By Ashley Stone, MAXImolding! Technology GmbH.

Cold-chamber die casting (best used for aluminum and other metals with high melting points) and hot-chamber die casting (best used for magnesium and other metals with lower melting points) are common methods for the production of complex parts. However, these two methods do not necessarily meet end-user expectations for quality, energy savings, and environmental sustainability. Semi-solid metal casting methods address these three issues, but present new challenges. For example, the three most commonly used semi-solid casting processes—thixomolding, thixocasting, and rheocasting—tend to be expensive, complex, and maintenance intensive. Therefore, a new process and machine is required.

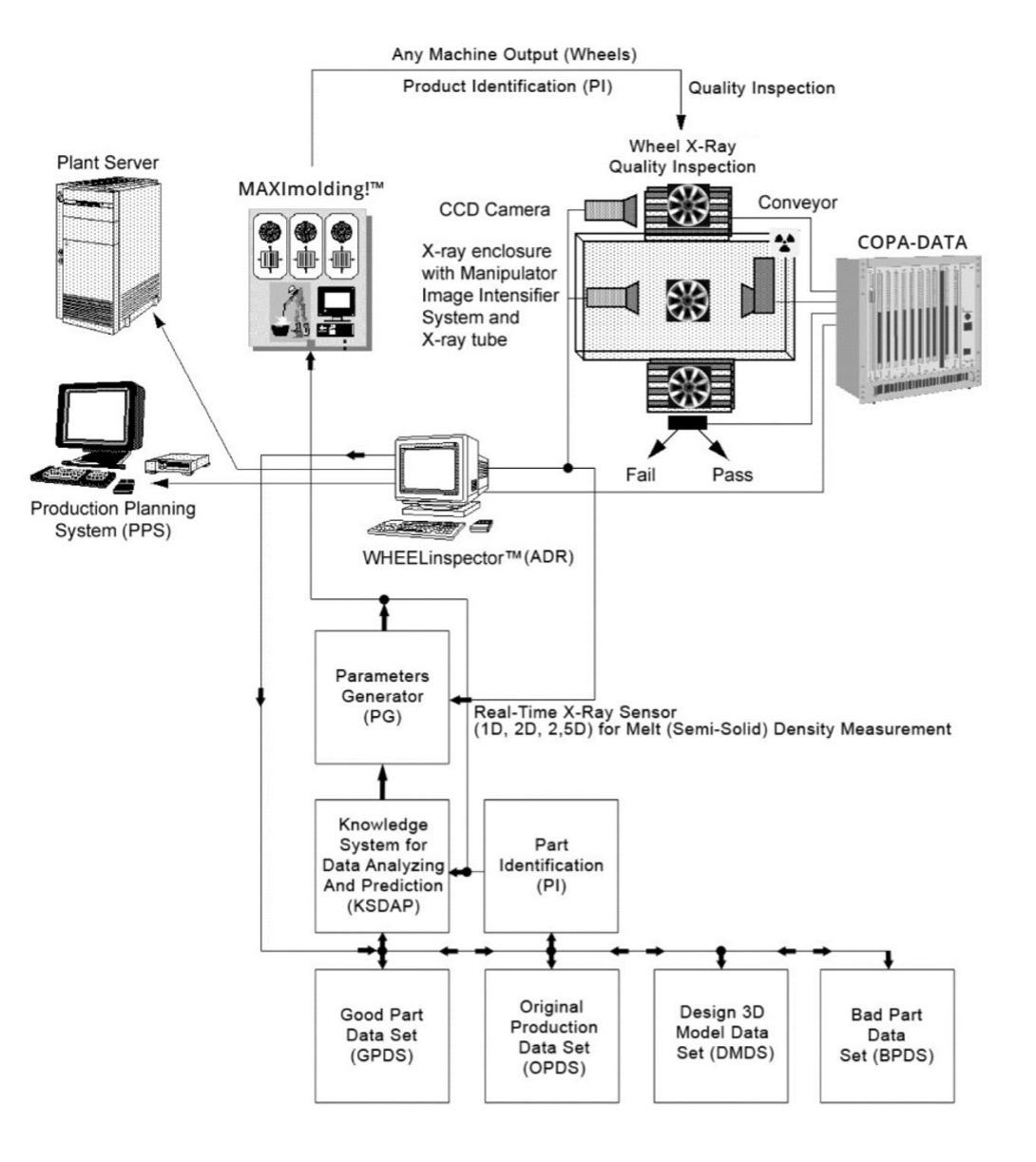

MAXImolding! Technology GmbH, based in Germany, is dedicated to solving manufacturing problems to enable the production of high integrity net-shape light metal parts while reducing porosity in molded metal parts (castings). The company is committed to improving the current unsustainable approach of molding, inspecting, separating, and remelting. To this end, the company has invented and patented MAXImolding®, a vertically oriented semi-solid metal alloy injection molding machine. The molding process parameters are optimized without the need for a human operator to be close by, resulting in a real-time x-ray feedback control loop based on part quality indicators and proper machine learning algorithms. This is an intrinsically safe, energy and material efficient, environmentally friendly intelligent magnesium molding machine with no emissions outside its parameter limits.

