ALUMINUM USA 2019 is around the corner. The event will be held on September 12-13, 2019 at the Music City Center in Nashville, Tennessee. In addition to hosting an extensive exhibition, the event will host a technical conference on the show floor as well as industry-focused workshops.

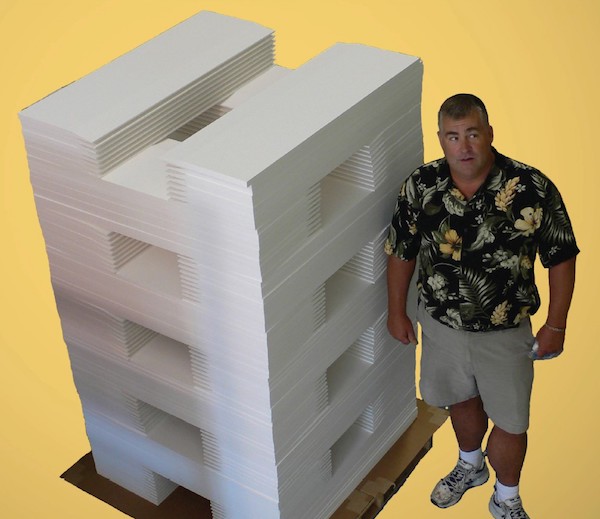

As the official media partner of ALUMINUM USA, Light Metal Age invites our readers to register for the exhibition and technical conference with a complimentary pass. We welcome visitors to Booth #537, where we will provide copies of our August 2019 issue. At 116 pages long, the August issue is our largest in over a decade. We’ll also be offering discounted subscriptions to the magazine (50% off U.S. rates, 25% off International rates, and complimentary digital).

Light Metal Age would not be able to provide high quality of aluminum industry articles and news without the support of our advertisers. We’re please to present (in alphabetical order) our many advertisers who will also be present at the ALUMINUM USA show to share their latest equipment and innovations.

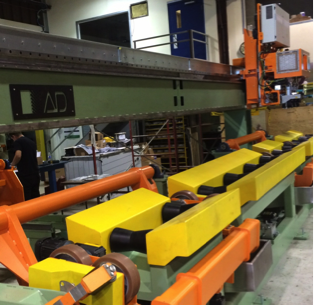

Advanced Dynamics – Ultrasonic Billet Testing

Advanced Dynamics has developed a 100% volumetric ultrasonic testing (UT) station for the aluminum extrusion billet industry. This unit can be integrated into any billet casthouse as a standalone piece of equipment or integrated into a complete sawing and packaging line. The UT station uses an overhead gantry and integrated Olympus RBIS™ phased array sensor heads, complete with a water sealing feature. The extrusion billet is positioned by a roller conveyor and then lifted via a set of arms with rotating driver rollers. The billet is rotated at a pre-determined speed based on the diameter. The sensor heads are lowered and move across the billet surface checking for inclusions or cracks. The testing station also features a calibration test billet stand to ensure that the billet meets the appropriate ASTM classification. For more information: Advanced Dynamics. Tel: (450) 653-7220. email: info@advanceddynamics.com. www.advanceddynamics.com.

Booth #503

Albarrie Canada – Protecting Aluminum Surfaces

Albarrie is a manufacturer of high temperature conveyance products and filtration media for the aluminum industry. Albarrie’s Defender™ heat felts and conveyance products are used extensively throughout extrusion and fabrication facilities to protect the critical surface finish of aluminum. Their smooth texture and impact absorption characteristics, combined with the ability to withstand temperatures up to 1,000°F, provide aluminum with unparalleled protection from damage during production, fabrication, shipping, and storage. Each product is customized to meet the application. Products include: Kevlar® rollers, roller covers, felt pads, durafiber boards, endless belts, Nomex® felt tape, and spacer bar sleeves. Albarrie also specializes in the production of filter media, filter bags, and components for dust collectors with several specialty filters for high temperature and/or spark resistance. Their team of filtration specialists are available for troubleshooting, cleaning, and servicing your dust collection system. For more information: Albarrie Canada, Ltd. Tel: 866-269-8275. email: apcfabrics@albarrie.com. www.albarrie.com/defender-heat-felts/.

Booth #542

Almex USA – From Furnace to Finish

Almex USA is a leading supplier of aerospace and commercial aluminum billet and slab casthouse technology. The company specializes in complete turnkey Furnace to Finish™ casthouse engineering and equipment supply, which is coupled with its comprehensive technology and know-how training program. The product line includes melting furnaces, degassing systems, DC casting machines, billet and slab casting systems, automated process controls, plant management SCADA systems, and homogenization furnaces. Almex is engaged in green technology for efficient recycling of aluminum alloys with a minimal environmental footprint. Their technology (in use at more than 30 plants around the world) is based on the principles of equipment and process safety, performance, and simplicity. These three fundamentals have created a tradition throughout the company, assuring innovative, quality conscious, and wallet-friendly casthouse solutions. For more information: Almex USA. Tel: (714) 739-0303. email: info@almexusa.com. www.almexusa.com.

