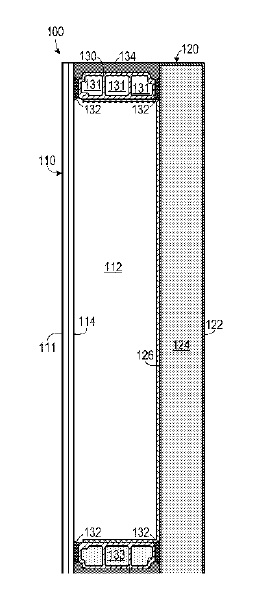

US10280679 — SYSTEM FOR RETROFITTING GLAZING SYSTEMS OF BUILDINGS — Inovues, Inc. (USA) — A glazing shield system for retrofitting glazing systems of buildings is disclosed. The glazing shield system includes a support frame and a unitized panel. In certain embodiments, the glazing shield system may be mounted on an existing glazing system in a non-intrusive and non-destructive method. In one embodiment, the support frame may be attached to an infill panel of an existing glazing system using structural adhesives, and the unitized panel may be mounted on the support frame, creating an insulating glazing shield. In one embodiment, the top, bottom, and side rail members may be made up of an extruded metal, such as aluminum.

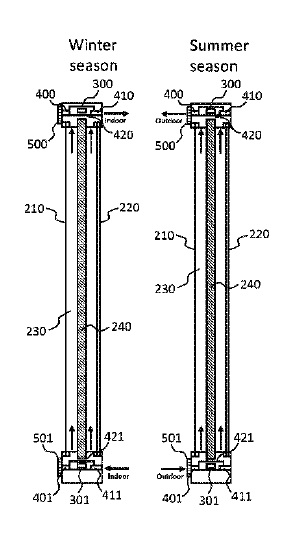

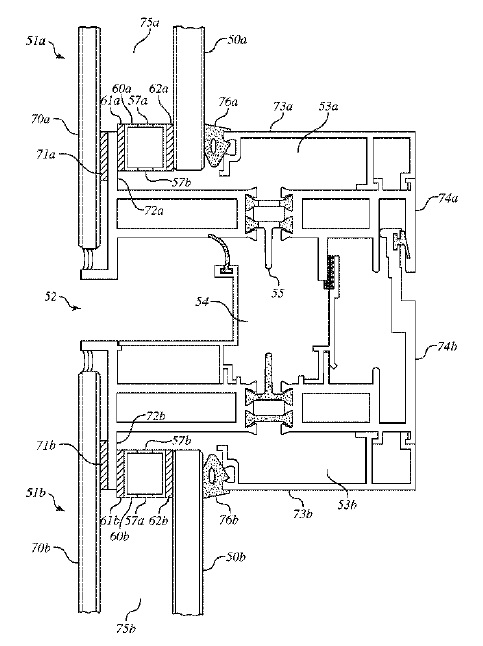

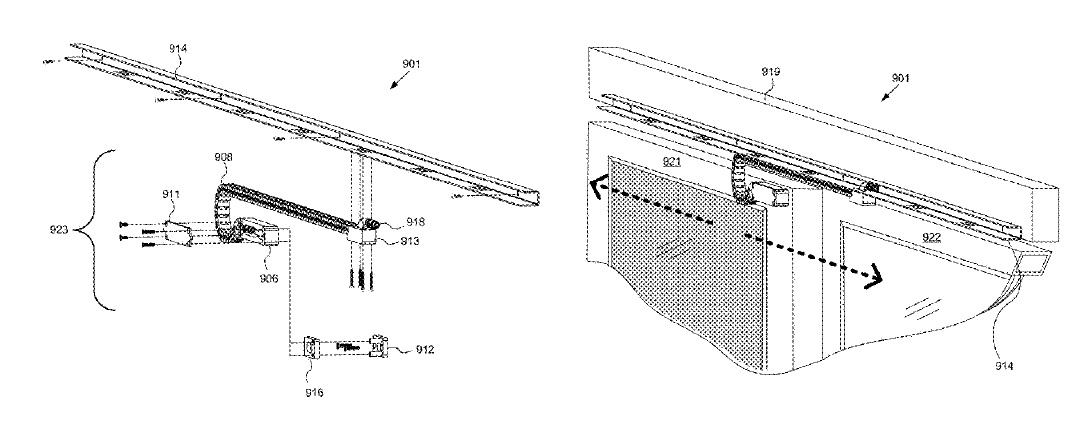

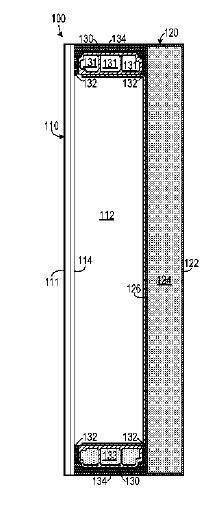

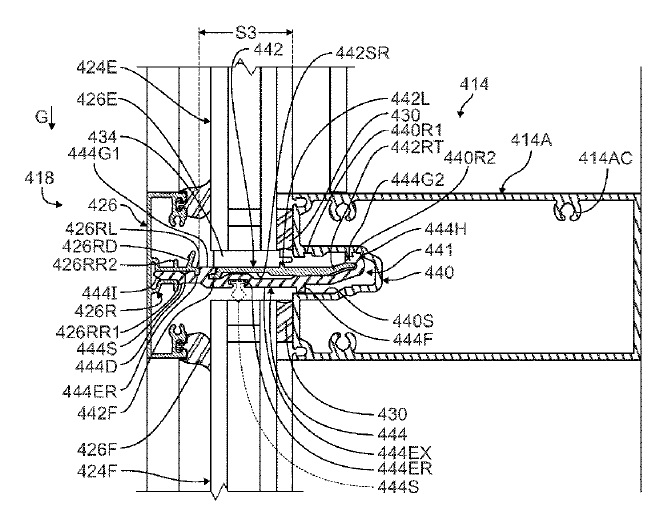

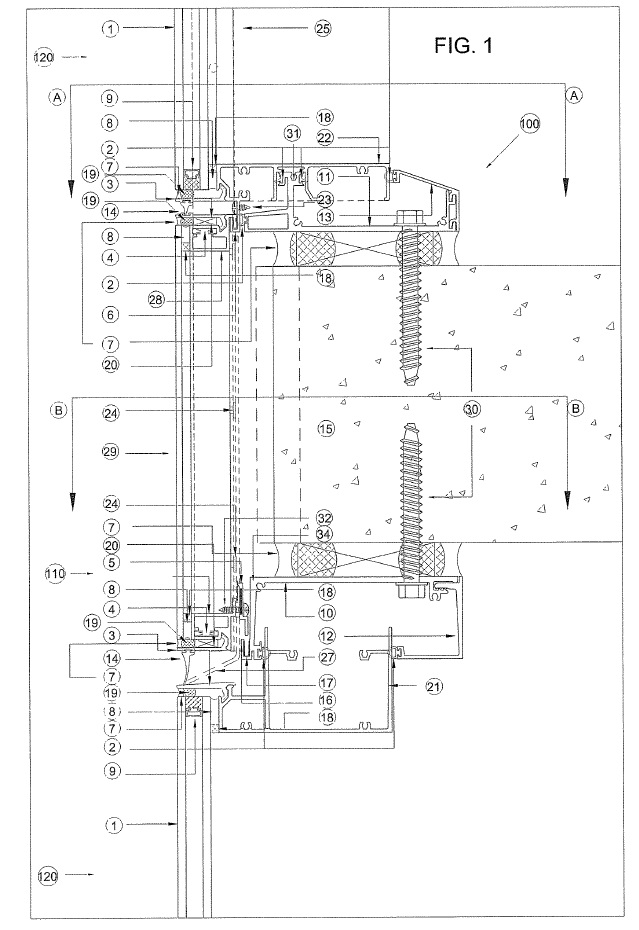

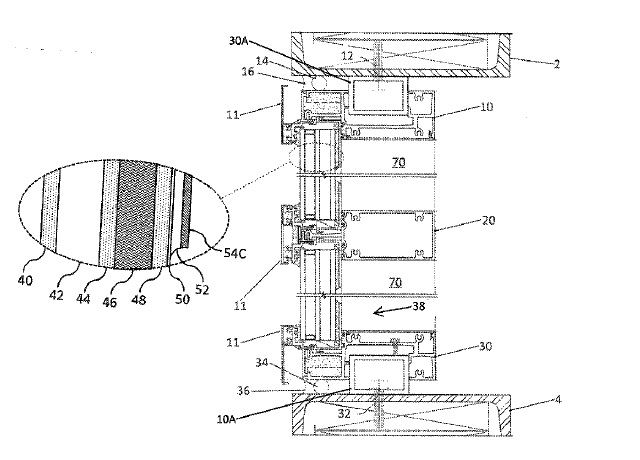

US10267087 — INTAKE-EXHAUST UNIT AND DOUBLE SKIN SYSTEM USING SAME — Device Co., Ltd. (Japan) — Provided is an intake-exhaust unit that easily controls the flow of air in an intermediate cavity of a double skin structure window glass, and a double skin system as in an aluminum curtain wall using the same. The intake-exhaust unit is comprised of: a first distribution port of passage of the air; a second distribution port of passage of the air, the second distribution port being separated from the first distribution port; a third distribution port of passage of the air, the third distribution port being separated from the first distribution port and the second distribution port; a fan for sending out the sucked air; a negative-pressure passage provided on the air-sucking side of the fan, the negative-pressure passage having intake holes that communicates with the first, the second, and the third distribution ports; and a positive-pressure passage provided on the air exhausting side of the fan, the positive-pressure passage having an exhaust hole that communicates with the first, the second, and the third distribution ports, wherein the air is sucked from any of the first, the second, and the third distribution ports; and the air is exhausted from any of the distribution port other than the port in use for sucking the air among the first, the second, and the third distribution ports.

