Researchers at RMIT University in Melbourne, Australia, developed a new 3D-printed metamaterial (an artificial material with unique properties not observed in nature) from a common titanium alloy. The metamaterial is said to achieve a level of strength to weight that is not available in current manufacturing. It is expected to be used in a wide range of industries, from medical implants to aircraft or rocket parts.

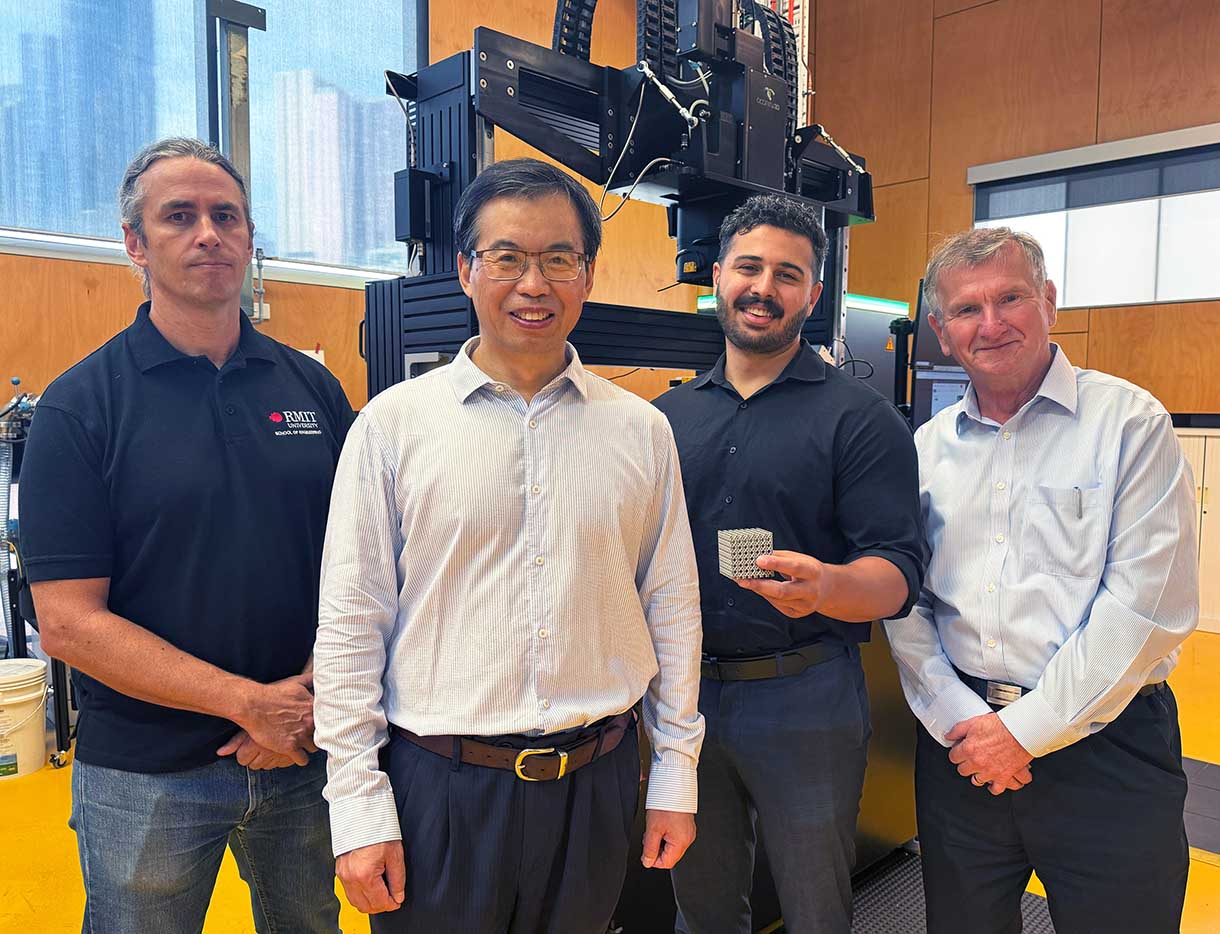

Scientific and technical support for the project was provided by the RMIT Advanced Manufacturing Precinct and the RMIT Microscopy and Microanalysis Facility. The project was funded by the Australian Research Council.

Innovative Lattice Design

While the titanium alloy may be common, it’s the lattice structure design that is unique — as it is inspired by nature. In particular, it is inspired by strong hollow-stemmed plants like the Victoria water lily or the hardy organ pipe coral (Tubipora musica), which are able to naturally combine lightness and strength.

