Experienced welders will tell you that, compared to welding steel, welding aluminum and its alloys is not difficult but different. Steel, being one of the common construction materials, most welders and myself included started by learning how to weld steel. As aluminum has especially gained market share in transportation, welding aluminum is challenged in various […]

Joseph C. Benedyk

-

-

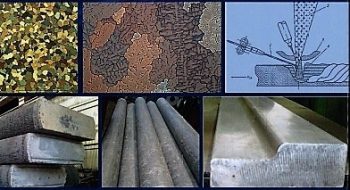

Editor’s Note: Various aspects of aluminum casthouse technology appear in almost every issue of Light Metal Age, no doubt because it is the first step and an important link in the wrought aluminum processing chain required for subsequent downstream processing and production of quality product. With no exception, the international patent survey presented here focuses […]

-

Editor’s Note: Unlike aluminum’s sustainable advantage in recycling, primary aluminum production (which uses carbon anodes in the Hall-Héroult process), continues to be energy intensive and a greenhouse gas (GHG) producer. Ignoring the effect of CO2 generation in the coal/hydrocarbon power equation, the use of carbonaceous anodes in the smelting process generates GHGs as carbon is […]

-

Posted in:

Applications of Aluminum Extrusions in Transportation, B&C, Industrial, and Consumer Products

Compiled and edited by Joseph C. Benedyk. U.S. Patents US9905214 — EXTRUDED SONAR CHASSIS — Navico Holding AS (Norway) — An aluminum transducer chassis prepared by a process having the following steps: performing an extrusion using a die and an aluminum billet to create an extruded chassis, wherein the die has a cross sectional shape […]

-

The Metallurgy of Anodizing Aluminum: Connecting Science to Practice Author: Jude Mary Runge Publisher: Springer International Publishing AG (2018) Review by Joseph C. Benedyk, Editor As a recognized international expert on nonferrous metallurgy, Jude Mary Runge, Ph.D., has devoted her career of some 30 years to surface science and most particularly to the metallurgy of […]

-

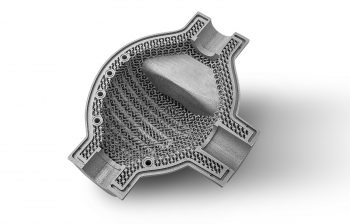

By Joseph C. Benedyk, Editor. Introduction For decades, additive manufacturing (AM), also known as 3D printing (3DP), has grown and proliferated worldwide into a multibillion dollar industry encompassing many different technologies and types of materials. AM methods embody a group of emerging technologies that create a functional 3D object from any one of a variety […]

-

Compiled and edited by Joseph C. Benedyk. U.S. Patents US9822457 — METHOD AND APPARATUS FOR LINING THE CATHODE OF THE ELECTROLYTIC CELL — United Company RUSAL Engineering and Technology Centre LLC (Russia) — The invention relates to method and apparatus for lining the cathode of the electrolytic cell for primary aluminum production. The method comprises […]

-

Light Metal Age (LMA) debuted a new short documentary that highlights the history of the magazine’s 75 years of continuous publication, which is intimately tied to the history of the aluminum industry. This video was presented during a celebration in honor of LMA’s 75th anniversary, held in October during the recent ALUMINUM USA trade show […]

-

Aluminum-Lithium Alloys: Process Metallurgy, Physical Metallurgy, and Welding Author: Olga Grushko, Boris Ovsyannikov, and Viktor Ovchinnikov Publisher: CRC Press, Taylor & Francis Group (©2017) Reviewed by Joseph C. Benedyk, Editor Written by three Russian metallurgists, with a trove of experience in Al-Li alloy development and processing spanning many decades, Aluminum-Lithium Alloys (part of the Advances […]