Editor’s Note: Various aspects of aluminum casthouse technology appear in almost every issue of Light Metal Age, no doubt because it is the first step and an important link in the wrought aluminum processing chain required for subsequent downstream processing and production of quality product. With no exception, the international patent survey presented here focuses on inventions covering the full scope of aluminum casthouse technology. This includes equipment and practices in DC and continuous casting of wrought aluminum alloys (for example, stirrers, flow controls, coolant controls, impurity removal, DC molds, heat retaining ladles, etc.) as well as a look at how aluminum casting practices in DC and continuous casting affect the product quality of everything from large ingot and slab to wire and fin stock. Some patents cover methods of preparing and casting special aluminum alloys, such as grain refiners and composites. Also, inventions relating to preventing aluminum-water explosions in the DC casting of Al-Li alloys are covered.

Aluminum casting practices affect all downstream operations, mainly as a result of the metallurgy of formation of coarse grains and primary intermetallics formed in casting. Cast grain size can be transformed by suitable grain refinement and casting rate to result in a fine grain crystal structure (fine dendritic arm spacing as well as fine grain size). Whether aluminum alloys are DC cast or continuously cast by twin roll, Properzi, or belt casting, grain size and primary intermetallic particle size and distribution are affected by the cooling rate during casting.

It is known that downstream plastic working and thermal treatments can turn the coarse cast grains into fine recrystallized grains; however, traces of the microstructure (including original orientations of the coarse crystal grains) remain and are visible in the metal flow pattern, especially if grain size and cooling rate control in casting is absent. Various patents hereafter demonstrate the importance of grain refining and cooling rate during casting for attaining high quality product, not just in terms of good mechanical properties, but also in relation to post processing, such as achieving a desired anodized finish. Also, the ultrasonic processing patents covered here include means of grain refining aluminum alloy melts as well minimizing segregation and degassing.

To be sure, many aluminum casthouses maintain piles of aluminum scrap for processing and remelting; however, the patent survey here does not cover this topic, except summarily as part of the general focus on wrought aluminum casting inventions. For interested readers, the focus of International Patents on Aluminum Recycling and Recovery has been covered in the August 2019 patent section.

— Joseph C. Benedyk, Editor

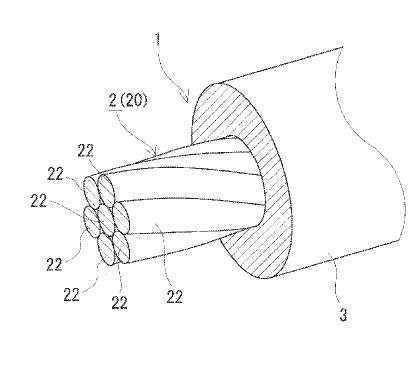

US10522263 — ALUMINUM ALLOY WIRE, ALUMINUM ALLOY STRAND WIRE, COVERED ELECTRICAL WIRE, AND TERMINAL-EQUIPPED ELECTRICAL WIRE — Sumitomo Electric Industries, Ltd., AutoNetworks Technologies, Ltd., and Sumitomo Wiring Systems, Ltd. (Japan) — An aluminum alloy wire composed of an aluminum alloy, wherein the aluminum alloy contains more than or equal to 0.03 mass % and less than or equal to 1.5 mass % of Mg, more than or equal to 0.02 mass % and less than or equal to 2.0 mass % of Si, and a remainder of Al and an inevitable impurity, Mg/Si being more than or equal to 0.5 and less than or equal to 3.5 in mass ratio, and the aluminum alloy wire has a dynamic friction coefficient of less than or equal to 0.8. When the voids in the surface layer is small and preferably when the sizes of the crystallized materials are also small, the Al alloy wire has excellent impact resistance and fatigue characteristic. By employing, as a base material, the cast material including such a small amount of the dissolved gas such as dissolved hydrogen, the state with the small amount of voids resulting from the dissolved gas in the Al alloy is readily maintained after casting by lowering the melt temperature so as to sufficiently reduce the voids included in the cast material. Both continuous casting and billet casting can be utilized. In the continuous casting, a long cast material can be manufactured continuously and the cooling rate can be readily increased, whereby the reduction of voids, the suppression of the coarse crystallized materials, the attainment of fine crystal grains or fine dendritic arm spacing, the dissolution of the added element in the solid state, and the formation of the supersaturated solid solution (thereby eliminating the need for solution heat treatment) depending on a cooling rate.

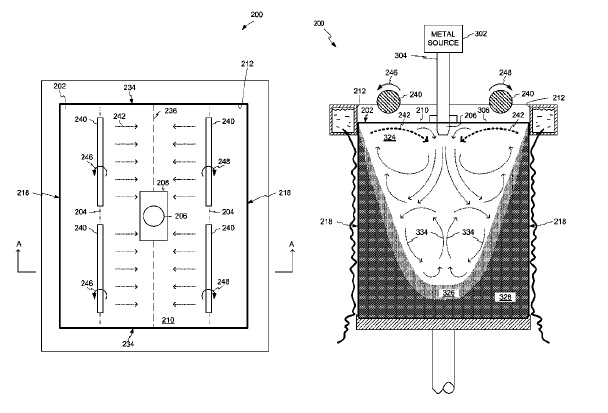

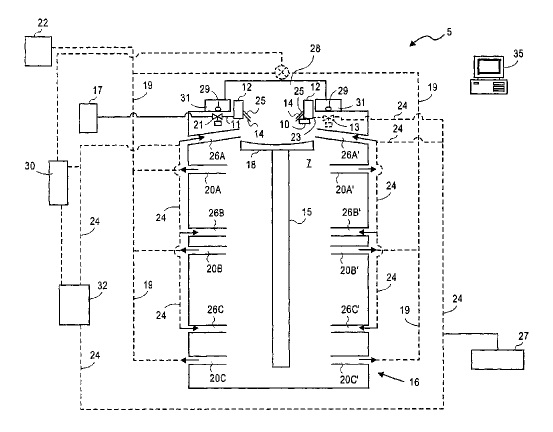

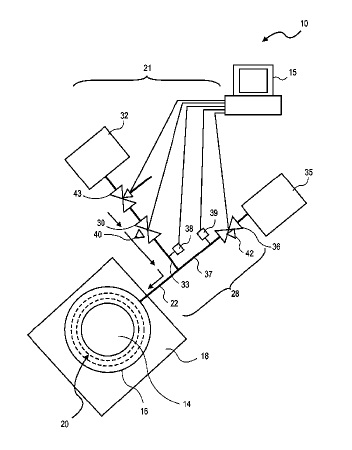

US10464127 — NON-CONTACTING MOLTEN METAL FLOW CONTROL — Novelis Inc. (USA) — Systems and methods are disclosed for using magnetic fields (e.g., changing magnetic fields) to control metal flow conditions during aluminum casting (e.g., casting of an ingot, billet, or slab). Successful mixing of aluminum includes challenges not present in other metals. Contact mixing of aluminum can result in the formation of structure-weakening oxides and inclusions that result in an undesirable cast product. Non-contact mixing of aluminum can be difficult due to the thermal, magnetic, and electrical conductivity characteristics of the aluminum. The magnetic fields can be introduced using rotating permanent magnets or electromagnets. The magnetic fields can be used to induce movement of the molten metal in a desired direction, such as in a rotating pattern around the surface of the molten sump. The magnetic fields can be used to induce metal flow conditions in the molten sump to increase homogeneity in the molten sump and resultant ingot.