The Value of Magnesium

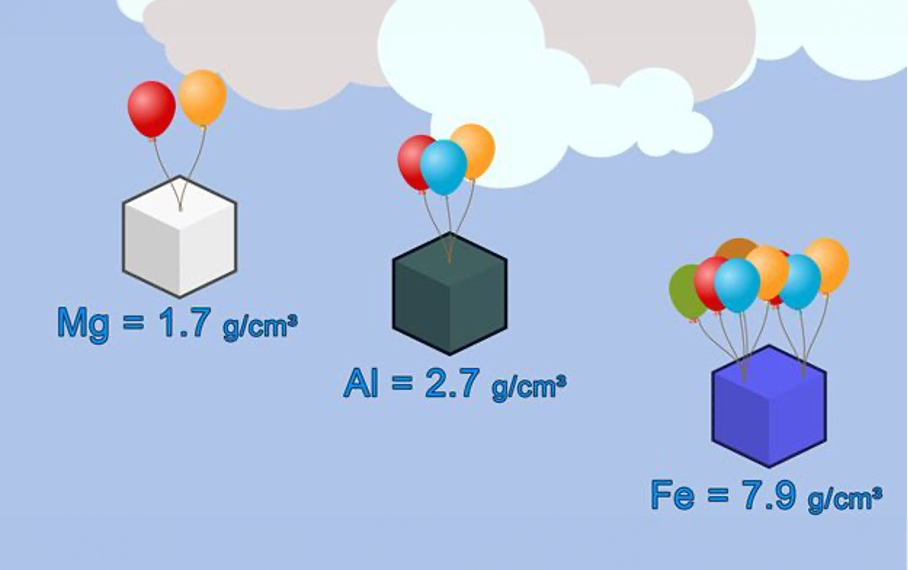

With the continuous quest for weight reduction across a wide array of industries, magnesium alloys are among the most promising materials for technological development. Magnesium is the lightest of all structural metals (Figure 1). With its unique blend of low density, high specific strength, stiffness, high electrical conductivity, high heat dissipation, and absorption of vibrations, magnesium is an excellent candidate to support a variety of industries.

Magnesium is the eighth most abundant element in the Earth’s crust and the fourth most abundant element on earth. Currently, the majority of primary magnesium production takes place with the Pidgeon process in China (which is energy and carbon intensive). However, there is vast potential for the production of magnesium from seawater, and Magrathea, a North American company, is moving toward developing a new facility for the production of low-carbon magnesium from seawater. Other Western companies, including Big Blue Technologies and Latrobe Magnesium, are also working on the development of low-carbon production methods.

New primary magnesium developments combined with ease of recycling (requiring only 4% of the energy compared to primary production) are representative of why magnesium alloys may be the material of the future. In addition, even when unrecycled and landfilled, magnesium metal degrades into magnesium oxide (MgO), a naturally occurring mineral that becomes a part of nature overtime without emitting pollutants, thus contributing to climate goals.

