AMAG components, a fully owned subsidiary of AMAG Austria Metall AG, signed an agreement with Ruag Aerostructures to deepen and expand their long-standing relationship. Under the agreement, Ruag Aerostructures will secure its existing scope of supply of aluminum parts and assemblies from AMAG for years to come, as well as put in place new orders for these kinds of components. The parties have not disclosed the exact details of the contract, which has a total volume of around €100 million.

“This [agreement] demonstrates the quality of the partnership and rewards the daily work of the teams on both sides,” said Johannes Pauli, manager of Strategic Procurement & Supply Chain Quality at Ruag Aerostructures. “With the extension of the supply contract we contribute towards the stable ramp-up in production of the A320 single-aisle program, under currently very challenging conditions. Our cooperation ensures customer satisfaction and proves the competitiveness of Germany as an aviation location.”

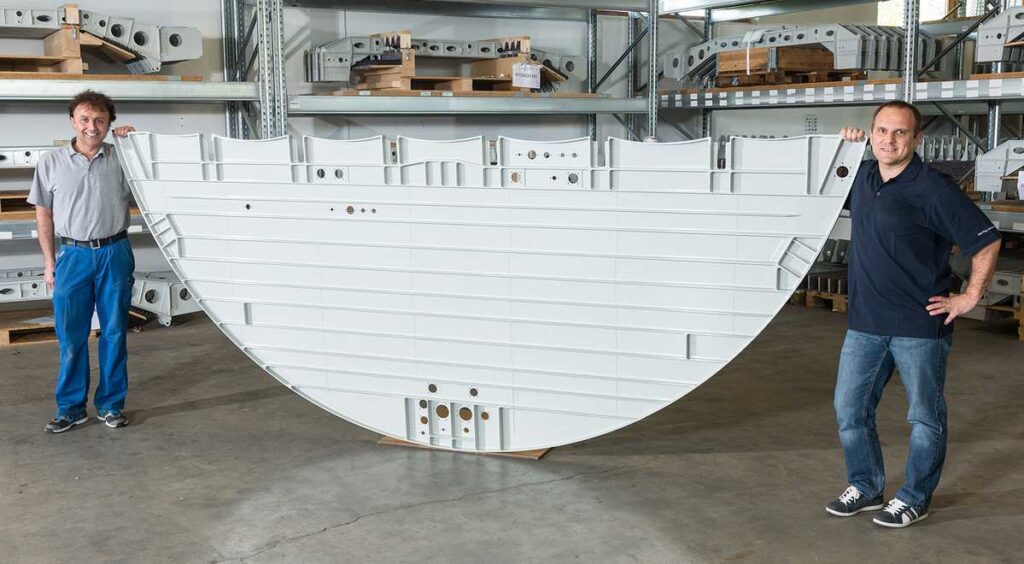

Under the agreement, AMAG components will be able to draw on its unique range of services, from raw materials to ready-to-install components, to successfully meet the technical requirements of the products. These components will be primarily used in the Airbus A320 single-aisle program.

In addition, the agreement will focus on limiting the use of raw materials in production in order to reduce the overall carbon footprint in the production of these components. AMAG is well-suited to achieve this, as the company is able to provide its aluminum products from a single source — from raw material (primary and secondary aluminum) and semi-finished products (sheet, plate) to ready-to-install individual parts or assemblies. Throughout every step of aluminum production, AMAG works to implement sustainable manufacturing solutions, including the installation of Austria’s largest rooftop photovoltaic system at its Ranshofen facility in Austria. The company’s sustainable manufacturing capabilities will enable it to provide closed-loop recycling to Ruag Aerostructures.

“This important and successful contract with our long-standing customer Ruag Aerostructures in Oberpfaffenhofen in Germany is a wonderful confirmation of our clear focus on high-quality special products, as well as our reliability when it comes to delivery assurance and service,” said Gerald Mayer, CEO of AMAG Austria Metall AG. “The combination of expertise in machining at the German sites and the sustainable production of aluminum input material, as well as recycling in Ranshofen, makes our offering unique.”

Headquartered in Übersee am Chiemsee, Germany, AMAG components is an an important supplier of complex individual parts and assemblies for the aerospace market. The division became a part of AMAG in January 2022, when the company acquired Aircraft Philipp.

Ruag Aerostructures, headquartered in Bern, Switzerland, is a global Tier 1 supplier of aerostructures for civil and military customers. This includes the development and manufacture of complete aircraft tail sections, wing and flight control components, structural elements, modules, and systems.