Editor’s Note: As the official media sponsor of ET ’24, LMA published a special January 2024 issue devoted to aluminum extrusion technology and breaking extrusion news for readers to “Get Ready for ET ’24.” In that issue the focus of our patent review was on aluminum extrusion design aimed at optimizing requirements for a wide range of extrusion applications.

This April issue now focuses on aluminum extrusion process/method inventions that seek to holistically optimize the individual links in the extrusion manufacturing chain to provide process and product advantage—including alloy composition, casthouse practices, billet processing, tooling, extrusion press practices, and more. Sometimes it is difficult to separate processing from a particular application, but that may exemplify aluminum extrusion technology itself.

As with the inventions presented in our special January issue, the inventions here were recently issued, that is, within the past 18 months, and were selected to complement the technical knowledge our readers gain at ET ’24. As is our practice for this department, the invention abstracts are presented in descending order of date of issue, rather than in successive links in the extrusion process chain. Copies of all U.S. patents are available online at: www.uspto.gov/patents/search.

— Joseph C. Benedyk, Editor

US11897013 — METAL PART EXTRUSION CONTROL — Boothroyd Dewhurst, Inc. (USA) — A technique for optimizing metal extrusion process parameters includes receiving values representing properties of an extrusion press machine, and calculating an estimated surface exit temperature of a metal work product resulting from an extrusion of a metal billet using the extrusion press machine based on the machine property values, an initial temperature of the metal billet prior to the extrusion, an extrusion force applied to the metal billet during the extrusion, and an extrusion speed of the metal work product. The estimated surface exit temperature of the metal work product is compared with a target hot shortness exit temperature of the metal work product. The initial temperature of the metal billet, the extrusion speed, and the extrusion force are changed based on the comparison until the estimated surface exit temperature equals the target hot shortness exit temperature.

US11885002 — HIGH-PERFORMANCE 6000-SERIES ALUMINUM ALLOY STRUCTURES — NanoAL LLC (USA) — This application relates to a family of 6000-series aluminum alloys with high strength, high electrical and thermal conductivity, and high thermal stability. The disclosed alloys are especially advantageous for improving performance of extruded aluminum conductors and connectors where a combination of high strength and electrical conductivity is important. Additionally, the disclosed alloys are also advantageous for improving performance of extruded components in thermal management systems, such as heat exchangers and heat sinks, where a combination of high strength and thermal conductivity is important. An aluminum alloy structure, comprising: 0.6% to 0.9% by weight magnesium, 0.35% to 0.7% by weight silicon, 0.2% to 0.5% by weight zirconium, and 0.005% to 0.2% by weight tin, with aluminum as the remainder; and Al.sub.3Zr nanoscale precipitates having an average diameter of no more than 20 nm, having an L12 structure in an α-Al face centered cubic matrix, and having an average number density of at least 1021 m-3; wherein the aluminum alloy structure has a thermal conductivity of at least 185 W/mK, a yield strength of at least 270 MPa, and a tensile strength of at least 290 MPa.

US11883869 — BUTT RETRIEVAL SYSTEM — Brilex Technical Solutions, LLC (USA) — A butt retrieval system having a butt retrieval receptacle supported outside the main footprint of an extrusion press such that maintenance and/or repair of the system is simplified. The butt retrieval system includes a butt retrieval receptacle moveable between a butt retrieving position and a butt unloading position. The butt retrieval receptable has a cantilevered arm extending from a base portion of the butt retrieval receptacle in a direction towards the centerline of the associated extrusion press. The butt retrieval system of the present disclosure is also readily retrofittable to existing extrusion presses and eliminates the need for a pit below an extrusion press.

US11879166 — 7XXX-SERIES ALUMINUM ALLOY PRODUCT — Novelis Koblenz GmbH (Germany) — The invention relates to a wrought 7xxx-series aluminum alloy product having a composition comprising, in wt. %., Zn 6.20 to 7.50, Mg 2.15 to 2.75, Cu 1.20 to 2.00, and wherein Cu+Mg<4.50, and wherein Mg<2.5+5/3(Cu-1.2), Fe up to 0.25, Si up to 0.25, and optionally one or more elements selected from the group consisting of: (Zr up to 0.3,Cr up to 0.3,Mn up to 0.45,Ti up to 0.25, Sc up to 0.5, Ag up to 0.5), the balance being aluminum and impurities. More specifically, the present invention is related to an age-hardenable, high strength, highly stress corrosion resistant aluminum alloy which is resistant to hydrogen embrittlement, and products made of that aluminum alloy. Products made from this alloy are very suitable for aerospace applications, but not limited to that. The aluminum alloy can be processed to various product forms, e.g. thin plate, thick plate, extruded or forged products.

US11866807 — ALUMINUM ALLOY PIPE AND METHOD OF PRODUCING THE SAME — UACJ Corporation and UACJ Extrusion Corporation (Japan) — An object of the technology described herein is to provide a 5000 series aluminum alloy pipe having good extrusion properties and increased strength and a method of producing such a 5000 series aluminum alloy pipe. An aluminum alloy pipe includes a pipe body portion made of an Al—Mg series alloy that includes Mg at a concentration equal to or higher than 0.7 mass % and lower than 2.5 mass % and Ti at a concentration higher than 0 mass % and equal to or lower than 0.15 mass %, with the balance being Al and unavoidable impurities, and a Zn-containing layer being outside the pipe body portion and including Zn being diffused in the Al—Mg series alloy at a concentration equal to or higher than 0.1 mass %. The technology described in this specification provides the method according to which the hot extrusion process is performed with porthole extrusion.

US11852336 — METHOD AND BURNER FOR HEATING A FURNACE FOR METAL PROCESSING — Messer Industries USA, Inc. (USA) — A method for heating a furnace (40) used for metal processing, e.g., for recycling aluminum alloys, by combusting a fuel in the furnace (40) by supplying an oxidizing gas through an oxidizing gas supply line (20) into the furnace (40) and by supplying a fuel through a fuel supply line (30) into the furnace (40), wherein the oxidizing gas is supplied in form of a central oxidizing gas flow (24) together with a first shroud gas flow (25), and/or the fuel is supplied in form of a central fuel flow (34) together with a second shroud gas flow (35), and to a corresponding burner (10).