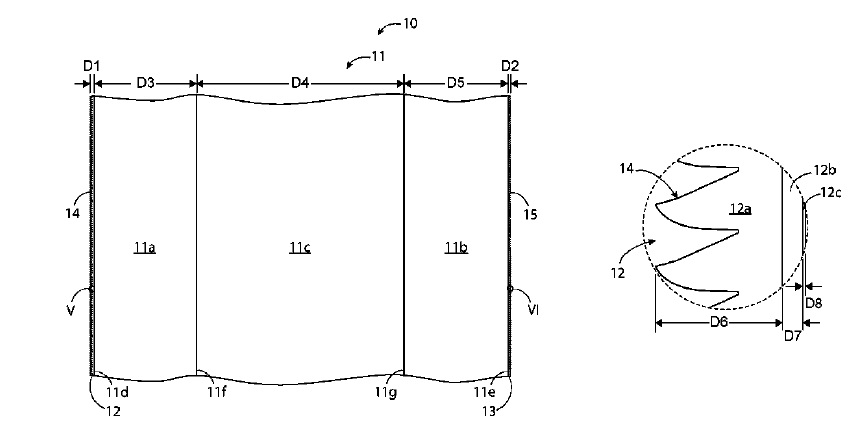

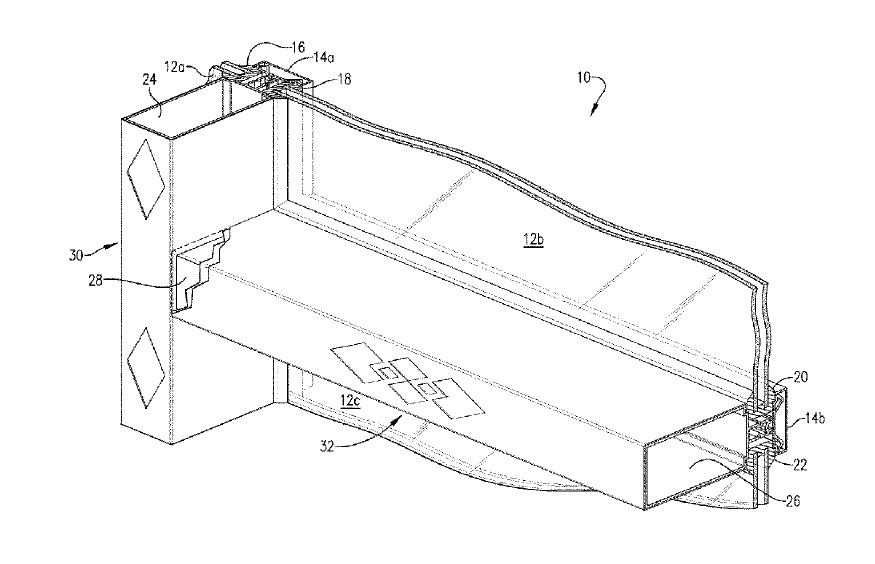

US10267084 — PANELIZED SHADOW BOX — Rainlight Studio LLC and Dow Silicones Corporation (USA) — In a method of supplying an element for covering a non-vision area in a curtain wall consisting of an aluminum facing and back structure on an architectural structure, a plurality of shadow boxes is prefabricated at a location remote from both a unitized curtain wall assembly shop and the architectural structure. The shadow boxes are prefabricated by sealing an interior spacer between a vision glass panel and a back structure. The back structure includes an insulating material surrounded by a rigid envelope. The vision glass panel, the back structure and the interior spacer define a hermetically sealed void therein. A structural seal is applied about the interior spacer and is affixed to the peripheral edge of the vision glass, the interior spacer and the back structure. The plurality of shadow boxes is then delivered to a selected one of the unitized curtain wall assembly shop and the architectural site.

US10233638 — BUILDING FACADE SYSTEM — Talon Wall Holdings LLC (USA) — A building facade system includes framework having shelf members preferably elongate extruded aluminum members which are cut to desired lengths. secured to the floor slabs. The top terminal ends of vertical mullions are fastened to the shelf members, thereby hanging the mullions therefrom. Horizontal support members preferably elongate extruded aluminum members which are cut to desired lengths fastened to the mullions support infill panels and are coupled to shelf members which are on the below floor slab. Intermediate support members fastened to the mullions support slab edge cover panels. Posts are fastened to the shelf members and are secured to the floor slabs within troughs formed with embedded channels. The posts are horizontally and vertically adjustably fastenable to the shelf members. The shelf members are thereby also horizontally and vertically adjustable relative to the floor slabs. Terminal edges of the floor slabs can project into mullion cutouts.