US10461441 — ALUMINUM ALLOY ELEMENT WIRE, ALUMINUM ALLOY STRANDED WIRE AND METHOD FOR PRODUCING ALUMINUM ALLOY STRANDED WIRE, AUTOMOTIVE ELECTRIC WIRE, AND WIRE HARNESS — Autonetworks Technologies, Ltd., Sumitomo Wiring Systems, Ltd., and Sumitomo Electric Industries, Ltd. (Japan) — An aluminum alloy element wire has a chemical composition including in mass percent: Mg: 0.3% or more and 0.9% or less, Si: 0.1% or more and 0.7% or less, Fe: 0.1% or more and 0.4% or less, at least one element selected from the group consisting of Cu, Cr, Ni, and Zr: 0.01% or more and 0.5% or less in total, and the balance being Al and unavoidable impurities. Casting can be performed employing any one of the casting techniques, however, continuous casting makes it possible to rapidly cool and solidify the molten metal, and thus is advantageous for producing a cast material of a fine crystal structure. When such a cast material is used as a raw material, it is made easy to produce an aluminum alloy stranded wire including an aluminum alloy element wire of a fine crystal structure with improved strength and enhanced wire drawability. The aluminum alloy element wire has a surface roughness Ra in the range of 0.15 µm or more and 2 µm or less as measured with a non-contact surface roughness measuring machine. An aluminum alloy stranded wire includes a plurality of the aluminum alloy element wires twisted together. An automotive electric wire includes the aluminum alloy stranded wire. A wire harness includes the automotive electric wire, and a terminal crimped to the aluminum alloy stranded wire of the automotive electric wire.

US10460849 — LIGHTWEIGHT, HIGH-CONDUCTIVITY, HEAT-RESISTANT, AND IRON-CONTAINING ALUMINUM WIRE, AND PREPARATION PROCESS THEREOF — Central South University (China) — The present invention relates to the technical field of electrical engineering materials, and to an aluminum wire for power lines and electrical cables, and specifically, to a lightweight, high-conductivity, heat-resistant, and iron-containing aluminum wire used for overhead power supply and power transformation lines, and a preparation process thereof. The aluminum wire is mainly composed of aluminum, boron, zirconium, iron, lanthanum, and inevitable impurity elements, and the preparation process for the wire is as follows: melting industrial pure aluminum; then adding intermediate alloys of boron, zirconium, iron, and lanthanum to the melt; performing stirring, refining, furnace front component rapid analysis, component adjustment, standing, de-slagging, and rapid cooling casting to obtain an aluminum alloy blank; and performing annealing, extrusion, and drawing on the cast blank to obtain an aluminum alloy monofilament. The wire obtained has density less than or equal to 2.714 g/cm3, electrical conductivity greater than or equal to 62% IACS, a short-term heat-resistance temperature as high as 230°C, a long-term heat-resistance temperature as high as 210°C, and tensile strength greater than or equal to 170 MPa.

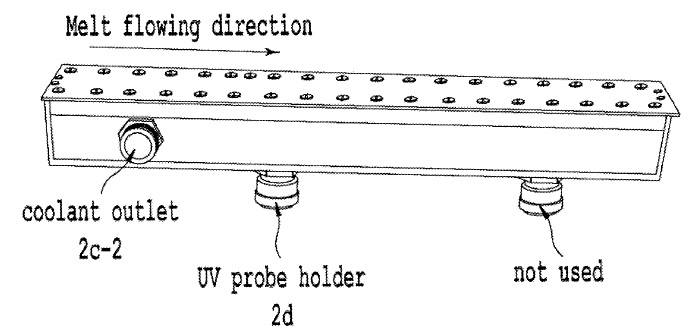

US10441999 — ULTRASONIC GRAIN REFINING — Hans Tech, LLC (USA) — Grain refining of metals and alloys is important for many reasons, including maximizing ingot casting rate, improving resistance to hot tearing, minimizing elemental segregation enhancing mechanical properties, particularly ductility, improving the finishing characteristics of wrought products and increasing the mold filling characteristics, and decreasing the porosity of foundry alloys. Usually grain refining is one of the first processing steps for production of metal and alloy products, especially aluminum alloys and magnesium alloys. The present invention is related to a method for producing metal castings with controlled grain size, a system for producing the metal castings, and products obtained by the metal castings. A molten metal processing device including a molten metal containment structure for reception and transport of molten metal along a longitudinal length thereof. The device further includes a cooling unit for the containment structure including a cooling channel for passage of a liquid medium therein, and an ultrasonic probe which operates at 5-40 kHz disposed in relation to the cooling channel such that ultrasonic waves are coupled through the liquid medium in the cooling channel and through the molten metal containment structure into the molten metal.