However, in order to take advantage of the many benefits of magnesium, some fundamental things in the foundry industry need to be reconsidered. For a long time, magnesium was regarded by foundrymen as being difficult to handle, and the appropriate technology for better utilization of magnesium was lacking. Today, processing magnesium is a safe and rewarding activity promising minimal climate impact and great growth opportunity.

The State of the Die Casting Industry

Research on the state of the art in the die casting industry, including magnesium studies conducted by Dr. Frank Czerwinski in Canada and Dr. Andreas Lohmüller, et al., in Germany,1-2 show that the use of magnesium alloys in applications, such as automotive, where light weight and material strength are required will contribute to improved fuel economy and environmental protection. Legislation to limit emissions has led to calls for mandatory requirements to reduce the weight of automotive components, especially for electric cars, creating a renewed and growing interest in magnesium.

North American manufacturers are considering the potential of magnesium over aluminum for two reasons, properties and price. For example, Magna International Inc., a leading Tier-1 supplier, is continuing its research into low-cost magnesium parts for automotive markets. This trend continues with other companies, as well, but progress is slow for many reasons.

One reason for the slow progress in the use of magnesium alloys in die casting is the general lack of new technologies and processes to facilitate the wider use of magnesium. The cost of ownership and entry into magnesium die casting is currently very high and the learning curve is long. This is mainly due to the lack of semi-solid expertise in the industry and resistance to adopting new technologies. The prevailing attitude observed by many companies can be summed up in two backward and inefficient sayings, “If it ain’t broke, don’t fix it” or “We’ve always done it this way.” These two phrases represent the most expensive philosophies in the business. Past success is no guarantee of future success, especially when the only constant is change. Being stuck in a “culture of the past” attitude can be both frustrating and limiting.

After inspecting millions of die castings, a common pattern was observed in which die casting companies try to improve quality through inspection, rather than closing the loop by integrating inspection into the overall process. Most often, the inspection process is separated from the die casting process, meaning that bad parts are simply separated from good parts and remelted. The energy cost of remelting adds to the cost of the part and is passed on to the customer without any consideration of the impact of this practice on the long-term survival of the die casting industry.

Magnesium alloys have some unique solidification characteristics, such as excellent flowability and a lower susceptibility to hydrogen porosity, which provide them with a better castability over other well-known casting metals, such as aluminum, zinc, and copper. The current methods of die casting include high pressure die casting (HPDC) and semi-solid forming, which are briefly discussed hereafter.

High Pressure Die Casting

HPDC is the most common method of casting magnesium alloys. It offers attractive flexibility in the design and manufacture of light metal components. Its good die filling characteristics allow large, complex castings to be produced, but at the risk of air entrapment and more internal defects. In addition, the process is not easily scalable and is energy intensive.

Semi-Solid Forming

Semi-solid metal forming is a near net shape variant of die casting. The process is used with magnesium and results in excellent part integrity. The process combines the advantages of casting and forging and is named for the thixotropic property of the fluid, which is the phenomenon that allows the process to work. Simply put, thixotropic fluids flow when sheared and thicken when stationary. In the temperature range between solid and liquid, semi-solid metal forming is similar to the ice-shear thixotropic fluid when water and ice are mixed. The potential for this type of process was first recognized by MIT researchers in the early 1970s.3 There are four semisolid metal molding processes in use today, including thixomolding, thixocasting, rheocasting, and stress induced melt activation (SIMA). The following sections will focus on thixomolding and SIMA.