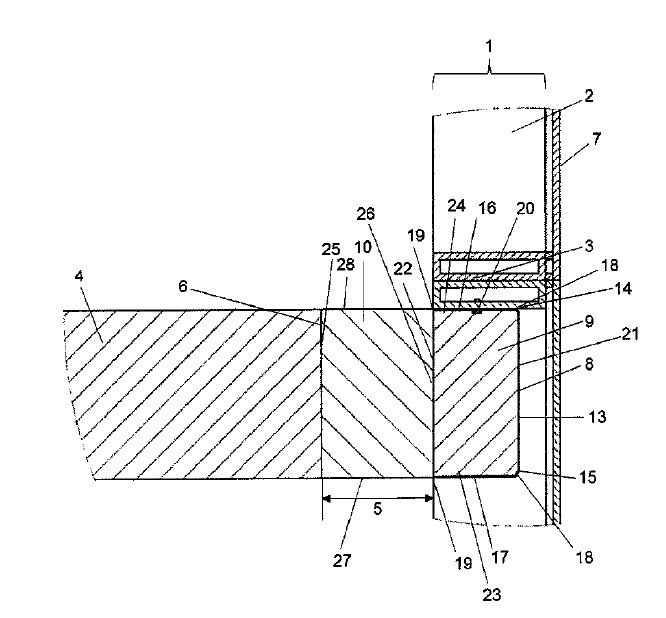

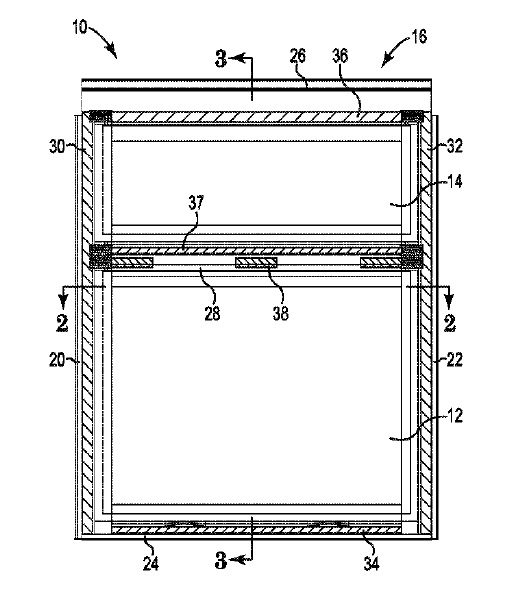

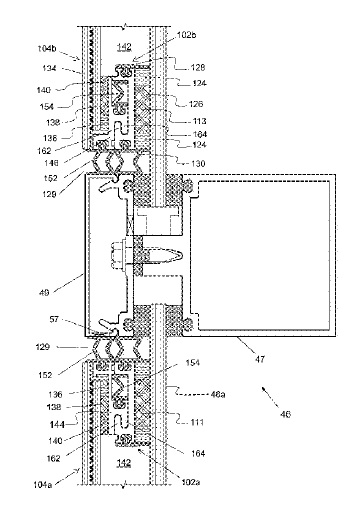

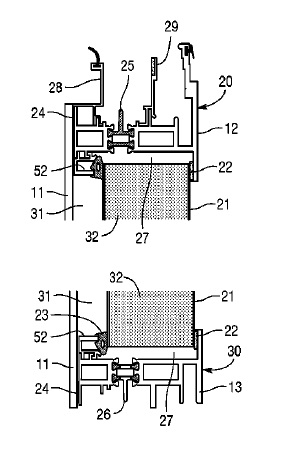

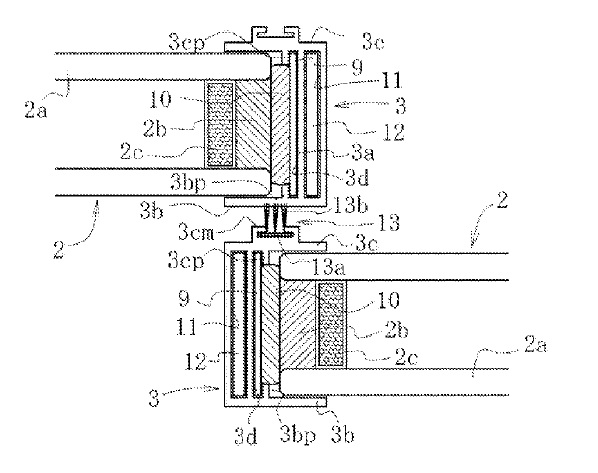

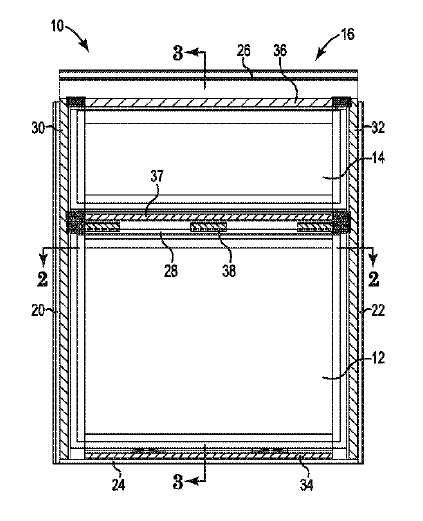

US10227817 — VENTED INSULATED GLASS UNIT — Advanced Building Systems, Inc. (USA) — An exterior wall panel with a vented insulated glass unit with the air space between the glass panes pressure equalized with exterior air. The vented insulated glass unit is configured to eliminate the requirement for a perfect seal around the insulated glass unit perimeter, limit water condensation within the insulated glass unit, limit water infiltration, and maintain thermal insulation performance. For the most commonly used panel frame material, aluminum, during the air conditioning season, the interior surface temperature of the aluminum extrusion frame will be lower than temperature of Face 3 on the glass surface. Therefore, water condensation on the aluminum frame surface inside the hidden air spaces 13a and 13b will happen first, resulting in reduced moisture content in the air before the air can go through air holes 17a and 17b to reach Face 3 on the glass surface. The condensed water on the hidden surface of the aluminum frame will be drained out from the airloop drainage system.

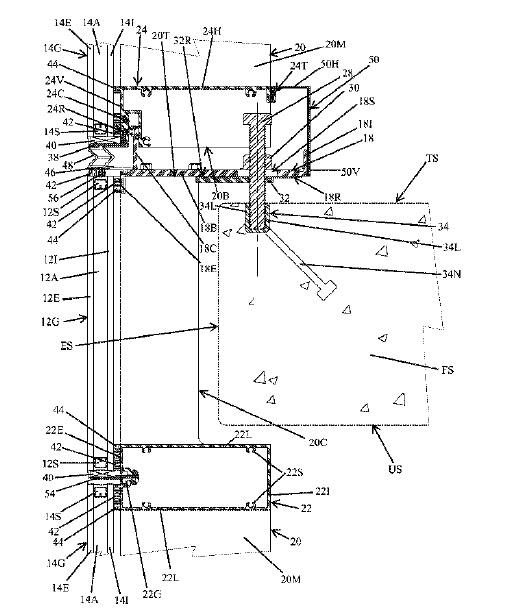

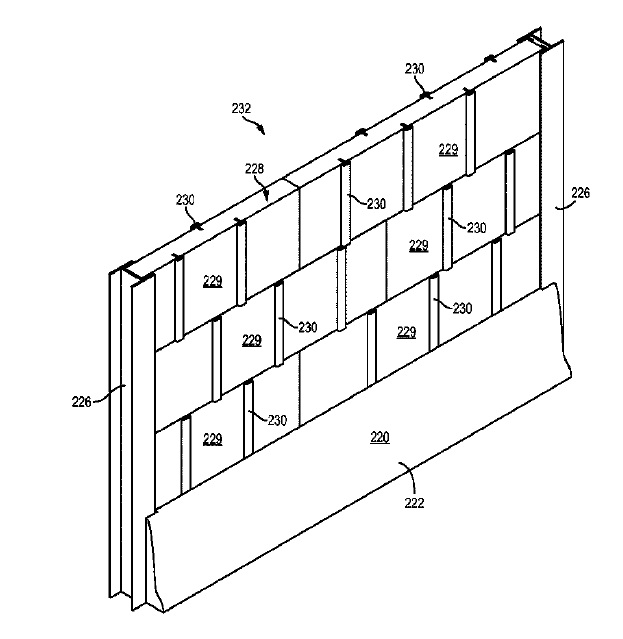

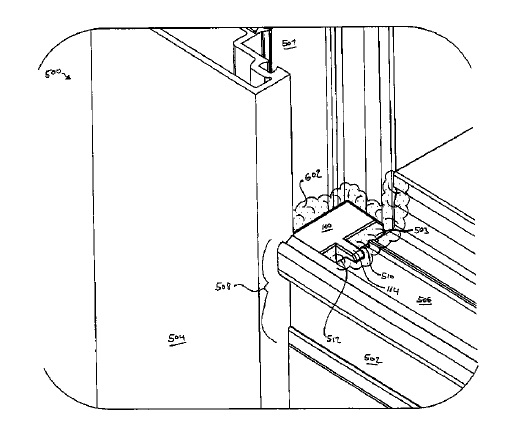

US10202763 — PERIMETER WALL — Cupples International Inc. (USA) — An outer covering of a building includes anchor bolts configured to extend outwardly from an exterior side of floor support structures of the building, a plurality of anchor plates that adjustably mount to the plurality of anchor bolts, and a plurality of spandrel units that mount to an exterior side of the plurality of anchor plates. The anchor plates can be made of aluminum extrusions mounted to the exterior side of floor support structures of a building via adjustable anchors, such as bolts. Each of the plurality of spandrel units includes a first mounting structure that receives a first outer covering section from above and supports a dead weight and lateral load of the first outer covering section via a corresponding one of the plurality of anchor plates and associated anchor bolts, and a second mounting structure configured to rotationally receive a second outer covering section after dead weight of the second outer covering section is loaded on an adjacent spandrel unit located below that one of the plurality of spandrel units.

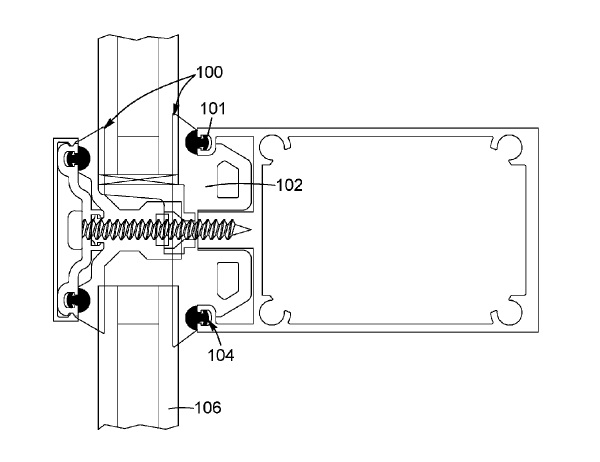

US10202762 — CONCEALED FASTENER WINDOW OR CURTAIN WALL ASSEMBLIES — New Jersey Institute of Technology (USA) — Window or curtain wall assemblies and concealed window fastening assemblies are disclosed. Each window panel includes two layers of glass or other material separated by a spacing mullion, which lines the perimeter of the window panel to create a sealed chamber. The depth of the sealed chamber between the two layers is variable to accommodate either thermal requirements, vertical and horizontal structural loads, or both. The chamber reduces heat loss due to convection allowing it to outperform current double or triple glazing window walls. Each chamber can connect through tubes to allow for air or gas transfer to enhance thermal performance and create the potential for other functional and aesthetic effects. When the window panels are assembled, the latching mechanism structurally unifies each panel to become a single monolithic surface that can also account for thermal expansion. Elements of the latching mechanism are arranged to allow the window or curtain wall to be assembled from the interior, leaving only caulking to be performed from the exterior. Concealing all of such elements helps eliminate the exposure of window mullions and minimizes maintenance of the window or curtain wall. Suitable materials include but are not limited to a thermally efficient composite or an aluminum extrusion with an integral thermal break.

US10202761 — CURTAIN WALL SYSTEM, CORNER BRACKET FOR CURTAIN WALL SYSTEM, AND ASSOCIATED METHOD — Stephen N. Loyd Irrevocable Family Trust (USA) — In certain embodiments, a curtain wall system comprises first and second curtain wall member supporting apparatuses and a corner latching apparatus. The first and second supporting apparatuses each have a respective: vertically-disposed member; horizontally-disposed supporting member; and locking member coupled to the vertically-disposed member. The locking member is disposed beneath a lower surface of the horizontally-disposed supporting member. The corner latching apparatus has a corner shape and comprises a first horizontally-disposed latching arm oriented in a first direction and adapted to engage with the locking member of the first supporting apparatus. The corner latching apparatus comprises a second horizontally-disposed latching arm oriented in a second direction and a stabilizing resilient member disposed beneath a lower surface of each of the first and second horizontally-disposed latching arms, at least a portion of the stabilizing resilient member adapted to compress against an upper surface of a curtain wall member.

US10202759 — DYNAMIC, FIRE-RESISTANCE-RATED THERMALLY INSULATING AND SEALING SYSTEM HAVING A F-RATING OF 120 MIN FOR USE WITH CURTAIN WALL STRUCTURES — Hilti Aktiengesellschaft (Liechtenstein) — Described is an approved dynamic construction for effectively thermally insulating and sealing of a safing slot between a floor of a building and an exterior wall construction wherein the exterior wall construction comprises a curtain wall configuration defined by an interior wall glass surface including one or more aluminum framing members, wherein the vision glass extends to the finished floor level below. The dynamic, thermally insulating and sealing system comprises a first element for receiving the insulating elements and positioned in the zero spandrel area of a glass curtain wall construction including only vision glass to maintain thermally insulating and sealing of the safing slot during exposure to fire and heat as well as movement in order to maintain a complete seal extending across the safing slot.

