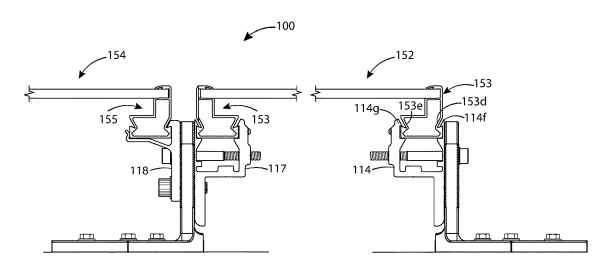

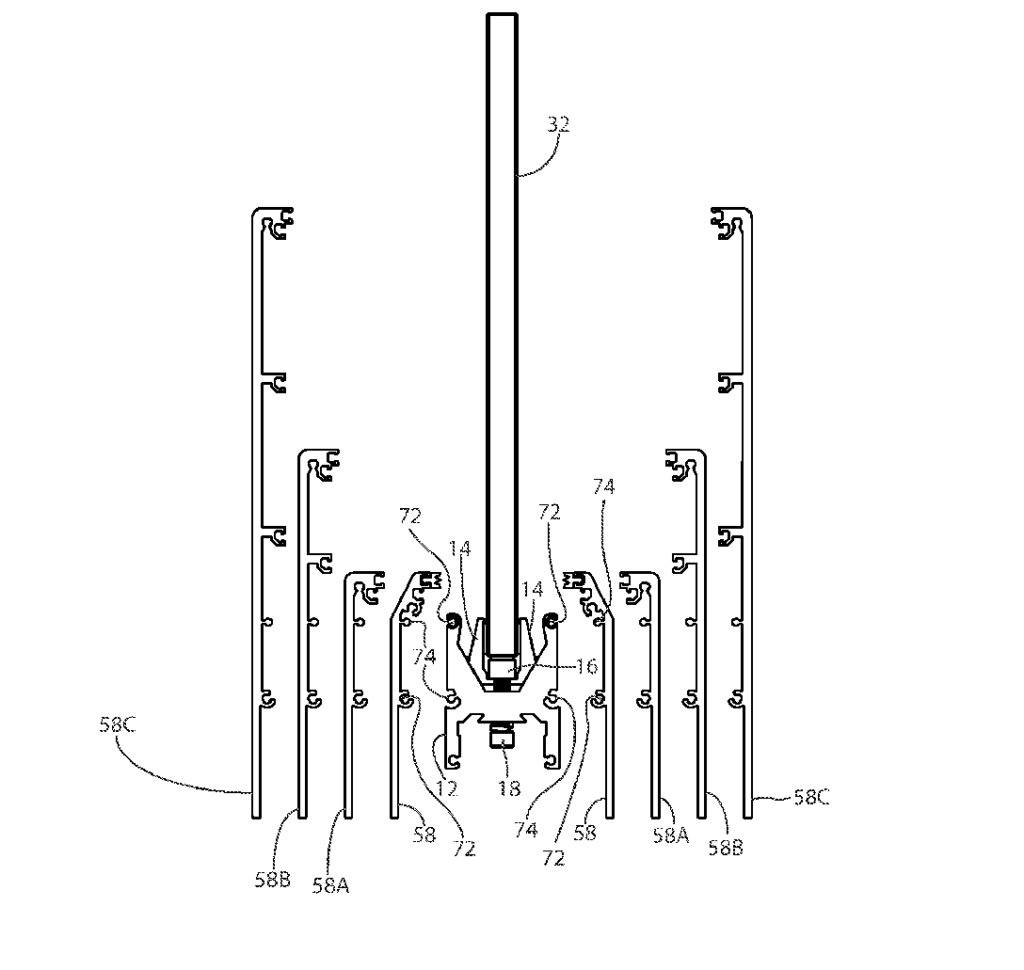

US11845323 — VEHICLE ROOF COMPRISING A SHADING ARRANGEMENT AND GUIDE RAILS — Webasto SE (Germany) — A vehicle roof having a plate-shaped body-shell element and a shading arrangement which has a shading element and guide rails for laterally guiding the shading element. At least one fixing element is formed integrally on each of the guide rails at an upper side facing the body-shell element, said fixing element being in engagement with at least one molded portion which is molded to the body-shell element and has at least one fixing counterpart. For example, fixing counterparts have a groove-like recess having a T- or mushroom-shaped undercut cross-section engaged by a rib whose cross section corresponds to the respective recess on the upper guide rail which is an extruded aluminum profile.

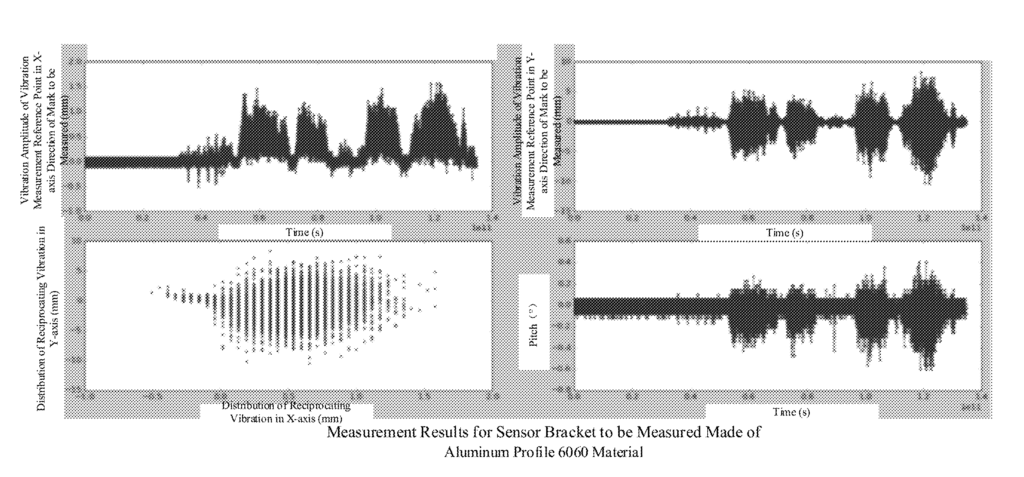

US11828828 — METHOD, APPARATUS, AND SYSTEM FOR VIBRATION MEASUREMENT FOR SENSOR BRACKET AND MOVABLE DEVICE — Beijing Tusen Zhitu Technology Co., Ltd. (China) — The present disclosure relates to sensor technology, and provides a method, an apparatus, and a system for vibration measurement for a sensor bracket which can be an aluminum alloy extrusion as well as a movable device. The method is applied in a system for vibration measurement for the sensor bracket. The system includes the sensor bracket to be measured that is mounted on a movable device, and a marker on the sensor bracket to be measured, and a first sensor provided on the sensor bracket to be measured for collecting marker information. The method includes collecting the marker information of the marker on the sensor bracket to be measured using the first sensor; determining a vibration measurement reference point based on the marker information and obtaining vibration condition data of the vibration measurement reference point; and determining a vibration evaluation result for the sensor bracket based on the vibration condition data of the vibration measurement reference point.

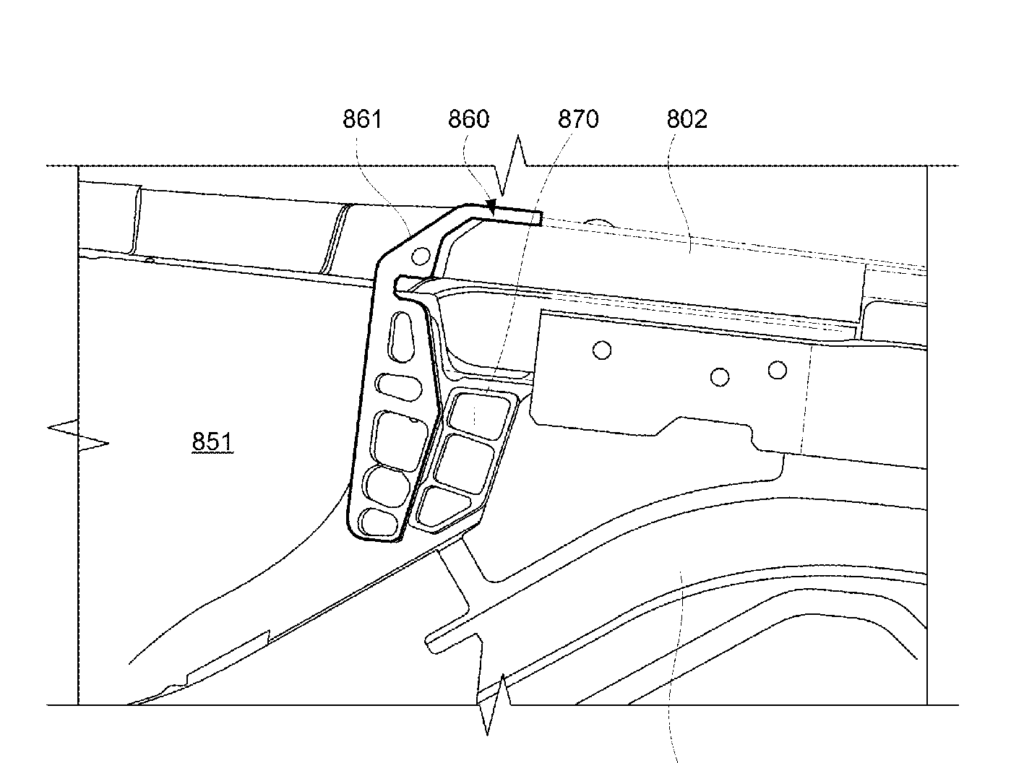

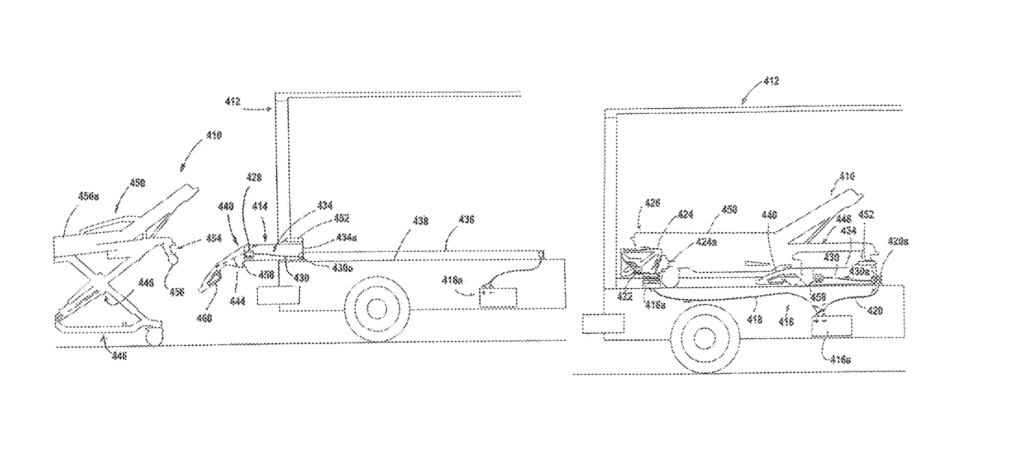

US11827167 — WHEEL DEFLECTOR FOR A SMALL OVERLAP CRASH — Rivian IP Holdings, LLC (USA) — A system for managing wheel kinematics during a small overlap collision event includes a deflector apparatus. The deflector is configured to direct a wheel away from an occupant compartment of a vehicle. The deflector includes a first section arranged at an inside wall of a wheel well facing a wheel, near the base of a hinge-pillar. The first section includes a hollow structure configured to absorb energy from the collision event by plastically deforming. The deflector also includes a second section arranged at an angle to the wheel and configured to deflect the wheel laterally outwards from the vehicle away from an occupant compartment during the small overlap collision event. The deflector may be formed of extruded aluminum. The system may include an absorber arranged behind the first section and configured to further absorb energy from the collision event by plastically deforming.

US11825964 — MIRROR WITH ILLUMINATED EXTRUDED FRAME — Electric Mirror, LLC (USA) — A frame lit mirror component includes an extruded frame member. The extruded frame member further includes a mirror mounting edge. The mirror mounting edge extends along a longitudinal direction of the extruded frame member. The mirror mounting edge is sized to receive an edge of a mirror. A light source volume extends along the longitudinal direction of the extruded frame member. An angle exists between the mirror mounting edge and the light source volume. The light source volume is sized to receive a light source, such that when the light source is in an on-state light radiates from the light source volume. When an opaque material is used for the extruded frame member, light is confined to radiate from an aperture of the light source channel.