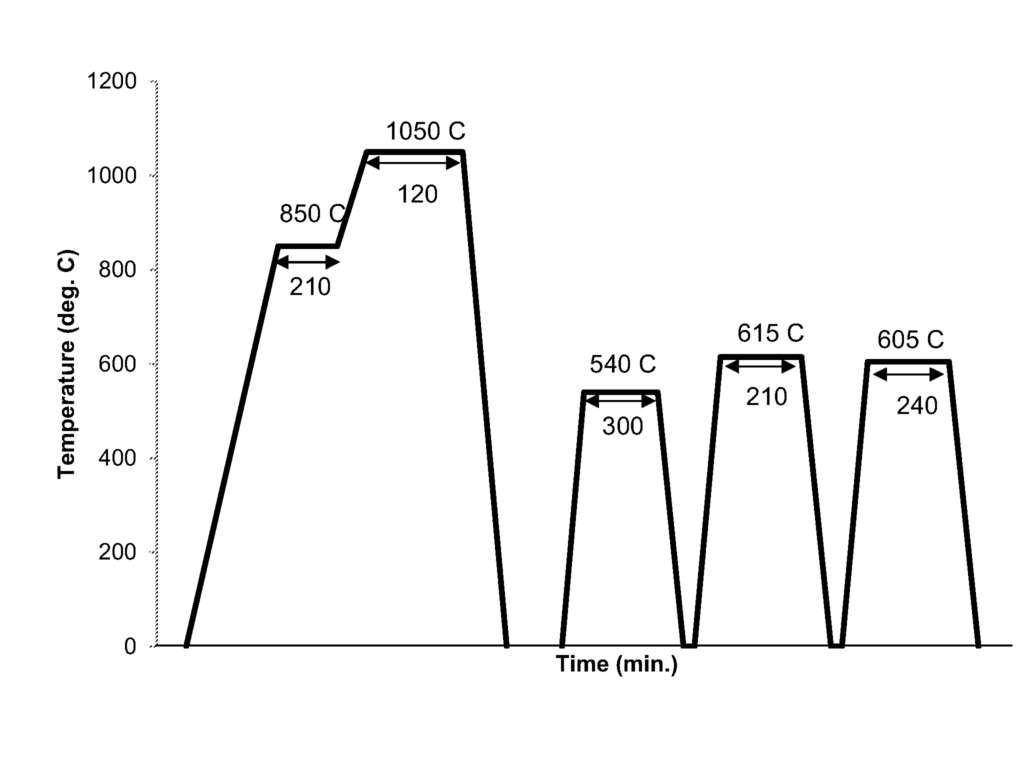

US11819910 — TOOL STEEL COMPOSITION FOR COMPONENT OF DIE-CASTING APPARATUS OR OF EXTRUSION PRESS — Exco Technologies Limited (Canada) — A tool steel composition for a component of a die-casting apparatus or of an extrusion press such as a dummy block, comprises, in weight percentage: from about 0.35% to about 0.40% carbon (C); from about 0.32% to about 0.50% silicon (Si); from about 4.50% to about 5.50% chromium (Cr); from about 3.75% to about 4.75% molybdenum (Mo); from about 0.80% to about 1.00% vanadium (V); and iron (Fe). In one embodiment, there is provided a method of preparing a tool steel, the method comprising: subjecting a steel having the composition described above to a heat treatment, the heat treatment comprising: a hardening heat treatment, comprising heating the tool steel to one or more temperatures from about 850°C to about 1125° C. for a total time of from about 1 hour to about 25 hours; and a tempering heat treatment, comprising heating the hardened tool steel to one or more temperatures from about 375°C to about 675°C for a total time of from about 1 hour to about 25 hours.

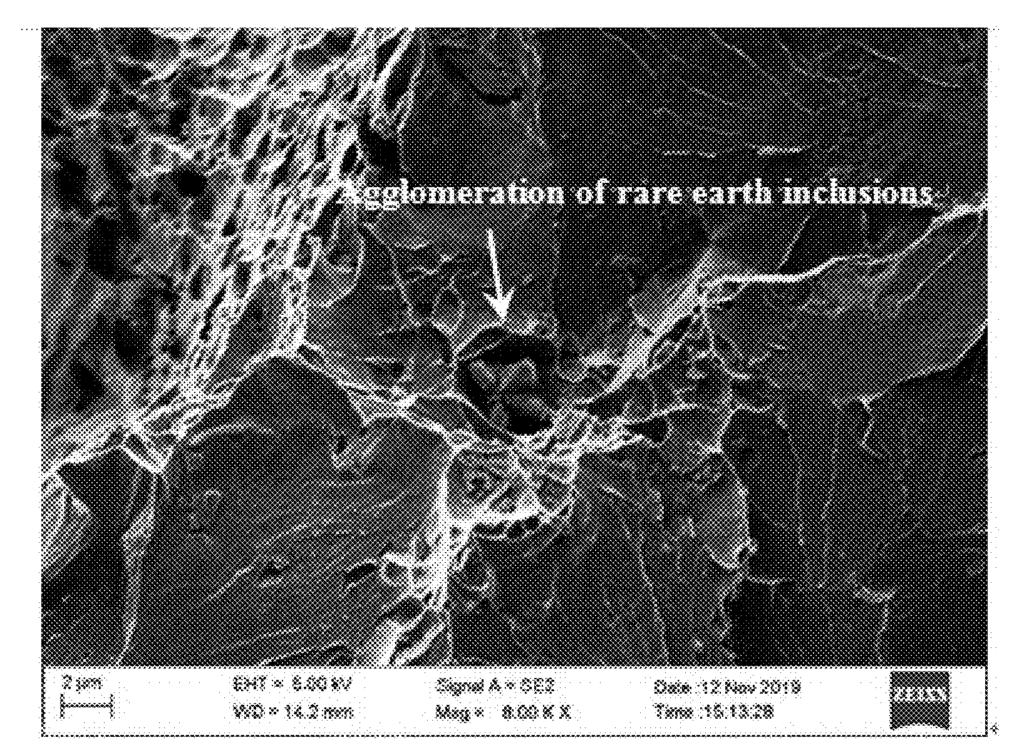

US11718902 — RARE EARTH DIE STEEL AND PREPARATION METHOD THEREOF — Jiangxi University of Science and Technology and Guorui Scientific Innovation Rare Earth Functional (China) — The present disclosure provides a rare earth hot working die steel that has high strength and good wear resistance, and is widely used in hammer forging dies, hot extrusion dies, die-casting dies and other dies. Mg and B elements are added based on the adding of rare earth element Y, so that the rare earth element purifies a matrix, and grain boundary occupation by Mg and B is fully utilized to regulate grain network chromium carbides. In addition, the B element can fully improve hardenability of austenite and ensure that non-martensite such as bainite does not appear during the cooling process, and therefore rare earth die steel with high impact toughness and high isotropy is obtained.

US11717882 — MOLD CASTING SURFACE COOLING — Wagstaff, Inc. (USA) — The present invention relates to a method, system, and apparatus for improving the efficiency of a continuous casting operation. A continuous casting mold component described herein includes: a mold wall substrate defining a groove proximate a bottom of the mold wall substrate; a graphite liner having a bottom edge defining a first angled surface and a top edge defining a second angled surface, where the bottom edge is received into the groove of the mold wall substrate; and a clamping element defining an angled clamping surface attached to the mold wall substrate with at least one fastener, where the bottom angled surface of the graphite liner is driven into the groove defined in the substrate in response to the angled clamping surface of the clamping element engaging the second angled surface of the graphite liner and the fastener pressing the clamping element toward the mold wall substrate.

