Editor’s Note: On August 3rd, 1888, Austrian chemist Karl Josef Bayer working in Saint Petersburg, Russia was granted German patent 43977 for his invention involving a process for the production of aluminum hydroxide. At the time, his invention was used by the textile industry that made use of aluminum hydroxide as a dye fixative. Other applications came later.

The aptly named Bayer process has evolved through the years and has become the principal means of refining bauxite and producing alumina or aluminum oxide. As mentioned in the patent review in the February 2020 issue of Light Metal Age, on April 2, 1889, Charles M. Hall was granted five U.S. patents for his discovery of reducing aluminum from its fluoride salts by electrolysis. So, some 130 years later, the aluminum industry still depends on the Bayer process for obtaining the raw material — alumina — for the Hall-Héroult electrolysis process for production of primary aluminum. Although the basic principles behind these processes have not changed, technical developments in the evolution of the underlying process parameters have brought about remarkable improvements in efficiency and sustainability.

This patent review focuses on some of the latest U.S. patents granted in alumina production, primarily via the Bayer process, which basically consists of three main stages: digestion of bauxite and sodium hydroxide to form an aluminate solution, precipitation to form Al(OH)3 particles, and calcining of the Al(OH)3 particles to form alumina (AL2O3) particles of optimum size for aluminum electrolysis production. These patents, granted over the last three years, aim to improve each stage of the Bayer or alternative processes in order to raise productivity, ease the maintenance of equipment, attain cost savings, and protect the environment.

Bauxite ore may contain 30-60% Al2O3, so the waste product in Bayer processing results in ~1.5 tons of “red mud” for every ton of alumina produced, a major disposal problem. Almost half of the patents in this review involve the development of processing technologies and inventive applications for the refinery of “red mud” residue. These innovations are designed to improve its separation, extract valuable metals from it, or to use the residue as a low-cost cement substitute. Therefore, these patents represent the ongoing progress made in the aluminum industry in its quest for sustainable production.

— Joseph C. Benedyk, Editor

US10898830 — SETTLER FOR DECANTING MINERAL SLURRIES AND METHOD FOR SEPARATING CLARIFIED LIQUID FROM THICKENED SLURRY OF SAID MINERAL SLURRIES — Rio Tinto Alcan International Limited (Canada) — The invention relates to settlers used for decanting or thickening slurries of minerals or mineral tailings, for example red mud, produced during the extraction of alumina from bauxite by the Bayer alkaline digestion or attack process. A settler for decanting mineral slurries includes a tank having a side wall, a bottom and a top, an outlet for a thickened slurry at the bottom of the tank, a first overflow outlet for withdrawing an overflow stream of a clarified liquid, a slurry inlet means for introducing fresh slurry into the tank, the slurry inlet means having a slurry opening through which fresh slurry joins a body of slurry in the tank, and a stirrer having a vertical axis around which the stirrer rotates or reciprocates, in said settler the slurry opening is displaced laterally relative to said vertical axis of the stirrer and said slurry inlet means comprises mixing means. A separation installation includes the above settler and a method for separating a clarified liquid from a thickened slurry of a mineral slurry.

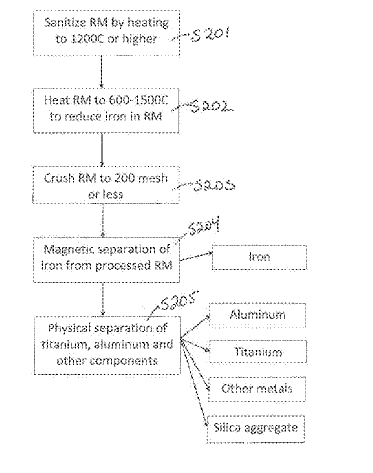

US10851007 — SYSTEM FOR PROCESSING RED MUD AND METHOD OF PROCESSING RED MUD — Red Mud Enterprises LLC (USA) — The present invention provides a method of processing red mud which does not require addition of chemicals to red mud to extract and recover aluminum, iron, and titanium metals from red mud. the present invention accomplishes recovery of these metals in high percentages, e.g., above 90% recovery, by using physical extraction and without chemically processing red mud by adding further chemicals to react red mud components. A system for processing red mud comprising: a first heating section controlled to heat red mud to a first temperature; a second heating section controlled to heat the red mud to a second temperature lower than the first temperature; a crusher configured to grind the red mud to a predetermined particle size; and one or more separators for physically extracting at least iron and aluminum from the red mud.