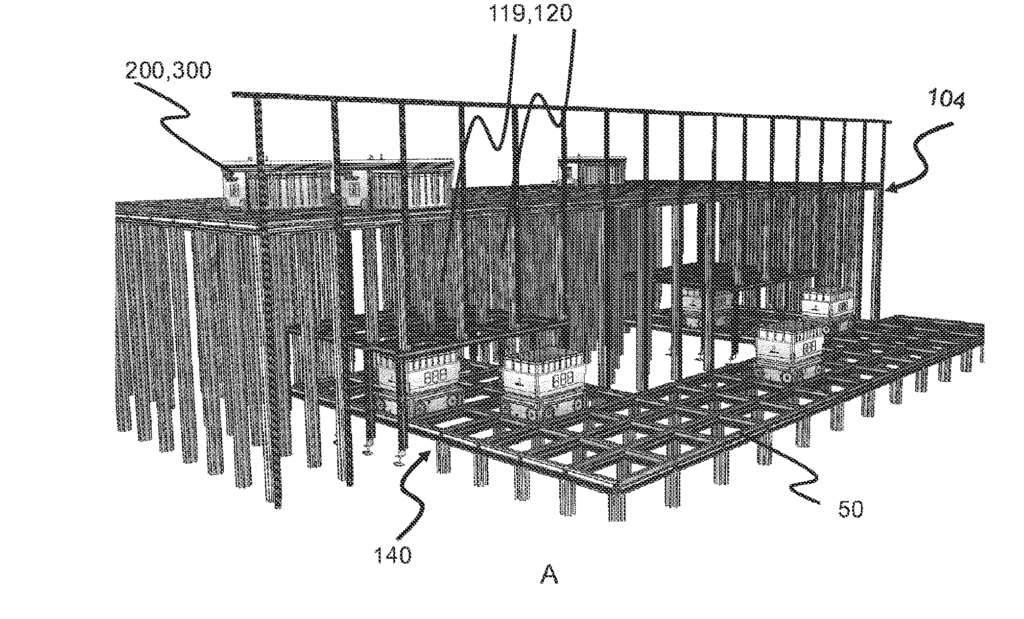

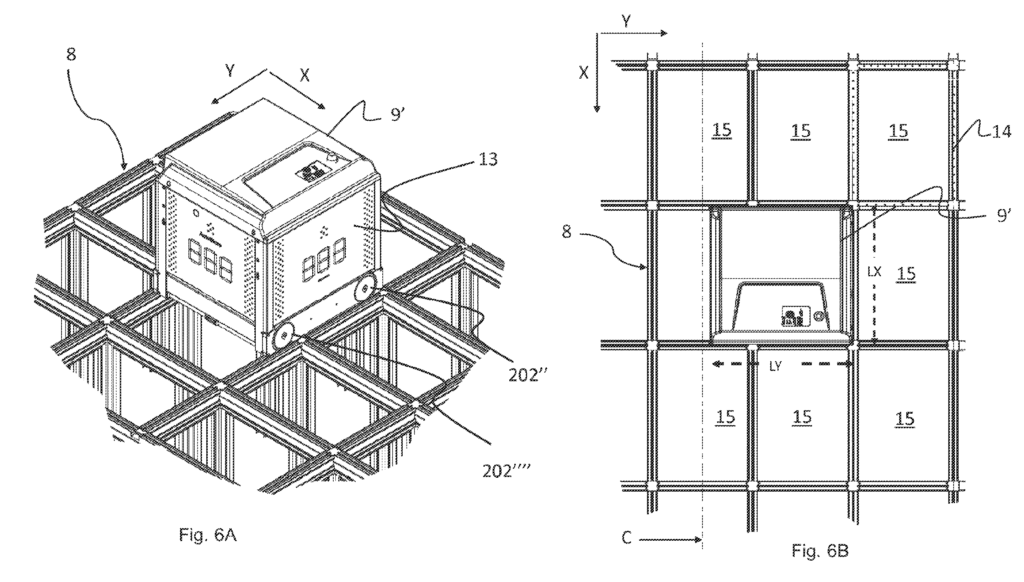

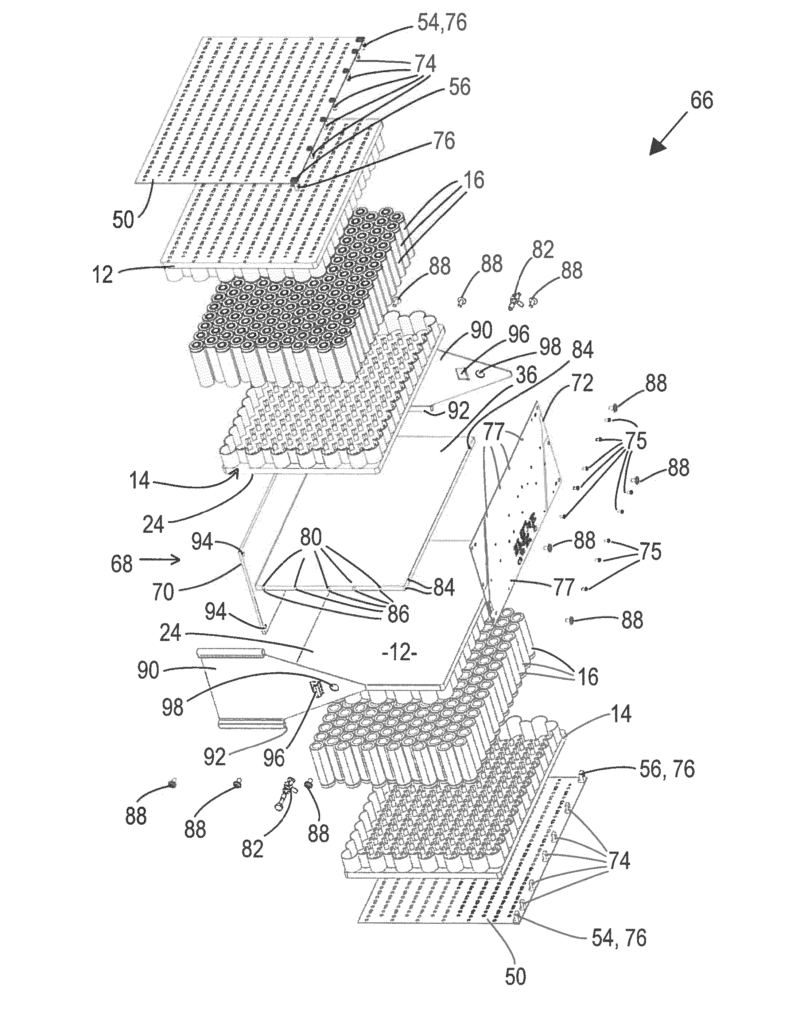

US11820389 — CONTAINER ACCESSING STATION WITH LIFTING DEVICE — Autostore Technology AS (Norway) — The present invention is related to a container accessing station comprising a lifting device arranged to retrieve a storage container from a first level beneath a base opening and lift it up through the base opening to a second level so that the container may be accessed through the access opening. The invention is also related to a container accessing system, an automated storage and retrieval system and a method of accessing a storage container. The automated storage and retrieval grid includes a container handling vehicle rail system for guiding a plurality of container handling vehicles. The framework structure comprises a plurality of upright members and optionally a plurality of horizontal members supporting the upright members. The members may typically be made of extruded aluminum profiles. The delivery vehicle is arranged to deliver the storage container to the lifting device of the container accessing station or receive a storage container from the lifting device and return the storage container to the delivery port for storage within the storage grid.

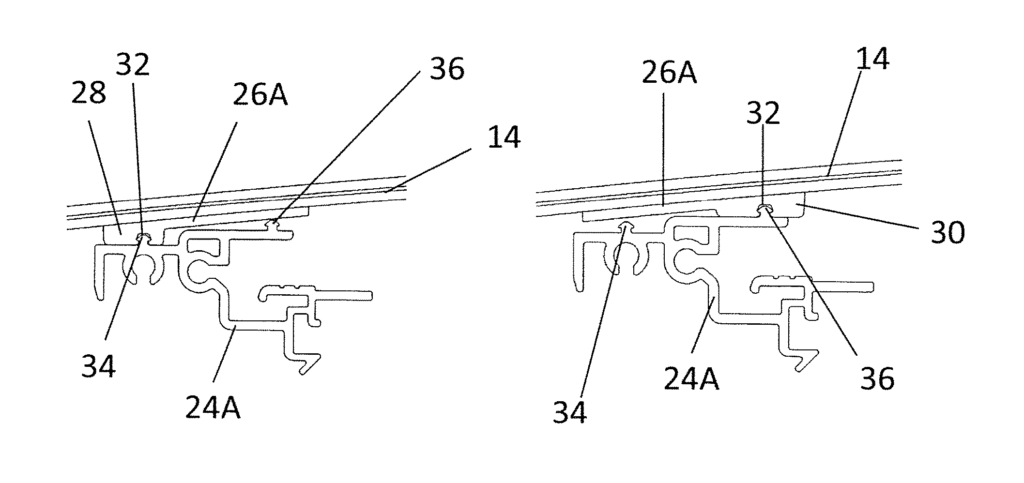

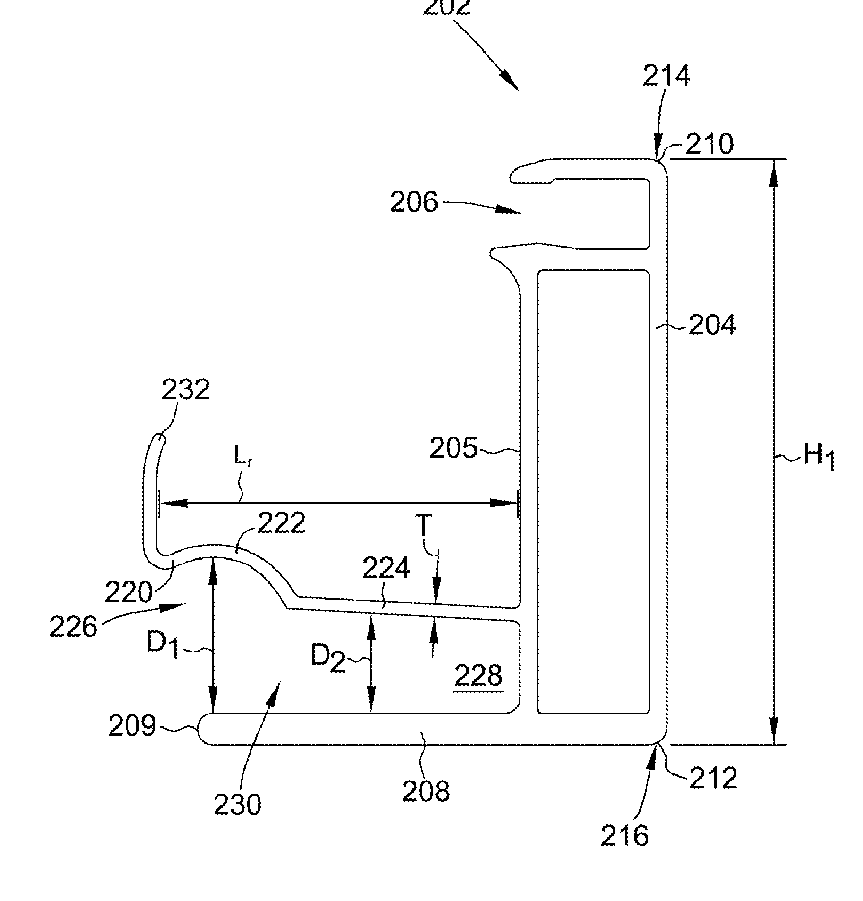

US11817818 — MODULE FRAME WITH CABLE MANAGEMENT FLANGE — TECSI Solar, Inc. (USA) — Photovoltaic (PV) module frames typically include aluminum extrusions having an upper cavity that receives the laminate when assembled. Frames for PV modules often include a mounting flange with pre-drilled holes for affixing the modules to mounting structures. A module frame includes a body having an interior surface, a lower flange extending from the interior surface of the body, and a cable management flange extending from the interior surface of the body. The lower flange and the cable management flange each include a distal end. The cable management flange and the lower flange define a cable cavity therebetween for retaining at least one cable. The distal ends of the lower flange and the cable management flange define an opening for inserting the cable into the cable cavity. The cable management flange is arranged to engage the cable and secure the cable in the cable cavity.