Booth #312

ALTEK – Dross Management Solutions

ALTEK specializes in providing dross management solutions and molten metal circulation systems. The company’s TARDIS Generation II dross press is the best available technology for treating hot dross—providing the highest overall metal recoveries. The versatile system is well suited to process white and black dross and salt cake. Customers typically achieve 10-25% drain from white dross with a secondary aluminum recovery from the pressed skull of 45-75%. ALTEK also provides versatile and cost-effective electromagnetic stirring systems (EMS).The air-cooled EMS from ALTEK requires little energy and, due to the system’s unique ability to dynamically control the stir, it has become the benchmark for non-contact furnace stirring technology. The EMS is the most efficient and effective means of increasing melt rate/productivity, reducing gas consumption, decreasing dross generation, improving alloying yields, and quickly homogenizing temperature and chemistry in a furnace. For more information: Altek. Tel: (484) 713-0070. email: sales@altek-al.com. www.altek-al.com.

Booth #318

AMCOL – Metalworking Fluid Systems

AMCOL Corporation is a recognized global leader in metalworking fluid systems used in manufacturing and fabricating of aluminum extrusions and castings. The AMCOL approach combines high performance lubricants with best in class application systems that work together to achieve optimal performance while reducing cost, waste, and environmental impact. Advancements in their Minimum Quantity Lubrication Systems, “SMART Metering,” can eliminate operator intervention and reduce lubricant consumption. SMART integrates directly with PLCs to give you ultimate precision and control of lubricants for a range of processes from sawing to complex fabrication cells. The company’s lubricants and systems are designed for a variety of manufacturing processes, such as extrusion billet release, hot shearing, CNC coolants, and mobile coolant reclamation systems. For more information: AMCOL Corporation. Tel: (248) 414-5700. email: info@amcolcorp.com. www.amcolcorp.com.

Booth #902

AMETEK Land – Temperature Measurement

AMETEK Land, the non-contact temperature measurement specialist with extensive expertise in the aluminum industry, provides its smart aluminum temperature sensors to achieve smart control and automatic alignment for autonomous operation and perfect aluminum production. The company presents its SPOT AL EQS, a spot pyrometer that runs complex embedded software algorithms for both temperature and emissivity outputs. Coupled with its latest innovation, a smart actuator for automatic alignment, the SPOT AL EQS can provide accurate temperature measurement for most current extrusion, quench, and strip applications. Designed in close collaboration with industry-leading aluminum producers and plant control system engineers, the SPOT AL EQS pyrometer with actuator is helping to lead the way in improving aluminum extrusion and strip plant throughput, quality, and energy efficiency. For more information: AMETEK Land. Tel: (412) 826-4444. email: land.enquiry@ametek.com. www.ametek-land.com.

Booth #130

Bloom Engineering – Combustion Solutions

Bloom Engineering is a combustion solutions company headquartered in Pittsburgh, PA, serving basic industry with particularly strong roots in steel and aluminum. The company specializes in problem solving through custom engineering of industrial burners, combustion systems, controls, and field services. It is Bloom’s mission to be the foremost provider of innovative energy and environmental solutions to industry. This is accomplished through technical expertise, product application, and quality services. The company works to exceed customer’s expectations with dedication to problem solving and ongoing research and development. Since 1934, they have been working with customers to address their efficiency requirements and production demands with integrity, accountability, and innovation, while at all times performing safely. For more information: Bloom Engineering Co. Tel: (412) 653-3500. email: jcheckeye@bloomeng.com. www.bloomeng.com/usa.

Booth #305

Butech Bliss – Custom Built Mill Equipment

Butech Bliss is a leading innovator that has been providing equipment solutions for coil processing, cold reduction, and mill application equipment for over 130 years. Metal producers, service centers, and extruders around the world have relied on Butech Bliss to create solutions for their production needs. They build cut-to-length lines, shears, hydraulic levelers, extrusion equipment, and scrap choppers. The company’s services include engineering, manufacturing, field service, and shop rebuild services on all types of metal processing equipment. Instead of using standard designs that may not be the best solution for your particular application, they provide custom-built equipment to fit a facility’s particular needs and circumstances. The Butech Bliss advantage means that equipment is designed to maximize return on investment through longer life, less need for maintenance, and higher productivity. For more information: Butech Bliss. Tel: (330) 337-0000. email: sales@butech.com. www.butechbliss.com.

Booth #1001

Castool Tooling Systems – Outcome-Centric

Castool and parent company, Exco Technologies Ltd., have been servicing aluminum extruders globally since 1952. The company uses a system and consultative approach to “make extrusion better.” The company is in the initial stages of integrating, monitoring, and measuring extrusion success with their Visual Optimizing System (VOS). The VOS connects Castool’s QR container, die ovens, and other tooling with various press PLCs and pyrometers. Automatic die copy and alloy specific recipe creation with minimal operator input is one of its core strengths. Embedded advanced calculations using real-time information along with user-friendly prompts empower press operators—realizing maximum productivity gains. Castool’s team offers their knowledge and experience with dummy blocks, stems, containers, die ovens, lubrication systems, lubricants, shear blades, clean-out blocks, heat felts, pyrometers and other press tooling, and software for the extrusion of alloys and profiles with various presses. For more information: Castool. Tel: (905) 852-0121. email: probbins@castool.com. www.castool.com.

