The International Magnesium Association (IMA) honored their peers with the IMA Awards of Excellence, which were handed out at the 76th Annual World Magnesium Conference in Budapest.

Established in 1962, the Awards of Excellence program is an annual award presented to companies for demonstrating outstanding examples of the different uses of magnesium, and presents a great opportunity for participants in the magnesium industry to showcase innovative products and manufacturing technologies. Honors annually bestowed by the IMA include five Awards of Excellence: Automotive Cast Products, Commercial Cast Products, Process, Wrought Products, and Environmental Responsibility.

Automotive Cast Product Design Category

Michael Schran from castwerk won in the automotive cast product design category for his gearbox design for an automatic tailgate lift system, which is in serial production. The gearbox was designed to reduce machining requirements. It also meets specific requirements for position and diameter of the holes (0.08 mm hole distance tolerance) in order to avoid axial displacement and reduce noise in the vehicle. A flatness of 0.18 mm over the entire part was achieved without any machining.

Commercial Cast Product Category

A magnesium alloy frame for a child’s bicycle designed by Zhenjiang Li, Hebi Jianglang Metals Co., Ltd. and the China Magnesium Association won in the commercial cast product category. The unibody magnesium frame in alloy AM60B/AM50A does not require welding, which reduces risk of breakage at the welded joint. In addition, the frame is lightweight and provides excellent shock resistance for decreased turbulence during the ride.

Process Category

In the process category, the award was presented to Chunjiang Ma and Daqing Fang of Allite, Inc. for their thermomechanical processing of Allite SuperMag ZE62. Forging, which pressurizes and deforms the crystalline structure of the material, holds great potential to create high strength and exceptionally light weight articles, particularly when the material grain size is kept small during deformation. However, the forging of magnesium alloys has traditionally been challenging due to the poor ductility of conventional magnesium alloys. Allite has developed a new alloy, ZE62, which uses rare earth elements to increase the strength and ductility of the magnesium. Combined with a proprietary forging method — including specific material flow analysis, tooling design and thermomechanical processing parameters — the company was able to successfully retain the material’s crystalline structure and grain size. This enables future production of high-strength forging products with exceptional performance, consistent material density and low-cost production from a range of magnesium alloys.

Wrought Product Category

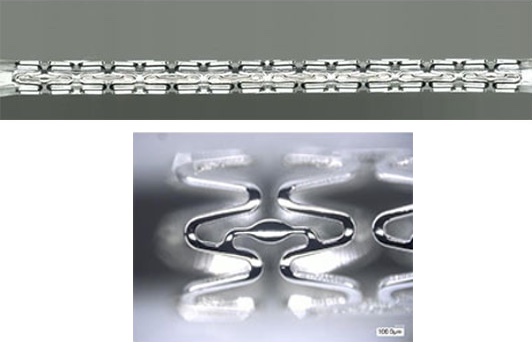

Masashi Inoue from Fuji Light Metal Co., Ltd., Shuzo Yamashita from Japan Medical Device Technology Co., Ltd.., and Kazumasa Yamasaki from the Japan Magnesium Association were presented with a wrought product category award for their bioresorbable scaffold comprised of a magnesium alloy extruded tube. The seamless tube (1.5~3.0 mm inner diameter, 0.11~0.30 mm thickness) is made from a newly developed alloy, which does not contain aluminum or rare earth elements. All steps of casting, extrusion, drawing, laser processing, and surface treatment were carried out by the company in-house. Used for vascular endothelialization (the treatment a coronary artery disease), the tube has several beneficial properties, including biological safety, an ultra thin strut, and a smaller contact area for vessel walls, as well as the suppression of inflammatory reaction from the treatment. It also provides the optimal degrading property, dissolving within 1 year after supporting the affected lesion for around 3 months.

Environmental Responsibility

The environmental responsibility award was presented to Qinghai Salt Lake Magnesium Co., Ltd.; Magontec Qinghai Co., Ltd.;

Prof. Fusheng Pan, Chongqing University; and Chunming Dong, Sunlight Metal Consulting(Beijing) Co., Ltd. for the production of the production of green magnesium based on a circular economy and low carbon model. Qinghai Salt Lake is using Salt Lake waste brine to produce magnesium, magnesium alloys, and castings with the electrolysis method combined with green energy sources and additional low carbon production technologies.