The demand for lighter automobile bodies in order to provide improved fuel efficiency and reduced CO2emissions has increased in recent years, and various types of aluminum alloys are now being used for automobile parts in an increasingly broad range of ways. Furukawa Electric Co., Ltd. in Japan developed a new fiber laser welding technology said to address welding defects common in aluminum alloys used for automobiles. This technology will enable the company to contribute substantially to the growth in automotive lightweighting.

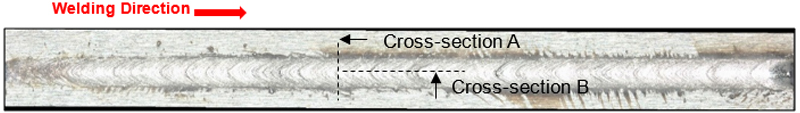

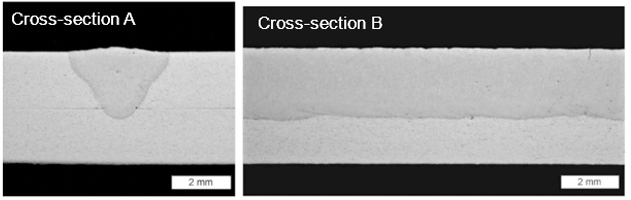

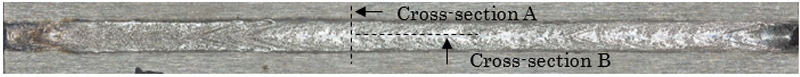

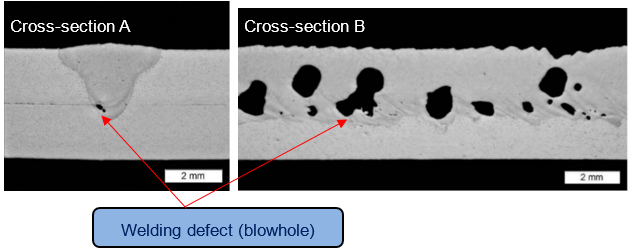

Welding is a vitally necessary technology in the automobile assembly process. However, aluminum welding can have issues. Although the appearance of the welded aluminum part might seem to offer a good weld joint at first glance, bead breakage and blowhole formation inside welded parts tend to occur easily.

The new welding technology developed by Furukawa addresses these challenges by implementing a fiber laser technology with optimized welding conditions and a novel beam-control method that the company has been developing over a number of years. Tests using the welding method were conducted on a 6000 series aluminum alloy, with the results as follows.

According to Furukawa, the new fiber laser welding welding technology is expected to improve productivity by enabling high-speed, high-quality welding of aluminum in automotive assembly plants. The company believes this will be able to broaden the application of aluminum for automobile panel and body construction materials. “We have been working continuously to improve the welding technology of our fiber laser,” stated the company. “It is now possible to investigate the benefits of implementing this technology at our Application Laboratory in Furukawa Electric’s Chiba Works [in Japan].”