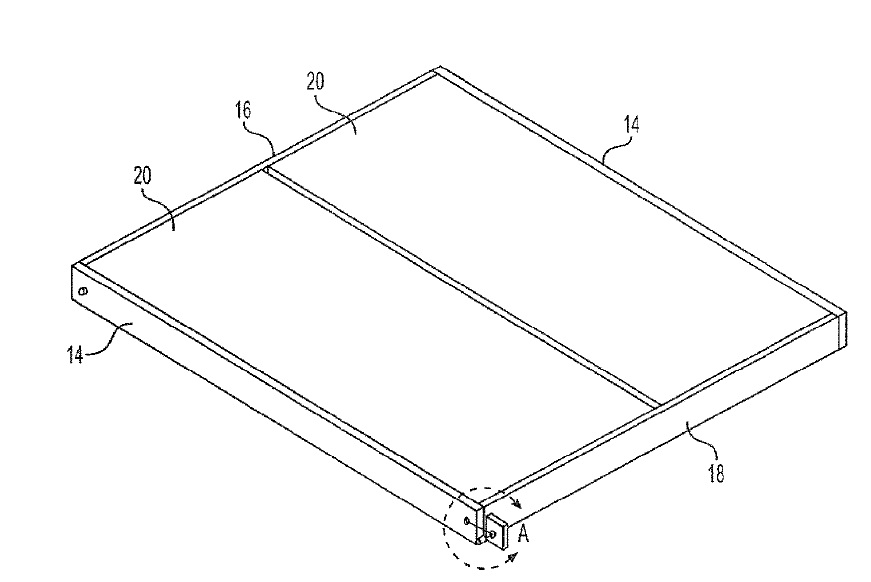

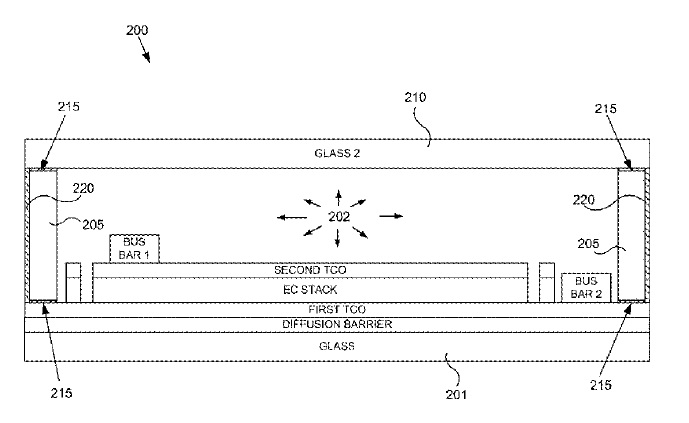

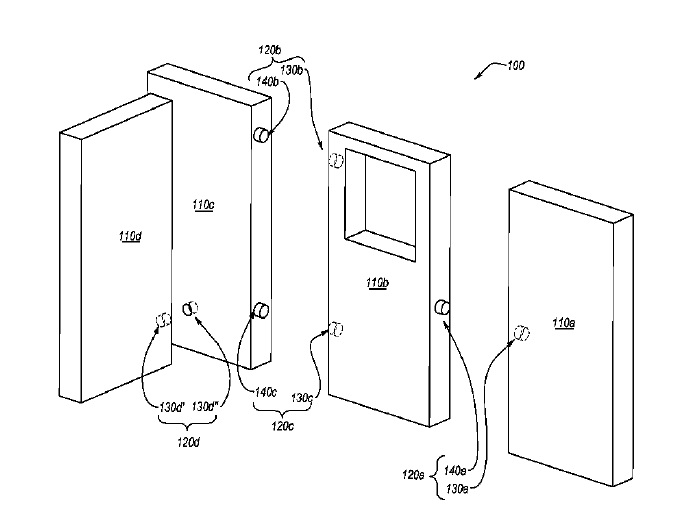

US10180606 — CONNECTORS FOR SMART WINDOWS — View, Inc. (USA) — This disclosure provides connectors for smart windows. A smart window may incorporate an optically switchable pane. In one aspect, a window unit includes an insulated glass unit including an optically switchable pane. A wire assembly may be attached to the edge of the insulated glass unit and may include wires in electrical communication with electrodes of the optically switchable pane. A floating connector may be attached to a distal end of the wire assembly. The floating connector may include a flange and a nose, with two holes in the flange for affixing the floating connector to a first frame. The nose may include a terminal face that present two exposed contacts of opposite polarity. Pre-wired spacers improve fabrication efficiency and seal integrity of insulated glass units. Electrical connection systems include those embedded in the secondary seal of the insulated glass unit.

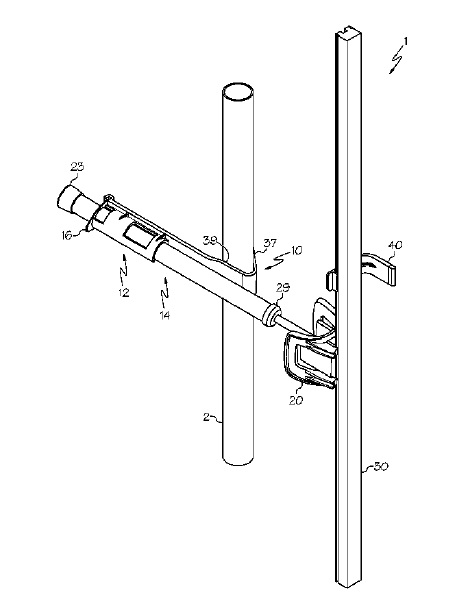

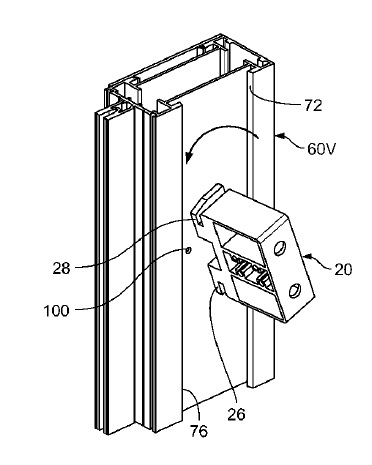

US10174514 — POLE CLAMP SYSTEM FOR PARTITION MOUNT — Zipwall, LLC. (USA) — A pole clamp system for mounting between a pole and an abutting surface includes a pole interface configured to interface with a side body portion of a pole, a guide portion extending from the pole interface, a locking plate extending from the pole interface adjacent to the guide portion, a biasing unit extending through the guide portion and the locking plate, and a head interface coupled to the biasing unit. The elongated head 30 comprises a rail body 41 generally having a U-shaped cross-section, the rail including a channel 32 that is shaped to receive an edge of a compressible pad, for example, in the form of a foam block 31. The rail may be formed, for example, of extruded aluminum, or may otherwise be molded or die cast, for example of plastic, PVC, graphite or other resilient material. The biasing unit outwardly biases the pole interface and head interface in opposite directions.

US10125536 — PANELIZED SHADOW BOX — Rainlight Studio LLC and Dow Chemical Company (USA) — In a method of supplying an element for covering a non-vision area in a curtain wall on an architectural structure, a plurality of shadow boxes is prefabricated at a location remote from both a unitized curtain wall assembly shop and the architectural structure. The shadow boxes are prefabricated by sealing an interior spacer between a vision glass panel and a back structure. The back structure includes a metal envelope, which can include aluminum, with an insulation material sealed therein. The vision glass panel, the back structure and the interior spacer define a hermetically sealed void therein. A structural seal is applied about the interior spacer and is affixed to the peripheral edge of the vision glass, the interior spacer and the back structure. The plurality of shadow boxes is then delivered to a selected one of the unitized curtain wall assembly shop and the architectural site.

US10119667 — LIGHT-REDIRECTING OPTICAL DAYLIGHTING SYSTEM — LightLouver LLC (USA) — Light-redirecting optical system for building fenestrations, such as glass doors and windows, storefront glazing systems, and curtain walls, that can collect and redirect daylight into the interior of a building. The light-redirecting optical system includes an outward-facing light-redirecting optical surface and an inward-facing light-redirecting surface. The outward-facing light-redirecting optical surface collects and redirects daylight mostly upward toward the inward-facing light-redirecting surface. The inward-facing light-redirecting surface receives the redirected daylight and further redirects it into the interior environment at pre-determined angles; so that all specular rays of light are at or above the horizon for a wide range of incident angles of daylight striking the outward-facing light-redirecting optical surface. The light-redirecting optical surfaces can be fabricated on a film or flexible substrate that may be directly applied to glass, acrylic, or other glazing surfaces. Alternatively, the light-redirecting optical surfaces may be fabricated directly on the glazing surfaces.