Booth #328

Combilift – Customized Narrow Aisle Forklifts

Combilift is a specialist narrow aisle forklift manufacturer producing a wide range of customized handling solutions, all of which are designed for the safe, space saving, and very productive handling of long and awkward loads. The forklift is essentially three machines in one: sideloader, counterbalance forklift, and narrow aisle truck. Its robust design and super elastic tires enable it to work both inside and out, on semi-rough terrain and in all weather conditions. Capacities range from 3,200 lbs to 180,000 lbs with a variety of attachments to cater to individual customer requirements. The Combilift concept is built around the efficient use of space and, with the use of multi-directional and articulated technology, can double the capacity of any warehouse. With diesel, electric, and LPG powered engine options, Combilift adapts to any environment seamlessly. For more information: Combilift. Tel: (877) COMBI-56. email: info@combilift.com. www.combilift.com.

Booth #830

Constellium – Leader in Value-Added Aluminum

Constellium is a global leader in innovative and high value-added aluminum products and solutions dedicated primarily to the automotive, aerospace, and packaging markets. For Constellium, aluminum is more than a metal. It’s part of the solution for tomorrow’s lighter, faster economy. With a global network of 25+ production facilities and state-of-the-art technology centers, their 13,000 employees serve customers where they are. They innovate beyond the material to bring customers complete, sustainable solutions, and endless possibilities. The company showcases specialty solutions with advanced bright and functional surfaces for a variety of applications, including automotive, architecture, cosmetics, and closures. They offer a range of rolled surfaces, including matte and structured. Combined with alloys and technical characteristics, they provide materials adapted to customers’ needs. For more information: Constellium. email: communications@constellium.com. www.constellium.com.

Booth #1012

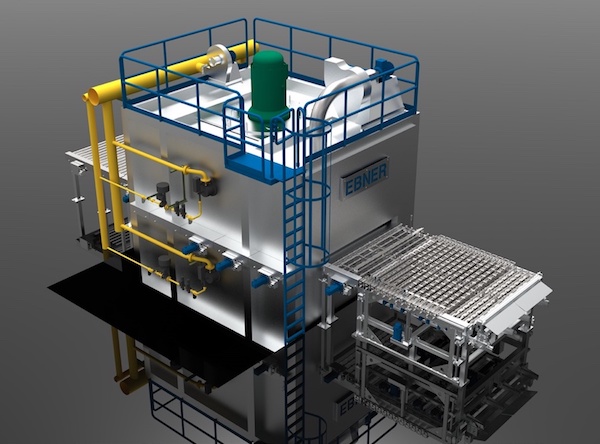

EBNER – Quick and Precise Heat Treating

EBNER introduces HOTFORM®, another technology milestone for heat treating aluminum, especially for demanding automotive and aerospace end user applications. This furnace with HICON®vection feeds aluminum blanks to maximize press production rates by heating quickly and precisely, without risk of overheating and without damage to the surface. A robot places a blank set on entry rollers to move through the furnace. After reaching the required, uniform temperature, the blank set quickly moves to exit rollers, so a robot can pick and place it directly into the press, for simultaneous forming and cooling. Furnace nozzles direct heat on blanks up to 2×3 m (6 ft 6 inches x 9 ft 10 inches) in a footprint of only 35-50 sq m (370-540 sq ft). The patented furnace is CQI9 certification-ready with a proven low, easy maintenance design and is available with combustion or electric heating. For more information: EBNER. Tel: (330) 335-1893. email: sales@ebner.cc. www.ebner.cc.

Booth #820

Emmebi – Profile Finishing, Handling, Packaging

Emmebi supplies profile finishing, handling, and packaging systems for extrusion, anodizing, and painting plants. All of their machinery represents the advanced evolutionary stage of original Emmebi prototypes, constantly perfected and custom-made to fit any production environment, thus meeting the functional requirements of their customers. Thoroughly Italian, Emmebi is able to integrate their machinery with various automation systems while optimizing available space and logistics. The company works side by side with clientele through the design, manufacture, and installation process. In the design stage, they provide 3D layouts in order to fine-tune the equipment and adapt it for installation. In the after sales phase, they equip each piece of machinery with a tele-assistance system to monitor progress at any moment and can even intervene remotely. For more information: Emmebi. Tel: (39) 432 675936. email: elena.mauro@emmebi.net. www.emmebi.net.

Booth #437

GES-AGM – Carbon and Graphite Solutions

For over 50 years, GES-AGM has committed to manufacturing the most effective and innovative solutions in carbon and graphite to their customers. They look forward to the challenge of solving customers’ requirements of the present and future. GES-AGM showcases its aluminum and non-ferrous metals, which include a product line of calcium silicate parts, graphite degas units (LoOx™), graphite sidewall blocks, graphite powders, graphite casting rings, and other machined graphite parts. The company has a group of experts in the field of servicing graphite electrodes. All of their technicians are trained engineers that have worked with furnaces or graphite manufacturers in the past. They have a vast knowledge of EAF, ladle, and foundry applications throughout the Americas. The company strongly believes in the values of an entrepreneurial spirit, having a collaborative team, being disruptive in the industry, and always transparent with their customers. For more information: GES AGM. Tel: (800) 842-8805. email: customersupport@ges-agm.com. https://ges-agm.com.