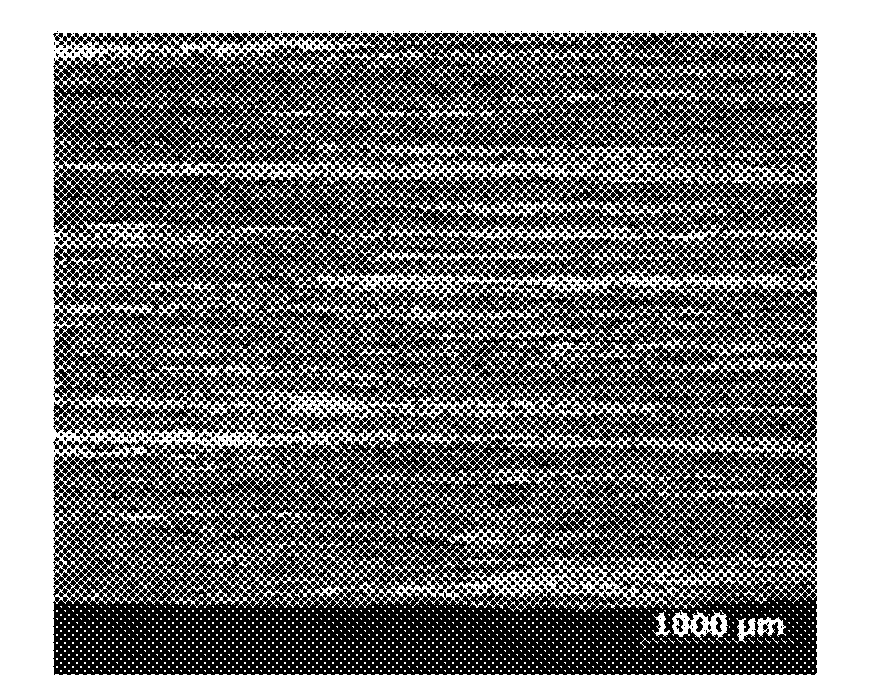

US11708629 — HIGH STRENGTH DUCTILE 6000 SERIES ALUMINUM ALLOY EXTRUSIONS — GM Global Technology Operations LLC (USA) — An alloy composition is provided. The alloy composition includes silicon (Si) at a concentration of greater than or equal to about 0.55 wt. % to less than or equal to about 0.75 wt. %, magnesium (Mg) at a concentration of greater than or equal to about 0.55 wt. % to less than or equal to about 0.75 wt. %, chromium (Cr) at a concentration of greater than or equal to about 0.15 wt. % to less than or equal to about 0.3 wt. %, and a balance of the alloy composition being aluminum (Al). The alloy composition has an intermetallic phase content of less than or equal to about 3 wt. %. Methods of preparing the alloy composition and of processing the alloy composition are also provided. In one aspect, extruding is performed with a ram pressure of about 2500-5000 psi and with an extrusion speed of about 2-10 ipm, the quenching is performed by water mist at a cooling rate of about 300-1200°C/min, the extrusion includes aging the cooled extruded part at a temperature of about 150- 250°C for a time of about 1-5 hours, and the extruded object has a bamboo grain crystal structure including greater than or equal to about 80% aligned longitudinal grains.

US11697866 — MANUFACTURING PROCESS FOR OBTAINING HIGH STRENGTH EXTRUDED PRODUCTS MADE FROM 6XXX ALUMINUM ALLOYS — Constellium Singen GmbH (Germany) — A manufacturing process for obtaining extruded products made from a 6xxx aluminum alloy, wherein the said manufacturing process comprises following steps: a) homogenizing a billet cast from said aluminum alloy; b) heating the said homogenized cast billet; c) extruding the said billet through a die to form at least a solid or hollow extruded product; d) quenching the extruded product down to room temperature; e) optionally stretching the extruded product to obtain a plastic deformation typically between 0.5% and 5%; f) ageing the extruded product without applying on the extruded product any separate post-extrusion solution heat treatment between steps d) and f) and characterized in that: i) the heating step b) is a solution heat treatment where: b1) the cast billet is heated to a temperature between Ts-15° C and Ts, wherein Ts is the solidus temperature of the said aluminum alloy; b2) the billet is cooled until billet mean temperature reaches a value between 400°C and 480°C while ensuring billet surface never goes below a temperature substantially close to 400°C; ii) the billet thus cooled is immediately extruded (step c), i.e. a few tens of seconds after the end of step b2).

US11691195 — SYSTEM, APPARATUS, AND METHOD FOR A DIRECT CHILL CASTING COOLING WATER SPRAY PATTERN — Wagstaff, Inc. (USA) — The present disclosure relates to a system, apparatus, and method for a cooling water spray pattern for a direct chill casting mold, and more particularly, to a spiral water spray pattern for a direct chill billet casting mold. An example direct chill casting mold includes a mold body defining a mold cavity there through; and a plurality of spray jets arranged proximate an exit of the mold cavity, wherein the plurality of spray jets are angled with respect to the mold cavity such that streams of fluid exiting the plurality of spray jets impinge upon a casting exiting the mold cavity at an angle offset from a centerline of the casting.

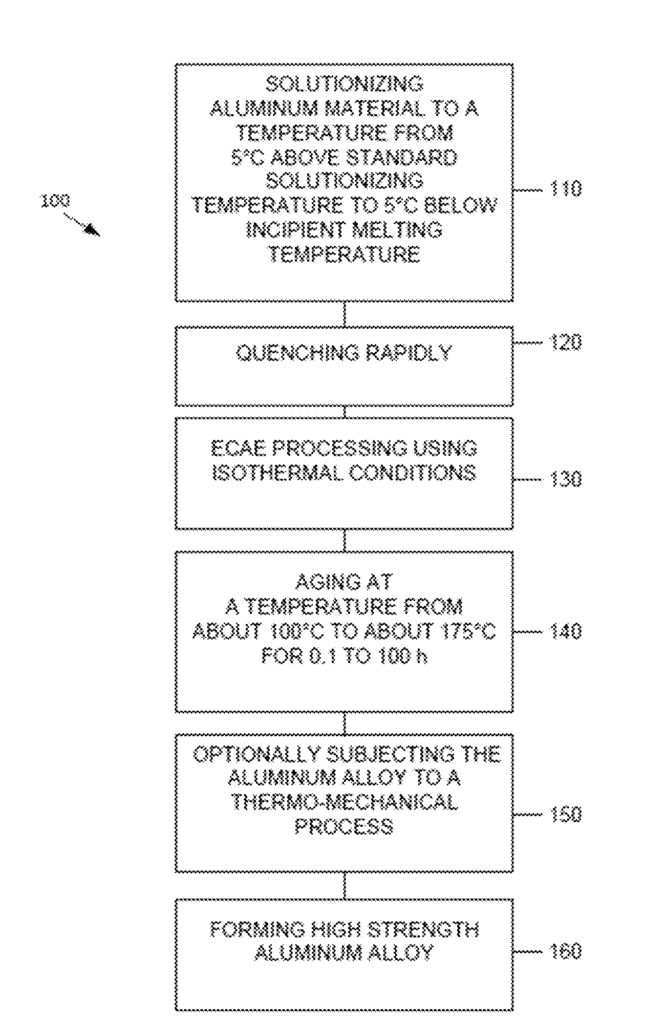

US11649535 — ECAE PROCESSING FOR HIGH STRENGTH AND HIGH HARDNESS ALUMINUM ALLOYS — Honeywell International Inc. (USA) — A method of forming a high strength aluminum alloy is disclosed. The method includes solutionizing to a temperature ranging from about 5°C above a standard solutionizing temperature to about 5°C below an incipient melting temperature for the aluminum material to form a heated aluminum material, which is then quenched. The aluminum material may include a 6xxx alloy such as AA6061 and AA6063. The cooled aluminum material is subjected to ECAE (equal channel angular extrusion) processing using one of isothermal conditions and non-isothermal conditions. Isothermal conditions include having a billet and a die at the same temperature from about 80°C to about 200°C. Non-isothermal conditions include having a billet at a temperature from about 80°C to about 200°C and a die at a temperature of at most 100°C. The aluminum material is than aged at a temperature from about 100°C to about 175°C.