US10106698 — COMPOSITION FOR POWDER COATING MATERIAL, POWDER COATING MATERIAL AND COATED ARTICLE — AGC Inc. (Japan) — To provide a composition for powder coating material capable of forming a coating film having excellent water and oil repellency, capable of maintaining excellent water and oil repellency even when the surface is rubbed or when used in an environment in contact with water, and having excellent resistance to adhesion of organisms such that organisms such as mold, algae, etc. are less likely to adhere thereto; a powder coating material; and a coated article. The composition for powder coating material comprises polymer (A) composed of at least one member selected from polymer (A1) and polyvinylidene fluoride, and polymer (B). The polymer (A1) is a fluorinated non-block copolymer having units based on a fluoroolefin and units based on a monomer having a crosslinkable group. The polymer (B) is a fluorinated block copolymer having a segment (.alpha.) in which the content of fluorine atoms is at least 20 mass %, and a segment (.beta.) in which the content of fluorine atoms is less than 20 mass %, wherein the difference in the numerical value of the content of the fluorine atoms represented by mass %, between in the segment (.alpha.) and in the segment (.beta.) is at least 10, and at least one of the segment (.alpha.) and the segment (.beta.) has a hydroxy group. The powder coating material of the present invention is particularly useful for coating of plumbing wall material for kitchen, bathroom, wash room, toilet, etc., surface material for storage furniture such as a cupboard, etc., road signs such as traffic lights, etc., exterior members for construction such as an aluminum composite panel, an aluminum panel curtain wall, an aluminum frame for curtain wall, an aluminum window frame, etc., exterior members for e.g. oil tanks, natural gas tanks, ceramic building materials, housing exterior materials, automobile parts, aircraft members, railway vehicle members, solar cells back seat members, wind power towers, wind power blades, etc.

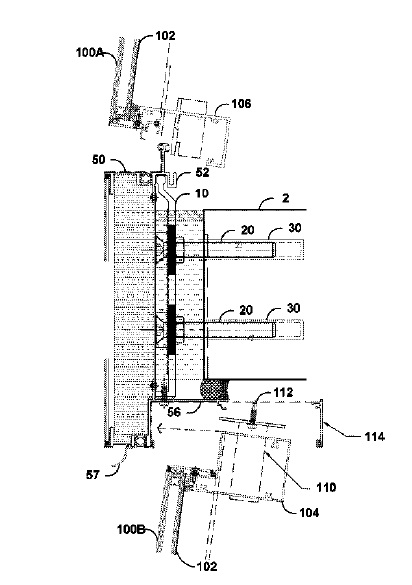

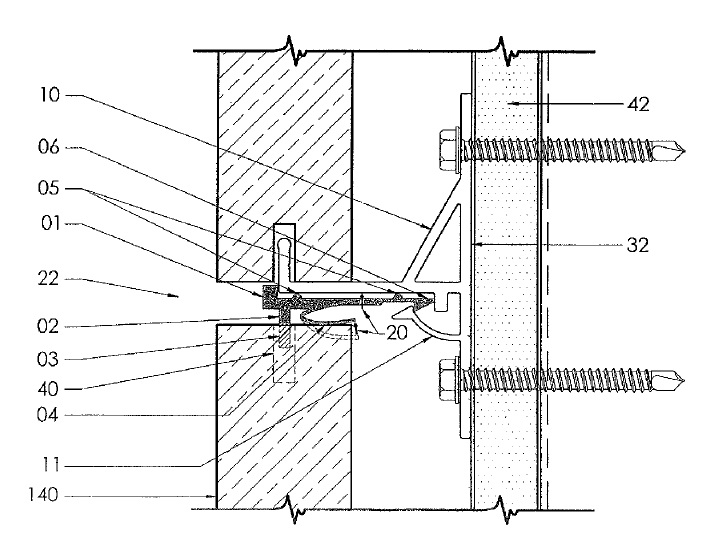

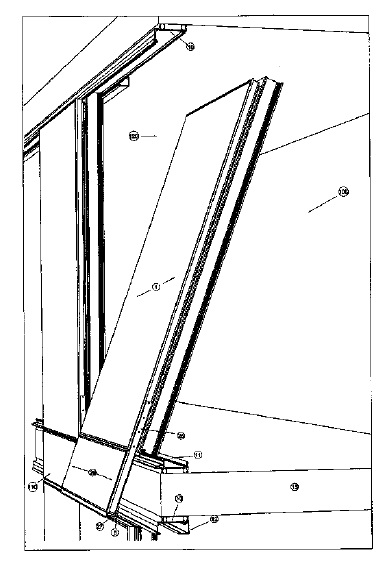

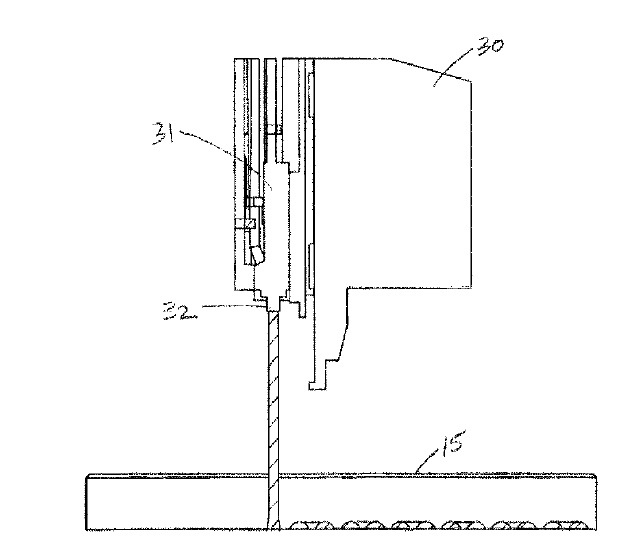

US10053859 — SYSTEMS AND METHODS FOR PROVIDING A WINDOW WALL WITH FLUSH SLAB EDGE COVERS — Reflection Window Company, LLC (USA) — Certain embodiments provide systems and methods for providing a window wall with flush slab edge covers, wherein at least one is made of aluminum extrusions. A window wall system can include a sill receptor configured to fixably attach to a top surface of a slab. The window wall system may include a head receptor configured to fixably attach to an underside surface of the slab. The window wall system can include a window wall panel including panel infill and a panel sill configured to detachably couple to the sill receptor. The window wall system may include a slab edge cover including cover infill. The slab edge cover can be configured to detachably couple to the window wall panel and the head receptor. In various embodiments, an exterior surface of the panel infill and an exterior surface of the cover infill are configured to flushly align when the slab edge cover is detachably coupled to the window wall panel.

US10035916 — COMPOSITION FOR POWDER COATING MATERIAL, POWDER COATING MATERIAL, AND COATED ARTICLE — Asahi Glass Company, Limited (Japan) — To provide a composition for powder coating material which can be sufficiently pulverized, and with which a powder coating material capable of forming a coating film excellent in weather resistance and adhesion to the substrate can be obtained; a powder coating material capable of forming a coating film excellent in weather resistance and adhesion to the substrate; and a coated aluminum article having a coating film excellent in weather resistance and adhesion to the substrate, on its surface. A composition for powder coating material comprising a polyvinylidene fluoride (A) having a melting point of from 151 to 200°C, and an acrylic resin (B) having a glass transition temperature of from 40 to 90°C. A powder coating material comprising the composition for powder coating material, and a coated article having a coating film formed of the powder coating material.

US10017939 — FIRE-RESISTANCE-RATED THERMALLY INSULATING AND SEALING SYSTEM FOR USE WITH CURTAIN WALL STRUCTURES — Hilti Aktiengesellschaft (Liechtenstein) — A construction for effectively thermally insulating and sealing of a safing slot between a floor of a building and an exterior wall construction is disclosed. The exterior wall construction includes a curtain wall configuration defined by an interior wall glass surface including one or more aluminum framing members, where the vision glass extends to the finished floor level below. The thermally insulating and sealing system includes an offset leg framing element for receiving the insulating elements and positioned in the zero spandrel area of a glass curtain wall construction including only vision glass to maintain thermally insulating and sealing of the safing slot during exposure to fire and heat in order to maintain a complete seal extending across the safing slot.