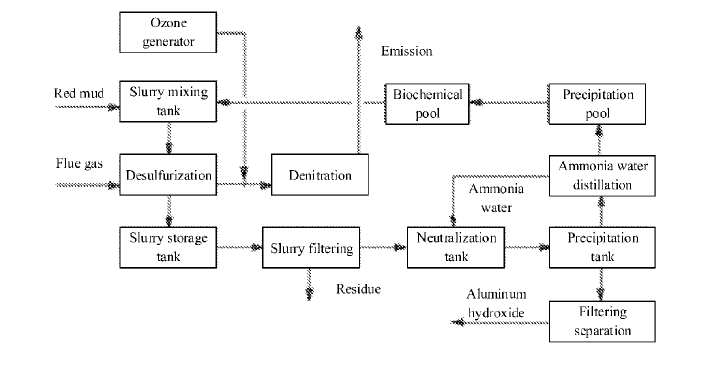

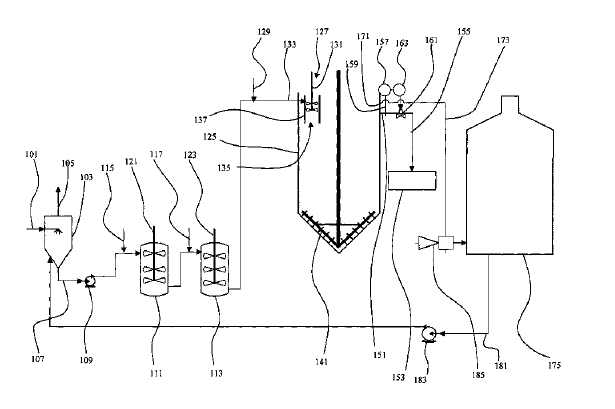

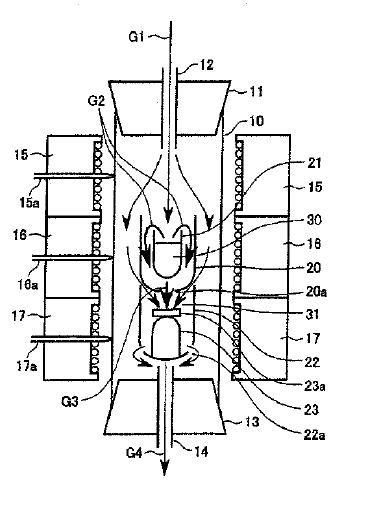

US10843131 — SYSTEM AND METHOD FOR DESULFURIZATION AND DENITRIFICATION INTEGRATED TREATMENT AND RECYCLING OF FLUE GAS BY USING RED MUD — Kunming University of Science and Technology and Pingxiang Huaxing Environmental Protection Engineering Technology Co., Ltd. (China) — The present invention relates to a system and method for desulfurization and denitrification integrated treatment and recycling of flue gas by using red mud, a waste product of the Bayer process of alumina extraction from bauxite, and belongs to the recycling and environmental protection technology field. The system includes a desulfurization spray tower, an ozone generator, a denitrification spray tower, a slurry mixing tank, a slurry storage tank, a vacuum filter, an ammonia water neutralization tank, an aluminum hydroxide precipitation tank, an ammonia water tank, an aluminum hydroxide storage tank, a filter press, an ammonia distillation tower, a dephlegmator, a cooler, a concentrated ammonia water storage tank, a gypsum precipitation tank, and an anaerobic biochemical pool. In the present invention, red mud slurry is used for desulfurization and denitrification treatment of flue gas to remove SO2 and NO in the flue gas, so that SO2 and NO in the flue gas reach an emission standard.

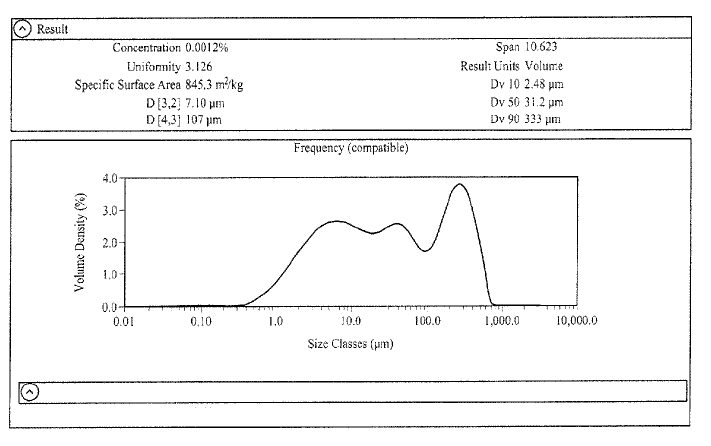

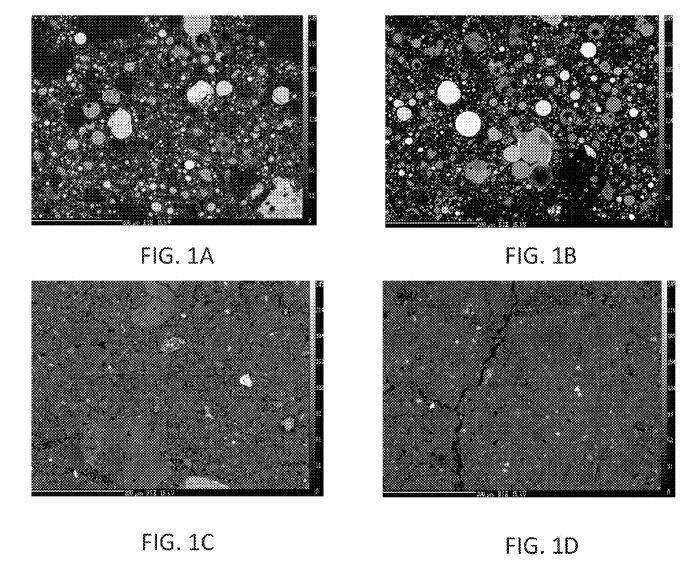

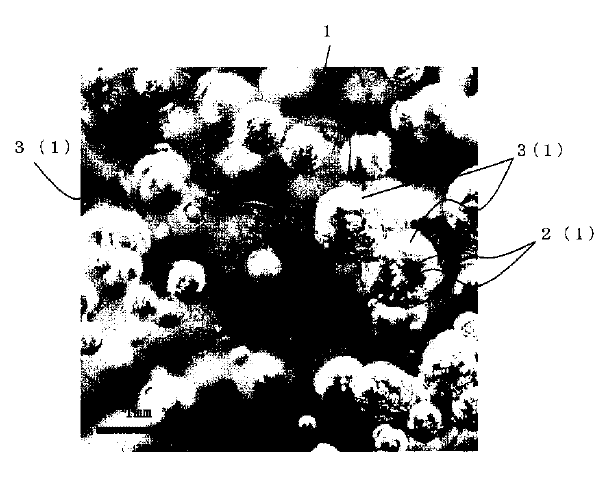

US10836667 — DRY WATER SOLUBLE POLYMER PARTICLES — Water Mark Technologies, Inc. (USA) — A method of dewatering sludge is provided herein. In some embodiments, the method includes introducing micronized dry water soluble polymer (DWSP) particles into a sludge, wherein the sludge includes water and solids; separating water of the sludge from solids of the sludge using the micronized DWSP particles; and collecting a wet solid including water and solids of the sludge, wherein a concentration of solids in the wet solid is higher than a concentration of solids in the sludge, wherein the micronized DWSP particles comprise a DWSP wherein the DWSP is selected from the group consisting of a dry anionic water soluble polymer, a dry cationic water soluble polymer, a dry nonionic water soluble polymer, and mixtures thereof, and wherein a mean particle size of the micronized DWSP particles ranges from about 100 to about 300 microns. Laboratory conditions simulative of a recovery process of sodium aluminate from red mud are described herein.

