Novelis and thyssenkrupp Materials Services are planning to set new standards for end-of-vehicle-life recycling by developing a digital hub called Automotive Circularity Platform (ACP). The aim is for ACP to be an open platform that will enable access to larger quantities of high-quality recycling materials. The first step will include the creation of a prototype for comprehensive testing and evaluation purposes.

The companies have formed a partnership to digitalize the market for secondary materials recovered from automobiles at the end of the consumer-use cycle and increase its transparency by creating an ecosystem for the automotive end-of-life value chain.

Achieving a Circular Ecosystem

While closed-loop aluminum recycling of production scrap has become a sustainability best practice in the automotive industry in recent years, the loop at the end of a vehicle’s life has yet to be closed.

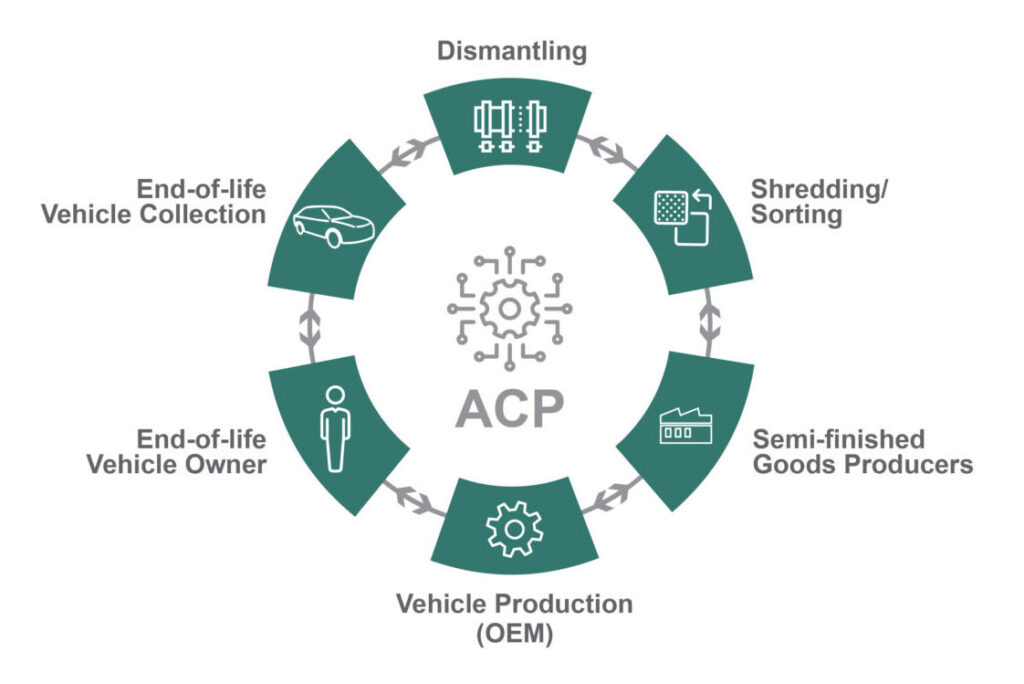

In a growing market, the partnership between Novelis and thyssenkrupp Materials Services is a major step toward achieving a circular economy and reducing carbon emissions. ACP will be a digital marketplace that connects stakeholders throughout the automotive end-of-life value chain and empowers automotive suppliers to capture and reuse aluminum and other materials, such as steel, plastics, glass, rubber, etc.

“ACP is a major step forward in creating an open, accessible trading platform for materials at the end of the consumer-use cycle for companies seeking to fulfill broader and deeper commitments to sustainability and circularity,” said Michael Hahne, Vice President and General Manager Automotive, Novelis Europe. “Not only will ACP increase circularity through optimized material flows and thus enable access to larger quantities of high-quality recycling materials, while minimizing waste to landfill, it will also create a transparent and trusted connection for all stakeholders to create and deploy their own value-generating recycling processes.”

Presently, internal combustion engines can account for up to 80% of total greenhouse gas emissions during automobile lifecycles. However, studies suggest that due to the rise in electric vehicles by 2040, emissions from material production may represent 60% of total automobile lifecycle emissions. Thus, the reduction of pollutants from tailpipes will become secondary to increasing supply chain and manufacturing efficiencies, as top targets for decarbonization. A circular ecosystem with unprecedented collaboration between all stakeholders will play an essential role in the automotive industry reaching its climate targets.

“Novelis and thyssenkrupp Materials Services have formed a relationship that leverages the best of our companies’ respective expertise, the strengths of which are complementary in every respect,” said Sebastian Smerat, Head of Customer Innovation at thyssenkrupp Materials Services. “Thyssenkrupp Materials Services delivers unmatched materials knowledge and experience in digital supply chains and market access to a broad, complex sector. Novelis brings in unique expertise in fields such as aluminium recycling, reuse processes and development of aluminium alloys with high-recycled content. With the idea of developing an automotive circularity platform for aluminium, we are consistently pursuing the path of our sustainability strategy BEYOND at thyssenkrupp Materials Services.”

For aluminum in particular, recycling is the epitome of sustainable practices representing an approximate 95% reduction in CO2 emissions compared to the more energy intensive requirements of primary production. Furthermore, aluminum is recyclable many times over with no loss of properties including strength, lightness, durability, and formability. The many advantages aluminum offers contribute to its increasing use across industries seeking to achieve greater sustainability.

The benefits of shifting to a circular model include:

- Reducing waste

- Decreasing need for primary materials and associated supply chain disruptions

- Lessening the need for primary extraction processes and associated higher emissions

- Improving regulatory compliance and reduces associated costs

- Creating opportunities to provide end-of-life services such as dismantling, recycling, and recovery of materials and marketing of remanufactured/refurbished components

- Building consumer trust and loyalty, especially among younger consumers who value sustainability and social responsibility