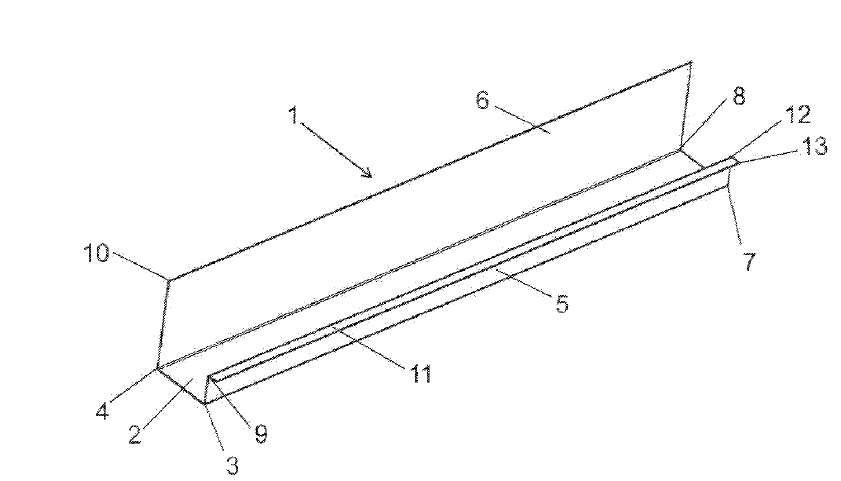

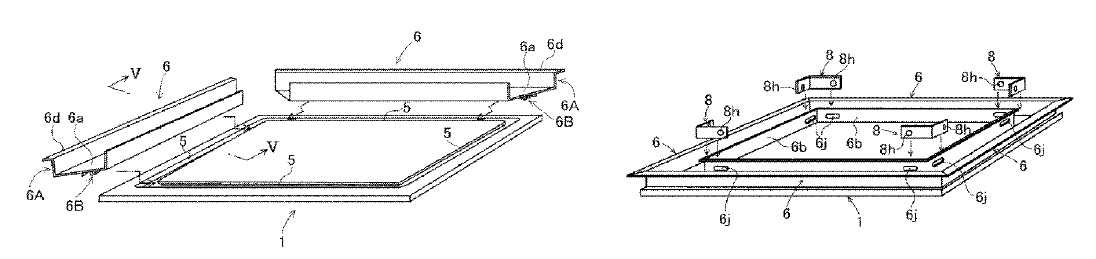

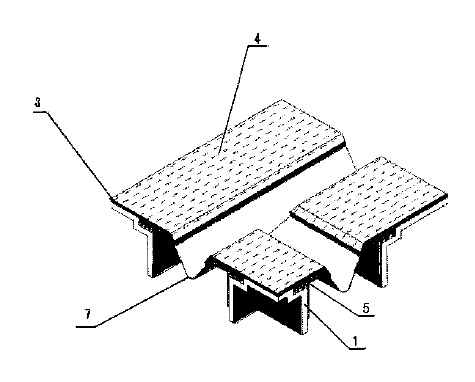

US9988820 — PANEL CONSTRUCTION MEMBER AND MOUNTING STRUCTURE THEREOF — Mitsubishi Chemical Corporation (Japan) — Provided are a panel construction member and a mounting structure for the same that can be rigidly mounted to a building and for which the panel, after being mounted, has excellent flexural strength and flexural rigidity. A panel construction member 1 has a layered structure in which a core plate 4 is disposed between a pair of metal plates 2, 3, made of aluminum, steel such as stainless steel or Galvalume steel plate, titanium, or the like wherein the panel construction member 1 is provided with a groove 5 that extends along at least one pair of edges of the panel construction member 1, and an undercut portion 5a that penetrates between the metal plates 2, 3 from the groove 5. A rail member 6 is mounted in the groove 5 of the panel construction member 1, and the panel construction member 1 is mounted to a ceiling or a wall by means of the rail member 6.

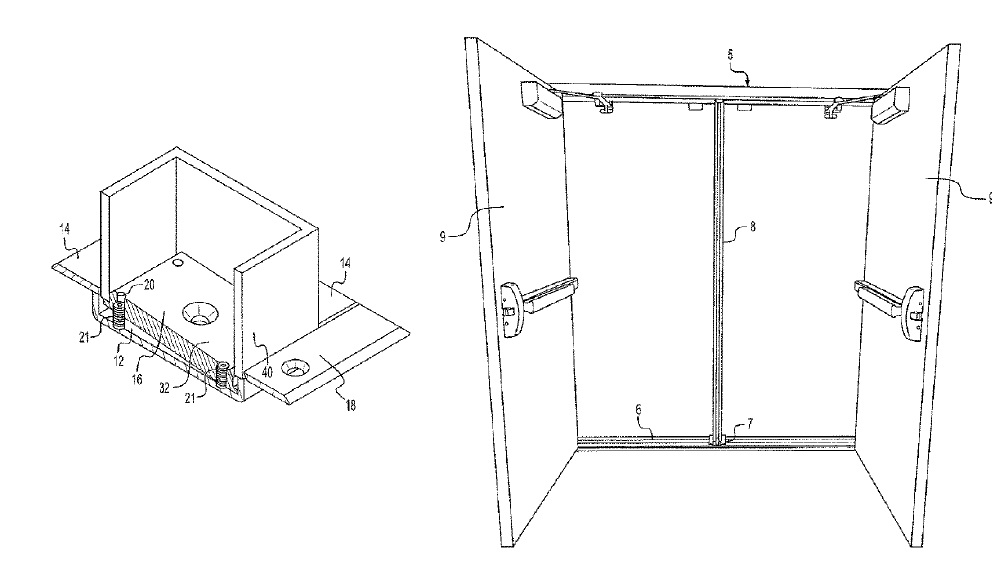

US9982476 — ADJUSTABLE MULLION RECEPTACLE — Frame & Mullions LLC (USA) — The invention is an adjustable removable mullion receptacle box that is flush mounted either directly into the floor or into a threshold at the center of an opening where a pair of doors meet. A removable mullion is a hollow rectangular steel or aluminum post that fits into the adjustable box behind the doors in a building or room and is locked or fastened into place to the frame header at the top of the mullion. The mullion can be temporarily removed when a wider opening is needed. An adjustable mullion receptacle includes a two-sided safety block adapted to sit in the well portion of the mullion receptacle. A receiving block face side of the block is adapted to fit into the hollow bottom of a hollow mullion tube. The opposite side of the block defines a smooth safety face that can be used to set in the receptacle well when the mullion is removed for any purpose. The block then fills the well and provides a smooth surface over the receptacle well.

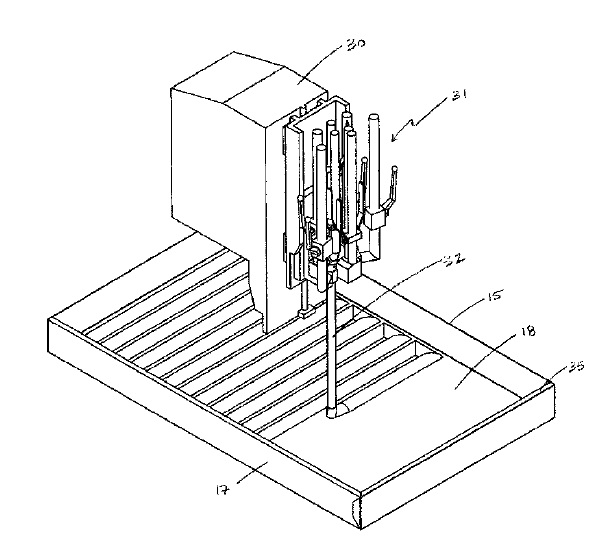

US9970194 — APPARATUS AND METHOD FOR MANUFACTURING INSULATED WALL PANELS — Lenmak Exterior Innovations Inc. (USA) — The present invention relates to an apparatus and method for manufacturing unitary insulated wall panels, wherein the panels are made of aluminum or steel and form a cavity for receiving expandable foam insulation, and form integral attachment means for attaching the panel to a building wall system, i.e., an exterior wall panel, or curtain wall, or back panel. Unitary foam insulated panels having integral attachment means are further provided.

US9926736 — ADJUSTABLE DOOR FRAME — Frame & Mullions, LLC (USA) — A door frame assembly includes integral shim screws in the vertical jambs, which may be made of aluminum or steel or fiberglass and that facilitate installation of the assembly into a rough opening or doorway. The vertical frame jambs have one or more holes therethrough. Shim screws are positioned in those apertures and are adjustably extendable outwardly therefrom to engage a rough opening to assist in fixing the frame in that opening.

US9909306 — MANUFACTURES, METHODS AND STRUCTURES TO REDUCE ENERGY TRANSFER IN BUILDING CURTAIN WALLS — Arconic, Inc. (USA) — A manufacture and method for reducing thermal transfer through window systems has a composite window cap retainer. The retainer has an aluminum extrusion at least partially covered by a thermal spacer having reduced relative thermal conductivity. The thermal spacer is mechanically supported by the metal extrusion and mechanically intermediates and thermally insulates between the cap and the metal window structures to which the cap is secured, reducing thermal transfer between the inside and outside environments of a building.

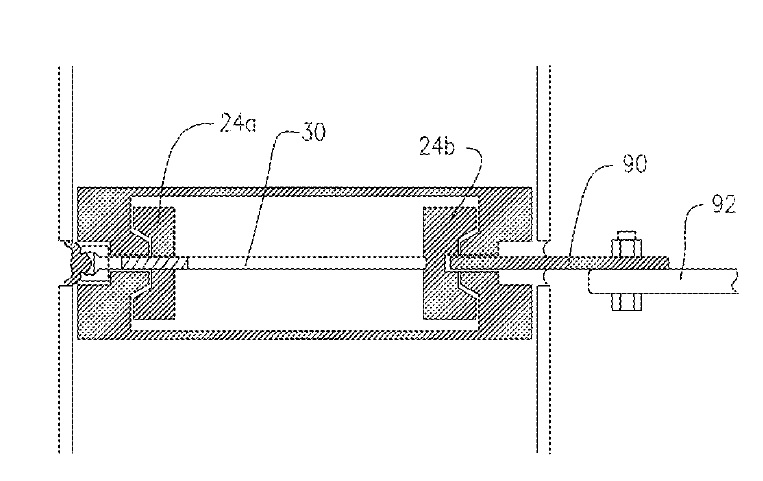

US9903113 — THERMAL BREAK FOR CURTAIN WALL — Pella Corporation (USA) — A curtain wall panel includes frame with a first frame member defining a channel, a cover configured to extend over the first frame member, a spacer formed of a thermally insulating material, the spacer including a first end, a body, and a second end, the first end being configured to be secured in the channel of the first frame member in a cammed interference fit by rotating a body of the spacer, and the second end being configured to form a cammed interference fit with the cover. An insert is supported from the first frame member by the spacer with the cover fit onto the spacer to capture and secure the insert relative to the frame. The mullions, sill, head, intermediate member, and covers are optionally formed of extruded aluminum or other material as desired.