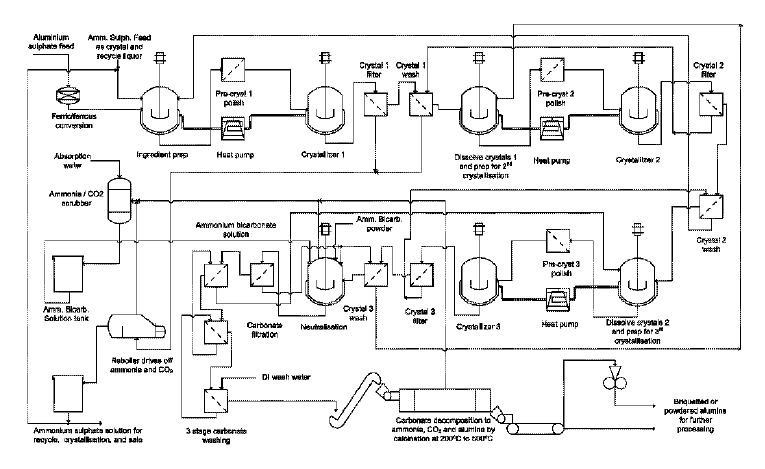

US10815549 — METHOD FOR THE PURIFICATION OF ALUMINA — AluChem Companies, Inc. (USA) — Digestion of impure alumina with sulfuric acid dissolves all constituents except silica. Resulting sulfates, produced from contaminants in the impure alumina, remain in solution at approximately 900°C. Hot filtration separates silica. Solution flow over metallic iron reduces ferric sulfate to ferrous sulfate. Controlled ammonia addition promotes hydrolysis and precipitation of hydrated titania from titanyl sulfate that is removed by filtration. Addition of ammonium sulfate forms ferrous ammonium sulfate and ammonium aluminum sulfate solutions. Alum is preferentially separated by crystallization. Addition of ammonium bicarbonate to ammonium alum solution precipitates ammonium aluminum carbonate which may be heated to produce alumina, ammonia, and carbon dioxide. The remaining iron rich liquor also contains magnesium sulfate. Addition of oxalic acid generates insoluble ferrous oxalate which is thermally decomposed to ferrous oxide. Carbon monoxide reduces the ferrous oxide to metallic iron. Further oxalic acid addition precipitates magnesium oxalate which is thermally decomposed to magnesium oxide.

US10793444 — METHODS AND COMPOSITIONS FOR BAUXITE BENEFICIATION — Ecolab USA Inc. (USA) — Disclosed herein are methods and compositions for increasing the alumina content of a bauxite ore prior to alumina extraction by an extractive process, such as the Bayer process. By adding a beneficiation agent to an aqueous ore slurry, then applying a gravitational force to separate, or partition, the slurry into a beneficiary and a gangue, a number of quantifiable benefits are observed. These include increased alumina content and reduced silica content in the beneficiary solids as compared to the starting ore. These benefits are in excess of those observed by pre-extraction gravitational separation of ore slurries without the addition of a beneficiation agent. Beneficiation agents include DADMAC polymers, and combinations of DADMAC polymers with dextrans. The beneficiary is collected and applied to an extractive process, such as the Bayer process.

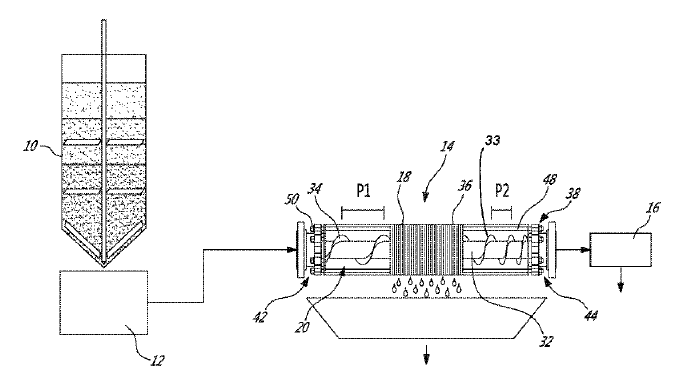

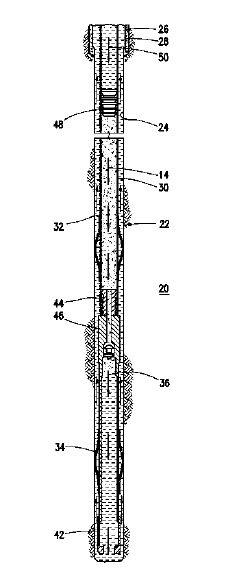

US10780664 — SCREW PRESS WITH FILTER PLATES — Rio Tinto Alcan International Limited (Canada) — The present invention relates generally to solid-liquid separation equipment and, more particularly, to a screw press for dewatering slurry, such as red mud generated in the production of alumina from Bauxite ore. A screw press for separating liquid from a solid-liquid mixture includes a casing having inlet and outlet sections, and a filter section there between. The filter section includes an axially extending stack of coplanar filtration plates defining a core passage for receiving a screw configured to convey the solid-liquid mixture from the inlet section to the outlet section while compressing and dewatering the solid-liquid mixture by forcing at least part of the liquid content of the mixture to be expelled out of the casing through inter-plate gaps defined between each pair of adjacent filtration plates. The filtration plates are fixed relative to one another and clamped in direct intimate face-to-face contact by a clamping assembly operable for applying a predetermined axially clamping pressure substantially uniformly about the core passage. The inter-plate gaps are controlled by the surface roughness of the plates and the clamping pressure.

