and Lafarge Canada Develop Cement Ingredient From Spent Potlining,” Aluminium Insider, October 19, 2020.

- Al Jawi, Mohammad, et al., “Environmental Benefits of Using Spent Pot Lining (SPL) in Cement Production,” ICSOBA 2019, Krasnoyarsk, 16-20, 2019; Light Metals 2020, pp. 1,251–1,260.

- Tabereaux, A. and D.S. Wong, “The Australasian Energy Crisis – A Bleak Future, or an Opportunity for Innovation at Aluminum Smelters” Light Metal Age, Vol. 78, No. 2, 2020, pp. 36–43.

- “Spent Pot Lining Project Stockpiles,” Final National Summary Report, Randell Environmental Consulting in association with Ascend Waste and Environment, 2016.

- Zimmermann, Y., “Spent potlining solution from Regain,” Aluminium, Vol. 93, No. 1-2, 2017, pp. 42–44.

- Sundby, Kristin, et al. “Purification of Graphite by Thermal Vacuum Treatment of Spent Potlining,” Light Metals 2020, pp. 1,231–1,236.

- “Alba Names Australia’s Regain as Technology Partner for Spent Pot Lining Treatment Plant,” Aluminium Insider, December 24, 2019.

- Banker, D.B., et al., “Detoxification of aluminum spent potliner by thermal treatment, lime slurry quench and post-kiln treatment,” U.S. Patent 5164174A, Reynolds Metals Co., 1991.

- Þórðardóttir, R., “Aluminum production waste mapping – A case study of the Icelandic aluminum industry,” 30 ECTS thesis, School of Engineering and Natural Sciences University of Iceland Reykjavik, May 2018.

- Ingólfsson, A., and J. Svavarsson, “Study of marine organisms round a cathode dumping site in Iceland,” Science of the Total Environment, Vol. 163, 1995, pp. 61–92.

Editor’s Note: This article first appeared in the February 2021 issue of Light Metal Age. To receive the current issue, please subscribe.