Booth #1102

Gillespie & Powers Inc. – Scrap Decoaters

For over 80 years Gillespie & Powers (G&P) has been providing high temperature system applications. Their staff is capable of handling design, engineering, and installation. Their teams can provide everything from a minor refractory repair to a complete turnkey project. The company provides repair, replacement or modification of equipment, including: single chamber/multi-chamber furnaces, scrap de-coating systems, tilting rotary melting furnaces, scrap charging machines, launder systems, casting/holding furnaces, homogenizing ovens, coolers, and sow pre-heaters repair and alterations. When designing a furnace, G&P carefully calculates forces that will be generated by the heating of its two distinctly different refractory systems, and provides for these forces with the addition of internal expansion and structural steel members placed in a systematic manner. Their unique patented supplemental equipment and patented processes help to increase production and decrease energy and maintenance costs. For more information: Gillespie & Powers, Inc. Tel: (314) 423-9460. email: imarsh@gillespiepowers.com. www.gillespiepowers.com.

Booth #422

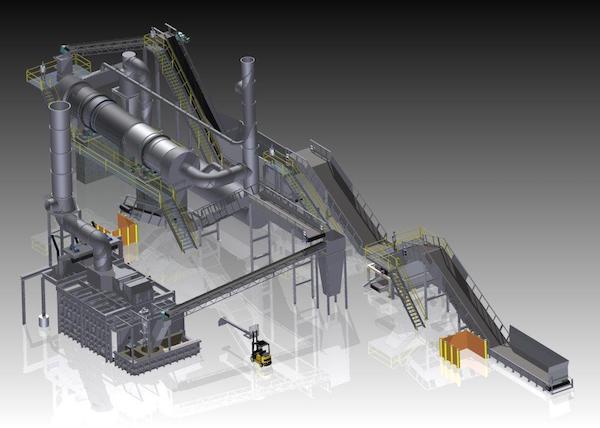

GNA alutech – Casthouse Process Innovations

GNA alutech inc., an Ebner® group member, specializes in the design and supply of casthouse equipment, technologies, technical services, and operation strategies for the global aluminum industries. From scrap yard layout through all major process steps to reach the shipping door, GNA will assist you with raw material segregation, metal flow, and process management. Furnace charging, melting and holding furnaces, bath skimming and alloying, metal treatment, filtration, and casting lines can all be integrated into an autonomous operation. Their casting capabilities include technologies for slab, extrusion logs, and foundry ingot. Whether melting prime metal, clean or contaminated scrap, GNA can help improve metal quality and increase yield while increasing energy efficiency, and reducing melt losses, emissions, and operating costs. Their heat treatment capabilities cover aging, homogenizing, annealing, and more using fully integrated and automated production lines. For more information: GNA alutech inc. Tel: (514) 956-1776. email: info@gna.ca. www.gna.ca.

Booth #402

Granco Clark – Automated Heating & Handling

Granco Clark of Belding, MI, is a full-service company and global leader in the aluminum extrusion industry, manufacturing all required equipment to heat, cool, pull, stretch, cut, stack, age, and store extrusion profiles. The company continually develops groundbreaking technology to improve its products—ranging from billet/log furnaces, hot log saws, and FusionBond® billet welding technology to age ovens and stacking equipment. The company was first to introduce an integrated control system technology that has since developed into SCSExtrude—a next-generation technology for optimizing automated extrusion line performance. Their automated equipment is CAD designed, fully assembled, and shop tested to meet specific requirements of each customer’s extrusion process, delivering exceptional efficiency, productivity, and longevity. The company backs up their commitment to quality with service over the entire lifecycle of the equipment, including remote diagnostics support and a 24-hour parts hotline. For more information: Granco Clark, Inc. Tel: (616) 794-2600. email: gcinfo@grancoclark.com. www.grancoclark.com.

Booth #500

Hazelett – 100 Years of Continuous Casting

For nearly 100 years, Hazelett has been a pioneer and world leader in continuous casting. The inventor of the twin-belt casting machine, they are the exclusive supplier of the Hazelett® continuous casting process. The company is committed to increasing the productivity and energy efficiency of the world’s metals industry through innovation in continuous casting. They employ leading experts in process engineering, mechanical and electrical design, automation, and metallurgy to ensure that their casters deliver the highest possible production rates and product quality at the lowest possible cost. The Hazelett process produces the world’s lowest-cost rolled aluminum sheet with the smallest carbon footprint. A Hazelett Model AS2000 twin-belt casting machine is capable of producing 2,000 mm wide aluminum strip at approximately 50 tonnes per hour. Alloy capabilities include 1, 3, 5, 6, and 8 series. For more information: Hazelett Corporation. Tel: (802) 863-6376. email: hazelett@hazelett.com. www.hazelett.com.