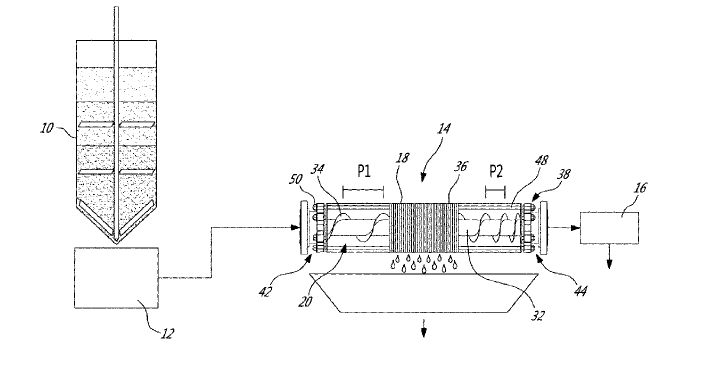

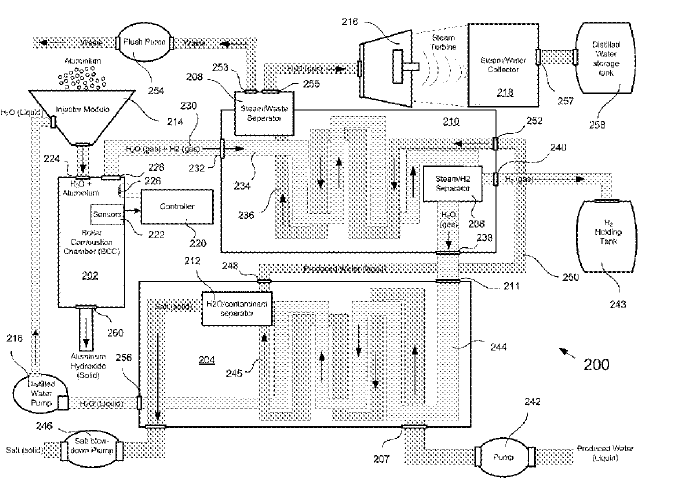

US10752518 — METHOD AND APPARATUS FOR WATER PURIFICATION USING CONTINUOUS HYDROTHERMAL OXIDATION REGIME — Clean Water Ventures, Inc. (USA) — This disclosure relates to a method and apparatus for cleaning dirty water using scrap aluminum as fuel for a hydrothermal oxidation process resulting in distilled water, aluminum hydroxide, produce hydrogen and energy, and thus provides an efficient and cost effect method and apparatus for both cleaning contaminated wastewater and producing economical and useful aluminum hydroxide (and other useful byproducts) in an environmentally clean and efficient way that is beneficial to the environment. The systems and methods may include two heat exchangers, including a high temperature/high pressure (HT/HP) heat exchanger that receives superheated steam and hydrogen gas and a low temperature/low pressure (LT/LP) that receives steam at a reduced temperature and pressure. The LT/LP heat exchanger provides first stage heating to dirty water that is input into the system for cleansing. The LT/LP heat exchanger has a first coil and a second coil. The first coil carries the dirty water to be cleaned. The HT/HP heat exchanger provides a second stage of heating to the dirty water that is output from the LT/LP heat exchanger. A first coil of the HT/HP heat exchanger carries the superheated steam and hydrogen gas. A second coil carries the preheated dirty water that is output from the LT/LP heat exchanger.

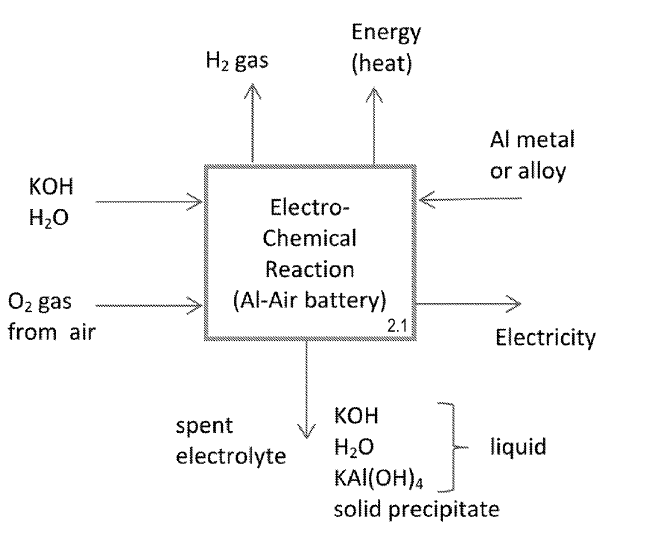

US10720659 — SYSTEMS AND METHODS FOR REGENERATION OF AQUEOUS ALKALINE SOLUTION — Phinergy Ltd. (Israel) — Metal-air system with alkaline electrolyte has a great electrochemical capacity (about 8 kWh/kg). However, during the operation of metal-air batteries, products of the dissolution of metal anodes are accumulated in the electrolyte thus lowering the efficiency of the metal-air battery. Accordingly, following a certain operation time, the electrolyte solution needs to be replaced or regenerated. One of the ways to regenerate the electrolyte is inducing the precipitation of the products of aluminum anode dissolution in the form of solid aluminum tri-hydroxide (ATH) and removing of ATH by filtration. This invention is directed to regeneration of solutions comprising metal ions, and production of valuable hydroxide compounds. Specifically, the invention is related to regeneration of spent electrolyte solutions comprising metal ions, e.g., Al ions, such as electrolyte solutions used in metal/air batteries. The invention is further related to production of layered double hydroxides, optionally ATH from aluminate.

