By Alexandre de la Chevrotière and Laurent Gérin, MAADI Group,

and Martin Hartlieb, Viami International Inc.

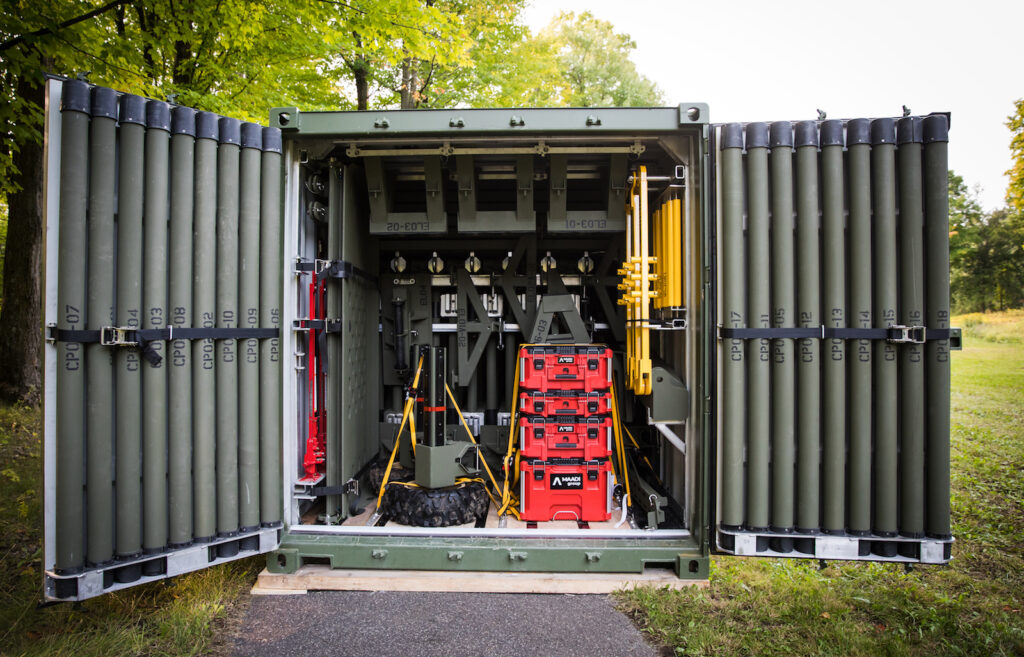

The amount and severity of natural disasters is increasing, and very often existing bridges get destroyed, requiring the construction of a new bridge in order to bring urgently needed material into the affected area or to transport people out of a danger zone and into nearby hospitals. In order to meet this growing need, a new aluminum bridge type was developed that can easily fit into a standard container, one that can either be transported by truck or train (intermodal) or even by helicopter (for fastest response). It was also designed to enable quick assembly on-site without any heavy machinery. The result is the light vehicle tactical bridge (LVTB), also nicknamed “Bridge in a Box,” developed by MAADI Group (Figure 1). It is made primarily from aluminum extrusions and connected by a mix of castings and machined components.

The Value of Aluminum

Due to aluminum’s lower modulus of elasticity (compared to steel), deflections and vibrations often govern structural designs for projects like bridges. Aluminum is resilient and, with its strength and flexibility, it can flex under loads and easily spring back from an impact, which is a big advantage for a bridge that is often moved, set up, and later disassembled again. Another advantage of aluminum, which is important for this application, is that it does not lose ductility (become brittle) in cold temperatures (in contrast with other materials). With the anticipated use of the LVTB across the world in the harshest of climates — from the arctic to the desert — only aluminum can provide the resiliency and safety expected by its users.

For many outdoor structures the greatest value of aluminum is often its durability, as it quickly forms a thin (invisible) protective oxide layer on its surface that gives it outstanding atmospheric corrosion resistance. Therefore, compared to steel, aluminum does not require any protective coatings like painting (unless it is purely for aesthetic reasons), which means that there is never any repainting required during its lifetime (MAADI structures are estimated to last 100 years). Nevertheless, if it is desired, aluminum can easily be surface coated with several common techniques like painting, powder coating, anodizing, or electroplating — giving aluminum structures great aesthetic values.

In the case of the LVTB, the bridge was coated in an army green color per the customer’s requirements (camouflage). However, should the coating be damaged, there would still be no risk of corrosion (unlike steel) and no impact on longevity. Additionally, the inherent corrosion resistance enables the bridge to be stored in its container outdoors, even in harsh environments such as a sea coastline, for extended periods of time without slowly rusting away and causing a bad surprise to the owner.

Last but not least, for a structure (like for anything else), the recyclability of aluminum and its very high scrap value are important factors often overlooked when making an initial investment decision. In the case of this bridge, all elements can be easily disassembled and materials (and even alloys) separated to allow optimum and highest value recycling at the end of its lifetime — which most likely will only be in more than a hundred years.

The LVTB Bridge

Aluminum has many great attributes and advantages that make it attractive for a variety of applications, including road and pedestrian bridges or overpasses.1 One of the most important attributes is its high strength-to-weight ratio. This combination makes it ideal for the construction of an emergency bridge structure, as it provides the high strength and light weight required. This advantage is extremely helpful for the transport, manipulation, and installation of the bridge structure. It also reduces the deadweight of the bridge deck, allowing heavier live loads to go over it. Since the bridge needed to be transportable globally in an intermodal container, it had to be limited to about 20,000 kg (44,000 lbs), including all tools and launching hardware. In order to make it transportable by helicopter, the max weight of the LVTB was actually limited to 12,700 kg (28,000 lbs), the maximum slinging payload for a Boeing H-47 Chinook (American twin-engined, tandem rotor, heavy-lift) helicopter. Every additional kilogram saved would improve its transportability and ease of handling and installation.