Booth #401

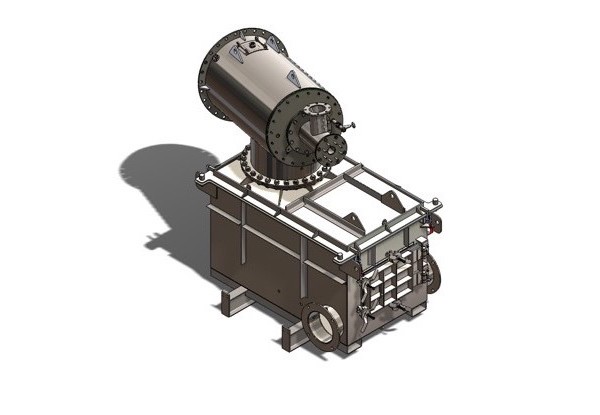

Inductotherm Corp. – Advanced Furnaces

Inductotherm Corp. headquartered in Rancocas, NJ, manufactures advanced and innovative furnaces for aluminum and other metals industries. The company produces both coreless and channel metal holding furnaces—each providing their own unique advantages. Coreless furnaces provide maximum alloy flexibility with significantly lower capital and installation costs, while channel furnaces are capable of holding large quantities of metal at low holding power levels for extended periods of time for economical high volume production. Inductotherm is now offering a hybrid furnace, which draws on advantages from both designs for aluminum melting, holding, and casting operations. This new furnace is designed to enable operational flexibility, allow for inert gas cover, and offer quick alloy changes—making it attractive for a variety of aluminum casting applications. For more information: Inductotherm Corp. Tel: 609-267-9000. email: sales@inductotherm.com. www.inductotherm.com.

Booth #932

InfoSight – Industrial Marking Machines

InfoSight is a global leader for identification and tracking products through extreme industrial environments. They help customers save time and money by accurately identifying metal products from their creation through end use—one time, with a tag that lasts a lifetime. InfoSight is a manufacturer of industrial marking machines, metal tags, metal tag printers, barcode readers, and custom machinery for manual and automatic identification and traceability applications worldwide. Their products are designed to withstand industrial environments. Their metal tags and identification information survive high temperatures, chemical processes, abrasion, and environmental exposure. AlumaTag™ is a high temperature aluminum barcode tag designed to be affixed to molten aluminum ingot and log, surviving homogenizing furnaces up to 1,000°F, ensuring positive product identification throughout processing. Additionally, InfoSight designs and manufactures equipment for automated tagging or direct marking on metal products. For more information: InfoSight. Tel: (740) 642-3600. email: sales@infosight.com. www.infosight.com.

Booth #834

Mega Persada Group – Aluminum Extrusion

Established in Indonesia in the year 2001, Mega Persada Group started as a distribution and retail company and has since expanded into manufacturing. Currently, they produce and ship more than 36,000 tons of aluminum products annually. The company’s melting furnaces are able to produce 6000 series billet grade alloy, such as 6005, 6061, and 6063; with billet sizes ranging from 3.5-6 inches in diameter. Mega Persada has 18 extrusion lines with presses ranging from 690 to 1,600 UST, accommodating custom designs to meet customer needs. In particular, their extrusion lines are equipped with triple pullers to ensure faster and efficient production. With a state-of-the-art vertical powder coating line and anodizing plant the company provides the finishing touch to the final product. For more information: Mega Persada Group. Tel: (62) 812 2888 8311. email: exportsales@megapersadagroup.com. www.megapersadagroup.com.

Booth #1133

MINO SpA – Hot and Cold Rolling Mills

The MINO Group designs and builds complete rolling mill plants. Since 1840, the company has provided innovation and technology for the world’s metals industry. Its latest portfolio includes hot, cold, and foil rolling mills for aluminum industries worldwide. MINO prides itself on an “under one roof” philosophy and approach to its products. With mechanical, electrical, and process control divisions, they are capable of complete design and supply of the latest state-of-the-art rolling mill solutions. The company’s unique selling proposition is to take ownership from the mill design through to final commissioning. With a complete suite of proven designs, they provide the end user with a bespoke but robust and proven solution to meet their desired production needs. Contact the company for details on their latest references, orders, services, equipment, and technology. For more information: MINO SpA. Tel: (39) 0131 363636. email: sales@mino.it www.mino.it.

Booth #213

Otto Junker – Continuous Innovation in Al

Established in 1924, Otto Junker GmbH draws on more than 90 years of experience and continuous product development. The company is represented by subsidiaries, service agencies, and sales offices worldwide. Otto Junker’s product range embraces melting, casting, heating, and heat treating equipment for the aluminum and copper industries as well as melting and casting equipment for iron and steel foundries. The company’s “thermo processing” business unit designs, manufactures, and installs equipment for customers in the aluminum and copper industries, including rolling mills, extrusion plants, casting shops, forging plants, and aluminum casthouses. Preheat and homogenizing furnaces, annealing, heat treatment and aging furnaces, degreasing, annealing and pickling lines, hot dip tinning line, and as-fired melting and pouring furnaces for aluminum casthouses are all products purchasable from Otto Junker. For more information: Otto Junker GmbH. Tel: (49) 2473 601-578. email: vera.engels@otto-junker.com. www.otto-junker.com.