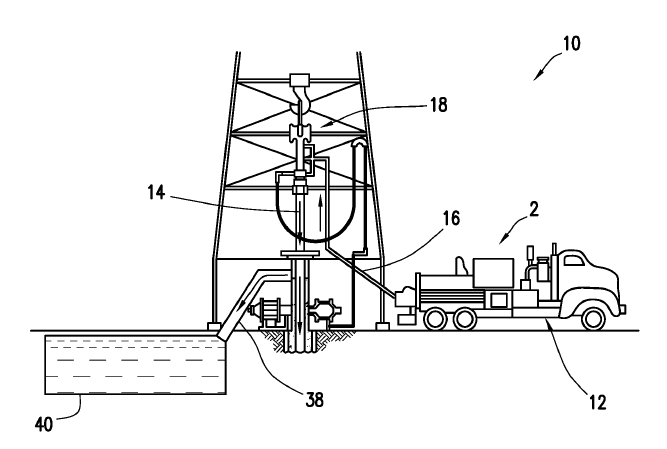

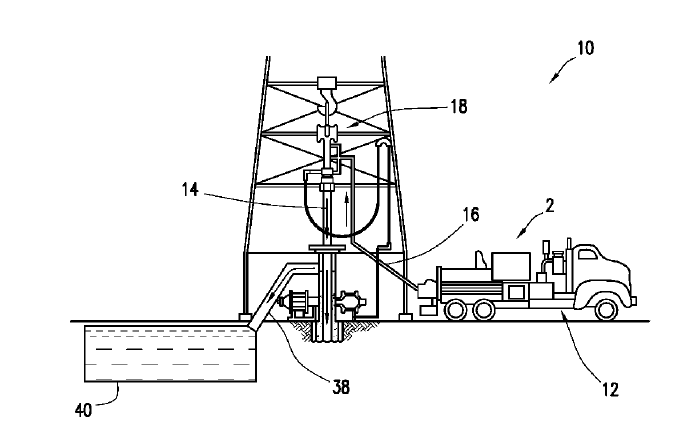

US10641059 — EXTENDED-LIFE SETTABLE COMPOSITIONS COMPRISING RED MUD — Halliburton Energy Services, Inc. (USA) — Settable compositions may be used in a variety of subterranean operations. For example, in subterranean well construction, a pipe string (e.g., casing, liners, expandable tubulars, etc.) may be run into a wellbore and cemented in place. A method for using an extended-life settable composition is disclosed. The method includes providing an extended-life settable composition comprising red mud, calcium hydroxide, water, and a cement set retarder. The red mud may be provided in any suitable form, including as dry solids or in a liquid form, which may comprise red mud solids and an aqueous based fluid. The settable component comprises the red mud, which serves as a low cost cement substitute. The method further includes activating the extended-life settable composition. The method additionally includes introducing the extended-life settable composition into a subterranean formation and allowing the extended-life settable composition to set in the subterranean formation.

US10633940 — LOST CIRCULATION MATERIALS COMPRISING RED MUD — Halliburton Energy Services, Inc. (USA) — This disclosure relates to servicing a wellbore and to the introduction of red mud lost circulation materials into a wellbore to reduce the loss of fluid into a subterranean formation. A method for reducing lost circulation in a subterranean formation. The method includes providing a treatment fluid comprising a base fluid and a lost circulation material comprising red mud. The treatment fluid is introduced into a wellbore within the subterranean formation such that at least a portion of the red mud bridges openings in the subterranean formation to reduce loss of fluid circulation into the subterranean formation.

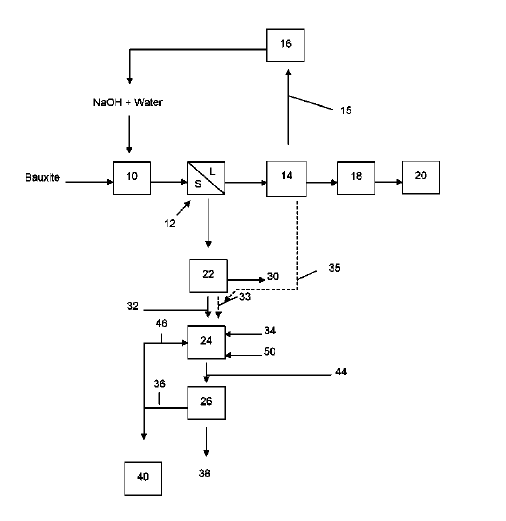

US10508042 — PROCESS AND INSTALLATION FOR PRODUCING ALUMINA TRIHYDRATE BY ALKALINE DIGESTION OF BAUXITE ORE — Rio Tinto Alcan International Limited (Canada) — A process for producing alumina trihydrate includes a digestion step, a separation step, and a precipitation step the separation step including: b1) pretreating a slurry from the digestion step by adding a flocculant to said slurry and mixing the flocculant and the slurry, b2) settling the resulting flocculated slurry in a gravity settler vessel, b3) determining a measured value representative of the concentration of solid particles in the resulting clarified liquor, b4) comparing the measured value with a predetermined threshold, b5) feeding said clarified liquor directly to the precipitation step, while the measured value is less than said predetermined threshold, and b6) redirecting said clarified liquor to the pre-treatment step b1), when the measured value is more than said predetermined threshold. An installation may be configured for operating said process.

US10494280 — TREATMENT OF ALKALINE BAUXITE RESIDUE — Rio Tinto Alcan International Limited (Canada) — A process is disclosed for treating a Bayer process waste comprising a slurry containing bauxite residue and dissolved aluminum. The process comprises supplying the waste to a settling area to cause the bauxite residue to settle out of the slurry, thereby producing a supernatant liquor. The process further comprises neutralizing the supernatant liquor with a solution containing magnesium and calcium to produce a neutralized slurry containing precipitated hydrotalcites and thickening the neutralized slurry to produce a clarified effluent and a compacted slurry containing the precipitated hydrotalcites, part of said compacted slurry being recirculated to the supernatant liquor to be neutralized and/or directly to the neutralizing step. The clarified effluent and the compacted slurry are disposed of separately. Also disclosed is a plant for treating a Bayer process waste.

US10457008 — MODULAR SCREW PRESS — Rio Tinto Alcan International Limited (Canada) — A screw press includes a filter casing having inlet and outlet sections and a filter section therebetween. A screw is mounted in the casing for conveying a solid-liquid mixture from the inlet section to the outlet section while compressing the solid-liquid mixture and forcing at least part of a liquid content thereof to be expelled out of the filter casing. The casing and the screw are of modular construction. The filter section has at least first and second serially interconnectable filter sections, and the screw has at least first and second serially interconnectable screw sections respectively disposed in the first and second filter sections for joint rotation as a unitary component. The first and second screw sections have a continuous screw flight having a flight outside diameter. The first and second screw sections are detachably coupled to one another by a coupling provided at the outside diameter of the flight.