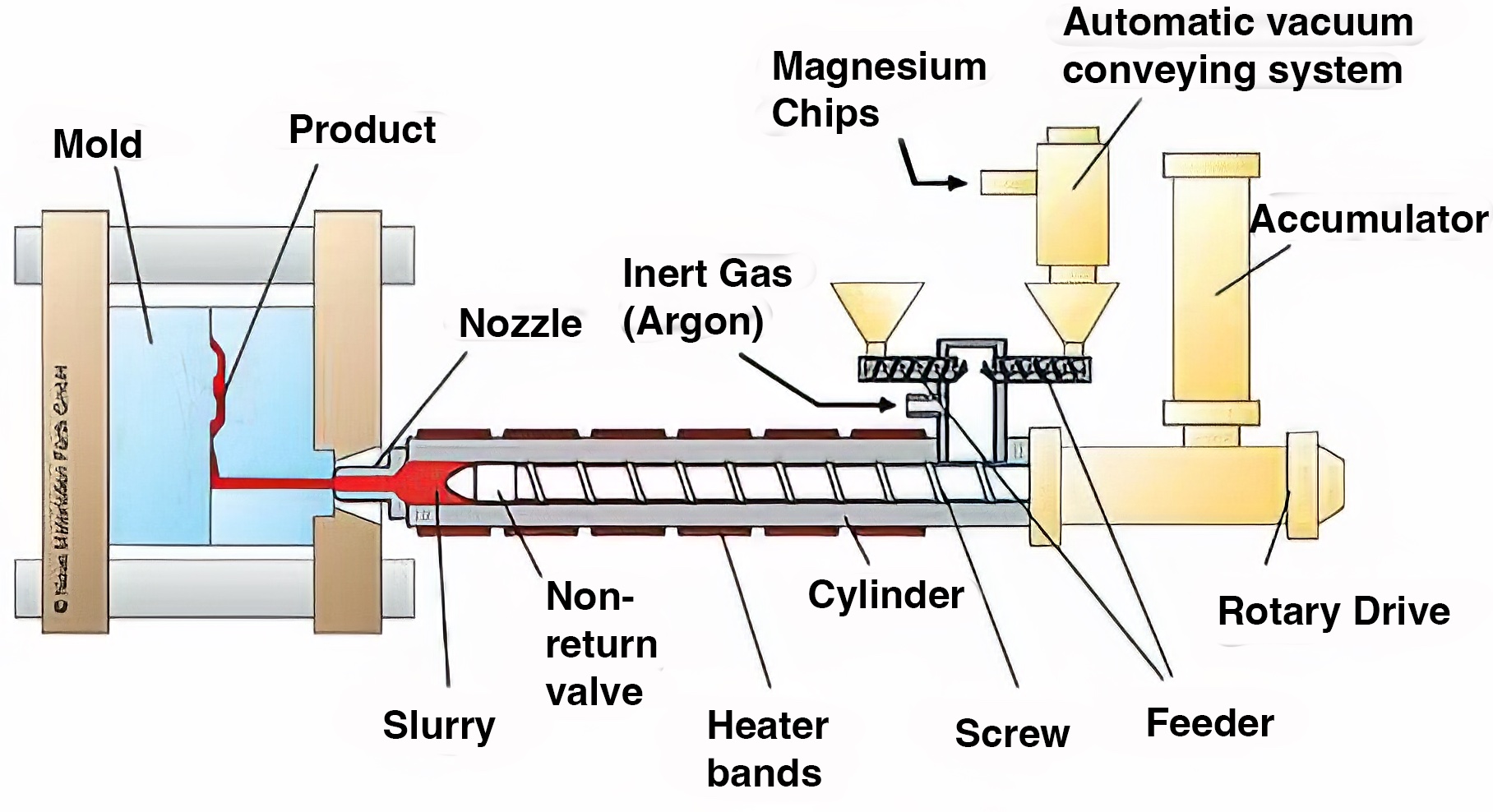

In the thixomolding process (Figure 2), the magnesium alloy in the form of metal granules is fed into a specially modified plastic injection molding machine, similar to the way plastic resin is processed. Thixomolding has several advantages over conventional die casting, most notably the ability to mold parts with higher integrity, safer operation without a melting furnace, and little negative environmental impact. Because thixomolding allows magnesium alloy slurries to be molded in a semi-solid state, there is no need for a smelting pot or environmentally harmful cover gas. In addition, it results in products with few defects and superior dimensional accuracy. In the thixomolding injection process, the microstructure appears to offer a new level of process control and much less energy per part compared to HPDC.