US9897888 — SPACERS FOR INSULATED GLASS UNITS — View Inc. (USA) — This disclosure provides spacers for smart windows. In one aspect, a window assembly includes a first substantially transparent substrate having an optically switchable device on a surface of the first substrate. The optically switchable device includes electrodes. A first electrode of the electrodes has a length about the length of a side of the optically switchable device. The window assembly further includes a second substantially transparent substrate a metal spacer between the first and the second substrates. The metal spacer has a substantially rectangular cross section, with one side of the metal spacer including a recess configured to accommodate the length of the first electrode such that there is no contact between the first electrode and the metal spacer. A primary seal material bonds the first substrate to the metal spacer and bonds the second substrate to the metal spacer.

US9714511 — APPARATUS AND METHOD FOR MANUFACTURING INSULATED WALL PANELS — Lenmak Exterior Innovations Inc. (USA) — The present invention relates to an apparatus and method for manufacturing unitary insulated wall panels, wherein the panels are made of aluminum or steel and form a cavity for receiving expandable foam insulation, and form integral attachment means for attaching the panel to a building wall system. Unitary foam insulated panels having integral attachment means are further provided.

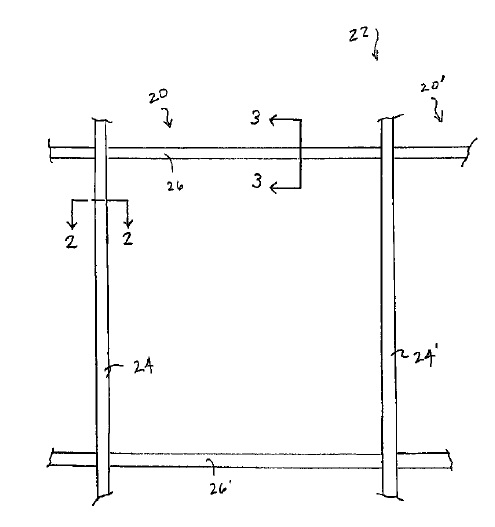

US9708781 — BARRIER WALL AND METHOD OF FORMING WALL PANELS BETWEEN VERTICAL WALL STIFFENERS WITH SUPPORT MEMBERS EXTENDING PARTIALLY THROUGH THE WALL PANELS — Mute Wall Systems, Inc. (USA) — A sound barrier wall has a plurality of footings spaced apart and vertical “I” beam wall stiffeners mounted to the footings. Alternatively, the vertical wall stiffeners are mounted to a crash barrier. A horizontal wall stiffener can be disposed between the adjacent vertical wall stiffeners. A plurality of wall panels is vertically stacked between adjacent vertical wall stiffeners. Each wall panel includes a sound insulating block, and plurality of support members disposed on opposite sides of the sound insulating block for providing structural support. Each support member has a head portion in contact with a surface of the sound insulating block and a stem portion extending into the sound insulating block. An “I” beam can be disposed between the vertically stacked wall panels. A top cap is mounted over the vertically stacked wall panels and protective layer is formed over the wall panels and vertical wall stiffeners.

US9683376 — REMOVABLE AND REPLACEABLE COVER FOR A WINDOW SUPPORT OF A CURTAIN WALL — A. Zahner Company (USA) — A substantially vertically extending removable and replaceable cover and a substantially horizontally extending cover for use with a curtain wall system broadly comprising an array of windows, a set of vertical and horizontal mullions that may be made of aluminum extrusions, and a set of window gaskets. The covers overlay the mullions and each include a front side, left and right or top and bottom sides, and rear tabs extending therefrom for removably connecting the covers on the mullions.

US9670679 — PANEL AND MOUNTING SYSTEM — West Tampa Glass Company (USA) — A composite panel system for attaching to a wall system includes a layer of continuous insulation covering the wall system and a plurality of vertical girts affixed the wall system such that the continuous insulation lays between the wall system and the vertical girts. Composite panels are mounted to a perimeter frame of aluminum extrusions, generally two horizontal and two vertical extrusions. The panel frame horizontal extrusions are mounted to the vertical girts by fasteners. In some embodiments, gypsum and a membrane are used in lieu of continuous insulation.

US9670669 — MODULAR BUILDING CONSTRUCTION SYSTEM — DIRTT Environmental Solutions, Ltd. (Canada) — Implementations of the present invention relate to systems, methods, and apparatus for constructing a building. More specifically, the present disclosure provides an interlocking wall system that can allow a builder to accurately position, orient, and/or secure various structural wall modules. The wall-side connectors can comprise material that can be the same as or different from the material of the supporting webbing, which can comprise metal such as steel or aluminum. Additionally, this disclosure provides systems and methods for securing one or more cladding layers to the building’s envelope. Furthermore, implementations of the present disclosure can allow for quick and modifiable installation of utility and communication lines within the building.

US9663946 — CURTAIN WALL MULLIONS, TRANSOMS AND SYSTEMS — FreMarq Innovations, Inc. (USA) — A curtain wall mullion or transom including a unitary component made of a thermally insulating material bonded to a metal structural segment or fastened, from the inside-out, to an outer side of the metal segment such that a stem of the component extends into a pocket defined by panels of a curtain wall system. The component may be a reinforced fiberglass polymer component and bonded to the metal segment with an adhesive and may isolate the metal structure from the atmosphere outside the curtain wall and may include a seal receiver which abuts a panel of the curtain wall. The metal segment may be made of steel or aluminum or other metal. A pultrusion method is used to make the fiberglass component to have a profile configured to cover an entirety of an outside of the mullion or transom and to have a pair of receivers for receiving seals to abut against panels of the curtain wall.

US9663945 — SYSTEMS AND METHODS FOR PROVIDING A WINDOW WALL WITH FLUSH SLAB EDGE COVERS — Reflection Window Company, LLC (USA) — Certain embodiments provide systems and methods for providing a window wall with flush slab edge covers, wherein one slab edge cover is an aluminum extrusion. A window wall system can include a sill receptor configured to fixably attach to a top surface of a slab. The window wall system may include a head receptor configured to fixably attach to an underside surface of the slab. The window wall system can include a window wall panel including panel infill and a panel sill configured to detachably couple to the sill receptor. The window wall system may include a slab edge cover including cover infill. The slab edge cover can be configured to detachably couple to the window wall panel and the head receptor. In various embodiments, an exterior surface of the panel infill and an exterior surface of the cover infill are configured to flushly align when the slab edge cover is detachably coupled to the window wall panel.

US9617733 — CURTAIN WALL ELEMENTS — A. & D. Prevost Inc. (USA) — A curtain wall structure that can provide a continuous sealing plane through the use of a dual density gasket and that offers improved sealing and thermal insulation properties. Air and water weatherproofing by means of the compression of the dual density foam provides for air and water weatherproofing using specifically designed gaskets on both the inside aluminum profiles making up the expansion joint and the specific pressure plate presenting a mechanical expansion assembly allowing for vertical displacement of up to 38 mm. The curtain wall structure also provides a structural reinforcement element assembly that is integrated into a mullion of the curtain wall structure to provide a better load bearing capacity. The aluminum portion of the mullion is designed in a manner such that it has the ability to accept the screws holding the pressure plate or any other external means of holding down the glass units, thus keeping intact and not breaking the insulation assembly, as none of the surfaces of either the mullion or pressure plate is exposed to the drained cavity. A curtain wall water drainage cross element assembly is also provided to prevent water from flowing vertically inside the curtain wall system. An expansion joint assembly is also provided and designed as two movable parts allowing provides a sound free vertical displacement of components by means of no direct metal to metal contact between sliding parts.

US9611642 — EXTERIOR OPAQUE HIDDEN FRAME WALL UNIT — Advanced Building Systems, Inc. (USA) — This invention is related to the building envelope system design applicable to an exterior wall design such as a curtain wall system or a window wall system. Exterior opaque hidden frame wall units and systems combining facing plates and composite insulated panels in a pressure-equalized Airloop system, permitting an opaque hidden frame wall unit without the need for intermediate stiffeners for resisting wind load, without exterior aesthetic problems associated with composite insulated panels, without a separate interior wall, and without interior condensation problems. Also provided are exterior opaque hidden frame Airloop wall units and systems with the air seal being isolated from the water seal on an offset vertical plane and away from the interior surface of the facing plate. The most commonly used material for the frame members are aluminum extrusions. Popular facing plate materials include aluminum plate, ACM (aluminum composite material), single pane spandrel glass, and finished natural stone.

US9567746 — CURTAIN WALL SYSTEM WITH ANTI-ROLLING SHEAR BLOCK — Arconic Inc. (USA) — A curtain wall has a plurality of hollow, extruded vertical and horizontal members. The members have a pair of spaced retainer walls which engage a shear block with a pair of tabs that twist locks onto the retainer walls before fastening the block to the member. A second member slips over the block and is fastened by screws. The abutment of the tabs limits rotation of the block and attached member, providing support for a glazing panel attached to the members. The members have longitudinal recesses accommodating wiring that may be covered with a cover. A bracket interacting with the retainer walls like a shear block may also be used. The teachings of the present disclosure may be used to form a curtain wall that features an anti-rolling shear block and that allows easy wiring to and from the attached electrical elements. The wiring can be done before or after assembly of the curtain wall and produces an installation where the wire is fully concealed.