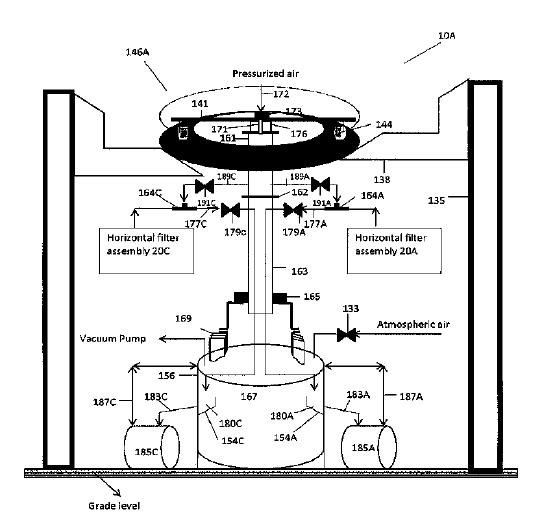

US10434444 — VACUUM FILTER SYSTEM FOR SOLID-LIQUID SEPARATION AND PROCESS FOR FILTERING SOLID PARTICLES — Enhanced Equipment LLC (USA) — A filter system for filtering solids includes a filtration tank for receiving a slurry containing the solids to be filtered. A filter assembly including a plurality of filter cells each having a filter medium at an exterior and a cavity at an interior is lowered into the filtration tank using a transport device carrying the filter assembly. A vacuum transfer system is connected to the filter assembly so as to transfer a vacuum to an interior of the filter cells. The vacuum transfer system is operable to perform the filtering and to retain the filtered solids while the transport device moves the filter assembly relative to the filtration tank. In an embodiment of the method of the invention, a filter assembly according to an embodiment of the invention is inserted into a crystallizer such as used in the production of alumina in the Bayer process and then establishes a recycle flow of nutrient through the filtration media. A vacuum pulls the mother liquor out to a separator tank and a pump returns it back to the crystallizer. In this way, the crystals get separated out of solution immediately after formation. This step may be followed by removing the crystals out of the crystallization environment or maintaining the vacuum to hold the crystals on the filtration media so that the circulation of nutrients over the crystals continues for further growth of crystals.

US10427950 — RECOVERY OF MINING PROCESSING PRODUCT USING BORONIC ACID-CONTAINING POLYMERS — Ecolab USA Inc. (USA) — Methods and compositions for improving performance of flocculants in an industrial production process. Methods include pH triggered cross-linking reaction between a flocculating agent, such as dextran, and a composition comprising a boronic acid-containing polymer. The pH trigger can be provided by a fluid having a pH of 8 or more. The production process can be a Bayer Process and the fluid is caustic liquor or slurry in the fluid circuit of the Bayer, wherein the reaction time is reduced over conventional methods and the cross-linked dextran composition effectuates improved flocculation of the trihydrate particles.

US10407343 — METHOD OF PRODUCING GEOPOLYMER CEMENT UTILIZING DESULFURIZED RED MUD — University of Tennessee Research Foundation (USA) and Hebei Research Institute of Construction and Geotechnical Investigation Co., Ltd. (China) — The presently disclosed subject matter relates to sustainable geopolymer compositions which can replace Portland cement and that comprise the reaction product of a reaction mixture comprising an alkaline solution, an alumina silicate material (e.g., Class C fly ash) and red mud, as well as to methods of preparing and using the geopolymer compositions. The red mud can be red mud that has been used as an acid neutralizing agent in a flue gas desulfurization process. The geopolymer compositions can be prepared using aqueous alkaline solutions comprising an alkali metal hydroxide and having a molarity of about 6 M or less and can be cured at ambient temperatures. The red mud-based geopolymer compositions can be cured at ambient temperatures using alkaline solutions of relatively low alkaline compound concentration compared to other geopolymer compositions. In particular, the use of a red mud previously utilized in a flue gas desulfurization process can provide high strength geopolymer compositions.

US10378084 — METHOD FOR CONCENTRATING METAL COMPOUND BY REDUCTION AND OXIDATION — Hosei University (Japan) — To concentrate metals such as gallium from ore which is extracted from mines, e.g., bauxite ore, or used electronic components while suppressing the quantity of waste liquid generated is difficult. A first solid metal compound which contains a metal selected from a group consisting of gallium, indium, germanium, tellurium, and cesium at a first metal content in a mixture of the first solid metal compound is reduced to form a gaseous metal compound, the gaseous metal compound is oxidized to form a second solid metal compound, and the second solid metal compound is collected at a second metal content which is higher than the first metal content.

US10323479 — EXTENDED-LIFE SETTABLE COMPOSITIONS COMPRISING RED MUD — Halliburton Energy Services, Inc. (USA) — A method for using an extended-life settable composition is disclosed. The method includes providing an extended-life settable composition comprising red mud, calcium hydroxide, water, and a cement set retarder. The method further includes activating the extended-life settable composition. The method additionally includes introducing the extended-life settable composition into a subterranean formation and allowing the extended-life settable composition to set in the subterranean formation. The extended-life settable compositions may have desirable rheological properties allowing them to be stored on the surface for extended time and subsequently activated prior to pumping downhole.

US10301414 — SILICON CONTAINING POLYMER FLOCCULANTS — Cytec Industries Inc. (USA) — Separation of undissolved suspended “mud” solids such as complex aluminosilicates from the alumina stream in the Bayer process is an important part of the process and ensures that the precipitation step in the alumina recovery process can be carried out efficiently, resulting in a high quality alumina trihydrate product. Removal of suspended mud solids from a continuous process stream of red mud can be accomplished with the use of flocculants, which act to agglomerate the suspended solids causing them to settle more quickly. Removal of suspended mud solids from a continuous process stream of red mud can be accomplished with the use of flocculants, which act to agglomerate the suspended solids causing them to settle more quickly. Disclosed herein are silicon containing polymers and compositions containing the same able to flocculate suspended solids in the Bayer or Sinter process stream.