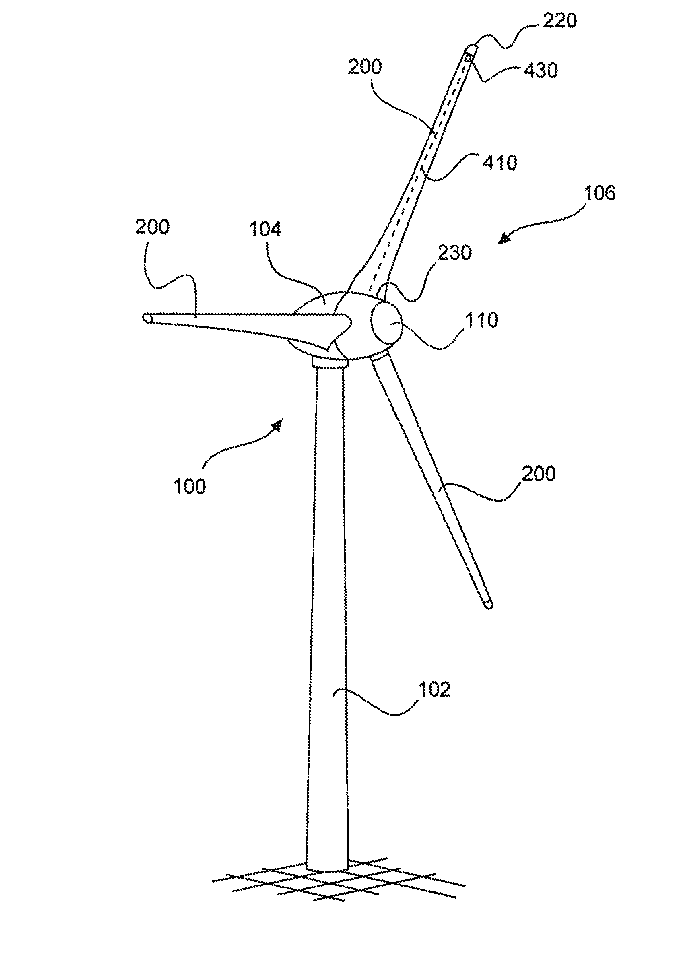

US11815064 — METHOD FOR TESTING A LIGHTNING PROTECTION SYSTEM IN A WIND TURBINE ROTOR BLADE — Wobben Properties GmbH (Germany) — A method for testing a lightning protection system in a wind turbine rotor blade is provided. The lightning protection system is contacted in the region of a rotor blade root. A measuring line having an electrically conductive tip is positioned in the interior of the rotor blade or outside on the rotor blade until the conductive tip is in contact with an element of the lightning protection system. A signal is fed via the measuring line and the signal arriving at the lightning protection system in the region of the rotor blade root is measured to check the mode of operation of the lightning protection system in the rotor blade. Alternatively, aluminum profiles can be used as a lightning arrestor section. As a result of the length of the rotor blades these can comprise screw connections which can serve as connections of web segment to web segment. Furthermore, aluminum profiles can be combined with cable trees. Here also exposed screw connections can be provided as connecting elements and be coupled to at least one lightning protection receptor in the region of the rotor blade tip.

US11807348 — OMNIDIRECTIONAL UNDERWATER VEHICLE — Guangdong Ocean University (China) — An omnidirectional underwater vehicle includes an open-frame mechanism including a frame with top thrusters at four corners of a top end of the frame; mechanical arms disposed at a front end of the frame; and a rotary holder disposed in the frame and including a motor fixing plate, an upper bearing fixing plate and a lower bearing fixing plate. A cylindrical roller bearing is fixed between the upper bearing fixing plate and the lower bearing fixing plate, and an inner edge of In an embodiment, an upper aluminum alloy plate and a lower aluminum alloy plate are respectively fixed at an upper end and a lower end of the frame, and the frame includes a plurality of aluminum profiles fixed between the upper aluminum alloy plate and the lower aluminum alloy plate, and the plurality of aluminum profiles are fixedly connected through connecting corner braces. A servo motor is fixed on the motor fixing plate, a bottom end of the bearing clip inner plate at the bottom is fixedly connected to a steering gear fixing plate, and a top end of the steering gear fixing plate is provided with fully waterproof steering gears installed with underwater thrusters.

US11802000 — CONTAINER HANDLING VEHICLE WITH FIRST AND SECOND SECTIONS AND MOTOR IN SECOND SECTION — Autostore Technology AS (Norway) — A container handling vehicle for picking up storage containers from a three-dimensional grid of an underlying storage system includes: a first set of wheels, arranged at opposite portions of a vehicle body of the container handling vehicle, for moving the vehicle along a first direction on a rail system of the grid; and a second set of wheels for moving the vehicle along a second direction on the rail system of the grid. The container handling vehicle further comprises a first section and a second section arranged side-by-side such that a center point of a footprint of the first section (F1) is arranged off center relative a center point of the footprint of the vehicle body (FV), and a size ratio of the footprint of the first section (F1) relative a footprint of the second section (F2) is at least 2:1. The framework structure comprises a plurality of upright members/profiles 2 and a plurality of horizontal members 3, which are supported by the upright members 2. The members 2, 3 may typically be made of metal, e.g. extruded aluminum profiles.

US11793699 — PATIENT SUPPORT WITH ENERGY TRANSFER — Stryker Corporation (USA) — A patient support system includes a patient support apparatus and a powered device mounted relative to the patient support apparatus and an electrical circuit to power the powered device, with the electrical circuit having a wireless power receiver to inductively couple to and transfer electrical energy from a wireless power transmitter when the wireless power receiver is in proximity to the wireless power transmitter. Base 720 is formed from an extrusion, such as aluminum extrusion, which is anchored to the cargo area by a sub-anchor assembly. Track 722 is also formed from an extrusion and straddles base 720 and, further, is guided on base 720 by bearings 732, such as rollers or wheels, which are mounted to base 720 and which ride along inner rails 728.

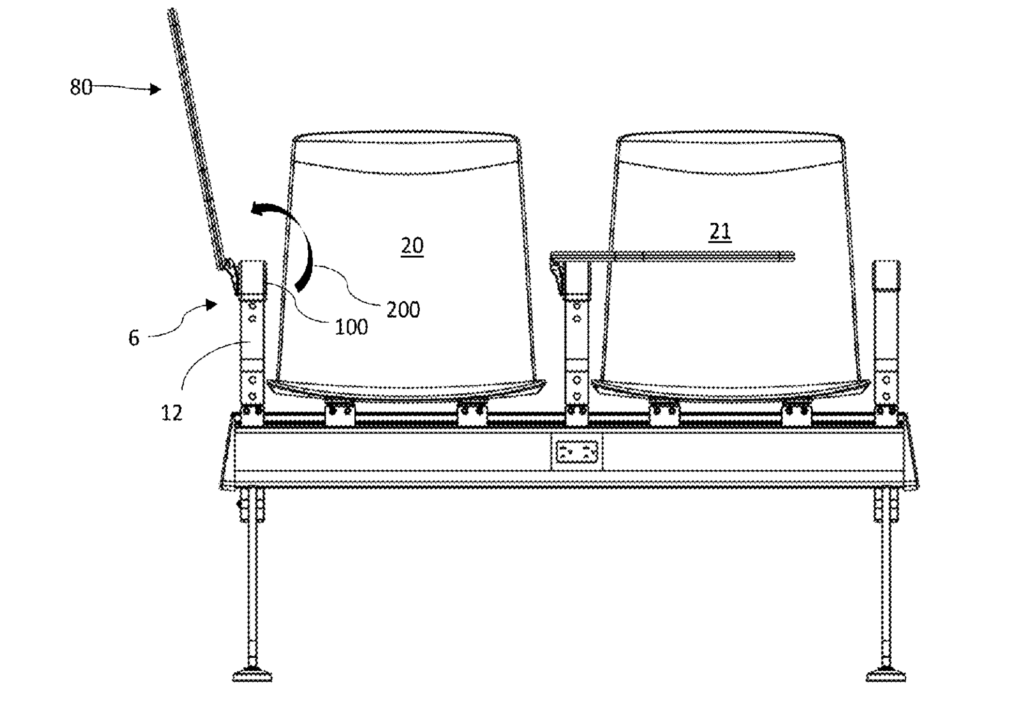

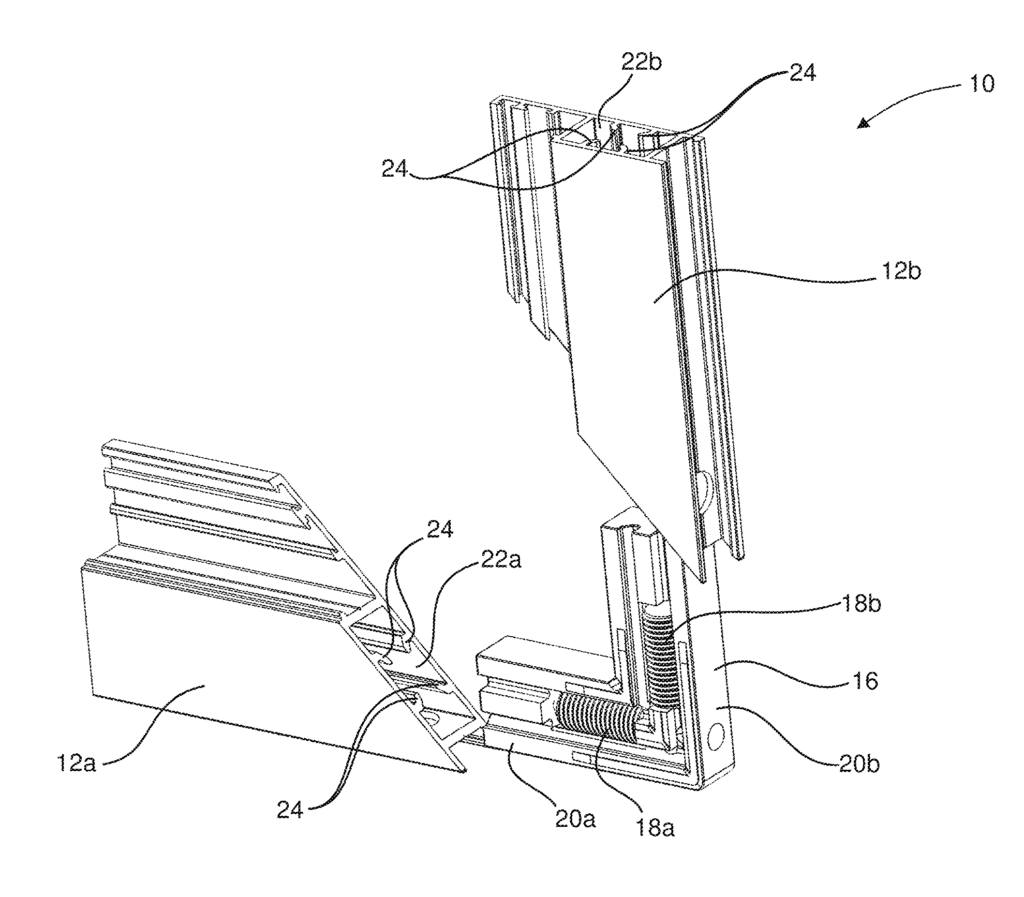

US11793315 — TABLET ARM WITH EXTRUDED HINGE — Series International, LLC (USA) — A tablet mechanism for chairs which allows the tablet to be stored higher and more rearward to enable the tablet to utilize more space available so that the tablet can be larger. The mechanism includes extruded hinge components and allows the tablet to rotate counter-clockwise and then down when viewed from the perspective of a seated user and when looking to the right. It is an object of the invention to simplify the tablet arm mechanism to use fewer parts and to also utilize metal extrusions, typically aluminum extrusions.

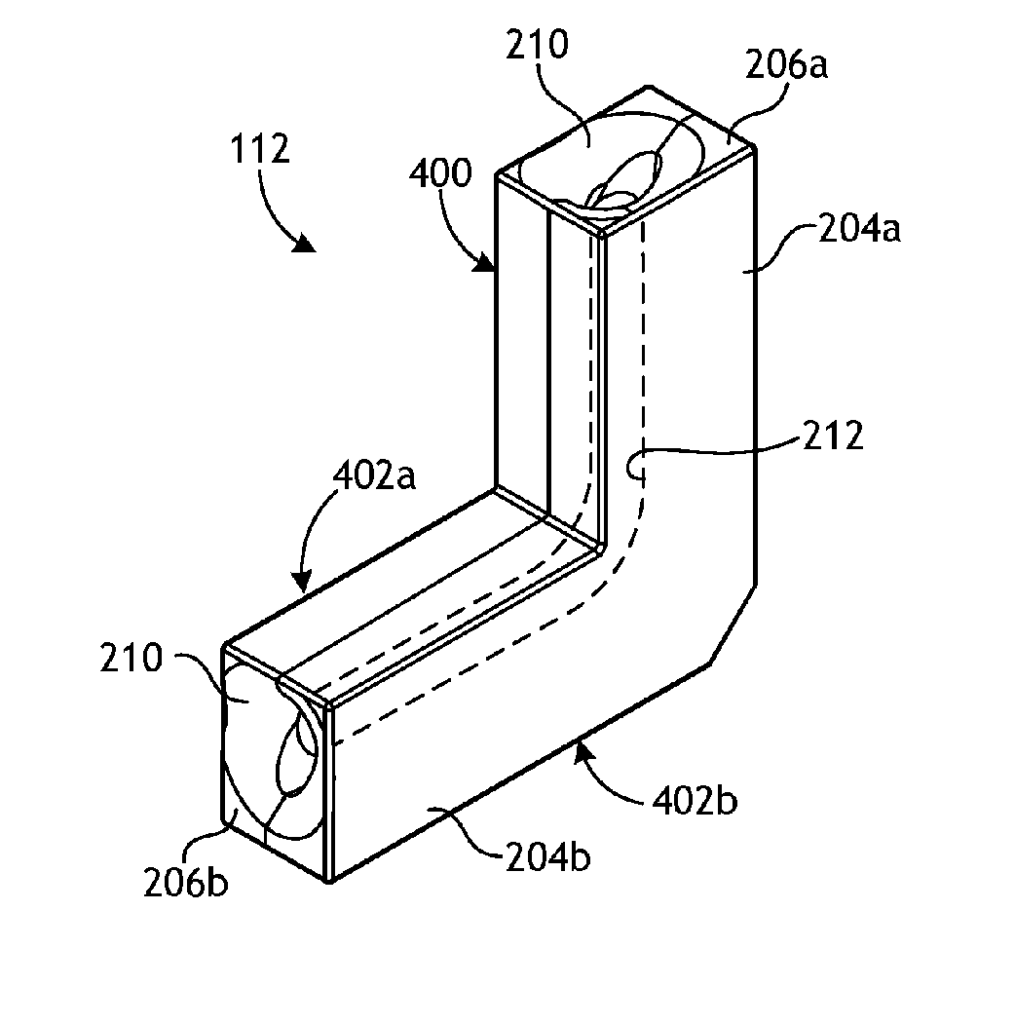

US11773646 — CORNER CLEATS WITH WIRING PASSAGEWAY — Arconic Technologies LLC (USA) — A framed assembly includes a first frame member defining a first inner channel, a second frame member defining a second inner channel and positioned adjacent the first frame member at a corner joint, and a corner cleat having a first leg received within the first inner channel and terminating at a first end of the corner cleat, and a second leg received within the second inner channel and terminating at a second end of the corner cleat. The frame members may comprise hollow, generally rectangular tubes made of a variety of rigid materials including, but not limited to, aluminum, rolled sheet metal, a polymer, a composite material, or any combination thereof. A passageway is defined in the corner cleat and extends between the first and second ends. The passageway places the first inner channel in communication with the second inner channel.