Currently, there are only a few manufacturers of thixomolding injection molding machines—and the machines are very complex, requiring intensive and very expensive service and maintenance due to the many complex moving parts that are in direct contact with the molten magnesium. The most expensive part of the machine is the extruder, which is made of special steel alloys that can withstand high temperatures and pressures. However, the screw (with a front-mounted check valve) is notoriously prone to leakage and inconsistent operation. Maintenance on these units, which is required after only 500,000 cycles, requires the use of special removal tools and a cleaning process that uses an environmentally unfriendly hydrochloric or phosphoric acid. While a step forward in producing high quality parts, this process is definitely complex and very expensive to operate.

The SIMA process begins with a conventionally cast magnesium ingot. This feedstock is then hot worked, e.g. it is rolled, forged, or extruded in the solid state above the recrystallization temperature and then cooled. Such feedstock develops a fine globular microstructure when heated to the semi-solid state. The SIMA process is best suited for industrial applications, because it is relatively inexpensive and provides an easy way to obtain a non-dendritic starting material by simply heating the highly stressed starting material to a semi-solid state.

Advanced Injection Molding Technology

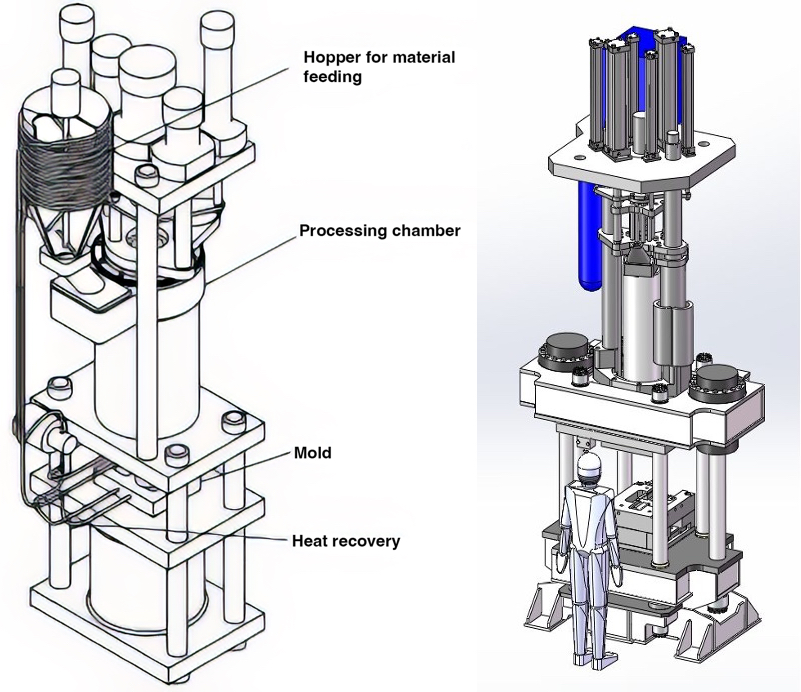

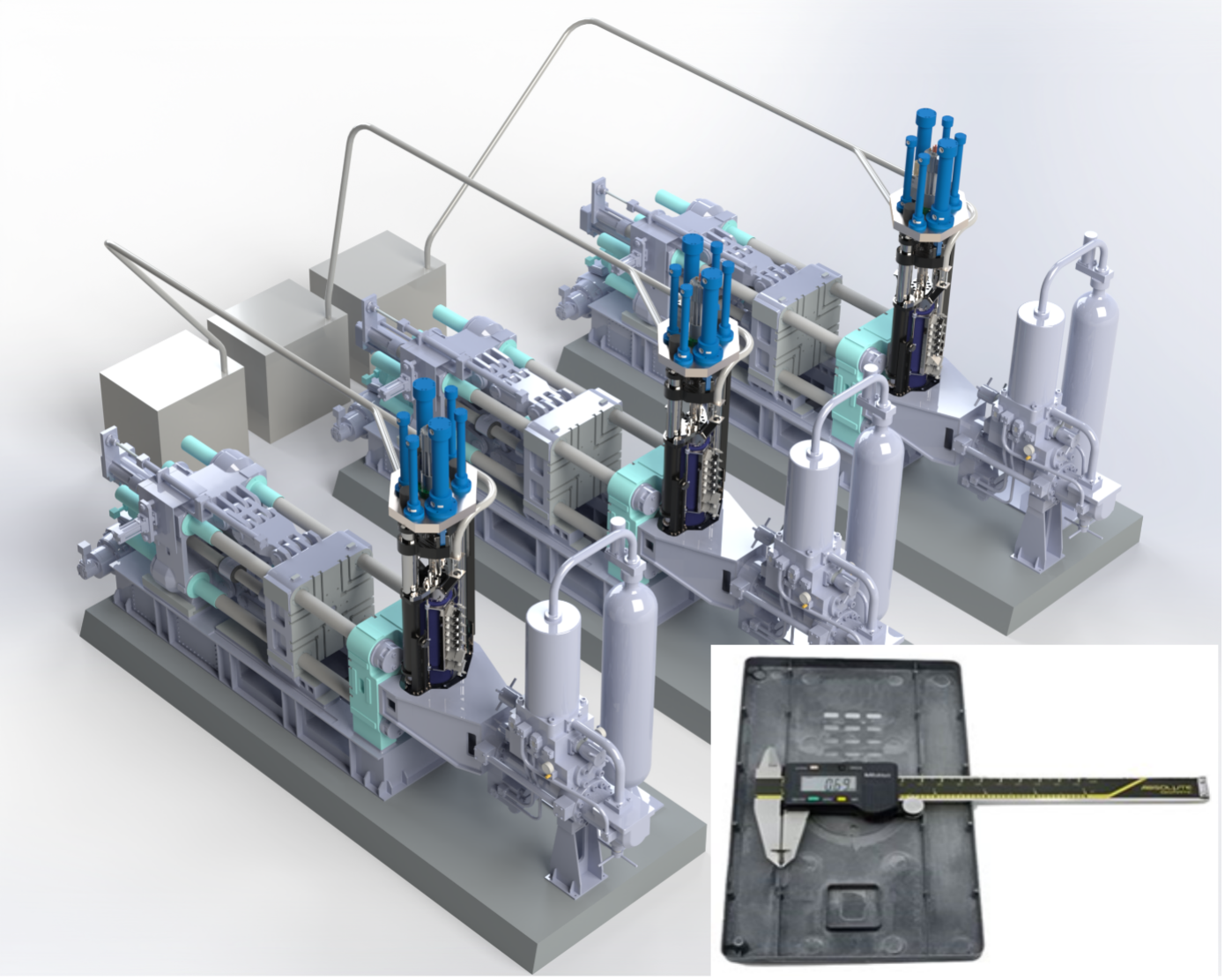

Between 1997 and 2023, the die casting industry made great strides in reevaluating the semi-solid magnesium casting process, resulting in the semi-solid molding/casting technology based on the one-step SIMA process. The new semi-solid injection molding machine, called MAXImolding (Figure 3), further simplifies the semi-solid molding/casting process by eliminating the complex extruder used in thixomolding machines and producing a spherical semi-solid slurry by melting mechanically stressed magnesium chips under the sole influence of external heat. No shearing of the chips in the extruder is required.