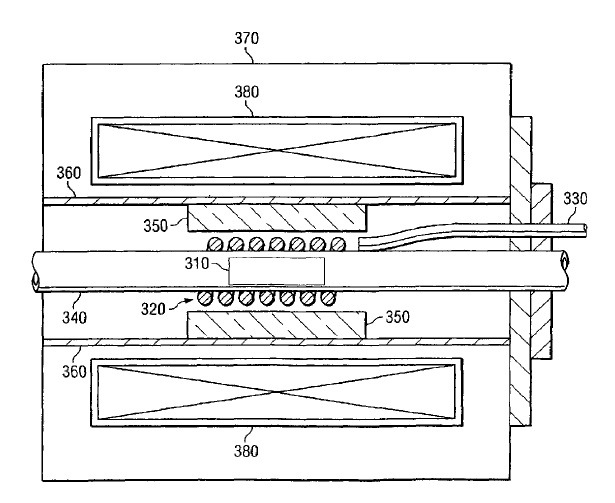

US10145630 — ALUMINUM ALLOY FIN MATERIAL FOR HEAT EXCHANGERS, AND METHOD OF PRODUCING THE SAME — UACJ Corporation (Japan) — An aluminum alloy fin material for heat exchangers, containing 0.5 to 1.5 mass % of Si; 0.1 to 1.0 mass % of Fe; 0.8 to 1.8 mass % of Mn; and 0.4 to 2.5 mass % of Zn, with the balance being Al and unavoidable impurities, wherein a metallographic microstructure before braze-heating is such that a density of second phase particles having a circle-equivalent diameter of less than 0.1 µm is less than 107 particles/mm2, and that a density of second phase particles having a circle-equivalent diameter of 0.1 µm or more is 5 x 104 particles/mm2 or more, achieved by means of a twin roll-type continuous casting and rolling method. In a twin roll-type continuous casting and rolling method, the cooling speed at the time of casting is larger by several times to several hundred times than that of a DC or a twin belt-type continuous casting method so the crystallization products, for example, of Al-Fe-Si-based, Al-Fe-Mn-based, and Al-Fe-Mn-Si-based compounds produced at the time of casting, are dispersed more finely and more densely, as compared to the DC or the twin belt-type continuous casting and rolling method.

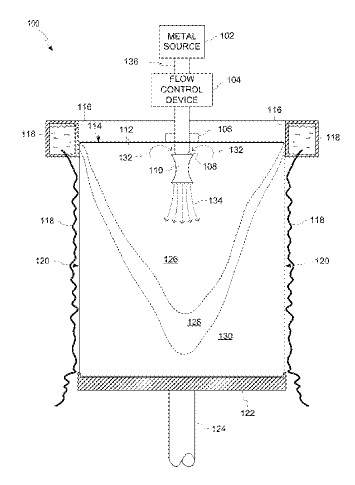

US10118221 — MIXING EDUCTOR NOZZLE AND FLOW CONTROL DEVICE — Novelis Inc. (USA) — Successful mixing of aluminum includes challenges that are not present in other metals. Contact mixing of aluminum can result in the formation of structure-weakening oxides and inclusions that result in an undesirable cast product, while non-contact mixing of aluminum can be difficult due to the thermal, magnetic, and electrical conductivity characteristics of the aluminum. Techniques are disclosed for reducing macro-segregation in metals and, in particular, aluminum alloys. Techniques include providing an eductor nozzle capable of increasing mixing in the fluid region of an ingot being cast. Techniques also include providing a non-contacting flow control device to mix and/or apply pressure to the molten metal that is being introduced to the mold cavity. The non-contacting flow control device can be permanent magnet or electromagnet based. Techniques additionally can include actively cooling and mixing the molten metal before introducing the molten metal to the mold cavity.

US9950360 — PROCESS AND APPARATUS FOR MINIMIZING THE POTENTIAL FOR EXPLOSIONS IN THE DIRECT CHILL CASTING OF LITHIUM ALLOYS — Almex USA, Inc. (USA) — It has been demonstrated that the explosive forces associated with adding lithium to aluminum alloys can increase the nature of the explosive energy several times than for aluminum alloys without lithium when the molten Al-Li alloy comes in contact with water. Thus, there remains a need for safer, less maintenance prone and more cost-effective apparatus and processes for casting Al-Li alloys that will simultaneously produce a higher quality of the cast product. The subject invention describes an apparatus and a system including a casting pit; a mold including a reservoir and a cavity; a coolant feed operable to introduce a coolant to a periphery of a metal emerging from the mold cavity; an array of water vapor exhaust ports about at least the top periphery of the casting pit; a mechanism to introduce an inert fluid into the coolant feed. A method for a direct chill (DC) casting including, after detecting a bleed out, exhausting generated gas from the casting pit at a flow volume rate that is enhanced relative to a flow volume rate prior to detecting bleed out or run out; introducing an inert gas into the casting pit; and introducing an inert fluid into a coolant feed to the casting mold.

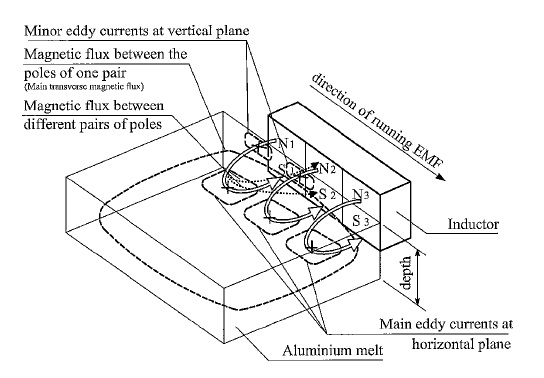

US9901978 — METHOD AND APPARATUS FOR MOVING MOLTEN METAL — Evgeny Pavlov (Russia) — This invention concerns improvements in and relating to apparatus for stirring molten metals and/or methods for stirring molten metals such as molten aluminum alloys. Methods and apparatus for moving a molten metal are provided in which the electromagnetic inductor includes at least two pairs of electromagnetic pole pairs and in which a first magnetic field component is generated between one pole in a first electromagnetic pole pair and a second pole in a different electromagnetic pole pair, and in which a second magnetic field component is generated between the two poles in one or more electromagnetic pole pairs, the second magnetic field component thereby generating one or more eddy currents in the molten metal. Those eddy currents are generally parallel to the surface of the molten metal and so have greater magnitude and extent that eddy currents perpendicular to the surface. Such eddy currents provide useful additional movement to the molten metal, for instance for stirring purposes, particularly when the depth of molten metal is small.

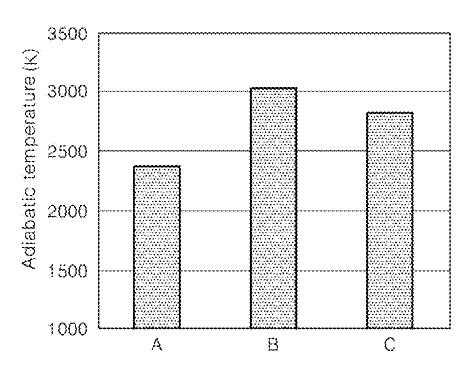

US9670568 — METHOD OF PREPARING ALUMINUM MATRIX COMPOSITES AND ALUMINUM MATRIX COMPOSITES PREPARED BY USING THE SAME — Korea Institute of Machinery & Materials (Korea) — One or more embodiments of the present invention include a method of stably preparing an aluminum composite with excellent mechanical properties while the temperature of molten aluminum is maintained at 950°C or less. A method of stably preparing an aluminum composite with excellent mechanical properties while the temperature of molten aluminum is maintained at 950°C or less, includes mixing aluminum powder, a source material for titanium, a source material for a nonmetallic element that is able to be combined with titanium to form a compound, and an active material to prepare a precursor; adding the precursor to molten aluminum; and casting the molten aluminum.