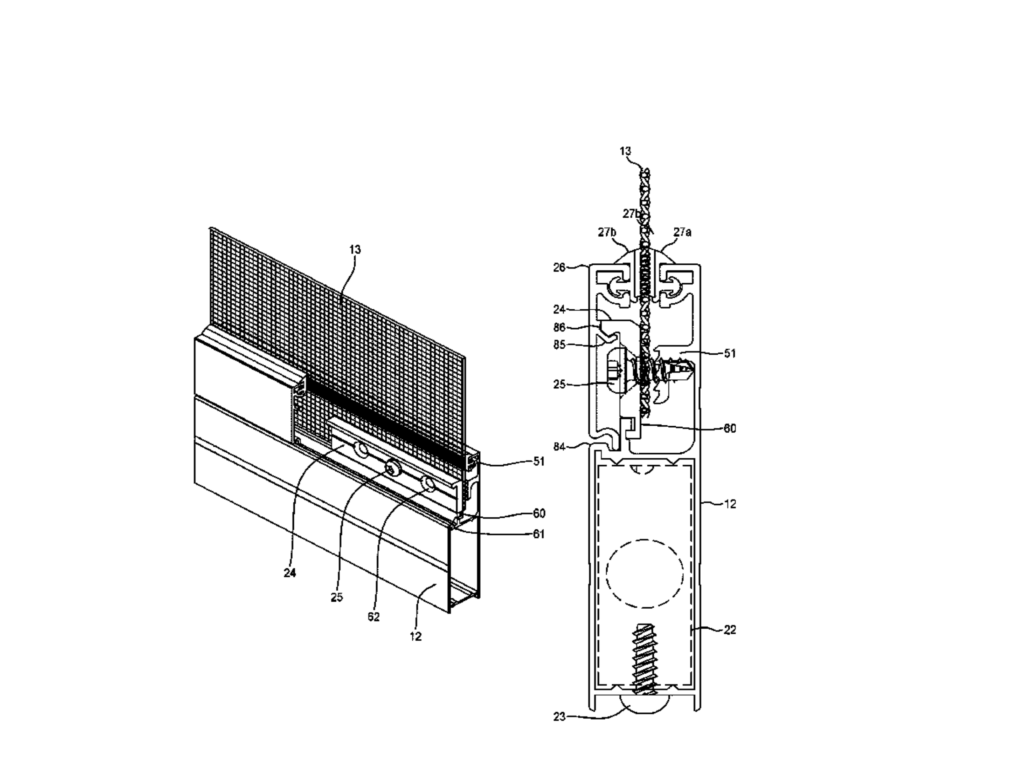

US11773641 — INTRUDER RESISTANT SCREEN — IPH International Pty Ltd. (Australia) — An intruder resistant screen providing improved strength. The improved intruder resistant screen comprises a frame, a woven wire intruder resistant mesh covering an opening enclosed by the frame, a plurality of clamp elements engaging with frame members to hold the mesh by a leveraged clamping action and at least one fastener holding each clamping member to the frame member. Each fastener has a drilling portion, a shank portion, a head and a thread. The frame comprises multiple frame members joined by corner stakes and there are two or more clamp elements engaging each frame member. The frame members and clamping members are formed from extruded aluminum.

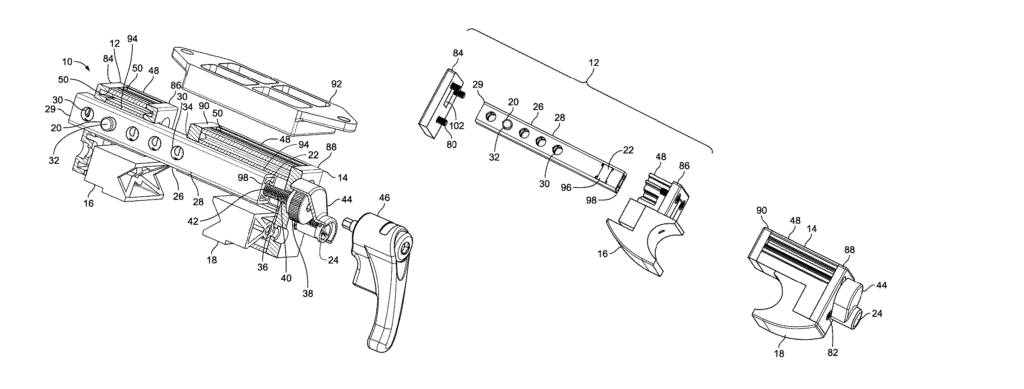

US11772567 — VEHICLE ROOF RACK ACCESSORY CLAMP — The Eastern Company (USA) — An improved modular vehicle accessory clamp for is disclosed. The clamp provides for gross and fine adjustment between the jaws to allow for differences in the width of vehicle roof rack cross bars. The clamp has a first body with a depending jaw and an extension portion and a second body portion also with a depending jaw and a receiving portion that receives the extension of the first body and allows for adjustment of the distance between the jaws. The clamp can be locked to the cross bar. Upper grooves in the clamp allow for easy attachment to vehicle accessories such as rooftop carriers. The invention also provides a system for attaching accessories to the top of a vehicle having a cross bar comprising a clamp having a first body and a second body with each body comprising an aluminum extrusion having an interior bore. In one embodiment, the clamp bodies are constructed of modular components, including an aluminum extrusion with T-shaped slots on the top and end plates.

US11766926 — BATTERY PACK CASE, BATTERY PACK INCLUDING THE SAME AND VEHICLE INCLUDING BATTERY PACK — CALB Co., Ltd. (China) — A battery pack case and a vehicle having the battery pack case are provided. The battery pack case includes a beam disposed in the battery pack case and a connection column connected to the beam. A first chamber extending in a length direction of the beam is disposed inside the beam, and the first chamber penetrates through the beam. The connection column penetrates through a side wall of the first chamber. In an extending direction of the first chamber, two sides of the first chamber located at the connection column are provided with blocking portions. In a specific embodiment, the beam is formed by extrusion of an aluminum profile, such that the battery pack case 10 may have a less weight and may be easily formed.

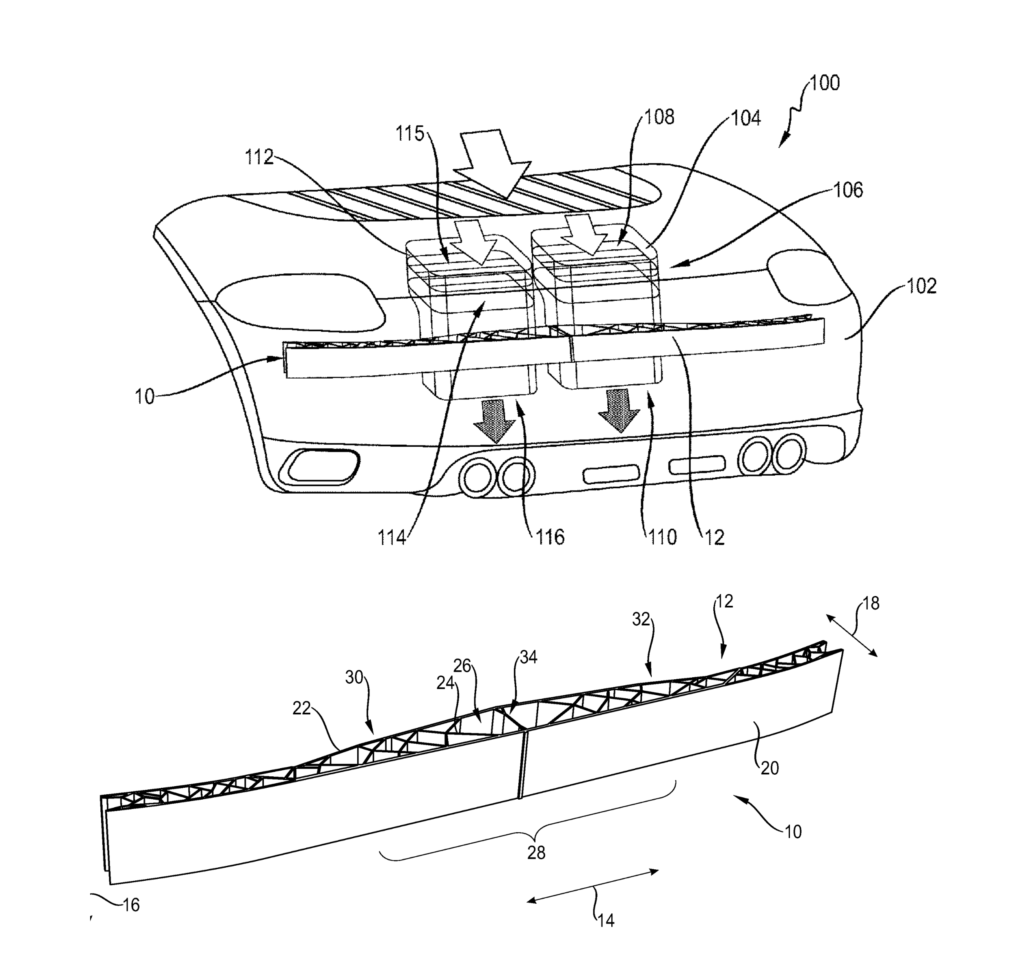

US11760286 — BUMPER CROSSMEMBER, AND VEHICLE REAR ARRANGEMENT WITH BUMPER CROSSMEMBER — Dr. Ing. h.c. F. Porsche Aktiengesellschaft (Germany) — A bumper crossmember for a vehicle, with a hollow profile body 10 which has a vehicle frame-side proximal vertical wall and a distal vertical wall which are connected to one another by way of transverse walls and extend along a vertical direction. The transverse walls laterally delimit hollow chambers which are arranged in the hollow profile body. The center longitudinal direction of the hollow chambers is oriented in each case along the vertical direction, and the hollow chambers are open on the end side. The hollow profile body can preferably be configured as an extrusion profile, for example as an extruded aluminum profile. In this way, inexpensive manufacturing even of complex profile shapes is possible.