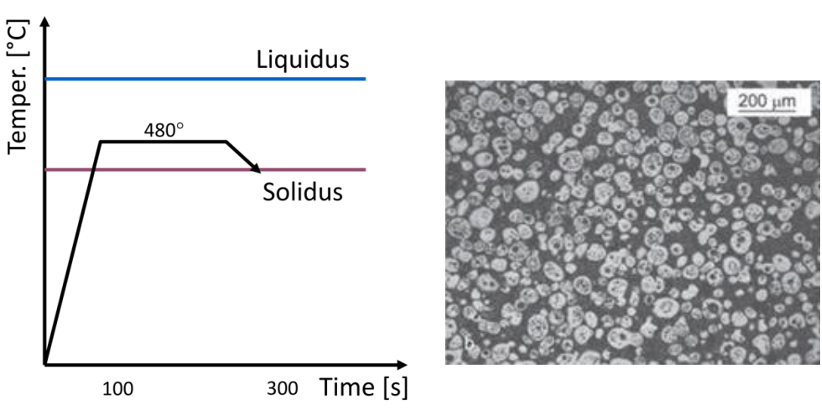

The use of mechanically stressed magnesium chips (instead of billet or ingot) represents a significant step forward in the production of high integrity castings. The magnesium chips produce semi-solid slurry with a spherical microstructure for injection into a permanent mold. When chipped, an ordinary die casting alloy, such as AZ91D, can only be processed directly into semi-solid slurry by reheating the chips to semi-solidus temperature due to the mechanical residual stress caused by the chipping process. Fractured magnesium chips can be made from standard die-cast alloy AZ91D (or any specialty alloy with the preferred globular structure), which is readily available on the market. The oval shape and size of the chips improves feed flow and thermal energy absorption due to the high surface area, which optimizes the MAXImolding process (Figure 4).

The MAXImolding machine loads the chips directly into the cavity of the main reactor, or preferably through a pre-conditioning reactor. The stuffer cavities are the processing and conditioning cylinders used to heat the chips. The stuffer cavities are arranged coaxially around the piston to ensure high structural integrity and temperature uniformity, which is critical for slurry generation and magnesium processing. The material is rapidly heated to semi-solid temperature by resistive heaters, and the slurry is transferred under the injection piston in the center of the same high thermal mass block to ensure a stable process temperature. The slurry, in the form of an ice water slurry, is transferred under a rapidly moving piston designed to inject the semi-solid slurry into a permanent mold to form the part. The part is then subjected to evaporative cooling at a very high rate of heat removal by a mixture of water vapor and air circulating just below the mold surface. This high cooling rate assists in freezing the globular structure of the part.

This cold-to-cold and solid-to-solid (S2S™) magnesium processing machine has several key advantages over other die casting or magnesium forming machines. The cylindrical structure and coaxial arrangement of the piston and plunger, surrounded by processing stuffers, allow for the processing of magnesium in very narrow temperature windows and with tight temperature control. Computer-controlled heating and high-speed injection, including holding pressures of 15,000 PSI (1,034 bar), enable a new level of molding, resulting in parts with properties that meet the requirements for use in high integrity applications.

MAXImolding machine maintenance is simple. The semi-solid slurry is completely contained within the machine. The mold is currently capable of casting over half a million parts due to reduced slurry temperatures. A significant advantage over any other die casting process is achieved by eliminating the need for a separate furnace and pot to produce fully molten metal. Everything is done in the same machine, in a fast cycle of 15 to 60 seconds.

The method of mold cooling, using a water-air mist system (80% air and 20% water) circulating just below the mold surface, is another advantage, as it provides very high cooling rates. Water-air generation in the closed cooling channels absorbs a large amount of heat from the solidifying part and is in turn used to preheat the incoming magnesium chips. This also results in significant process savings. By comparison, the current state of the art with other manufacturing methods is to dissipate all of the heat removed from the parts to the environment. In these other processes, mold heat is lost to the atmosphere. Therefore, no heat recovery is possible, due to the use of liquid cooling with a very small temperature differential, which is inefficient for the heat recovery process because a small temperature differential in turn requires a large volume of coolant.

