Impression Technologies collaborated with FEV, an automotive engineering company, to develop and present a battery housing concept for electric vehicles. The new concept utilizes Hot Form Quench (HFQ®) Technology in order to provide optimal space for energy storage. It will be manufactured and presented as a demonstrator in the coming months.

“With our latest battery housing development, we are once again showing that FEV is thinking in many directions when it comes to sustainable mobility,” said Prof. Stefan Pischinger, president and CEO, FEV Group. “We offer solutions that the market demands — for example, to increase the range of e-mobility. With ITL, we have the ideal partner for lightweight construction on board for this project to make the concept tangible for our customers and partners in the form of a demonstrator in a timely manner.”

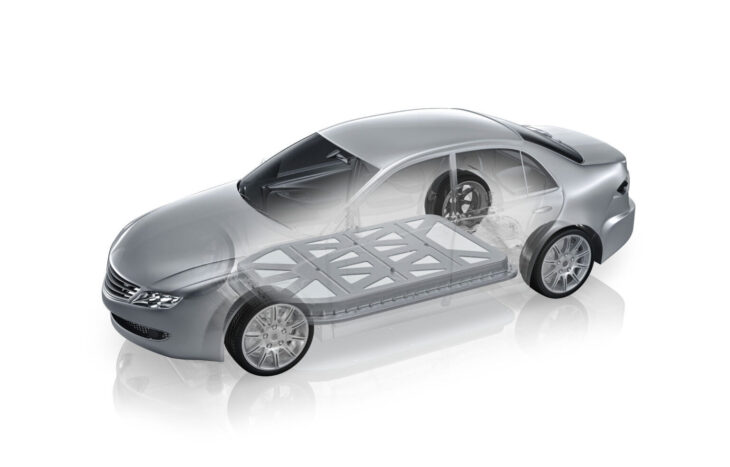

While developing the battery housing with Impression Technologies, FEV approached the challenge of meeting the demanding structural requirements by implementing an an “exoskeleton” concept, essentially placing the structurally relevant components on the outside of the housing. When the battery housing is integrated into the overall vehicle, the installation space for additional battery cells is created. This leads to a reduced installation space requirement, while maintaining the same range — or it can allow for the installation of additional batteries, providing a longer range. The structural design also protects the battery cells during a crash, while also optimizing the rigidity of the overall battery and vehicle body shell system.

In order to achieve the required structural performance in a small battery cell installation space, the housing concept developed by FEV requires the implementation of complex structures with low radii and draft angles. These structures were made possible with Impression Technologies’ aluminum HFQ Technology.

“The HFQ technology expands our portfolio of possible manufacturing technologies for new developments and enables us to implement more complex structures compared to cold forming technologies,” said Christian Kürten, Head of Vehicle Architecture at FEV Vehicle. “Added to this is the use of high-strength aluminum alloys, which, in conjunction with the HFQ process, ultimately deliver the required performance in optimized installation space.”

Developed by Impression Technologies, HFQ Technology is a production method for stamping complex-shaped aluminum components from high-strength and ultra-high-strength alloy sheet. By using hot forming, the pressing/deep drawing process is able to achieve complex shapes from aluminum sheet, while the quenching process ensure that the metal retains the full mechanical properties of the alloy.

“FEV’s pioneering approach to design excellence and open-mindedness in developing new lightweight concepts and solutions for electric vehicles is a great fit for [Impression Technologies] and the benefits of HFQ’s light-weighting technology,” said Jonathan Watkins, CEO of Impression Technologies. “With our expertise in ultra-high strength aluminum alloy characterization, design-for-manufacture, forming simulation and production, and FEV’s global network in the automotive industry, we complement each other perfectly and ensure that all automotive manufacturers can benefit from the novel battery housing concept.”