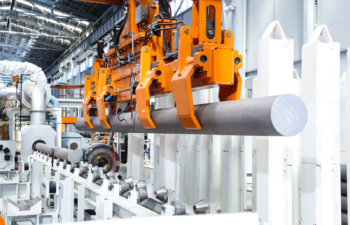

By Andrea Svendsen, Managing Editor. Alexandria Industries completed an investment project at its operations in Alexandria, MN, where the company has expanded its manufacturing space, installed a new 7 inch, 26 MN front-loading extrusion press line with advanced automation capabilities, and added a new front office and entry. The new press line allows the company […]