Booth #1013

Plibrico Company – Refractory Experts

For more than a century, the Plibrico Company has been pioneering the research and development of monolithic refractory technology used in the aluminum industry. Organizations trust Plibrico to develop innovative and reliable refractory solutions that consistently increase efficiency, improve production uptime, and safely boost the performance of their thermal processing operations and equipment. Refractory, engineering, and construction expertise allows the company to fully service a concept to completion. Committed to growth and focused on providing value, their knowledge and experience supporting thousands of refractory needs provide customers with a seasoned partner that can support reliable refractory solutions throughout any facility. Plibrico has built a business based on trust, knowledge, and experience. These qualities create close lasting relationships to deliver superior refractory heat control solutions. For more information: Plibrico Company. Tel: (312) 337-9000. email: contact@plibrico.com. www.plibrico.com.

Booth #1033

Precimeter – Controlled Casting Process

Precimeter is a premium supplier of molten metal control sensors, offering more than 20 years of experience in casting automation specializing in solutions for metal level, transfer, and flow control. The company’s products include metal level sensors, flow actuators, pumps and control systems that will improve casting quality, provide extremely accurate measuring, give repetitive cast results, improve worker safety and reduce scrap rate. Precimeter provides solutions for all metals and alloys. Their customers include OEM metal casting machine manufacturers, system integrators, and metal casting end users. R&D and engineering teams at Precimeter also help with system design and commissioning work. Customers to the metal processing industry are demanding new levels of quality that can only be achieved with the precision and flexibility offered by a Precimeter controlled casting process. For more information: Precimeter Inc. Tel: (480) 829-1923. email: sales@precimeter.com. www.precimeter.com.

Booth #336

Primetals Technologies – Cutting Edge Aluminum Rolling

Primetals Technologies is a single source supplier of cutting-edge technologies for aluminum rolling mills. With process technology, mechanical engineering, automation, and electrical engineering—the company offers customized solutions to fit customer’s needs. The company boasts the most powerful roll drives for higher throughput and state-of-the-art mechanical and hydraulic solutions to optimize performance and operational efficiency. Online process models and neural networks enable more accurate production than ever before. Proven automation solutions maximize consistency, reliability, and security. Primetals Technologies will participate in the ALUMINUM USA technical conference with a presentation entitled “Achieving Strip-Edge Dryness for Maximum Yield, Product Quality and Cost Savings.” The presentation will be held Thursday, Sept. 12 at 10:15 a.m. in Learning Theatre 2. For more information: Primetals Technologies. Tel: (724) 514-8500. email:

contact@primetals.com. www.primetals.com.

Booth #510

SECO/WARWICK – Custom-Engineered Furnaces

SECO/WARWICK manufactures complete custom-engineered furnaces and systems for the aluminum industry, from primary and secondary production applications to downstream processes for finished and semi-finished products. Industries include aerospace, automotive, architectural, chemical processing, marine, defense, telecommunications, and electronics. The company offers industrial furnaces equipped with advanced technology to reduce cycle times, conserve energy and improve cooling rates. Their basic product groups include: coil/foil annealing, solution heat treatment and aging, homogenizing, reheat, and melting/holding furnaces. Each system has control and material handling packages designed to provide optimum performance in each unique production environment. The VORTEX® Jet Flow heating technology provides efficient aluminum coil annealing by reducing overall cycle time of furnaces by up to 30%. The patented vortex nozzle technology also provides unparalleled temperature uniformity, eliminates local overheating, and minimizes costs and utility consumption. For more information: SECO/WARWICK Corp. Tel: (814) 332 8400. email: keith.boeckenhauer@secowarwick.com. www.secowarwick.com.

Booth #403

Sistem Teknik – Industrial Furnaces Worldwide

Sistem Teknik has specialized in design and production of industrial furnaces for non-ferrous metals and composite industries all over the world since 1979. As a global player in the industrial furnaces business, the company is now focusing on digital transformation aspects of casthouses in the light of 40 years of experience and 1,500 operating furnaces all around the world. Equipped with state-of-the-art automation and technological architecture helps its partners be more efficient and cost oriented, enabling quality based production. Product quality, reliability, and customer satisfaction are key reasons they offer a 24/7 flexible hybrid service. Their after-sales services department works in accordance with your request. Ready to be your solution partner with innovative designs, effective engineering knowledge, and continuous observation capability, they provide customers with advanced technology for heat treatment facilities. For more information: Sistem Teknik. Tel: (90) 262 658 22 25. email: info@sistemteknik.com. www.sistemteknik.com.