US9616493 — PROCESS AND APPARATUS FOR MINIMIZING THE POTENTIAL FOR EXPLOSIONS IN THE DIRECT CHILL CASTING OF ALUMINUM LITHIUM ALLOYS — Almex USA, Inc. (USA) — An apparatus and a system including a casting pit; a mold including a reservoir and a cavity; a coolant feed operable to introduce a coolant to a periphery of a metal emerging from the mold cavity; an array of water vapor exhaust ports about at least the top periphery of the casting pit; a mechanism to introduce an inert fluid into the coolant feed. A method for a direct chill casting including, after detecting a bleed out, exhausting generated gas from the casting pit at a flow volume rate that is enhanced relative to a flow volume rate prior to detecting bleed out or run out; introducing an inert gas into the casting pit; and introducing an inert fluid into a coolant feed to the casting mold. The instantly described apparatus and method improve the safety of DC casting of Al-Li alloys by minimizing or eliminating ingredients that must be present for an explosion to occur. It is understood that water (or water vapor or steam) in the presence of the molten Al-Li alloy will produce hydrogen gas.

US9481031 — ULTRASONIC GRAIN REFINING — Hans Tech, LLC (USA) — The present invention is related to a method for producing metal castings with controlled grain size, a system for producing the metal castings, and products obtained by the metal castings. A molten metal processing device including a molten metal containment structure for reception and transport of molten metal along a longitudinal length thereof. The device further includes a cooling unit for the containment structure including a cooling channel for passage of a liquid medium therein, and an ultrasonic probe disposed in relation to the cooling channel such that ultrasonic waves are coupled through the liquid medium in the cooling channel and through the molten metal containment structure into the molten metal.

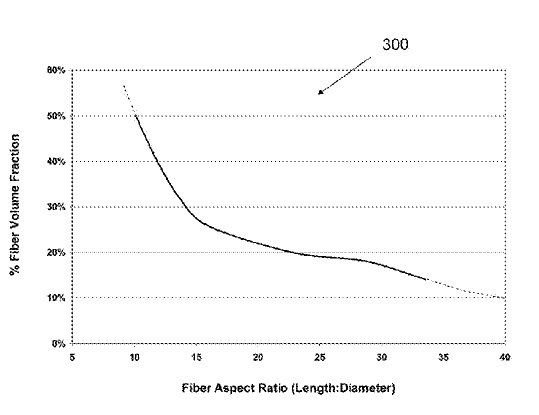

US9375783 — DISCONTINUOUS SHORT FIBER PREFORM AND FIBER-REINFORCED ALUMINUM BILLET AND METHODS OF MANUFACTURING THE SAME — Triton Systems, Inc. (USA) — Discontinuous fiber preforms, fiber-reinforced metal matrix composites, and methods of making same are disclosed. A fiber preform includes a milled ceramic fiber material such as alumina silicate having a weighted average fiber length of about 0.03 mm to 0.12 mm and/or a percent fiber volume fraction of the fiber preform of about 15% to about 55%. The milled fiber material is at least substantially free of a binder material. A fiber-reinforced MMC includes a milled fiber material having a weighted-average fiber length of about 0.03 mm to 0.12 mm and/or a percent fiber volume fraction of the fiber preform of about 15% to about 55%. The fiber-reinforced MMC further includes a metal infiltrated into the milled fiber material. The milled fiber material is at least substantially free of a binder material. The milled fiber can be substantially uniformly oriented and/or randomly oriented in the fiber preform and/or the fiber-reinforced MMC.

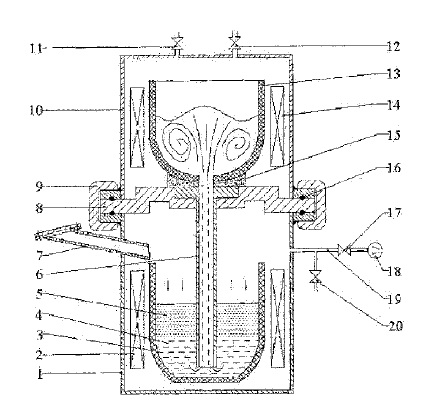

US9284622 — DEVICE AND METHOD FOR REMOVING IMPURITIES IN ALUMINUM MELT — Guangxi University (China) — A device and a method for removing impurities in an aluminum melt are provided, in which the device includes an upper furnace body, a lower furnace body, an intermediate partition plate, a crucible, heating elements and a charging opening. The intermediate partition plate is mounted between the upper furnace body and the lower furnace body. The upper furnace body, a mixing chamber and a heating element are above the intermediate partition plate. The crucible is mounted in the lower furnace body. A heating element is provided around the lower furnace body. The mixing chamber and the crucible are connected by a jet pipe passing through the intermediate partition plate. For the device and the method, impurity removal is quick, efficiency is high, and the process is closed, so there is no environmental pollution, and the aluminum melt after impurity removal may be directly cast.