US11608551 — ALUMINUM ALLOYS, AND METHODS FOR PRODUCING THE SAME — Howmet Aerospace Inc. (USA) — New aluminum alloys are disclosed and generally include 0.6-1.4 wt. % Si, 0.25-0.90 wt. % Mg, wherein the ratio of wt. % Si to wt. % Mg is from 1.05:1 to 5.0:1, 0.25-2.0 wt. % Cu, 0.10-3.5 wt. % Zn, 0.01-1.0 wt. % Fe, up to 0.8 wt. % Mn, up to 0.25 wt. % Cr, up to 0.20 wt. % Zr, up to 0.20 wt. % V, and up to 0.15 wt. % Ti, wherein the total of Fe+Mn+Cr+Zr+V+Ti is not greater than 2.0 wt. %, the balance being aluminum and impurities. The new aluminum alloys may include Q phase precipitates. In some embodiments, the solvus temperature of the Q phase precipitates is not greater than 950°F. The new aluminum alloys may be produced in wrought form, such as in rolled form (e.g., as sheet or plate), as an extrusion, or as a forging, among others. Generally, the new aluminum alloy products are press-quenchable, where solution heat treatment after hot working is not required to achieve final properties.

US11608550 — HOT WORKING DIE STEEL WITH HIGH THERMAL STRENGTH AND HIGH TOUGHNESS AND MANUFACTURING PROCESS THEREOF — Rugao Hongmao Heavy-duty Forging Co., Ltd. (China) — The most common hot working die steel is 4Cr5MoSiV1(H13) steel used in high temperature and high-pressure production environments. The inventors have found that, by adding cobalt, titanium, yttrium, and niobium and adjusting the content of each component in the steel, the high-temperature stability of the steel can be improved. The present application relates to the technical field of die steel, and particularly discloses a hot working die steel with high thermal strength and high toughness and a manufacturing process thereof. The hot working die steel with high thermal strength and high toughness includes the following components in percentage by mass: 0.20-0.40% of carbon, 0.05-0.20% of silicon, 0.30-0.60% of manganese, 1.00-4.00% of chromium, 0.50-1.50% of molybdenum, 0.20-0.60% of vanadium, 0.60-1.00% of cobalt, 0.06-0.16% of titanium, 0.03-0.08% of yttrium, 0.03-0.08% of niobium, 0.005-0.012% of phosphorus, 0.003-0.008% of sulfur, and a balance of iron and inevitable impurities.

US11577305 — SYSTEM, APPARATUS, AND METHOD FOR DIRECT CHILL CASTING VENTING — Wagstaff, Inc. (USA) — Provided herein is a system, apparatus, and method for venting a direct chill casting mold by venting excess casting gas and retaining oxide from atop a casting during the direct chill casting process. Methods of venting casting gas from a direct chill casting mold include: supplying the direct chill casting mold with molten metal through a transition plate; supplying a casting gas through a casting surface of the direct chill casting mold; venting the casting gas from a gas pocket in the transition plate, wherein venting the casting gas from the gas pocket in the transition plate is performed in response to a pressure of the casting gas in the gas pocket reaching a predetermined pressure.

US11559831 — EXTRUSION PRESS WITH ELECTRO-HYDROSTATIC CONTROL SYSTEM — Moog GmbH (Germany) — The present invention relates to an extrusion press (10, 20, 30) with a press cylinder (111), the press cylinder (111) being driven with an electro-hydrostatic control system (104) for a power transmission and being connected to a separate drive (120, 400) for rapid traverse, with a container (115), wherein the container (115) is connected to a hydraulic cylinder (117) for a power transmission and to a further separate drive (119, 300) for rapid traverse, with a hydraulic cylinder (101) with a locking device (103) for driving a shearing tool (102), wherein the hydraulic cylinder (101) is connected to the electro-hydrostatic control system (104), and wherein the press cylinder (111) in the power transmission and the hydraulic cylinder (101) for driving a shearing tool (102) are controlled alternately via the common electro-hydrostatic control system (104).