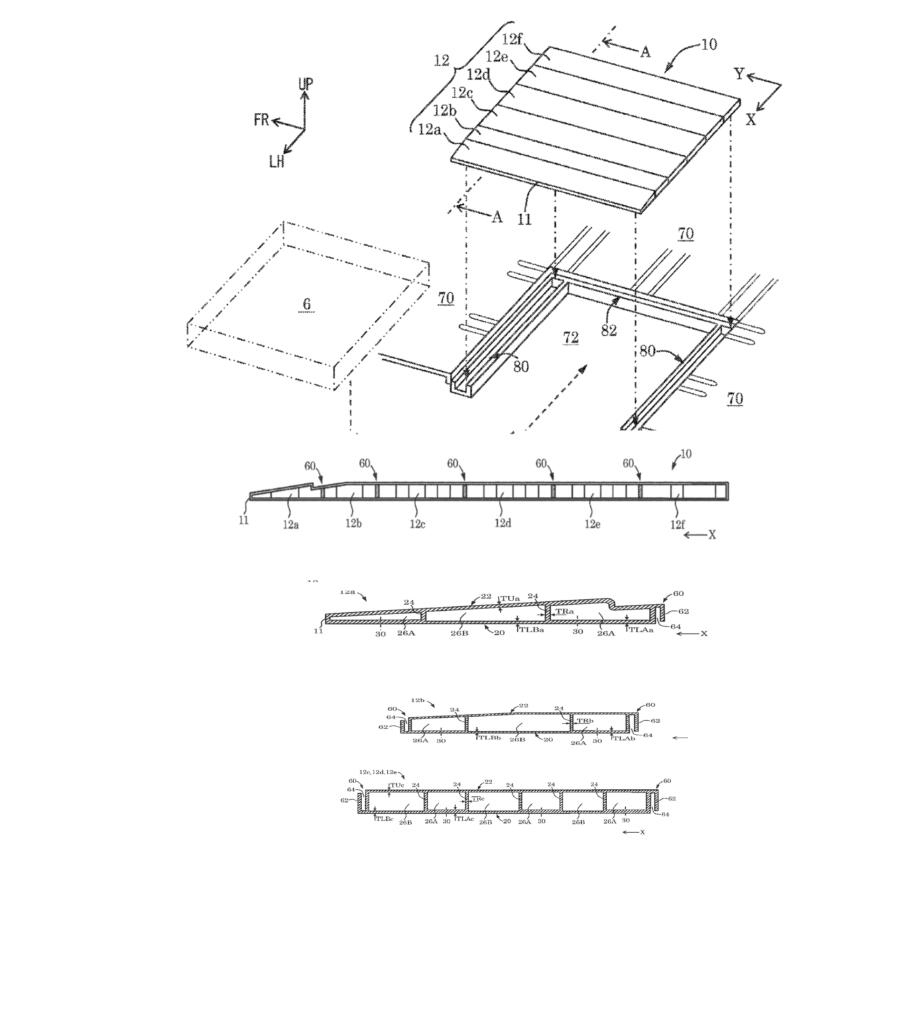

US11760250 — VEHICLE FLOOR STRUCTURE — Toyota Jidosha Kabushiki Kaisha (Japan) — An aluminum vehicle floor structure includes a floor member having an opening and a floor panel covering the opening. The floor panel is configured by sequentially arranging and integrating a plurality of kinds of unit panels in a lateral direction of the unit panels, the unit extruded panels having rectangular shapes as viewed from above a vehicle. With the vehicle floor structure according to the present disclosure, each unit panel may have a hollow plate shape and include ribs that extend in a longitudinal direction of the unit panel inside the unit panel and connect an upper wall and a lower wall of a hollow cross section, and a rib of the unit panel of which the one side is supported by the floor member may be thinner in the lateral direction of the unit panel than a rib of the unit panel including the free side. Two end sides of the floor panel extending along a direction in which the unit panels are arranged (x direction) and one side of at least one of two unit panels arranged at opposite ends of the floor panel are supported by support portions of a floor member. A unit panel of which the one side is supported by the support portion of the floor member has a lighter weight per unit area than other unit panels having lateral lengths equal to or greater than a lateral length of the unit panel.

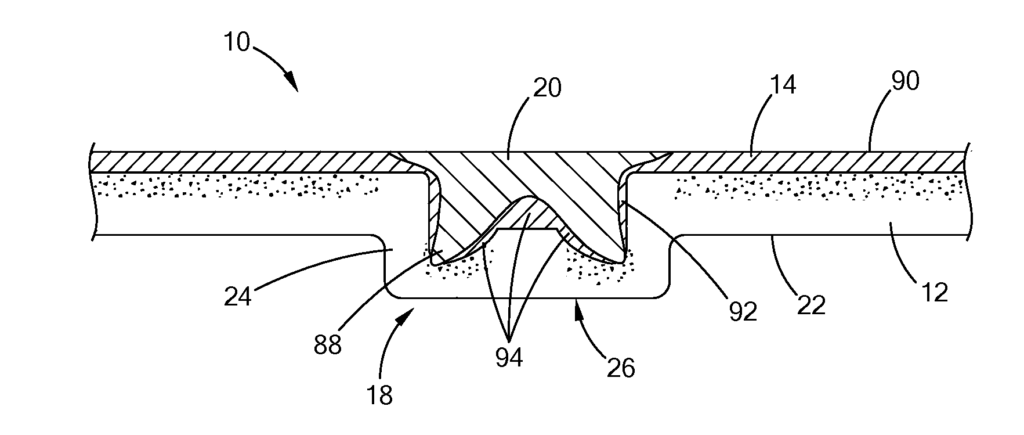

US11759845 — NET SHAPED SUBSTRATE MATERIAL FOR SUBSTRATE JOINT — Ford Global Technologies, LLC (USA) — An assembly includes an upper substrate, a lower substrate, and a self-piercing rivet. In the case of aluminum intensive vehicles and other mixed metal joining applications, self-piercing rivet technology prevails. The lower substrate defines a preformed interior cavity and a preformed exterior profile adjacent the interior cavity to define a variable thickness wall. The self-piercing rivet extends through the upper substrate and into the preformed interior cavity of the lower substrate. The upper substrate 14 may be made of steel, aluminum, a fiber reinforced composite material, or other materials. The lower substrate 12 may be a cast part, a molded part, or a 3D-printed part, among others. In various forms of the present disclosure, the substrate 12 is an aluminum casting, an aluminum extrusion, or a composite material.

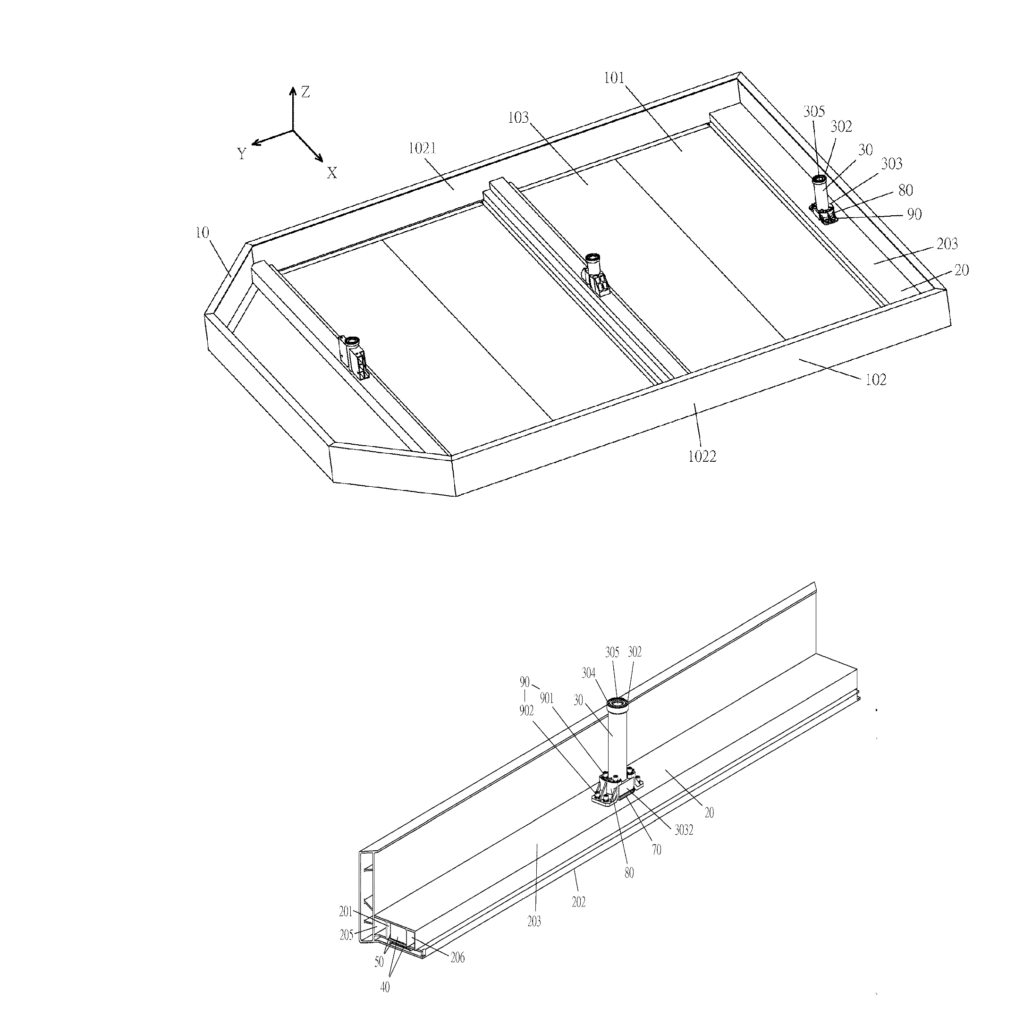

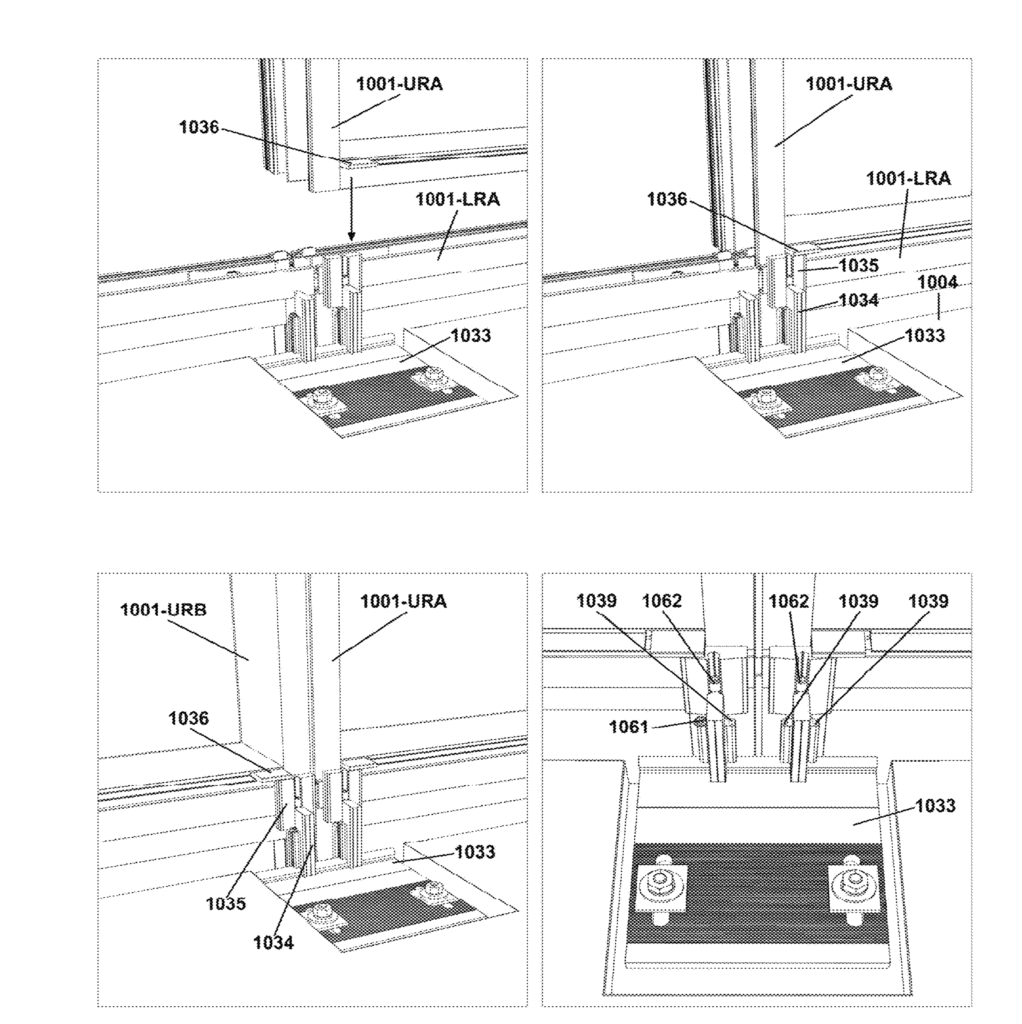

US11757400 — DEVICES FOR MOUNTING SOLAR PV PANELS TO ROOFS AND OTHER MOUNTING STRUCTURES — Sunmodo Corporation (USA) — This disclosure discusses devices for mounting solar PV panels to a roof and other mounting structures. One device may include a railless mounting assembly that includes a roof attachment bracket and a panel attachment bracket. Railless solar racking systems can secure solar PV panels to roofs without using rails. They typically use bracket assemblies to clamp and secure the solar PV panel onto roofs or other mounting structures. The roof attachment bracket may include a spring clip and a hook. The device may include a solar panel frame with built-in detents for mounting. It may include a solar panel frame capable of attaching to the spring clip and hook. The solar panel frames and the railless mounting assemblies discussed in this disclosure are typically aluminum extrusions. Extruded aluminum is durable, electrically conductive, and can have enough strength for typical solar panel installations.

