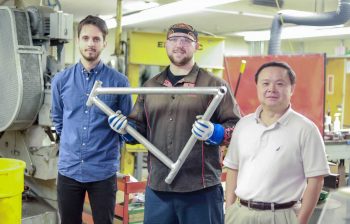

Taber Extrusions, an NMLP group company, installed a new friction stir welding (FSW) line at its Russellville, Arkansas, manufacturing facility for the aerospace, rail, automotive, marine, transportation, and other industries. With this machine, Taber will be able to weld large double sided thick profiles with minimal cycles of the machine, providing greater efficiency and more precise results. […]