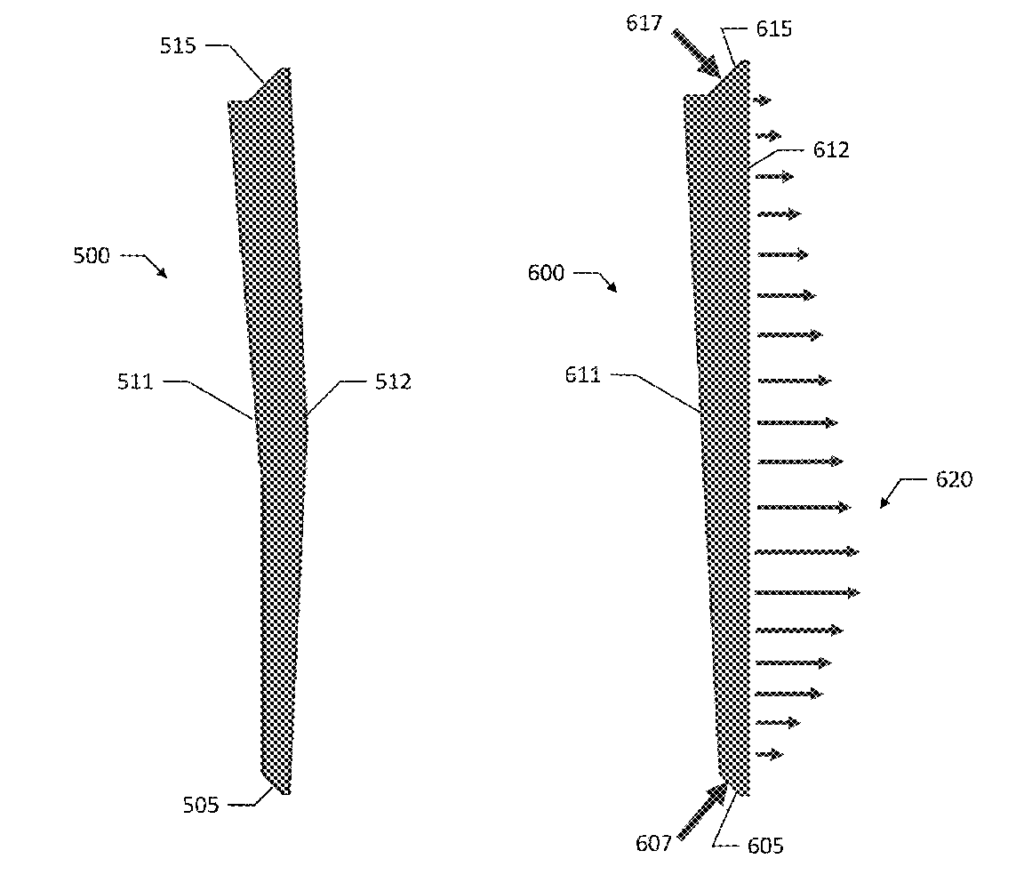

US11554399 — SYSTEM AND METHOD FOR FACILITATING PULSED SPRAY QUENCH OF EXTRUDED OBJECTS — Tesla, Inc. (USA) — Systems and methods for quenching an extrudate using an atomized spray of liquid are described. A system includes a billet die at a proximal end configured to accept a billet and form an extrudate, a quench chamber located adjacent to the billet die for receiving the extrudate and comprising at least one pulsed width modulation (PWM) atomizing spray nozzle and a control module in communication with the at least one PWM atomizing spray nozzle and configured to independently control a liquid pressure, a gas pressure, a spray frequency, a duty cycle and flow rate of each at least one PWM atomizing spray nozzle. In some embodiments, the extrudate is an aluminum metal or metal alloy. In some embodiments, the extrudate is an aluminum-silicon-magnesium alloy. In some embodiments, the quenched extrudate has a yield strength of about 100-600 MPa.

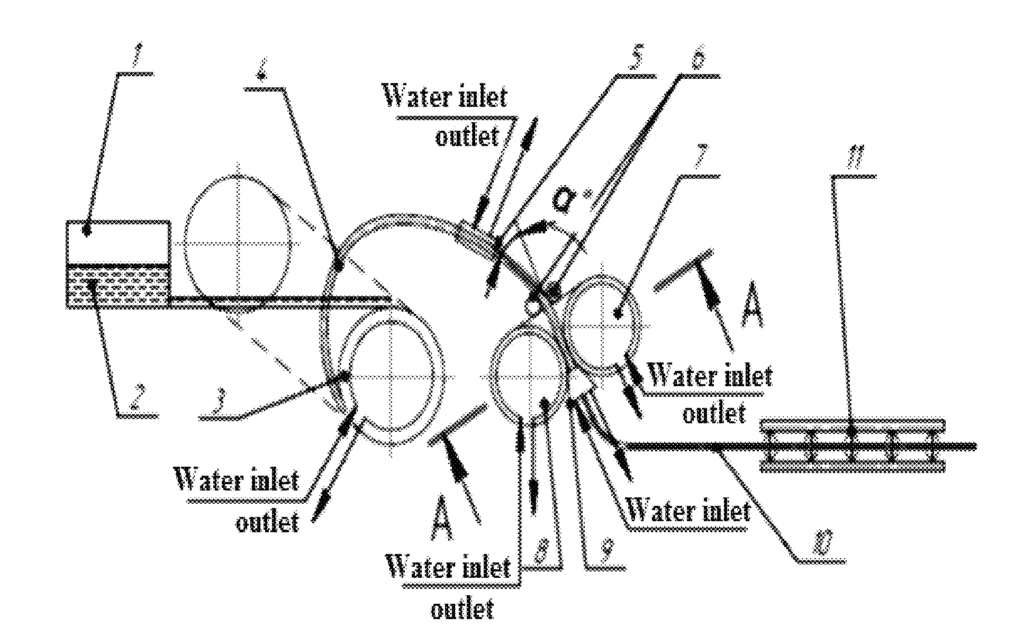

US11554398 — COMBINED ROLLING AND EXTRUDING METHOD AND THE DEVICE FOR PERFORMING THE SAME — United Company Rosal Engineering and Technology Centre LLC (Russia) — The invention relates to the field of metals deformation treatment and can be used to produce extrusions, wire rods, and sector-shaped conductors mainly of aluminum and aluminum alloys, by the method for combined rolling and extruding. A method for combined rolling and extruding of cast billet is proposed. When implementing the method for combined rolling and extruding of metals or alloys, a cast billet with a predetermined temperature is fed to the working gauge, in which it is rolled and then to the die, through which the cast billet is extruded. When the cast billet is fed into the working gauge, a cladding layer of metal or alloy is created on the surfaces of the rolls by extruding the cast billet through the gaps formed between the surfaces of the rolls and the die. This invention makes it possible to improve the quality of the resulting products, as well as to increase the efficiency of the process.

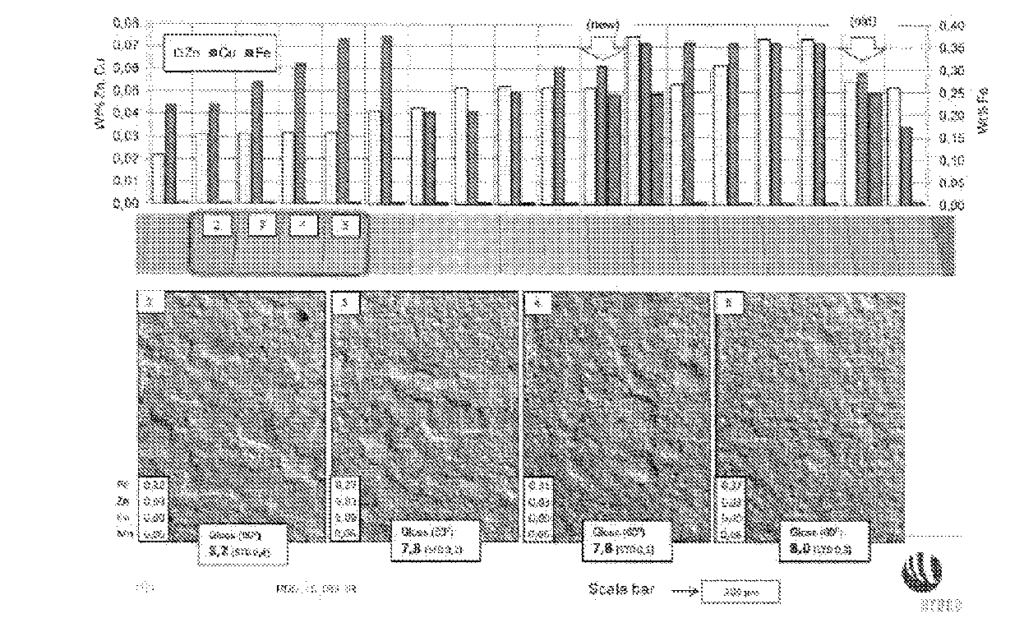

US11542576 — ALUMINUM EXTRUSION ALLOY SUITABLE FOR ETCHED AND ANODIZED COMPONENTS — Norsk Hydro ASA (Norway) — Aluminum alloys suitable for etched and anodized components, in particular aluminum extrusion alloys of the types containing magnesium and silicon, which after being extruded to any wide variety of forms for different applications such as house buildings and other building applications is subjected to etching in a conventional alkaline etching bath and subsequent anodizing, wherein the relation between Cu and Zn is controlled to avoid preferential grain etching and the ratio of Cu/Zn is below 1. With the present invention is provided a selection alloy solution where the Zn and Cu alloying elements of the 6060 and 6063 types of alloys, based on extensive testing in many experiments, are controlled to obtain the desired and consistent, optimal gloss and PGE appearance of such alloys.