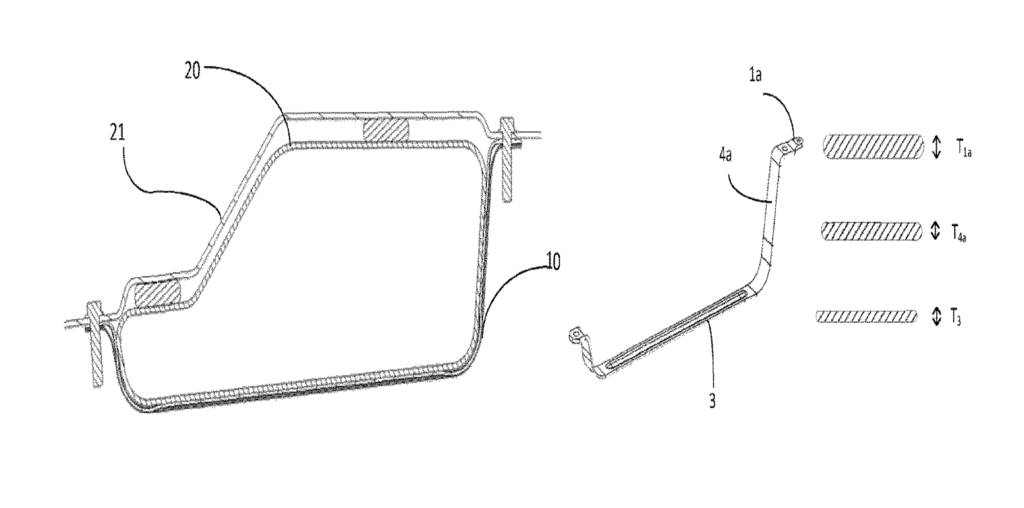

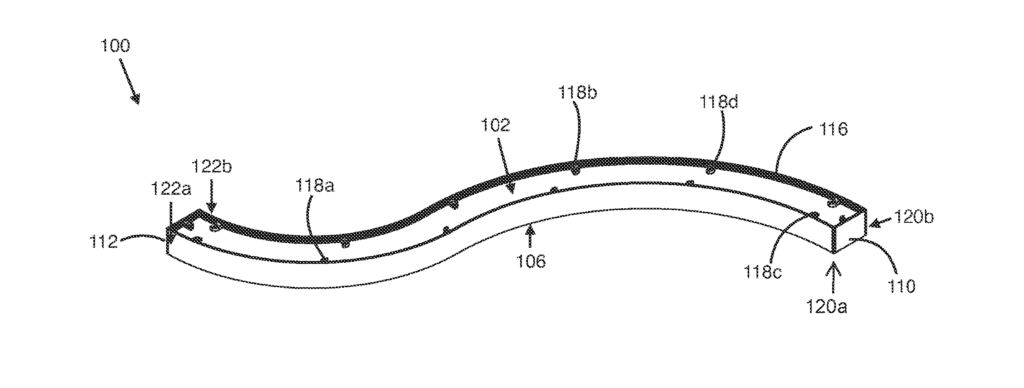

US11745238 — CLAMPING STRAP — Hydro Extruded Solutions AS (Norway) — A method (100) of manufacturing a clamping strap (10) configured to hold and support a hanging object (20) against a structure (21), which is to carry the hanging object, and a clamping strap obtainable by said method; said method comprising providing (101) an extruded elongated aluminum profile having an initial material thickness (T.sub.0) and an initial cross-sectional area (A.sub.0), said profile having a longitudinal direction, which coincides with the extrusion direction of the profile; forming the profile in a bending step (102) into a shape comprising a first end attachment portion (1a), a second end attachment portion (1b), and an intermediate portion (2) located between said first and second end attachment portions (1a; 1b) in a longitudinal direction of the profile (11), said intermediate portion (2) being configured to at least partially encircle the hanging object (20) when mounted to the structure (21); said method including forming said profile by means of locally thinning the profile in a longitudinal direction of the profile (11), in a thinning C operation (103) to obtain one or more thinned portions having a lower material thickness than the initial material thickness (T0); or locally axially compressing the profile in an axial compression step (104) to obtain one of more axially compressed portions having a higher material thickness than the initial material thickness (T.sub.0) and/or greater cross sectional area than the initial cross-sectional area (A0); or by a combination of said thinning operation (103) and said axial compression step (104).

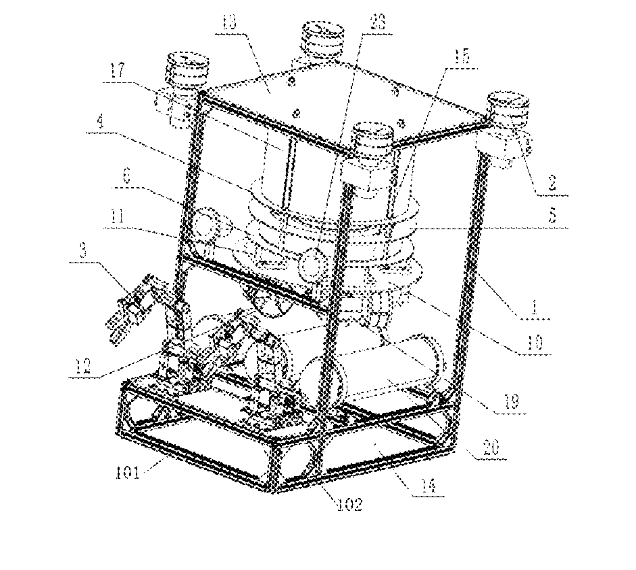

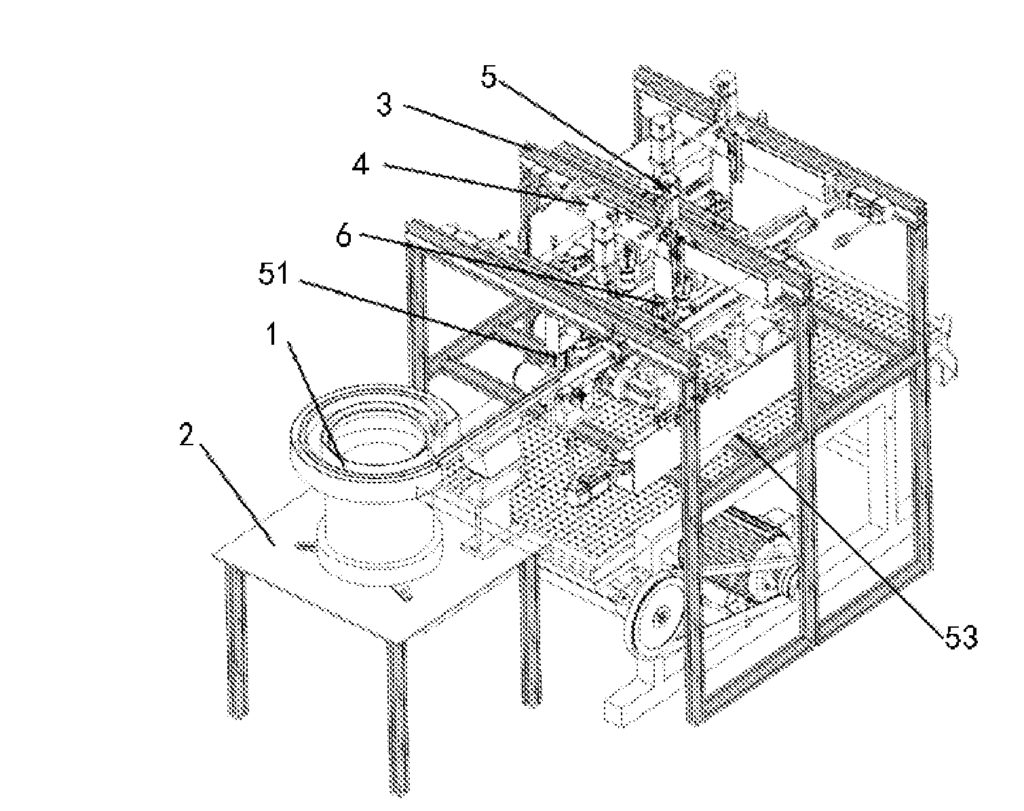

US11744274 — FULLY AUTOMATIC PEANUTS PEELING ROBOT FOR SEEDS RETENTION AND METHOD FOR USING THE SAME — Liaocheng University (China) — A fully automatic peanuts peeling robot for seeds retention and a method using the same are provided. The robot includes a processing mechanism, a feeding mechanism, and a screening mechanism. The processing mechanism includes an aluminum profile support bracket, a bracket assembly, a conveyor belt device, and a conversion device, a sensor device and a cut-off device; the aluminum profile support bracket is fixedly connected to the bracket assembly; the bracket assembly includes a first bracket assembly, a second bracket assembly, and a third bracket assembly; and the aluminum profile support bracket is fixedly connected to the conveyor belt device; the conveyor belt device includes a first conveyor belt assembly, a second conveyor belt assembly, and a third conveyor belt assembly; the conveyor belt device is fixedly connected to the conversion device.

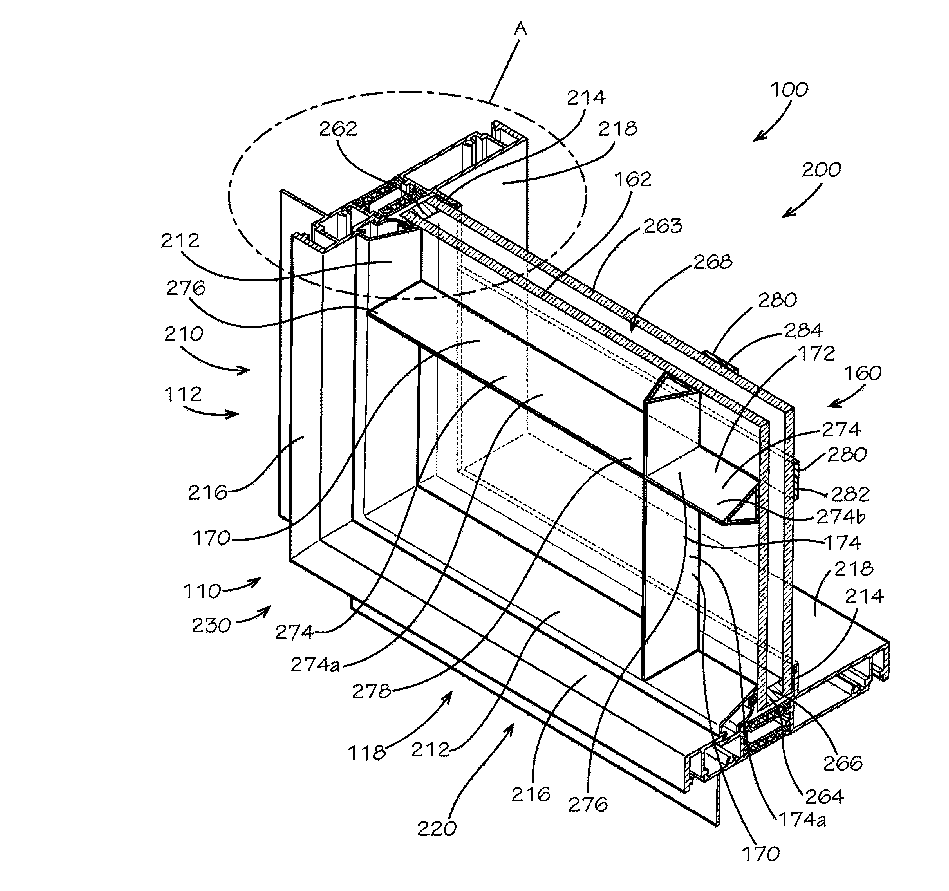

US11739585 — SIMULATED STEEL FENESTRATION SYSTEM — WWS Acquisition, LLC (USA) — Example aspects of a simulated steel fenestration system, an insulated fenestration system, and a method for insulating a fenestration system are disclosed. The simulated steel fenestration system can comprise a frame, a pane assembly assembled with the frame, and a muntin bar, wherein the frame and the muntin bar comprise a non-steel material configured to resemble steel. Various elements of the fenestration system 100 can comprise a non-steel material configured to simulate a steel material. For example, various elements can comprise an aluminum extrusion, which can be treated to resemble steel. In the present aspect, the outer and inner muntin bars 170,280 and the frame 110, or portions thereof, can each be shaped to resemble the form of steel glazing. A benefit of forming various elements from non-steel materials configured to simulate steel, such as aluminum, can be lower material and manufacturing costs when compared to steel itself. Additional benefits can be reduced manufacturing and assembly times and reduced labor costs.