The final bridge itself weighs in at only 4,800 kg (10,500 lbs), and, when packed in its container with all accompanying hardware, the total weight was measured at 9,090 kg (20,000 lbs), of which almost a third was the weight of the container itself. A comparable steel construction would have weighed far more and, with the combined weight of the tools and launching equipment, would certainly have exceeded the capacity of even a Chinook helicopter.

Beyond the weight for transportation, one of the essential design criteria was that a small crew be able to assemble the bridge without any machinery. Most mobile military bridges make use of large vehicles to install them, as they are simply too heavy to be reasonably handled by their crew. By minimizing the weight, the LVTB can in fact be launched entirely by a crew of ten from only one side of the obstacle (Figure 2).

At the same time, the bridge needed to be strong enough to support both the weight of a light vehicle (1,500 kg) and people walking over it (about 21,000 kg or 230 people). This was achieved by designing and optimizing the main members using hollow custom extrusions that both minimized weight and maximized the strength and stiffness of the structure (Figure 3). Considering the intended use of the bridge in emergency situations, the serviceability criteria were relaxed, which allowed for further reduction of weight.

Designing with Extrusions

The LVTB is built almost entirely of custom aluminum extrusions, which were critical in the development of the bridge. Through the use of sophisticated software analyses, extruded profiles were designed that met the exact needs of this product. The profiles are made of 6005A-T61 and 6061-T6 alloys, which were chosen for their superior strength, as well as the necessary extrudability, with a yield strength of 240 MPa and ultimate tensile strength of 260 MPa. The profiles are connected by castings made of A357-T61 aluminum.

One of the main structural pieces is a principal truss that supports the bridge, also known as a chord. While it may look like a simple square profile from the outside, the top chord’s interior reveals the magic of aluminum extrusions (Figure 4). The chord undergoes significant compression and can be subject to buckling. Therefore, it was optimized to meet these demands, while minimizing weight. To eliminate local buckling, longitudinal stiffeners were added exactly where they would have the most benefit and the wall thicknesses were varied as a function of their length. Overall, the buckling of the top chord was prevented and controlled by adjusting the width of the cross-section.

One of the challenges of the bridge design was that the entire 80 ft (23.4 m) bridge needed to fit inside a single standard intermodal container, which is generally 20 ft (6 m) long. This meant that the components of the bridge had to be limited to the 20 ft length of the container, resulting in a greater number of joints during assembly. This can be a cause of concern, because often joints are considered to be weak points in structural design. Therefore, in order to achieve the desired strength across the entire length of the bridge, sophisticated connections were implemented, which are only possible using aluminum extrusions. This can be seen in the top chord, in which the weld-free joints are able to provide continuity without the risk of buckling.

Another example of interlocking joints is seen in the decking of the bridge, which also greatly benefited from the use of aluminum extrusions. Since the bridge would be airlifted after being constructed, every component needed to be solidly secured in place. With almost 80 deck planks, securing each one to the main trusses could be quite time-consuming — were it not for aluminum extrusions. A system was designed that allowed the decking and support rails to quickly and securely interlock (Figure 5). Inside the rail, a plate with hollow dowels is designed to move and connect with the grooves on the planks. With this integrated system, all 80 planks can be “locked-in” in less than a minute.

It’s important to note that there are no welds on any of the major principal members of the bridge, which allows for quick, flexible joining without the use of complicated equipment. In addition, this supports the bridge’s structural integrity. Since aluminum’s mechanical properties are significantly reduced in the heat-affected zone near a weld, a weld-free bridge enables a much higher strength-to-weight ratio.2 This also reduces fatigue, because welds can create high residual stresses and often create a notching effect that make them a common location for cracks to grow.

By combining the lightweight aluminum structure with duplex 2205 stainless steel fasteners, both high strength and ease of assembly were achieved. The interlocking mechanisms provided by extrusions also reduce the amount of pieces needed to securely assemble the bridge. To fully assemble the LVTB over its 80 ft (23.4 m) span, a total of only 28 bolts are required (Figure 6). That means there are fewer components to lose or break. Most importantly, this provides a much faster assembly time, which may be crucial in life-threatening scenarios.

In addition to being designed to join together in the construction of the bridge, all of the components were optimized to fit tightly into the container in the most efficient way possible. In many cases, the components have less than 1 mm of clearance between them.

Conclusion

With the new concept of the Bridge in a Box, MAADI Group has been able to develop a flexible, lightweight bridge design that can be easily and quickly transported (and stored) in a container and assembled by a few people without any heavy machinery. It is the perfect answer to any needs for an emergency bridge after a natural disaster, or any immediate need for a bridge to be installed in minimal time. It makes full use of all the advantages that aluminum — especially extruded forms — has to offer.

References

- de la Chevrotiére, Alex and Martin Hartlieb, “Aluminum’s Advantages for Bridges,” Canadian Consulting Engineer Magazine, December 2020, pp. 15-17.

- “Deploy-Ready Aluminum Bridge Decking – Addressing the Challenges of Aging Infrastructure,” Light Metal Age, August 2019, pp. 30-33.

Editor’s Note: This article first appeared in the April 2021 issue of Light Metal Age. To receive the current issue, please subscribe.