Posted in:

October 2023

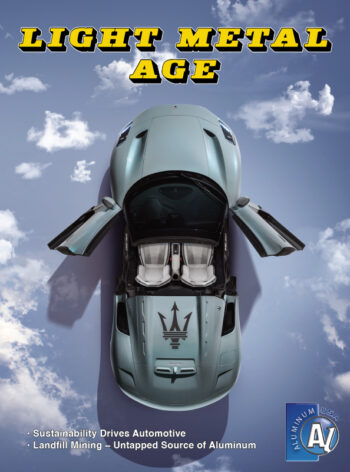

Cover The Maserati MC20 Cielo convertible supercar features structural aluminum components as part of its mixed-material strategy to improve performance and lighten weight. The ICE version has the most aluminum in its class segment. The MC20 Cielo with 621 horsepower engine can propel the car from zero to 60 mph in 2.9 seconds, seemingly lifting […]