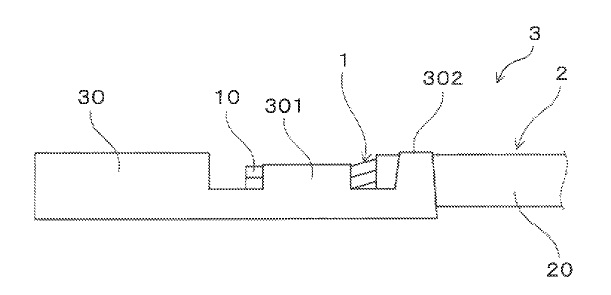

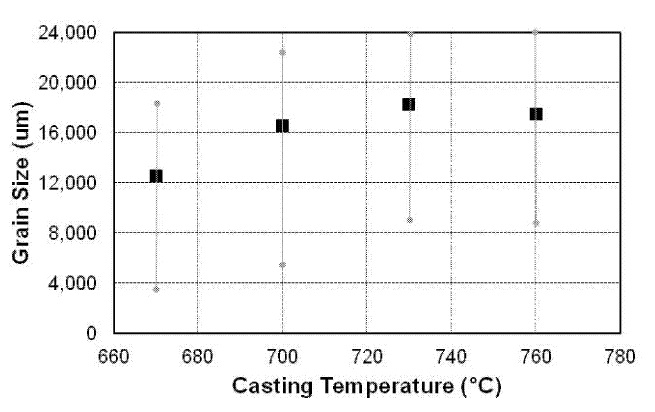

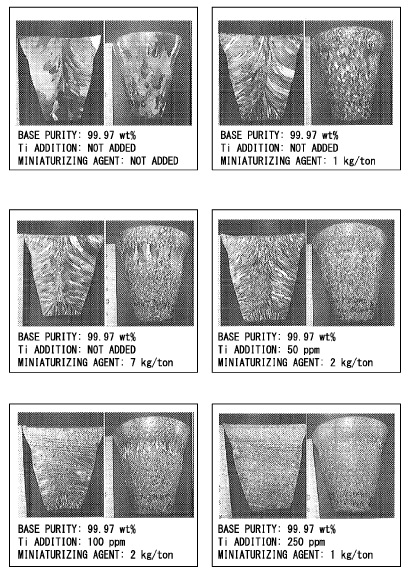

US9138936 — STAMPER, ARTICLE AND METHOD FOR MANUFACTURING THE SAME — Nippon Light Metal Company, Ltd. and Mitsubishi Rayon Co., Ltd. (Japan) — To reduce reflected light from the liquid crystal surface of a television, a mobile phone or the like by providing an antireflection structure having a fine concave-convex structure one of such methods involves forming a fine concave-convex structure through the anodizing of the surface of high purity aluminum (stamper) and transferring the fine concave-convex structure to a molding material, such as a resin. However, when high-purity aluminum having a purity of 99.9% or more is simply cast, crystal grains are liable to become coarse and when the surface of aluminum is anodized with the coarse crystalline pattern the crystalline pattern also emerges on the surface, impairing the appearance of the stamped resin surface. The invention relates to a stamper in which an oxide film having a fine concave-convex structure made up of a plurality of fine pores having an aspect ratio represented by [the depth of the fine pores/the average interval between the fine pores] of 1 to 4 is formed on the surface of an aluminum base material which is made of aluminum having a content of Ti of 150 ppm to 500 ppm, a content of B or C of 1 ppm to 50 ppm and a purity of 99.9% or more. According to the invention, it is possible to provide a low-cost stamper in which the emergence of a pattern derived from the traces of crystal grains on the surface of the oxide film is suppressed, an article having a favorable appearance, which is manufactured using the above stamper, and a method for manufacturing the above.

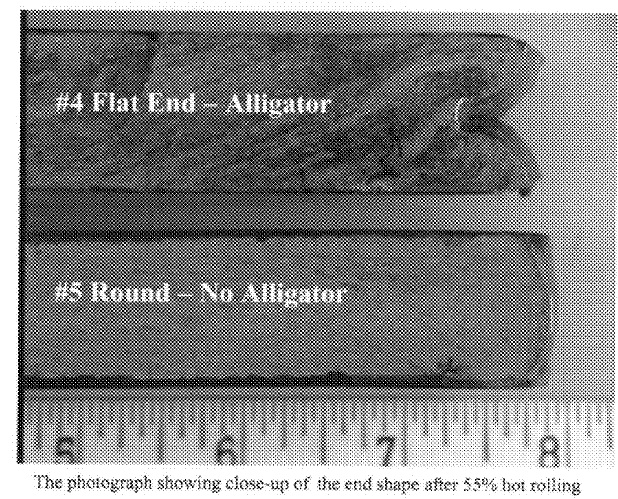

US9023484 — SHAPED DIRECT CHILL ALUMINUM INGOT — Tri-Arrows Aluminum Inc. (USA) — There is disclosed a method of rolling an ingot of aluminum to avoid alligatoring as the ingot is reduced in thickness to produce a slab or sheet, the ingot being rolled in a rolling mill wherein the ingot is subject to multiple rolling passes. The method comprises providing a rolling mill and providing an ingot to be rolled, the ingot comprising opposed surfaces to be rolled and having at least one shaped or formed end. The shaped end comprises a tapered portion, the taper being in the direction of rolling, and being in the range of 2 to 20° from the surface to be rolled and extending into the thickness of the ingot towards the end of the ingot. The ingot is subject to multiple rolling passes in the rolling mill to reduce the ingot in thickness and extend the ingot in length to produce a slab or sheet, the slab or sheet being free of alligatoring. The invention also includes a specially shaped bottom block for producing the shaped ingot end which minimizes alligatoring. Controlling the ingot end shape in accordance with the invention greatly minimizes scrap generation when rolling. Further, at the end of the cast, a top mold may be used to form the shaped end at the top of the ingot.

US8707543 — PROCESS FOR MAKING HIGH ELECTRICAL CONDUCTIVITY ALUMINUM PLATES — 9128-5270 Quebec Inc. (Canada) — The specification relates to electrically-conductive aluminum plates usable in components of large bus bar networks, such as those leading to electrodes of aluminum production plants, and more particularly to a process for making such plates. The process can include obtaining a rectangular aluminum panel size; obtaining a cast aluminum ingot having a length and width housing said aluminum panel size; sawing the annealed aluminum ingot along its length and across its width, thereby yielding a plurality of aluminum panels having said aluminum panel size and a given plate thickness; and cutting the plates across the thickness of the aluminum panels.

US8695684 — METHOD FOR PREPARING ALUMINUM–ZIRCONIUM–TITANIUM–CARBON INTERMEDIATE ALLOY — Shenzhen Sunxing Light Alloys Materials Co., Ltd. (China) — The present invention relates to a method for preparing an intermediate alloy serving as a grain refine for improving the properties of metals and alloys, and, in particular, to a method for preparing an aluminum-zirconium-carbon intermediate alloy for refining the grains of magnesium and magnesium alloys. The present invention discloses a method for producing an aluminum-zirconium-titanium-carbon (Al-Zr-Ti-C) intermediate alloy; the Al-Zr-Ti-C intermediate alloy comprises 0.01% to 10% Zr, 0.01% to 10% Ti, 0.01% to 0.3% C, and Al in balance; the producing method comprising the steps of: preparing commercially pure aluminum, zirconium, titanium, and graphite material according to the weight percentages of the aluminum-zirconium-titanium-carbon intermediate alloy; the graphite powder is subjected to the following treatments: being added to the aqueous solution of KF, NaF, K2ZrF6, K2TiF6 or the combination thereof, soaked for 12 to 72 hours, filtrated or centrifuged, and dried at 80 to 200°C for 12 to 24 hours; melting the commercially pure aluminum and keeping it at 700°C to 900°C to provide aluminum liquid, in which the prepared zirconium, the titanium and the treated graphite powder are added and melted to provide an alloy; and keeping the alloy at 700 to 900°C under agitation and casting. The present method produces a high-quality Al-Zr-Ti-C intermediate alloy in low cost.