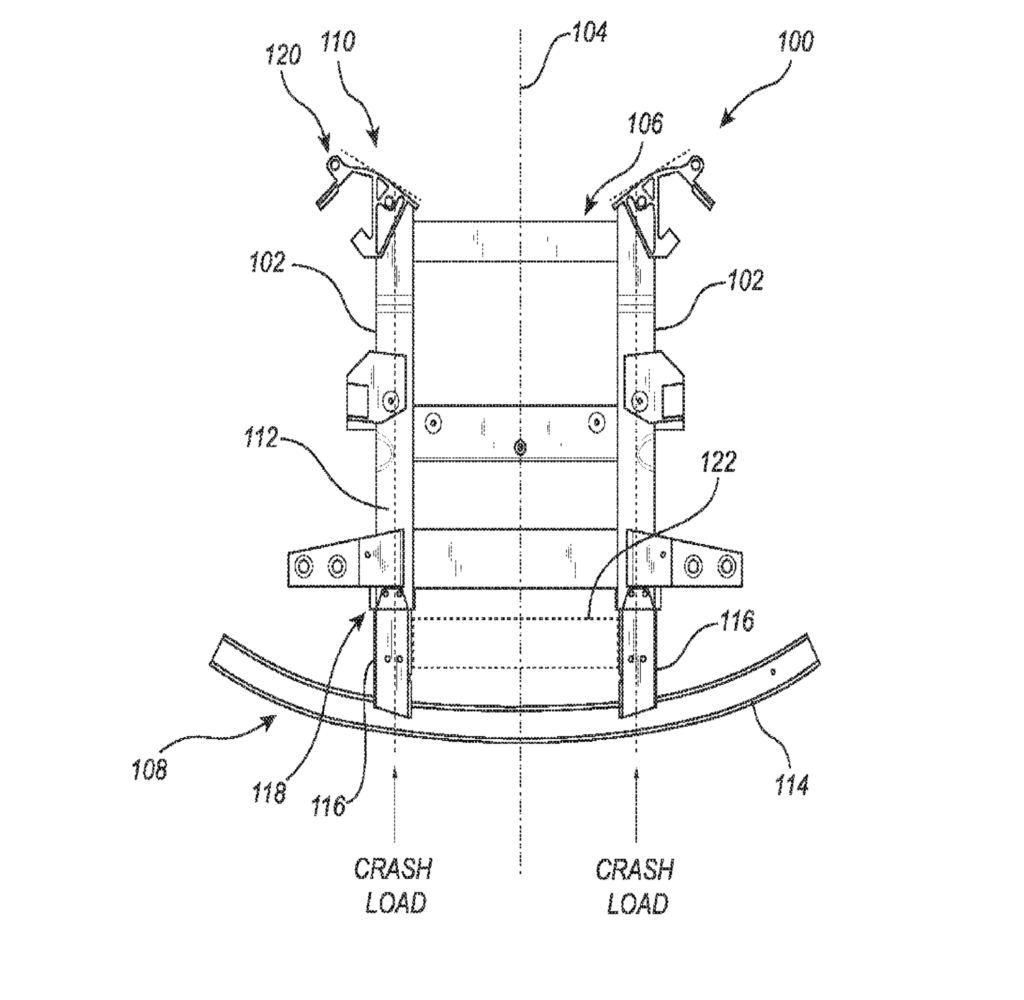

US11713083 — SUBFRAME ASSEMBLY FOR A VEHICLE UTILIZING SCALEABLE MULTI-CELL EXTRUDED SIDERAIL MEMBERS — Volvo Car Corporation (Sweden) — The present disclosure relates to a subframe assembly for a vehicle utilizing scaleable multi-cell extruded siderail members that provide robust crash energy absorbance. A siderail member for a subframe assembly of a vehicle, including: an elongate body, wherein the elongate body includes a hollow extruded structure including an inboard wall, an outboard wall, a top wall, a bottom wall, and one or more internal walls. Optionally, the bottom wall has a thickness that is greater than a thickness of the top wall. Optionally, the outboard wall has a thickness that is greater than a thickness of the inboard wall. Optionally, one or more internal walls include a top internal wall and a bottom internal wall forming a plurality of horizontally-disposed cells within an interior of the elongate body. The bottom internal wall has a thickness that is greater than a thickness of the top internal wall. The hollow extruded structure is manufactured from an aluminum material. Optionally, the top wall of the hollow extruded structure defines a flexure recess.

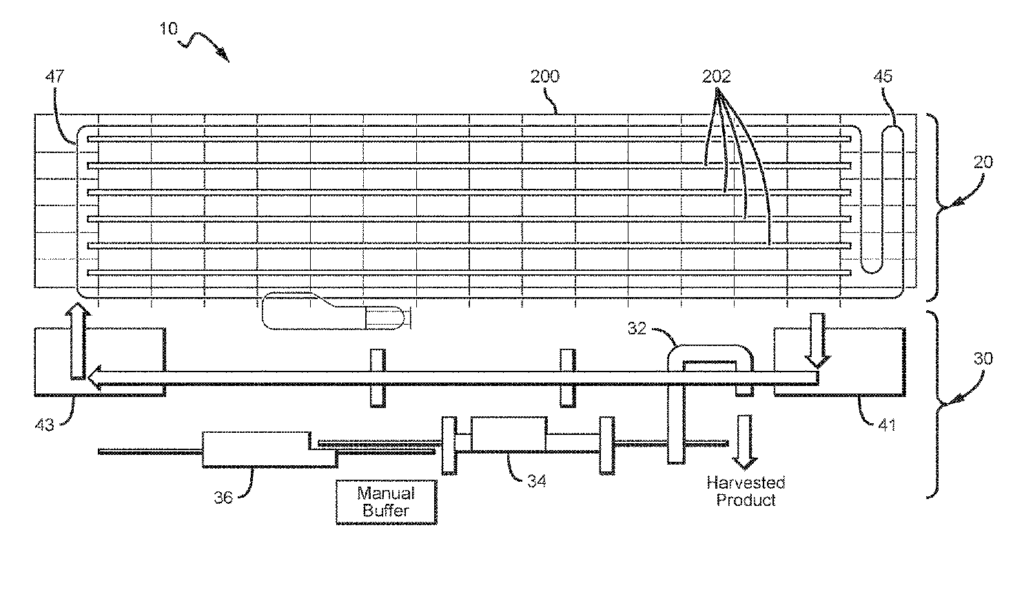

US11700804 — PRODUCTION FACILITY LAYOUT FOR AUTOMATED CONTROLLED ENVIRONMENT AGRICULTURE — MJNN LLC (USA) — Facility layouts and configurations for an automated crop production system for controlled environment agriculture. The core of the facility comprises a controlled growth environment and a central processing system. The controlled growth environment includes systems for exposing crops housed in modules, such as grow towers composed of long grow lines 202 that can be made of aluminum extrusions, to controlled environmental conditions. The central processing system may include various stations and functionality both for preparing crop-bearing modules to be inserted in the controlled growth environment for harvesting crops from the crop-bearing modules after they have been extracted from the controlled growth environment, and for cleaning or washing crop-hearing modules for re-use. The remaining aspects of the crop production facility—such as seeding stations, propagation facilities, packaging stations and storage facilities—are arranged to achieve one or more desired efficiencies relating to capital expenditures or operating costs associated with an automated crop production facility.

US11692346 — SYSTEMS AND METHODS FOR ANCHORING CURTAINWALLS — New Hudson Facades, LLC (USA) — Unitized curtainwall is an exterior cladding product for buildings that is prefabricated and preassembled prior to shipment to the project site. The perimeter framing members of a unitized curtainwall system may be designed with gaskets and male/female mating aluminum extrusions which, when fitted together, create an air and water barrier between the interior and exterior. An anchoring system for anchoring curtainwall units may include an anchor base structure to be attached to the floor slab, a vertical anchor structure and a horizontal anchor structure. The vertical anchor structure may be connected to a lower portion of the upper row curtainwall unit and bear a load of the upper row curtainwall unit on the anchor base structure, thereby fixing a distance between the floor slab and the lower portion of the upper row curtainwall unit while allowing horizontal motion. The horizontal anchor structure may be configured to be connected to an upper portion of the lower row curtainwall unit, and to use the anchor base structure to secure the upper portion of the lower row curtainwall unit against horizontal motion while allowing vertical motion.

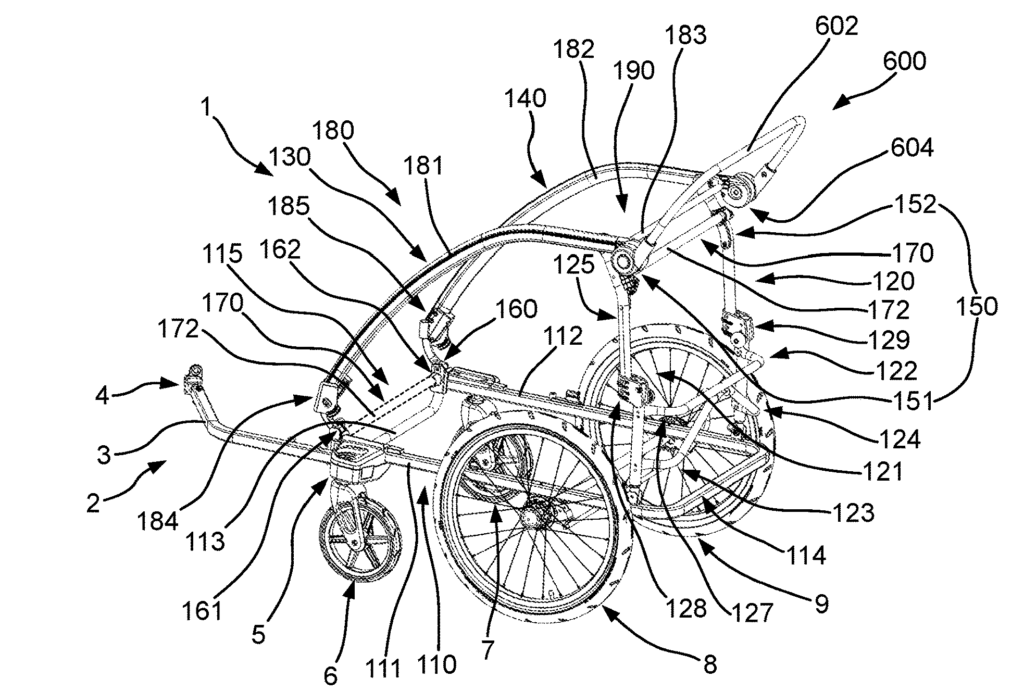

US11691691 — BIKE TRAILER — Thule Sweden AB (Sweden) — Disclosed is a bike trailer having a main frame and a seat structure. The main frame defines an accommodating space for a passenger or load to be transported. The main frame can comprise multiple frame members that are coupled to form the different frame portions. Such frame members may include elongate members, such as profiles, for example made of aluminum, and coupling members connecting such elongate members. The seat structure is transferable between an operational state in which the seat structure forms a seating area for the passenger, and a stowed state in which the seat structure is folded away thereby allowing the transport of loads other than passengers. The seat structure comprises a backrest portion with a seating side for at least partially contacting the back of a passenger. The backrest portion is accommodatable in the bike trailer such that at least the seating side of the backrest portion is protected against contact with loads to be carried when the seat structure is in the stowed state.

US11613923 — DOOR RAIL SYSTEM — C.R. Laurence Co., Inc. (USA) — An improved door rail system for holding a panel, such as a glass panel, is presented. The door rail system includes a core rail and clamping rails having a wedging geometry so that when the clamping rails are actuated with respect to the core rail, clamping force is applied to the glass panel to secure the panel within the core rail. The improved door rail system accommodates panels of varying thickness, features the use of modular side covers and incorporates a door to door jamb adjustment device allowing for angular adjustments. The core rail 12, clamping rails 14 and pulling rails 16 may be made from variety of metallic materials with aluminum extrusions and castings generally being preferred for their combination of strength, light weight and ease of manufacturing.

US11611126 — CONTAINMENT APPARATUS FOR BATTERY CELLS — Borgwarner Akasol GMBH (Germany) — The present invention relates to a battery unit comprising one or more pairs of oppositely disposed receptacles, each said pair of receptacles defining a respective chamber for accommodating one or more cylindrical battery cells, each cylindrical battery cell having a first end adjacent a first end wall of a first one of said receptacles and a second end adjacent a second end wall of a second one of the pair of said receptacles. The invention further relates to a battery module comprising one or more battery units and to a battery system comprising a plurality of battery modules. In this way a compact assembly of a battery module can be achieved through use of an inverted T shaped carrier, e.g. formed from aluminum, which accepts two cell assemblies and a top side PCB to form a battery module. Preferably the T shaped carrier can be formed from an extruded section, e.g. of aluminum. The extruded section can feature multiple extruded tube-like channels, which can be interconnected to form a liquid coolant plate of large size and hence a module with integrated coolant plate.

US11598143 — JOINT FOR A FENESTRATION UNIT — Garner Aluminum Extrusions Limited (Great Britain) — A miter joint for a metallic frame of a fenestration unit includes first and second frame members; a connector configured to locate the first and second frame members in relation to one another; and first and second fasteners configured to secure the first and second frame members to the connector. The frame may comprise external and internal aluminum profiles with a thermal break of plastics or foam material. The connector has a first arm configured to extend within a hollow profile defined by the first frame member, and a second arm configured to extend within a hollow profile defined by the second frame member. A longitudinal axis of each of the first and second fasteners is configured to be parallel to a longitudinal axis of the respective connector arm. Each of the first and second fasteners is configured to engage the respective frame member when the respective connector arm extends within said frame member.