US11532407 — ALUMINUM CONDUCTOR ALLOYS HAVING IMPROVED CREEPING RESISTANCE — Universite du Quebec a Chicoutimi (Canada) — Creep resistance is one of the most important properties required in aluminum conductor alloys. Due to the Joule effect, temperature increase in the aluminum conductor and creep resistance is needed to avoid long term deformations. This disclosure concerns aluminum conductor alloys having increased creep resistance, aluminum products comprising same and process using same. In some embodiments, the aluminum conductor alloy comprises, in weight percent: up to about 0.10 Si; up to about 0.5 Fe; up to about 0.30 Cu; between about 0.02 and about 0.1 Mg; up to about 0.04 B; and the balance being aluminum and unavoidable impurities.

US11525175 — ALUMINUM ALLOY AND PREPARATION METHOD THEREOF — Guangdong Hoshion Industrial Aluminum Co., Ltd. (China) — The present invention is applicable to the technical field of material processing and provides an aluminum alloy and a preparation method thereof. The preparation method of the aluminum alloy includes: weighing raw material components according to a preset weight ratio; melting the weighed raw materials, sequentially performing refinement, standing, slag removal, degassing and filtering, and then performing horizontal casting to obtain an aluminum alloy ingot; homogenizing the ingot; heating the ingot to 440-500°C, and placing the ingot in an extruder with an extrusion ratio of 30-100 for extrusion treatment; annealing the extruded blank; heating the annealed blank to 440-480°C for deformation treatment, and controlling the deformation amount in the thickness direction to be 12%-28%; carrying out solution treatment on the deformed blank; and subjecting the blank after the solution treatment to artificial aging treatment. An objective of the present invention is to provide an aluminum alloy, where the size of recrystallized grains in the aluminum alloy is 500-3000 μm and the yield strength of the aluminum alloy is not less than 280 MPa.

US11519599 — OPPOSED-INJECTION ALUMINUM MELTING FURNACE UNIFORM COMBUSTION SYSTEM — Guangdong University of Technology (China) — The invention discloses an opposed-injection aluminum melting furnace uniform combustion system which comprises: a furnace body, a first heat storage unit, a second heat storage unit, and four fuel injection guns disposed diagonally on two end walls of the furnace body comprising a first fuel injection gun located on the first end wall of the furnace body adjacent to the second heat storage unit, a second fuel injection gun located on the second end wall of the furnace body adjacent to the first heat storage unit, a third fuel injection gun on the second end wall of the furnace body adjacent to the second heat storage unit, and a fourth fuel injection gun located on the first end wall of the furnace body adjacent to the first heat storage unit, the gas injection direction of the first fuel injection gun is parallel with that of the second fuel injection gun with a spacing H between the axes thereof, the gas injection direction of the third fuel injection gun is parallel with that of the fourth fuel injection gun, with a spacing H between the axes thereof, and the spacing H between the axes is set to a quarter to one tenth of the furnace body width, such that the gas entering the chamber are oppositely-injected to form a swirling flow.

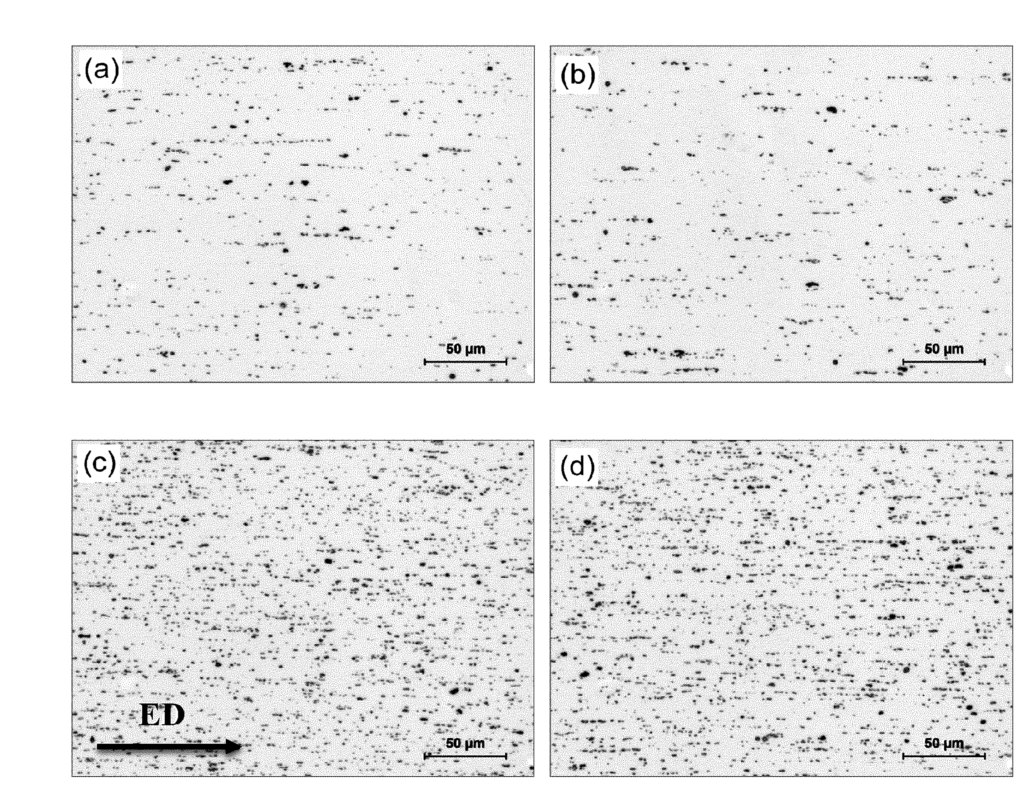

US11519058 — 6XXX ALUMINUM ALLOY EXTRUDED FORGING STOCK AND METHOD OF MANUFACTURING THEREOF — Constellium Extrusions Decin S.R.O. (Czechoslovakia) — The invention concerns an aluminum extruded product as feedstock for forging comprising in weight percent Si: 0.6% to 1.4%, Fe: 0.01% to 0.15%, Cu: 0.05% to 0.60%, Mn: 0.4% to 1%, Mg: 0.4% to 1.2%, Cr: 0.05% to 0.25%, Zn≤0.2%, Ti≤0.1%, Zr≤0.05%, the rest being aluminum and unavoidable impurities having a content of less than 0.05% each, total being less than 0.15%, wherein the number density of Mn containing dispersed particles is at least equal to 2.5 particles per μm2, preferably 3.0 particles per μm2. The invention also concerns the process to obtain the aluminum extruded product as feedstock for forging. The alloying composition and the corresponding microstructure of the aluminum extrusion feedstock for forging allows the subsequent production of forged products with the good balance between strength, ductility, and fatigue.