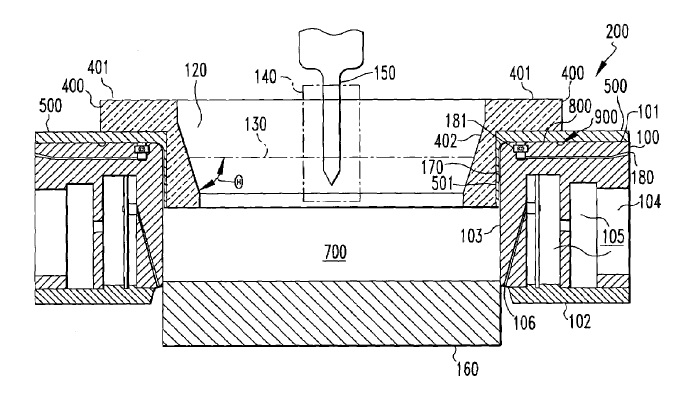

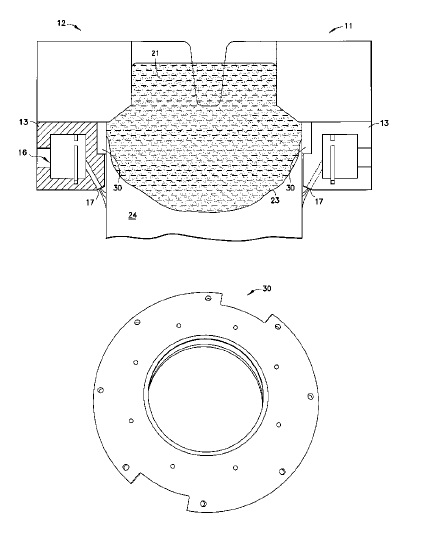

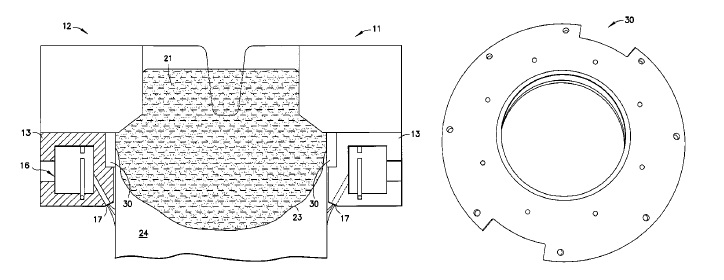

US8561670 — PROCESS AND APPARATUS FOR DIRECT CHILL CASTING — Alcoa Inc. (USA) — An apparatus for direct chill casting of metal such as aluminum or an aluminum alloy having an open ended mold cavity formed by a casting surface, a refractory sleeve adapted to receive molten metal, a coolant delivery system for supplying coolant to chill the descending hot metal body, and a boron nitride ring mounted between the refractory sleeve and the peripheral wall of the mold cavity. A downspout may be used instead of a refractory sleeve having a flow control rod or floating baffle to control the amount of molten metal entering the mold cavity. A process for direct chill casting of a metal including continuously filling the cavity with molten metal and permitting the metal to move downwardly through the mold to form an ingot, and simultaneously chilling the ingot by spraying coolant on the ingot from the coolant delivery system.

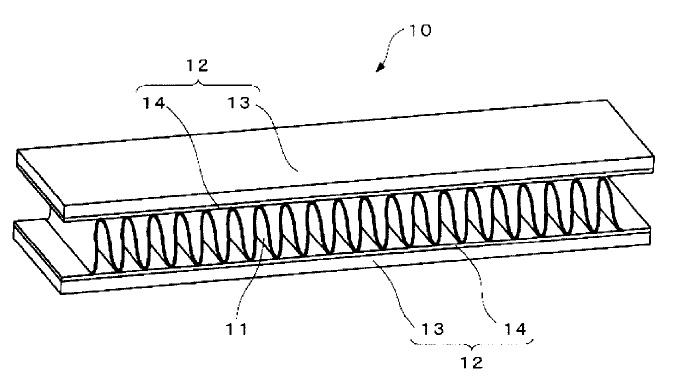

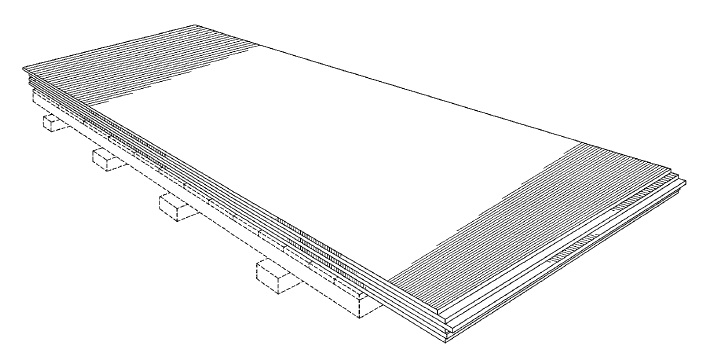

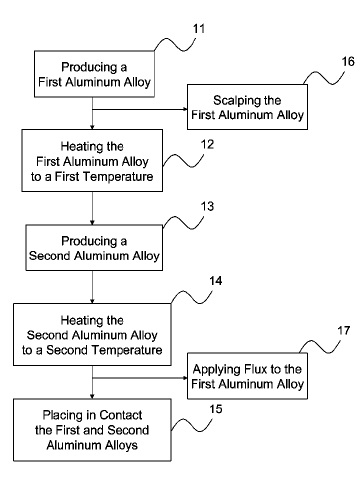

US8534344 — SYSTEM AND METHOD OF PRODUCING MULTI-LAYERED ALLOY PRODUCTS — Alcoa Inc. (USA) — Clad sheets including brazing sheets and aerospace skin sheet are used in applications where it may be necessary to have surface properties different from that of the core. To date, clad sheets may be produced by roll bonding a liner layer to a core ingot. Roll bonding requires, in some instances, at least one of casting, scalping, rolling, trimming, and mechanically attaching a liner material to a core material. The quality of the bonding, productivity of the process, and cost associated with scraps remain challenging for roll bonding. A system and method of producing multi-layered aluminum alloy products are disclosed. A multi-layered aluminum alloy product may be formed by first heating a first aluminum alloy to a first temperature where the first temperature is at least about 5°C lower than the eutectic temperature of the first aluminum alloy, second heating a second aluminum alloy to a second temperature where the second temperature is at least about 5°C higher than the liquidus temperature of the second aluminum alloy, and coupling the second aluminum alloy to the first aluminum alloy to produce a multi-layered aluminum alloy product.

US8479802 — APPARATUS FOR CASTING ALUMINUM LITHIUM ALLOYS — Almex USA, Inc. (USA) — Direct chill casting that allows for the continuous or serial introduction of an inert fluid into the coolant stream during casting while allowing for stoppage of the coolant flow and introduction of only inert fluid as the coolant in the event of a “bleed out” or “run out”. Water during a “bleed-out” or “run-out” can cause an explosion from conversion of water to steam from the thermal mass of the aluminum heating the water to >212°F or the chemical reaction of the molten metal with the water resulting in release of energy causing a chemical reaction generated explosion.