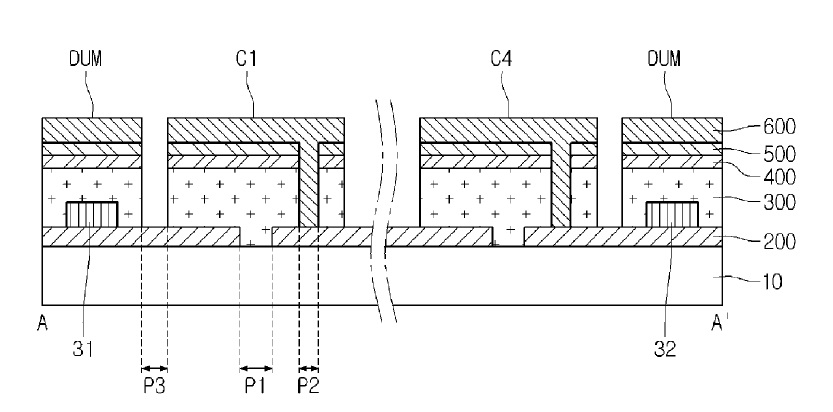

US9553213 — SOLAR CELL APPARATUS AND METHOD OF FABRICATING THE SAME — LG Innotek Co., Ltd. — Disclosed are a solar cell apparatus, and a method of fabricating the same. The solar cell apparatus includes: dummy parts disposed on a support substrate; a plurality of solar cells disposed on the support substrate and disposed between the dummy parts; and a bus bar electrically connected to the solar cells and disposed between the support substrate and the dummy parts. Each of the solar cells and the dummy parts has a back electrode layer, a light absorbing layer, and a front electrode layer sequentially disposed on the support substrate. In the solar cell apparatus according to the embodiment, the bus bar is disposed between the support substrate and the dummy. Accordingly, the solar cell apparatus according to the embodiment can prevent exposure of the bus bar to the outside without using a separate shielding unit. Thus, an aesthetic feature of the solar cell apparatus according to the embodiment can be significantly improved, and the solar cell apparatus can be easily applied to a curtain wall solar cell module, for example, used on an outer wall of a building.

US9540862 — INNER GLASS SKIN STRUCTURE FOR DOUBLE GLASS SKIN — Device Co., Ltd. (Japan) — An inner glass skin structure is configured by a sashless plate glass that overcomes the difference in the coefficients of linear expansion and insufficient rigidity of aluminum and glass having a superior design, in which the four sides of each of the sashless plate glass are covered by an aluminum covering material having narrow width. The inner glass skin structure is configured by a plurality of sashless plate glasses four sides of which are covered with an aluminum covering material, a door roller and a securing foot member respectively fixed on the bottom of each plate glass on the movable side and immovable side of the plate glass of the sliding door formation, and a lower rail member arranged underneath the plate glass and an upper rail member arranged directly above each plate glass. On the top and bottom of the plate glass, the inner face of an end face cover part of the covering material is bonded to an elastic intervening piece that is fixed to the end face of the plate glass; on both the lateral sides of the plate glass, a plurality of coupling strip plates are inserted in a coupling plate retaining section on the inner face of the end face cover part of the covering material in series with a predetermined spacing therebetween; and each coupling strip plate is bonded to an elastic intervening piece that is secured to the end face of the plate glass.

US9464435 — METAL CURTAIN WALL SYSTEM OF MONOLAYER STRUCTURE AND CONSTRUCTION METHOD THEREOF — Evergrow International Trading (Shanghai) Co., Ltd. (China) — Disclosed are a metal curtain wall system of a monolayer structure and a construction method thereof. The metal curtain wall system comprises a plurality of composite material curtain wall units (1) that are produced in a numerical control manner and have complex models. The plurality of composite material curtain wall units (1) is spliced to form an inner-outer wall body model. Embedded members (2) are arranged in the composite material curtain wall units (1). Lead-out parts of the embedded members are oriented towards the inner and outer wall bodies and are fixed to inner and outer wall bodies. The composite material curtain wall units (1) in vertical adjacency are arrayed in a staggered manner. An elastic structural adhesive (3) is coated on surfaces of the composite material curtain wall units (1). Thin-type metal sheets (4) are covered on the elastic structural adhesive (3). The metal curtain wall system can be produced continuously in a numerical control manner in the production and manufacturing process. The precision of hyperbolic metal is improved in the environment-friendly and energy-saving manufacturing process. With a simple and mature process, the construction difficulty and the construction cost are reduced; resources or space is saved; and the complex digital building project is improved to the rank of the modern scientific and technical industry.

US9464432 — METHOD AND SYSTEM FOR IMPROVED CURTAIN WALL SEALING — Oldcastle BuildingEnvelope, Inc. (USA) — In one aspect, the present invention relates to a plug of the type utilized for sealing a junction between a horizontal member and a vertical mullion of a curtain wall. The plug may include a plug body. The plug body may include a front body portion, a rear body portion, a left body portion, a right body portion, a top surface disposed between the left body portion, the right body portion, the front body portion, and the rear body portion. A rabbet is disposed across the front body portion. A spacer flange extends from the front body portion. A plurality of chamfers are disposed between the top surface and the left body portion, the right body portion, and the rear body portions. The plug is sized to occupy a gap formed in the junction between the horizontal member and the vertical mullion of the curtain wall. The rabbet and the plurality of chamfers form a plurality of large crevices between the plug, the horizontal member, and the vertical mullion. The large crevices allow penetration of a sealant therein.

US9453362 — SHELTER CURTAIN WALL SYSTEM — West Tampa Glass Company (USA) — A curtain wall system includes a plurality of laminated glass sections or insulated-laminated glass sections, held within a plurality of horizontal aluminum extrusions and vertical aluminum extrusions. Each laminated glass section includes glass reinforcing bars having a flat bar shape. For insulated-laminated glass, the reinforcing bars have a cross-sectional shape of a `Z` such that a top cap of the glass reinforcing bars extends over the glass section and a bottom cap of the glass reinforcing bars extends over an opposing side. The laminate glass has a layer of glass, a layer of thermoplastic polymer, another layer of glass and a safety shield. The insulated-laminated glass has an outer layer of glass, a gap, a first inner layer of glass, a layer of thermoplastic polymer, a second inner layer of glass and a safety shield. Such curtain wall systems resist wind loads and wind borne debris from ultimate hurricanes and tornadoes.

US9371646 — THERMAL BREAK FOR CURTAIN WALL — Pella Corporation (USA) — A curtain wall panel includes frame with a first frame member defining a channel, a cover configured to extend over the first frame member, a spacer formed of a thermally insulating material, the spacer including a first end, a body, and a second end, the first end being configured to be secured in the channel of the first frame member in a cammed interference fit by rotating a body of the spacer, and the second end being configured to form a cammed interference fit with the cover. An insert is supported from the first frame member by the spacer with the cover fit onto the spacer to capture and secure the insert relative to the frame. The mullions, sill, head, intermediate member, and covers are optionally formed of extruded aluminum material or other material as desired.

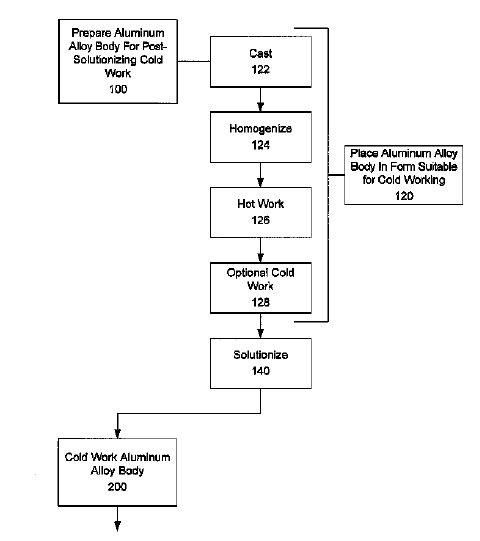

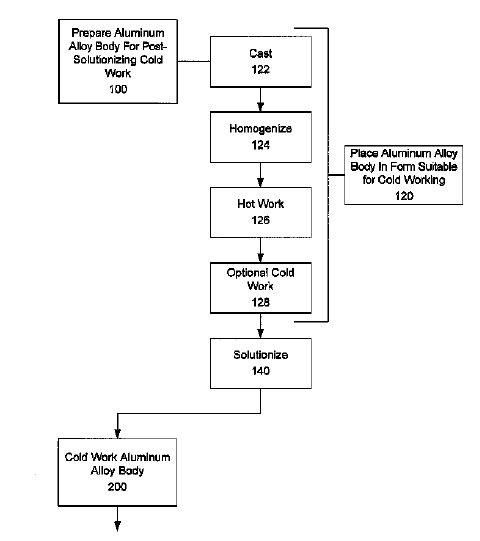

US9359660 — 6XXX ALUMINUM ALLOYS, AND METHODS FOR PRODUCING THE SAME — Alcoa Inc. (USA) — New 6xxx aluminum alloy bodies and methods of producing the same are disclosed. The new 6xxx aluminum alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new 6xxx aluminum alloy bodies may realize improved strength and other properties.