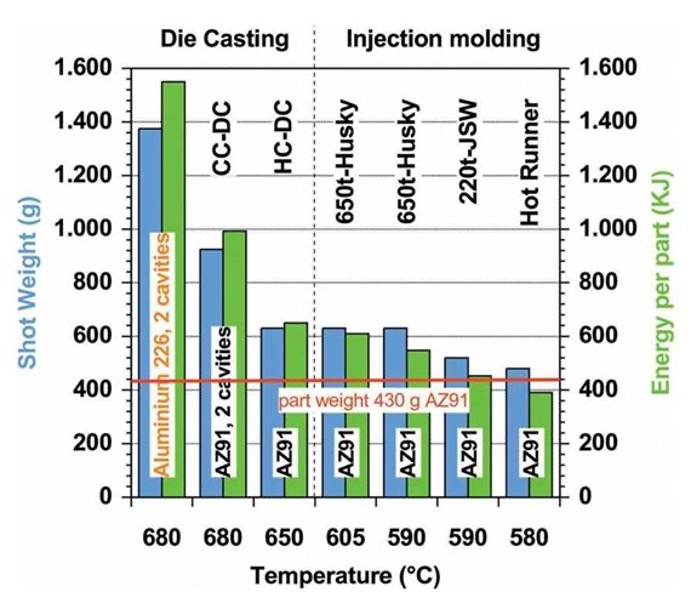

A major advantage is that the MAXImolding magnesium machine operates at temperatures just above the solidus temperature (Figure 5), i.e., 896°F (480°C) to 1.076°F (580°C). This results in a significant energy savings compared to the 1,112°F (600°C) to 1,292°F (700°C) melt temperatures of today’s die casting processes. The energy savings are significant, which is especially true for cold chamber die casting (Figure 6).

A recent German study by FAU-LGT and Neue Materialien Fürth GmbH concluded that light metal foundries consume 17 times more energy than required and two times more material than required. As a result, light metal foundries are polluting the atmosphere with 1.22 million tonnes of CO2e per year. Keep in mind that German light metal foundries are some of the best in Europe, if not in the world. This is where MAXImolding technology comes in. With further improvements, energy consumption can be reduced by a factor of 14, material consumption by a factor of two, and CO2e pollution by two-thirds. This has the power to change everything and save magnesium producers a lot of money.

Intelligent Digital Light Metal Foundry

The MAXImolding semi-solid molding/casting machine with novel S2S processing and water-air mist cooling system has been patented and is available for licensing and commercialization. In addition, the production control system with data feedback from the x-ray machine has also been patented and will allow the construction of a fully automated intelligent digital casting plant for the 21st century (Figure 7). All of this will contribute to the development of a new, advanced semi-solid die casting process. The operator only needs to turn on the machine, make sure material is available, take safety precautions, select a part to form, and make sure formed parts are removed. Machine intelligence performs data analysis, prediction, and optimum setup of all process parameters.

By networking production facilities across companies, it is possible to respond flexibly to fluctuating market conditions or order situations. Such smart factories, integrated into an ecosystem, also reduce costs and promote more resource-efficient production. For example, Company A shares its spare capacity with Company B, which is operating at full capacity. This allows both companies to keep order fluctuations to a minimum. In addition, maintenance procedures based on the evaluation of process and machine data can be carried out proactively.

MAXImolding is an intrinsically safe, energy and material efficient, environmentally friendly magnesium casting plant with no gas emissions outside plant parameters. All casting machines and x-ray inspection machines, as well as linear robotics, vision systems, and automated guided vehicles are integrated into this semi-solid state die casting process. This will ensure fast production of high-performance parts and maintain stable automatic closed-loop process control.

References

- Czerwinski, Dr. Frank, Magnesium Injection Molding, Springer, 2008.

- Lohmüller, A., C. Körner, and R.F. Singer, “Neue Gießtechnologien: Ressourceneffizient und wirtschaftlich” (New casting technologies: Resource-efficient and economical), in Ressourceneffiziente Technologien für den Powertrain, International Chemnitz Manufacturing Colloquium 2012 (ICMC 2012), pp. 67–81.

- Spencer, D.B., R. Mehrabian, and M.C. Flemings, “Rheological behavior of Sn-15 pct Pb in the crystallization range,” Metallurgical Transactions, Vol. 3, No. 7, 1972, pp. 1,925–1,932.

Editor’s Note: This article first appeared in the February 2024 issue of Light Metal Age. To receive the current issue, please subscribe.