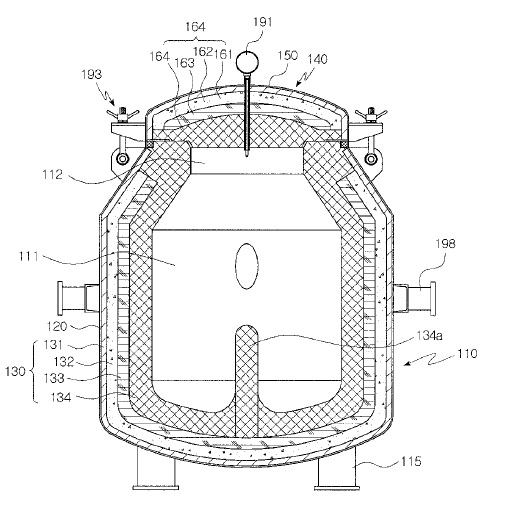

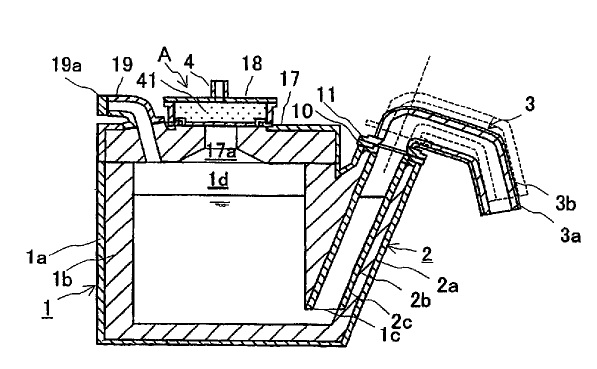

US8430281 — HIGH-HEAT-RETENTION LADLE FOR CARRYING MOLTEN ALUMINUM — Korea Institute of Industrial Technology (Korea) — he present invention relates to a high-heat-retention ladle that can carry molten aluminum for a long time in a heat-insulated state in order to cast a product by directly pouring the molten aluminum into a mold without having to convert raw materials into an ingot and then melt the ingot again. A high-heat-retention ladle comprising a castable refractory provided on a side wall in the outlet side, the castable refractory including silicon dioxide, aluminum oxide, and calcium oxide and a castable refractory provided on a bottom of the ladle body, the castable refractory made of silicon nitride coupled to silicon carbide for carrying molten aluminum includes a ladle body defining therein a storage space, which contains molten aluminum therein, the ladle body including a molten metal inlet and a molten metal outlet, which allow the storage space to communicate with outside, a cover opening and closing the inlet of the ladle body, and a stopper opening and closing the outlet of the ladle body. Each of the ladle body and the cover has an outer shell, which defines a contour thereof, and a multi-layer insulation structure inside the outer shell. The multi-layer insulation structure includes two or more refractory layers. The molten aluminum contained inside the storage space has a temperature drop rate of 5°C/min or less. It is possible to carry the molten aluminum for a long time in a heat-insulated state and cast a product by directly pouring the molten aluminum into a mold.

US8365807 — REDUCTION OF BUTT CURL BY PULSED WATER FLOW IN DC CASTING — Novelis Inc. (USA) — The invention provides a method of reducing butt curl during DC casting of a metal ingot. The ingot is cast in at least two stages, including an initial casting stage and then a steady-state casting stage carried out at higher casting speed. The emerging ingot is cooled by directing a liquid coolant onto its outer surface. During the first casting stage, the liquid coolant is directed in the form of at least two streams, including a constant first stream in the form of a series of first jets, and an intermittent second stream in the form of a series of second jets. The first and second jets impact the outer surface at locations spaced from each other peripherally and/or longitudinally of the ingot. Both the first and second streams experience film boiling when they contact the ingot. The invention includes apparatus for the method.

US8167970 — METHOD FOR PURIFYING AL-Ti-B ALLOY MELT — Shenzhen Sunxing Light Alloys Materials Co., Ltd. (China) — A method for purifying Al-Ti-B) alloy melt includes melting industrial aluminum ingot in an electromagnetic induction smelting furnace, the melt of Al being covered by a high-temperature covering agent, and its temperature up to at about 670-900°C; adding K2TiF6 and KBF4 into the smelting furnace and then stirring the compounds therein to react; adding compound comprising Mg, L, Na and F to the evenly stirred K2TiF6 and KBF4, the compound having an amount about 0.01-0.1% of a sum weight of total K2TiF6 and KBF4, and uniformly stirring for about 15-60 minutes under a reaction temperature being constantly at about 670-900°C, the dregs being removed, the Al alloy being cast.

US8056611 — PROCESS AND APPARATUS FOR DIRECT CHILL CASTING — Alcoa Inc. (USA) — In one embodiment, an apparatus for direct chill casting of metal includes an open ended mold cavity formed by a casting surface with an upper end and a lower end, a refractory sleeve located at the upper end of the mold cavity being adapted to receive molten metal, a coolant delivery system below the lower end of the mold for supplying coolant to chill the descending hot metal body, and a boron nitride ring mounted between the refractory sleeve and the peripheral wall of the mold cavity. Another embodiment further includes a downspout instead of a refractory sleeve that is located at the upper end of the mold cavity being adapted to receive molten metal having a flow control rod or a floating baffle where the flow control rod controls the amount of molten metal to enter the mold cavity.

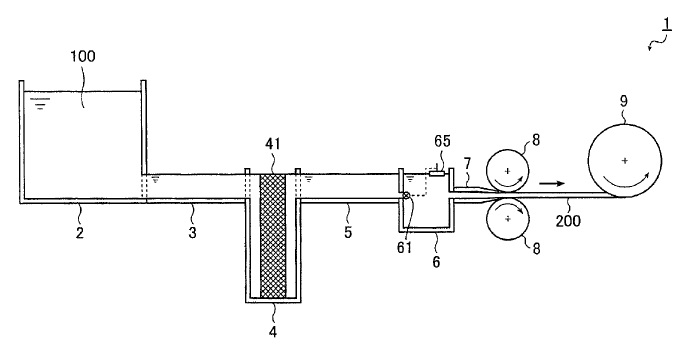

US8042603 — METHOD OF MANUFACTURING ALUMINUM ALLOY PLATE FOR LITHOGRAPHIC PRINTING PLATE, ALUMINUM ALLOY PLATE FOR LITHOGRAPHIC PRINTING PLATE OBTAINED THEREBY AND LITHOGRAPHIC PRINTING PLATE SUPPORT — Fujifilm Corporation (Japan) — In a method of manufacturing an aluminum alloy plate for a lithographic printing plate by continuous casting which includes feeding an aluminum alloy melt through a melt feed nozzle between a pair of cooling rollers and rolling the aluminum alloy melt while solidifying between the pair of cooling rollers, a vessel for feeding the aluminum alloy melt to the melt feed nozzle contains the aluminum alloy melt which is adjusted in such a manner that a vertical amplitude at a level of the aluminum alloy melt existing within the vessel is 10 mm or less. This manufacturing method is capable of obtaining an aluminum alloy plate for a lithographic printing plate with a uniform surface composition and manufacturing a lithographic printing plate support having no surface defects.