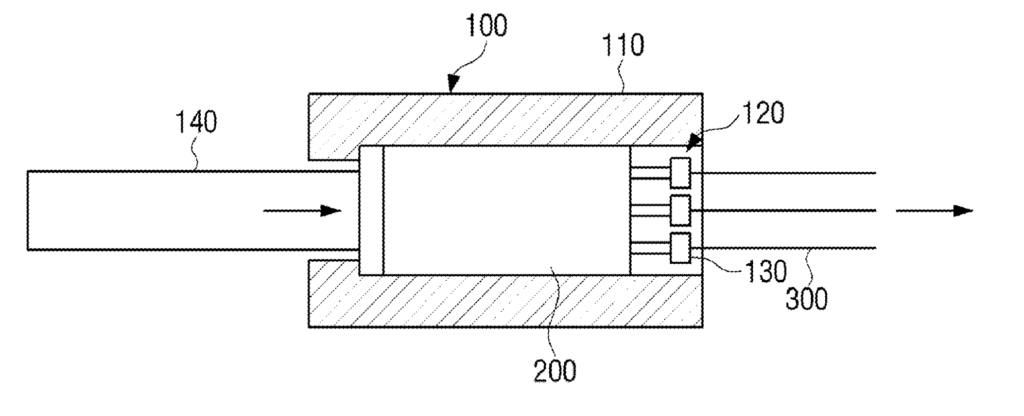

US11498104 — EXTRUSION APPARATUS AND METHOD FOR MANUFACTURING ALUMINUM CAPILLARY TUBE USING SAME — Samsung Electronics Co., Ltd. (Korea) — An extrusion apparatus and a method for manufacturing an aluminum capillary tube using the same are provided. The extrusion apparatus includes a container, a housing mold provided on one side of the container and including a plurality of dies formed with a plurality of holes, and a ram pressing an aluminum billet accommodated in the container in a direction from another side to the one side of the container so that the aluminum billet accommodated in the container is extruded into a plurality of aluminum capillary tubes having cross-sectional shapes corresponding to the plurality of holes, and the number of the plurality of holes is determined based on an inner diameter of the container and a diameter of each of the plurality of holes.

US11479838 — MANUFACTURING PROCESS FOR OBTAINING HIGH STRENGTH SOLID EXTRUDED PRODUCTS MADE FROM 6XXX ALUMINUM ALLOYS FOR TOWING EYE — Constellium Singen GmbH (Germany) — The invention relates to a manufacturing process for obtaining 6xxx-series aluminum alloy solid extruded products, comprising Si: 0.3-1.7 wt. %; Mg: 0.1-1.4 wt. %, Cu: 0.1-0.8 wt. %, Zn 0.005-0.7 wt. %, one or more dispersoid element, from the group consisting of Mn 0.15-1 wt. %, Cr 0.05-0.4 wt. % and Zr 0.05-0.25 wt. %, Fe at most 0.5 wt. %, other elements at most 0.05 wt. % the rest being aluminum, having particularly high mechanical properties, typically an ultimate tensile strength higher than 400 MPa, preferably 430 MPa, and more preferably 450 MPa without the need for a post-extrusion solution heat treatment operation. The invention also concerns a manufacturing process for obtaining a bumper system in which is integrated a towing eye, said towing eye being made with said high mechanical properties aluminum alloys.

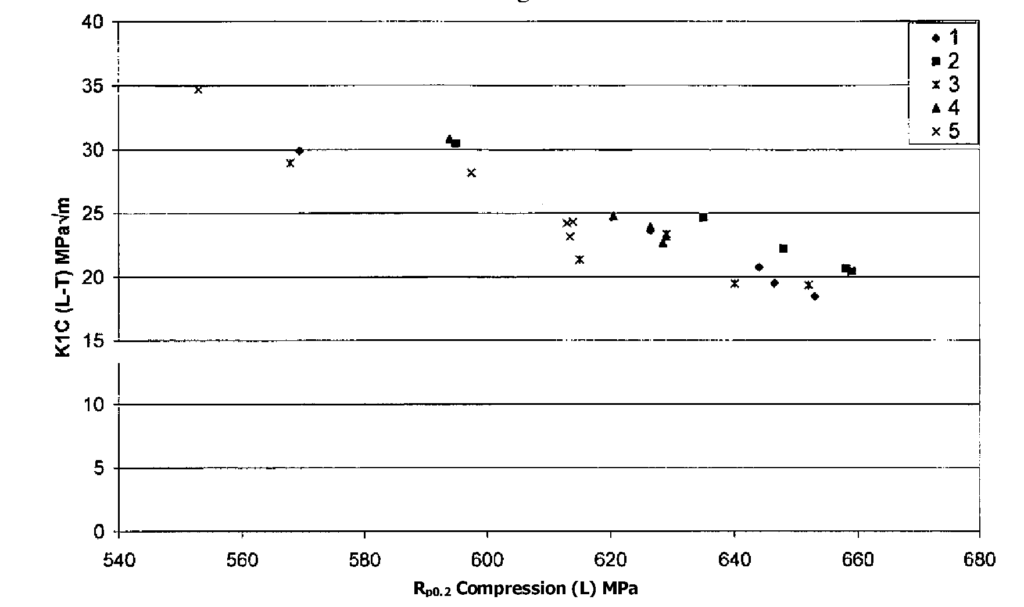

US11472532 — EXTRADOS STRUCTURAL ELEMENT MADE FROM AN ALUMINUM COPPER LITHIUM ALLOY — Constellium Issoire (France) — Extrados structural element made from an aluminum, copper and lithium alloy and method for manufacturing same. An alloy with composition (in wt. %) 4.2-5.2 Cu, 0.9-1.2 Li, 0.1-0.3 Ag, 0.1-0.25 Mg, 0.08-0.18 Zr, 0.01-0.15 Ti, an Fe and Si content level less than or equal to 0.1% each, and other element with content level less than or equal to 0.05% each and 0.15% in total, is poured, homogenized, deformed hot, placed in a solution at a temperature of at least 515°C, pulled from 0.5 to 5% and annealed. The combination of magnesium, copper, and manganese content with the temperature in solution can reach an advantageous elasticity under compression limit. Products having a thickness of at least 12 mm have, in the longitudinal direction, an elasticity under compression limit of at least 645 MPa and an elongation of at least 7%. For the manufacture of sections by extrusion, the addition of manganese also notably improves fracture toughness in the T-L direction. In another embodiment, it may be advantageous that the manganese content be less than 0.05% by weight for the manufacture of certain sections by extrusion.