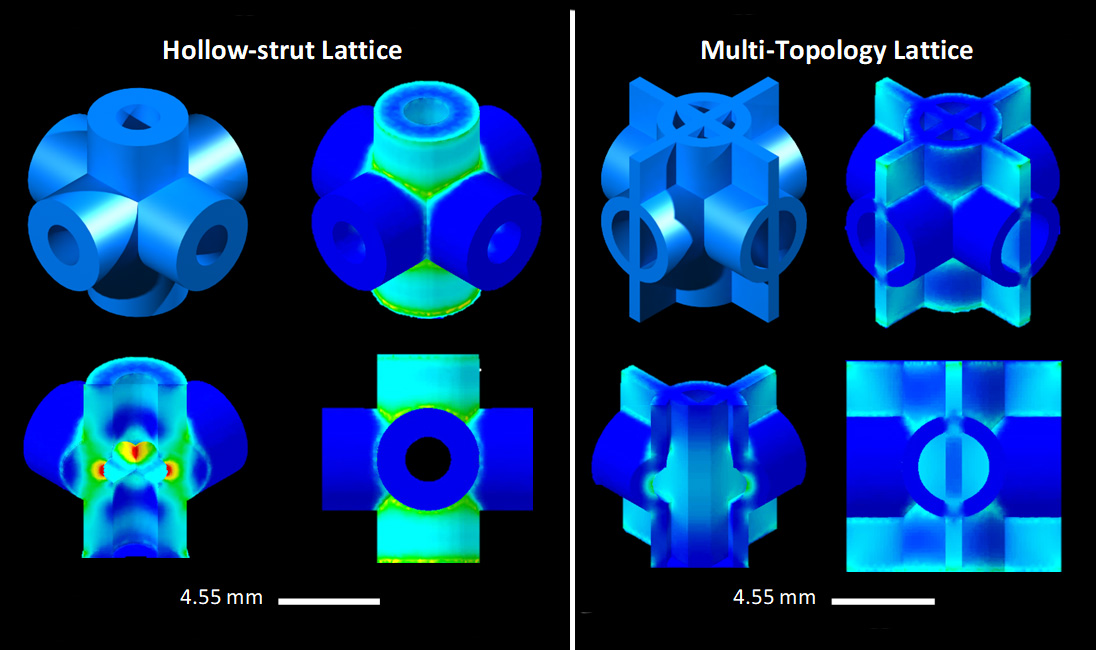

However, these natural structures have been researched for decades. As Prof. Ma Qian explains, trying to replicate these hollow ‘cellular structures’ in metals has been frustrated by the common issues of manufacturability and load stress concentrating on the inside areas of the hollow struts, leading to premature failures.

“Ideally, the stress in all complex cellular materials should be evenly spread,” said Qian. “However, for most topologies, it is common for less than half of the material to mainly bear the compressive load, while the larger volume of material is structurally insignificant.”

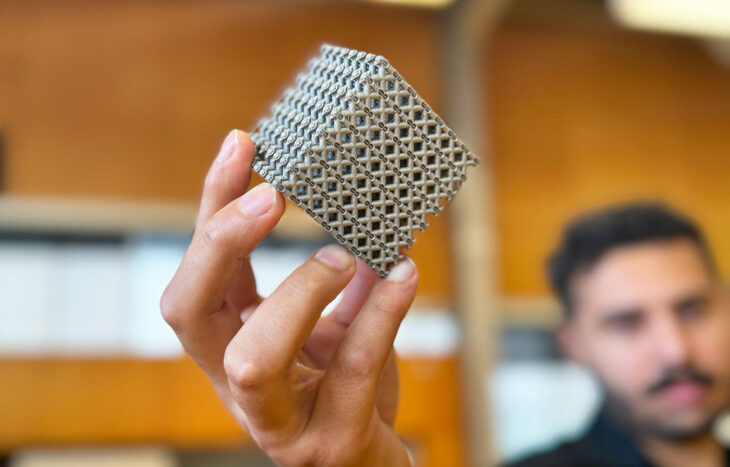

In order to achieve this unique lattice design, the RMIT research team turned to 3D printing — specifically the laser powder bed fusion process (where layers of metal powder are melted into place using a high-powered laser beam). This process enabled them to push the design to its limits. The team was able to optimize a new type of lattice structure to distribute the stress more evenly, enhancing its strength or structural efficiency.

“We designed a hollow tubular lattice structure that has a thin band running inside it. These two elements together show strength and lightness never before seen together in nature,” said Qian. “By effectively merging two complementary lattice structures to evenly distribute stress, we avoid the weak points where stress normally concentrates.”

Lightweight and Incredibly Strong

Testing at the Advanced Manufacturing Precinct showed that the titanium lattice cube was 50% stronger than cast magnesium alloy WE54, the strongest alloy of similar density used in aerospace applications. The new structure effectively halves the amount of stress concentrated on the lattice’s infamous weak points. In addition, the double lattice design is able to deflect any crack along the structure, further enhancing the toughness.

“Compared with the strongest available cast magnesium alloy currently used in commercial applications requiring high strength and light weight, our titanium metamaterial with a comparable density was shown to be much stronger or less susceptible to permanent shape change under compressive loading, not to mention more feasible to manufacture,” noted Jordan Noronha, the study’s lead author and a RMIT PhD candidate.

Noronha added that this structure could be produced in a range of sizes, from several millimeters or several meters, by using different types of printers. This printability — along with the strength, biocompatibility, corrosion, and heat resistance — make it a promising candidate for many applications, including aircraft or rocket parts.

The team plans to further refine the material for maximum efficiency and explore applications in higher-temperature environments. While currently resistant to temperatures as high as 350°C, they believe it could be made to withstand temperatures up to 600°C using more heat-resistant titanium alloys, making it ideal for applications in aerospace or firefighting drones.

Since the technology to make this new material is not yet widely available, its adoption by industry might take some time. Therefore, the RMIT team is open to proposals from companies wanting to collaborate on potential applications.

“Traditional manufacturing processes are not practical for the fabrication of these intricate metal metamaterials, and not everyone has a laser powder bed fusion machine in their warehouse,” said Noronha. “However, as the technology develops, it will become more accessible and the printing process will become much faster, enabling a larger audience to implement our high-strength multi-topology metamaterials in their components. Importantly, metal 3D printing allows easy net shape fabrication for real applications.”

Learn more about this new meta material in the paper, “Titanium Multi-Topology Metamaterials with Exceptional Strength,” published in Advanced Materials in December 2023.