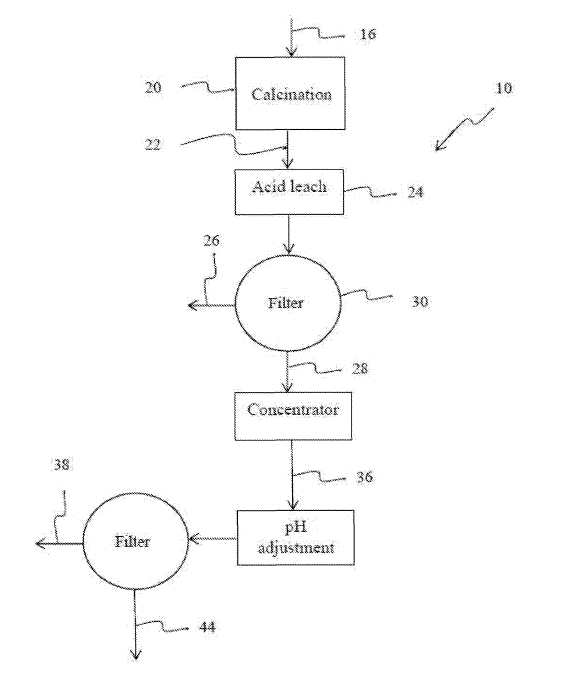

US10273561 — DERIVING HIGH VALUE PRODUCTS FROM WASTE RED MUD — Peloton Resources Pty Ltd. (Australia) — The present invention arises from our research into processes that utilize seawater for partial red mud neutralization, followed by a novel extraction technique that separates valuable metals and/or their oxides contained within. The resulting products are iron oxides (hematite & magnetite), high purity alumina (HPA), smelter grade alumina (SGA), high purity silica (HPS), along with other metals and rare earth metals. Disclosed is a process for recovering valuable metals and/or their oxides from red mud bauxite residues or similar. The process comprises: calcining a red mud residue having a pH of less than about 10 to provide a calcinated red mud residue; acid leaching the calcinated red mud residue to provide a silica rich solid component and an acid leachate; separating the silica rich solid component and the acid leachate; precipitating an iron rich solid component from the acid leachate; and separating the precipitated iron rich solid component from the acid leachate to provide an aluminum rich liquor.

US10259721 — OIL FREE CRYSTAL GROWTH MODIFIERS FOR THE BAYER PROCESS — Cytec Industries Inc. (USA) — Disclosed herein are methods of producing alumina trihydrate crystals from an alumina trihydrate recovery process stream wherein an aqueous emulsion comprising a crystal growth modifier, which is at least one of an acyclic anhydride or an alkyl or alkenyl succinic anhydride, is added to the alumina trihydrate recovery process stream, wherein the aqueous emulsion is substantially free of mineral oils. The method provides a decrease in percentage of alumina trihydrate crystals having a volume average diameter of less than about 45 micrometers compared to the percentage of alumina trihydrate crystals produced in the absence of the crystal growth modifier. The process does not require the addition of a defoamer/anti-foam agent in order to control foam generated in the process.

US10246759 — METHOD OF RECOVERING RARE-EARTH ELEMENTS — Nippon Light Metal Company, Ltd. (Japan) and The Jamaica Bauxite Institute Limited (Jamaica) — Provided is a method of recovering rare-earth elements by performing slight pH adjustment of a leachate, which does not require such significant pH adjustment as in conventional methods, reduces cost and effort, and can efficiently recover rare-earth elements in a bauxite residue in a good yield. The method of recovering rare-earth elements is a method of recovering rare-earth elements, the method including: a leaching step of bringing a raw material bauxite residue, which is produced as a by-product in a Bayer process, into contact with a liquid leaching agent to recover a leachate containing rare-earth elements; an extraction step of bringing the leachate into contact with an extraction treatment liquid containing a phosphoric acid ester-based extractant to recover an extract liquid containing the rare-earth elements; and a back extraction step of bringing the extract liquid into contact with a back extraction treatment liquid to recover the rare-earth elements, the leaching step including recovering a leachate having a pH of 0.5 or more and 1.2 or less by using an acidic liquid leaching agent, the extraction step including adjusting the pH of the leachate to 1.0 or more and 1.7 or less and then bringing the leachate into contact with the extraction treatment liquid.

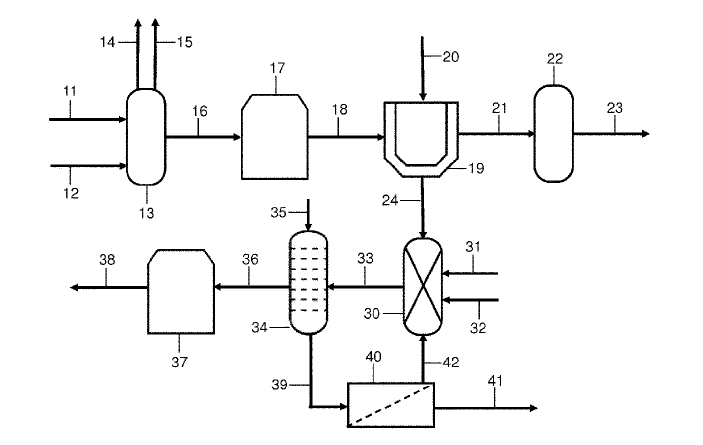

US10174402 — PROCESSES FOR PREPARING ALUMINA AND VARIOUS OTHER PRODUCTS — Orbite Technologies Inc. (Canada) — There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides, sulphates, and chlorides of various metals, as well as rare earth elements, rare metals, and aluminum.

