Editor’s Note: As many Light Metal Age articles and items have noted, the friction stir welding (FSW) process, which joins aluminum components in the solid state, has been applied throughout the world in various industries that produce products for transportation, B&C, and industrial and consumer sectors. The November 2020 selection of patents covered a wide […]

joining technology

-

-

Editor’s Note: As many articles have appeared in Light Metal Age (both in the magazine and online) describing and following the friction stir welding (FSW) process, especially its application in joining aluminum alloys in various forms and tempers, readers should be familiar with its advantages. In the FSW process, aluminum components are joined in the solid […]

-

FABTECH 2019, North America’s largest metal forming, fabricating, welding, and finishing, was held on November 11-14 in Chicago, Illinois. The event achieved record attendance, with a total of 48,278 attendees from 95 countries over the course of four days. During FABTECH, Light Metal Age spoke with Prof. Xiaochun Li, founder of MetaLi, about the company’s groundbreaking […]

-

Vehicle manufacturers are exploring the use of aluminum, high-strength steel, magnesium, carbon-fiber composites, and other lightweight materials to reduce vehicle mass and improve fuel economy. This approach requires new adhesive chemistries that will mitigate corrosion and thermal expansion issues associated with joining dissimilar materials. PPG was selected for a U.S. Department of Energy (DOE) partnership, […]

-

Showa Denko in Japan developed an innovative technology to directly bond aluminum alloys and polycarbonate resin (a commodity amorphous engineering plastic) without using an adhesive. One possible application for this technology is the housings for smart phones, which require a high level of durability. It is common to join aluminum alloys and polycarbonate resin through […]

-

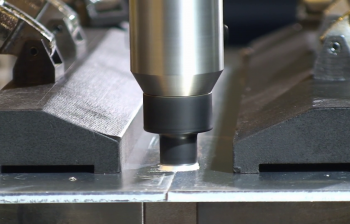

The Materials Testing Institute at the University of Stuttgart has developed a process, based on friction stir welding (FSW), for the high-strength welding of aluminum and steel plates. The plates can have different thicknesses and the seam is so stable that the hybrid plates can even be deep drawn. This enables lightweight yet sturdy hybrid […]

-

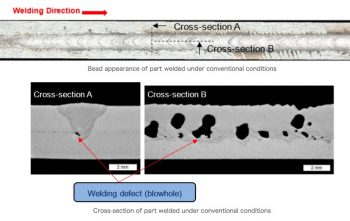

The demand for lighter automobile bodies in order to provide improved fuel efficiency and reduced CO2emissions has increased in recent years, and various types of aluminum alloys are now being used for automobile parts in an increasingly broad range of ways. Furukawa Electric Co., Ltd. in Japan developed a new fiber laser welding technology said to address […]

-

Posted in:

GALM Detroit 2019: Lightweighting and Advanced Material Solutions for Next Generation EVs

The 8th Global Automotive Lightweight Materials Summit Detroit (GALM 2019) is the world’s leading automotive lightweighting conference providing design solutions, modeling, material strategies, joining processes, advanced structures & manufacturing innovation insights. The new agenda reflects major automotive industry investment into a new generation of EVs and autonomous vehicles by established and start-up OEMs. The rapid […]

-

US9951971 — SOLAR MIRROR ARRAY SYSTEM, METHODS AND APPARATUSES THERETO — Werner Extrusion Solutions LLC (USA) — An apparatus for transferring force to a frame of a solar mirror array. The frame has at least one structural element. The apparatus includes a torque plate. The apparatus includes at least one node attached to and in […]