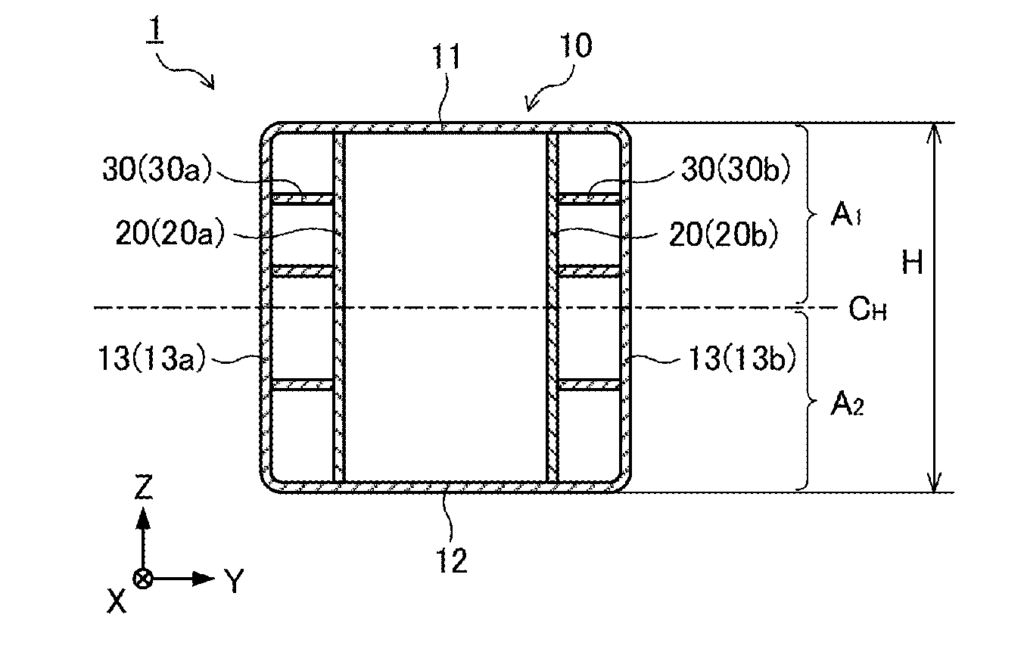

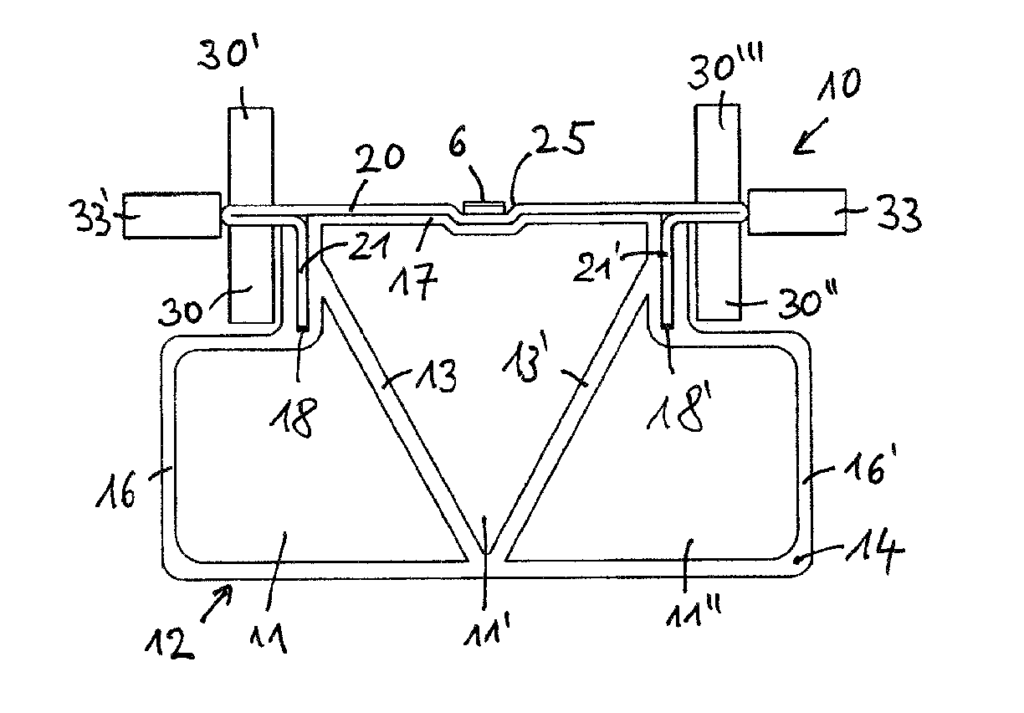

US11597441 — AUTOMOBILE STRUCTURAL MEMBER — Nippon Steel Corporation (Japan) — An automobile structural member being a hollow automobile structural member such as an aluminum extrusion having: a top wall part; a bottom wall part facing the top wall part; and a first heightwise wall part and a second heightwise wall part being a pair of heightwise wall parts that connect to the top wall part and the bottom wall part, the automobile structural member including: a first reinforcing part having one end portion joined to the top wall part and the other end portion joined to the bottom wall part; and a second reinforcing part having one end portion joined to either the first heightwise wall part or the second heightwise wall part, and the other end portion joined to the first reinforcing part, in which a plurality of the second reinforcing parts are provided along a height direction of the heightwise wall part. The object of the present invention is to improve an energy absorption efficiency and to realize both reduction in weight and improvement of energy absorption performance in an automobile structural member.

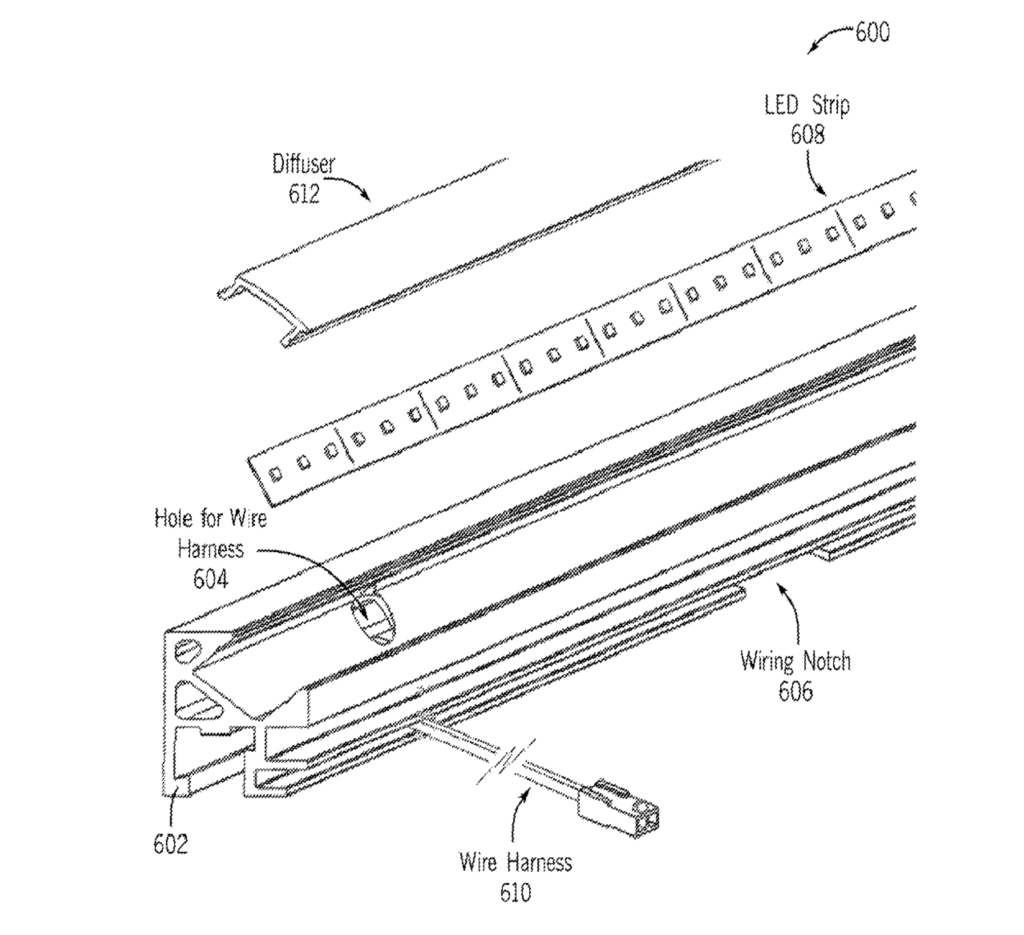

US11592151 — CUSTOMIZABLE LED LIGHTING FIXTURE USING EXTRUSIONS — Klus, LLC (USA) — A custom LED lighting fixture system has a planar opaque top element and an opposing planar translucent bottom element that can be custom fabricated to take any number of shapes. Upon fabrication of the top and bottom elements into an irregular circumferential shape, for example, a first aluminum extrusion is fitted to the left side, and a second aluminum extrusion is fitted to the left side. The first and second extrusions adapt to the shapes of the top and bottom elements. The extrusions comprise a first channel on the interior surface configured to accept the top element, and a second channel configured to accept the bottom element. A first end cap couples to a first end of the first and second extrusions. A second end cap couples to a second end of the first and second extrusions. An LED strip is operational on an interior surface of the top element.

US11571172 — CIRCULAR-ARC-SHAPED HYBRID C-PROFILE FOR A C-ARM X-RAY APPARATUS — Ziehm Imaging GmbH (Germany) — The present technology relates to a circular-arc-shaped hybrid C-profile for a C-arm X-ray apparatus, said profile having a lightweight profile as the main body and a steel profile as a support profile for a bearing unit, the lightweight profile and the steel profile being connected to one another by connecting means. Forming the lightweight profile as a hollow profile is provided in the present technology. Furthermore, a U-shaped or V-shaped lightweight profile from an aluminum extrusion, open on the convex side thereof toward the steel profile, can be provided as the lightweight profile, and a hollow profile can be formed by covering the open lightweight profile with the steel profile.

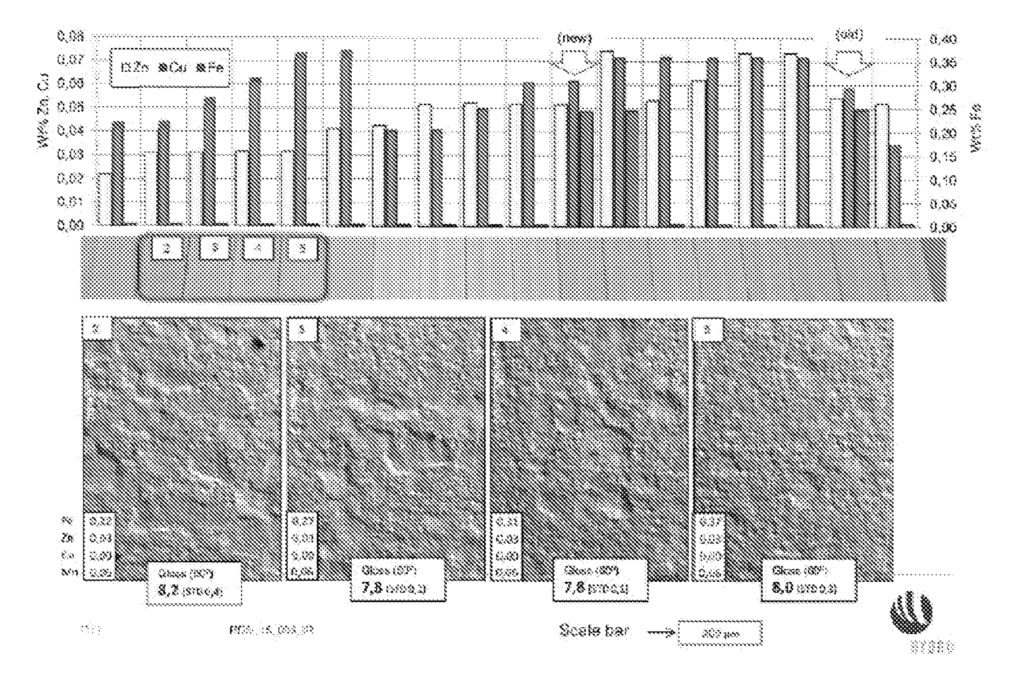

US11542576 — ALUMINUM EXTRUSION ALLOY SUITABLE FOR ETCHED AND ANODIZED COMPONENTS — Norsk Hydro ASA (Norway) — Aluminum alloys suitable for etched and anodized components, in particular aluminum extrusion alloys of the types containing magnesium and silicon, which after being extruded to any wide variety of forms for different applications such as house buildings and other building applications is subjected to etching in a conventional alkaline etching bath and subsequent anodizing, wherein the relation between Cu and Zn is controlled to avoid preferential grain etching and the ratio of Cu/Zn is below 1. Due to environmental issues, it is foreseen that there will be an increased demand for re-melting post consumed aluminum products in the future. This may lead to somewhat higher levels of trace elements, like Zn in the re-melted metal, i.e. an enrichment over time. Customers sometimes explicitly ask for recirculated aluminum, likely due to concern for the environment and reduced carbon footprint.

US11519058 — 6xxx ALUMINUM ALLOY EXTRUDED FORGING STOCK AND METHOD OF MANUFACTURING THEREOF — Constellium Extrusions Decin S.R.O. (Czechoslovakia) — The invention concerns an aluminum extruded product as feedstock for forging comprising in weight percent Si: 0.6% to 1.4%, Fe: 0.01% to 0.15%, Cu: 0.05% to 0.60%, Mn: 0.4% to 1%, Mg: 0.4% to 1.2%, Cr: 0.05% to 0.25%, Zn≤0.2%, Ti≤0.1%, Zr≤0.05%, the rest being aluminum and unavoidable impurities having a content of less than 0.05% each, total being less than 0.15%, wherein the number density of Mn containing dispersed particles is at least equal to 2.5 particles per μm.sup.2, preferably 3.0 particles per μm. The invention also concerns the process to obtain the aluminum extruded product as feedstock for forgings, especially in the production of automotive suspension arms made of 6xxx aluminum alloy.