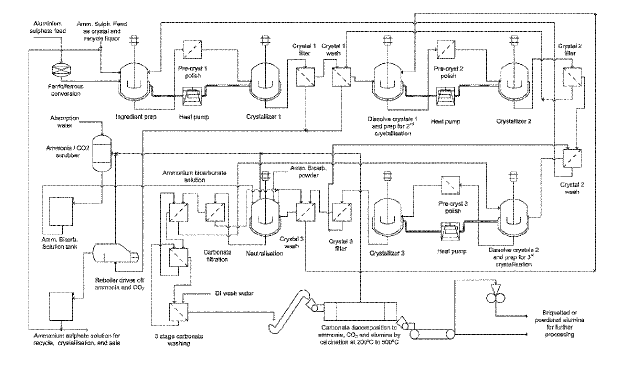

US10144650 — METHOD FOR RECOVERY OF THE CONSTITUENT COMPONENTS OF LATERITES — AluChem Companies, Inc. (USA) — Digestion of a laterite with sulfuric acid dissolves all constituents except silica. The resulting sulfates–aluminum sulfate, ferric sulfate, titanyl sulfate, and magnesium sulfate–remain in solution at approximately 90°C. Hot filtration separates silica. Solution flow over iron reduces ferric sulfate to ferrous sulfate. Controlled ammonia addition promotes hydrolysis and precipitation of hydrated titania from titanyl sulfate that is removed by filtration. Addition of ammonium sulfate forms ferrous ammonium sulfate and ammonium aluminum sulfate solutions. Alum is preferentially separated by crystallization. Addition of ammonium bicarbonate to an ammonium alum solution precipitates ammonium aluminum carbonate which may be heated to produce alumina, ammonia, and carbon dioxide. The addition of oxalic acid generates insoluble ferrous oxalate which thermally decomposes to ferrous oxide and carbon monoxide which is used to reduce the ferrous oxide to metallic iron. Further oxalic acid addition precipitates magnesium oxalate which is thermally decomposed to magnesium oxide.

US10087359 — EXTENDED-LIFE CEMENT COMPOSITIONS COMPRISING RED MUD SOLIDS — Halliburton Energy Services, Inc. (USA) — Extended-life cement compositions are provided and, more particularly, extended-life cement compositions are provided that comprise a cementitious component comprising red mud solids and hydraulic cement. A method of cementing may comprise providing an extended-life cement composition comprising a cementitious component, water, and a cement set retarder, wherein the cementitious component comprises red mud solids and a hydraulic cement; activating the extended-life cement composition; introducing the extended-life cement composition into a subterranean formation; and allowing the extended-life cement composition to set in the subterranean formation.

US10066124 — METHOD OF REDUCING SCALE IN THE BAYER PROCESS — Cytec Industrial Inc. (USA) — In heat exchangers used to reheat spent Bayer process liquor, the high temperatures increase the rate of aluminosilicate precipitation. As a result, aluminosilicates form as scale on the inside walls of the heat exchangers and other associated process equipment. The scale is usually in the form of sodalite or cancrinite, but other aluminosilicate scales can form. The reduction in heat transfer caused by aluminosilicate scaling can be so severe that the heat exchange units have to be taken out of service and cleaned frequently, as often as every 1-2 weeks. In addition to the obvious cost of maintenance and labor required to clean the scale from the heat exchangers, the impact of scale on the equipment can also be seen in increased energy consumption, reduced liquor flows, reduced throughput, reduced evaporation and even. Methods for reducing aluminosilicate containing scale in a Bayer process involving treating a Bayer process equipment surface with a scale inhibiting composition having high ionic strength prior to exposure to a Bayer process stream. The scale inhibiting composition comprises a liquor comprising an aqueous solution of one or more water-soluble salts containing at least about 0.004% of total dissolved salts (TDS) or a liquor having a pH of about 11.0 or greater.

US10046977 — PROCESS AND PLANT FOR PURIFYING RED MUD — Outotec (Finland) Oy (Finland) — A process for purifying red mud including reduction of the red mud to reduced material and traversing the reduced material with an oxygen-containing gas in the presence of a catalyst suitable for iron oxidation. It is the object of the invention to provide a process and a plant for carrying out this process, with which the waste quantities obtained in the aluminum production can be decreased in an economically expedient way and at least parts of the red mud can be recovered as valuable products. In accordance with the invention, in a first step, the red mud is at least partly reduced, whereby a reduced material is obtained. The reduction in step 1 is carried out at a temperature between 800 and 1500° C., preferably at 1000 to 1450° C., whereby the load of the reactor can be reduced. It is the object of the reduction step to reduce the obtained iron oxide to metallic iron, so that the same can be reacted further in the second step. Hydrogen, hydrocarbons (here preferably methane), carbon monoxide and/or coal are equally suitable as reducing agents. In a second step, an oxygen-containing gas subsequently flows through (traverses) this reduced material in the presence of a suitable catalyst. Furthermore, it was found to be positive when before the first process step (the reduction), the red mud is washed and dried. n a final drying step, the solids left after leaching out the iron oxide are liberated from water residues still contained, so that the desired product mixture is obtained. The product mixture substantially contains silicon dioxide (SiO2), magnesium oxide MgO), aluminum oxide (Al2O3) and titanium oxide (TiO2). Due to its comparatively high aluminum content between 40 and 60 wt. %, this powdery material can be admixed to the feed of a Bayer process.

US9988282 — SURFACTANT BASED SMALL MOLECULES FOR REDUCING ALUMINOSILICATE SCALE IN THE BAYER PROCESS — Ecolab USA Inc. (USA) — The invention provides methods and compositions for inhibiting the accumulation of DSP (desilication product) scale in the liquor circuit of Bayer process equipment. As DSP accumulates in Bayer process pipes, vessels, heat transfer equipment, and other process equipment, it forms flow bottlenecks and obstructions and can adversely affect liquor throughput. In addition because of its thermal conductivity properties, DSP scales on heat exchanger surfaces reduce the efficiency of heat exchangers. The method includes adding one or more GP (glycidoxypropyltrimethoxysilane) surfactant based small molecules to the liquor fluid circuit. These scale inhibitors reduce DSP scale formation and thereby increase fluid throughput, increase the amount of time Bayer process equipment can be operational and reduce the need for expensive and dangerous acid washes of Bayer process equipment. As a result, the invention provides a significant reduction in the total cost of operating a Bayer process.