Booth #534

SMS Technical Services – Extrusion Press Lines

SMS group provides the world’s most advanced extrusion lines—from press feeding to finish saw. With over 1,400 installations worldwide, the company’s extrusion presses possess industry leading technology, including: laminated tie rods, which provide the most rigid press frame on the market, and linear guided alignment systems that provide the accuracy and high tolerances demanded in today’s automotive and aerospace markets. SMS created the first HybrEx® extrusion press, which uses a servo drive system reducing energy consumption, cycle times, hydraulic systems requirements, and maintenance. SMS Technical Service, headquartered in Pittsburgh, PA, is staffed with over 600 skilled employees spread over 17 locations throughout the U.S., dedicated to providing customers with unmatched after-sales service and support. From spare parts, emergency service, installations, and repairs to modernizations and upgrades, SMS is the only extrusion press manufacturer to offer such domestic support. For more information: SMS Technical Services. Tel: (724) 553-3427. email: info.technicalservices@sms-group.com. www.sms-technicalservices.com.

Booth #612

Thorpe Technologies – Aluminum Heat Processing

Thorpe Technologies Inc. is a designer and constructor of complete, custom engineered lines for heat processing equipment, as well as engineering, parts, and services for the aluminum, forging, heat treating, and incineration industries. They supply melters, holders, homogenizers, auxiliary equipment, delacquering, and chip drying systems to the nonferrous industry. Thorpe offers services and expertise in the following areas: turnkey equipment design and installations, system mechanical installation, general maintenance, repair and shutdown work, engineering consulting, process review and optimization, combustion/controls review, new project feasibility studies, and budgeting. Thorpe Technologies’ equipment is in successful operation at leading companies around the world, with installations in the U.S., Brazil, Canada, Egypt, Iceland, India, Japan, Mexico, Russia, and Thailand. The company’s work force has a combined 250 years of experience. For more information: Thorpe Technologies Inc. Tel: (562) 903-8230. email: sales@thorpetech.com. www.thorpetech.com.

Booth #313

TOMRA – Sensor-Based Sorting Solutions

TOMRA introduces X-TRACT X6 Fines for high-purity sorting of mixed non-ferrous metal fractions, including aluminum. Sensor and software enhancements allow the sensor-based sorter to detect and sort metals nearly half the size of current small fractions material for sensor-based sorting equipment. X-TRACT X6 Fines combines x-ray transmission and Duoline® technology, which use two independent devices with different spectral sensitivities, for high-precision sorting of a range of secondary resources. TOMRA’s innovative dual processing technology distinguishes differences between overlapping objects on the sorting line, a significant advantage when lines are running higher throughputs. Through the company’s exclusive high-speed x-ray processing technology, exceptional resolution levels make it possible to identify even the smallest fractions in high-throughput applications. X-TRACT X6 Fines pushes purity levels as high as 98-99%, while delivering fewer product losses. For more information: TOMRA Sorting Recycling. Tel: (916) 388-3987.email: eric.thurston@tomra.com. www.tomra.com/recycling.

Booth #806

TSI | Chemlogix – The LIBS Experts

TSI manufactures a complete line of LIBS metal analysis tools for the aluminum market: desktop, handheld, and online measurements with ChemReveal™, ChemLite™, and ChemLine™ tools. ChemLite handheld metal analyzers are the fastest, safest, and most accurate LIBS guns on the market today: no x-ray radiation emissions; no consumable Argon tanks; and they operate with a class 1M laser. The ChemLine is an industrial LIBS online sensor, that is integrated into an automatic scrap sorting system. The TSI LIBS sensor has successfully been installed in systems all around the world, and is installed in the world’s first LIBS automatic scrap sorting system in production that sorts aluminum alloys at greater than 5 tons per hour. For more information: TSI Inc. Tel: (651) 490-2860. email: todd.hardwick@tsi.com. www.tsi.com.

Booth #700

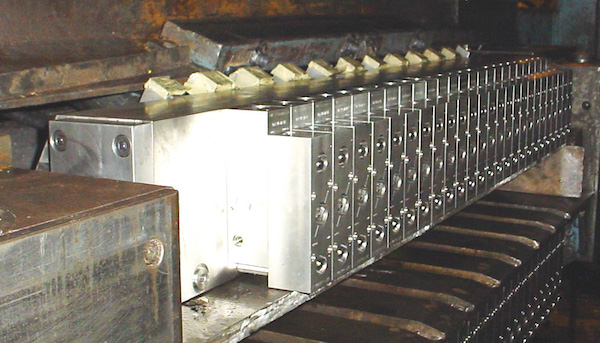

United States Controls – Rolling Spray Systems

With more than 250 installations worldwide, United States Controls (USC) is the leader in the design and manufacture of selective spray bar cooling systems for rolling mills. Innovative modular design and self-cleaning valve technology offer mill operators improved performance and reliability, making USC the preferred choice for both new and retrofit installations around the world.

Their technology includes current limiting electronics for longer life, reduced energy consumption, and superior protection for electrical connections allowing customers to upgrade their water soluble valve systems. The USC 38LPM spray valve complements their industry leading 77LPM valve platform featuring narrow edge control, precise control on 26 mm centers: on/off and pulse delivery; one, two, and three row designs; and a low maintenance design. For more information: US Controls. Tel: (330) 758-1147. email: customerservice@unitedstatescontrols.com. www.unitedstatescontrols.com.