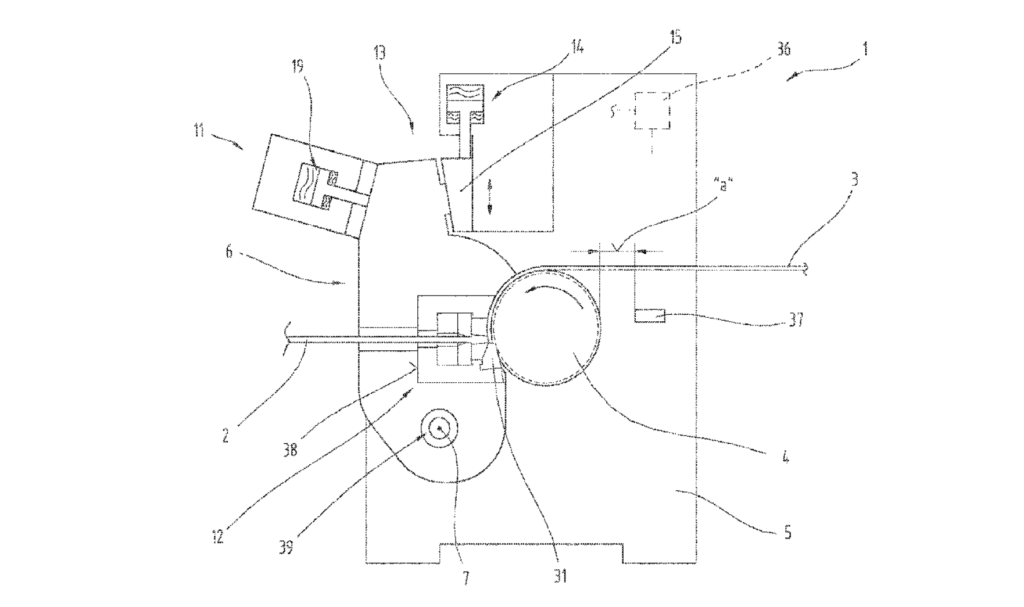

US11446721 — EXTRUSION MACHINE, METHOD FOR DISTANCE CONTROL AND METHOD FOR CHANGING A FRICTION WHEEL IN AN EXTRUSION MACHINE — Asmag-Holding GmbH (Austria) — The invention relates to an extrusion machine (1) comprising a main frame (5), a friction wheel (4), a tool holding device (6), a locking device (11) and a tool unit (12) supported on the tool holding device (6). Furthermore, a shielding unit (28) with at least one first nozzle (32) and at least one second nozzle (33) is provided, wherein the nozzles (32, 33) are formed to emit a gas which is free of gaseous oxygen. The first nozzle (32) is directed at a peripheral portion (29) of the friction wheel (4). The second nozzle (33) is arranged below a stripping area (30) of the tool unit (12). The invention further relates to an extrusion machine (1) with a sensor unit (25) between the tool holding device (6) and the tool unit (12) as well as a method for distance control between two tool components of the extrusion machine (1). Furthermore, the invention also relates to different extrusion machines (1) as well as methods for changing friction wheels. This continuous process is mainly used for profiles 2 of small and medium dimensions. A wide variety of materials, such as aluminum, copper, and other non-ferrous metals or their alloys can be formed.

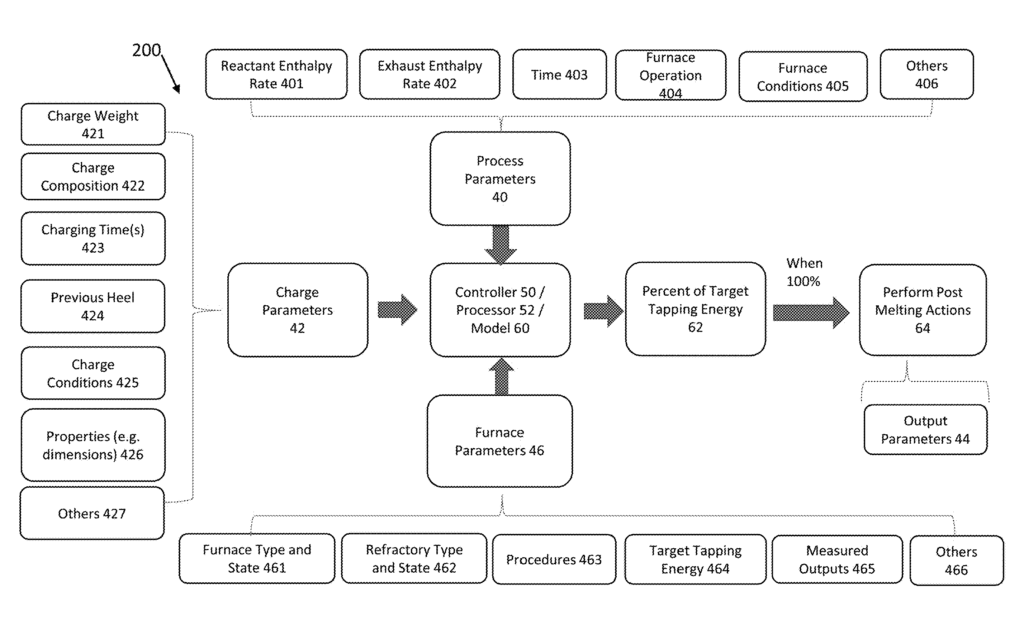

US11441206 — SYSTEM AND METHOD OF OPERATING A BATCH MELTING FURNACE — Air Products and Chemicals, Inc. (USA) — A system and method of controlling a metal melting process in a melting furnace, including determining at least one furnace parameter characterizing a melting furnace, adding a charge containing solid metal into the melting furnace, detecting at least one charge parameter characterizing the charge, firing a burner into the melting furnace to provide heat to melt the charge, and exhausting burner combustion products from the furnace, detecting at least one process parameter characterizing progress of melting the charge, calculating a furnace efficiency based on the at least one furnace parameter, calculating a predicted process pour readiness time based on the at least one charge parameter, the at least one process parameter, and the furnace efficiency, and controlling the metal melting process based on the predicted process pour readiness time.

US11383280 — DEVICES AND METHODS FOR PERFORMING SHEAR-ASSISTED EXTRUSION, EXTRUSION FEEDSTOCKS, EXTRUSION PROCESSES, AND METHODS FOR PREPARING METAL SHEETS — Battelle Memorial Institute (USA) — Devices and methods for performing shear-assisted extrusion processes for forming extrusions of a desired composition from a feedstock material are provided. These processes can use a device having a scroll face having an inner diameter portion bounded by an outer diameter portion, and a member extending from the inner diameter portion beyond a surface of the outer diameter portion. Extrusion feedstocks and extrusion processes are provided for forming extrusions of a desired composition from a feedstock. The processes can include providing a feedstock having at least two different materials and engaging the materials with one another within a feedstock container. Methods for preparing metal sheets are provided that can include preparing a metal tube via shear assisted processing and extrusion; opening the metal tube to form a sheet having a first thickness; and rolling the sheet to a second thickness that is less than the first thickness. The technology produces a grain size for magnesium and aluminum alloys at an ultra-fine regime (<1 micron), representing a 10 to 100 times reduction compared to the starting material.