Booth #426

Wagstaff – Scalable Casting Automation

Wagstaff helps aluminum producers achieve high-performance ingot and billet casting with technologies fine tuned to the latest product trends, which require greater metallurgical flexibility and complexity. The company assists producers in reaching peak production through cutting edge controls for maximum safety, productivity, and versatility in conjunction with leading DC casting technologies and best-in-class service. AutoCast 2020™, the all-new scalable automation package compliments Wagstaff ingot and billet casting systems through accessible flexible functionality in a new user interface. The full-featured control system for the casthouse has tools for: recipe management, process deviation analysis, equipment operation analysis, and peak performance. The system offers increased accessibility through multiple clients, text messaging notifications for alarms and casting events, and true server redundancy for the greatest level of system availability. For more information: Wagstaff. Tel: (509) 891-8058. email: info@wagstaff.com. www.wagstaff.com.

Booth #518

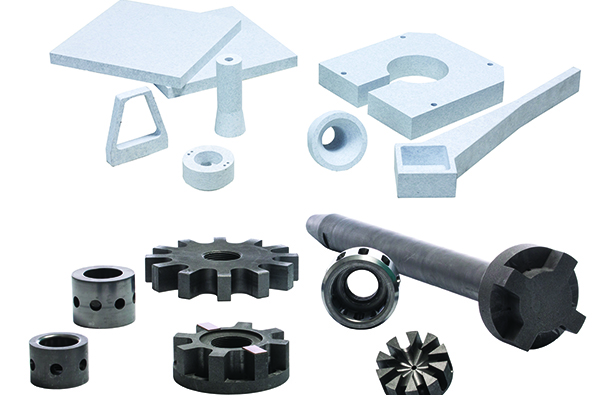

ZIRCAR Ceramics – Casthouse Consumables

ZIRCAR Ceramics, Inc. manufactures engineered casthouse consumables that help continuous aluminum sheet casters make their metal better. Products include castertips and nozzles, vacuum formed boards shapes, and ceramic fiber insulated heaters. Other engineered consumables include ceramic fiber papers, textiles, and machined graphite shafts and rotors. Coating products include boron nitride, colloidal graphite, and other refractory coatings. The company’s modern, fully equipped machine shop cost-effectively produces custom-machined calcium silicate, microporous insulation, soluble fiber insulation, and other refractory products that all work toward improving a casting facility’s bottom line. For more information: ZIRCAR Ceramics, Inc. Tel: (845) 651-6600. email: sales@zircarceramics.com. www.zircarceramics.com.

Booth #225

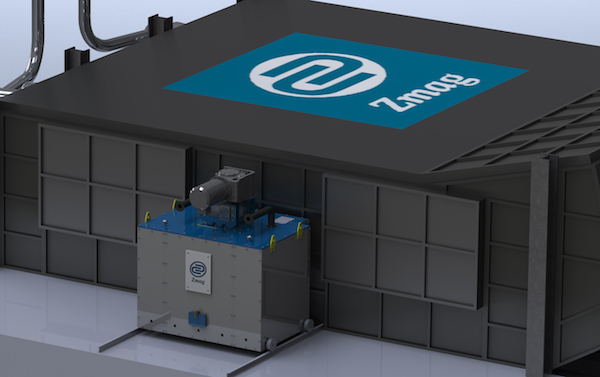

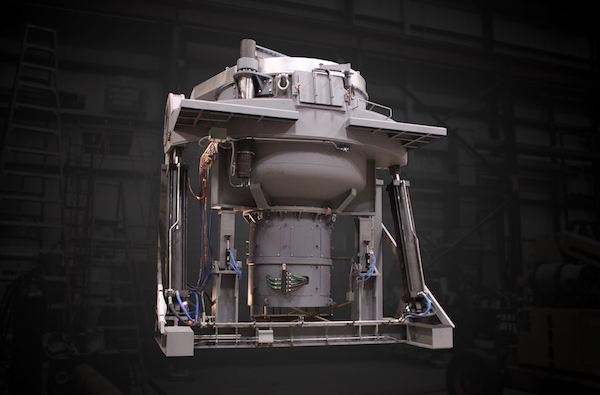

Zmag America – Permanent Magnet Stirring

Zmag is a pioneer in the field of magnet engineering. Leveraging this expertise, the company has introduced technologies for the smelting and remelting industries. MagStir™ is the world’s first and only stirrer for molten aluminum that utilizes the zPMC™ (Zmag Permanent Magnetic Circuit). MagStir has been successfully adapted for various types of furnaces, up to 420,000 lbs, and is contactless with no component touching molten aluminum. This leads to low operating costs, providing companies operational safety, reduced downtime, and faster furnace turnaround time. Compared to manual stirring, furnace doors can be kept closed, and molten aluminum is not oxidized. Compared to mechanical pumps, MagStir has no repair or downtime issues from direct contact with molten aluminum. Compared to electromagnetic stirrers (EMS) and pumps, MagStir requires only a few kW per hour of electricity, as MagStir is powered by zPMC and does not need to generate magnetic fields. For more information: Zmag America, Ltd. Tel: (971) 271-7084. email: info@zmag.net. www.zmag.net.

Booth #327