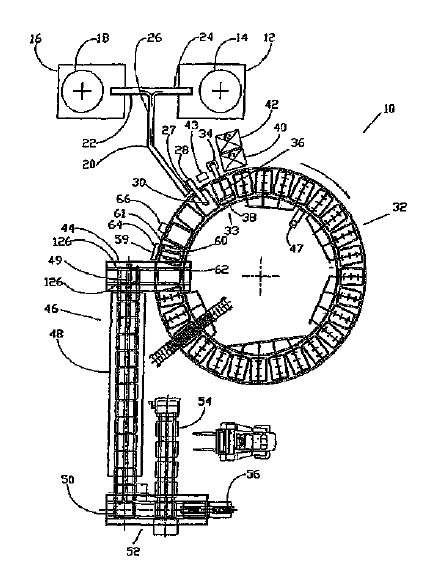

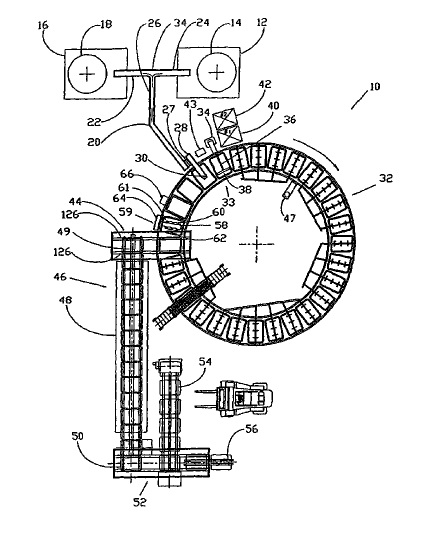

US7637304 — ALUMINUM INGOT CASTING MACHINE — Outotec Oyj (Finland) — An aluminum ingot casting machine having a source of molten metal, a rotatable annular ring, carrying ingot casting molds and a drive member for indexing the molds. The machine includes a vacuum de-molder having a vacuum seal arrangement having a sealing element having a flexible core which can deform to form a vacuum seal against an ingot and a flexible abrasion resistant outer layer on the core, and retaining elements located on a lower face of the vacuum lifting head for releasably retaining the sealing element onto the lifting head. The vacuum seal has a flexible ring-shaped body, being rounded in cross section, having a fiber cord core and an abrasion resistant flexible sheathing surrounding the core.

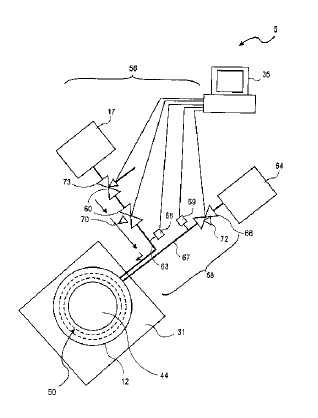

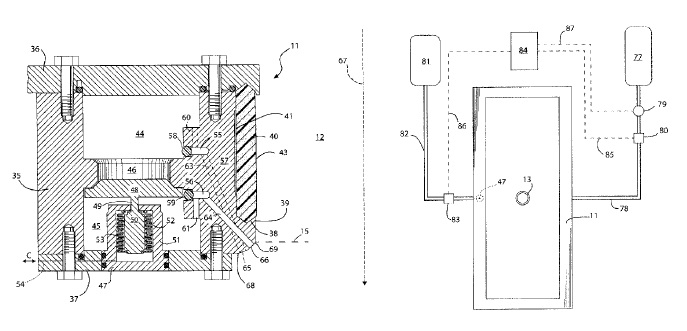

US7534980 — HIGH MAGNETIC FIELD OHMICALLY DECOUPLED NON-CONTACT TECHNOLOGY — UT-Battelle, LLC (USA) — Ultrasonic processing can be used to assist in grain refinement and to minimize segregation during solidification of aluminum alloys, and degassing with ultrasonics has resulted in reduced gas concentration, higher density, and improved mechanical properties. Commercially available ultrasonic processing systems require direct contact with the melt, resulting in undesirable chemical interactions when the acoustic probe/horn is inserted directly into the molten material. Methods and apparatus are described for high magnetic field ohmically decoupled non-contact treatment of conductive materials in a high magnetic field. A method includes applying a high magnetic field to at least a portion of a conductive material; and applying an inductive magnetic field to at least a fraction of the conductive material to induce a surface current within the fraction of the conductive material, the surface current generating a substantially bi-directional force that defines a vibration. An apparatus includes a high magnetic field coil defining an applied high magnetic field; an inductive magnetic field coil coupled to the high magnetic field coil, the inductive magnetic field coil defining an applied inductive magnetic field; and a processing zone located within both the applied high magnetic field and the applied inductive magnetic field. The high magnetic field and the inductive magnetic field are substantially confocal, and ohmic heating of a conductive material located in the processing zone is ohmically decoupled from a vibration of the conductive material.

US7481967 — MOLTEN METAL TRANSPORTING CONTAINER — Nippon Crucible Co., Ltd. and Daiki Aluminum Industry Co., Ltd. (Japan) — The present invention relates to a molten metal transporting container that is used for supplying molten metal to a holding furnace at a casting site or for delivering molten aluminum from a manufacturer to a user. The present invention provides a molten metal transporting container having a long-reach-pouring spout connected to a pouring outlet of a pouring spout, and projects toward the outside of the container body, the molten metal transporting container further having a spout operating member for separating the long-reach-pouring spout from the pouring spout by raising the long-reach-pouring spout while it is projected from the container body, and a spout drawing member for drawing the long-reach-pouring spout that was separated from the pouring spout toward the container body.

US7406997 — ALUMINUM INGOT CASTING MACHINE — Outotec Oy (Finland) — An aluminum ingot casting machine comprising a source of molten metal, a rotatable annular ring, carrying ingot casting molds and a drive means for indexing the molds. The machine includes a vacuum de-molder having a vacuum seal arrangement comprising a sealing element having a flexible core which can deform to form a vacuum seal against an ingot and a flexible abrasion resistant outer layer on said core, and retaining elements located on a lower face of the vacuum lifting head for releasably retaining the sealing element onto the lifting head. The vacuum seal comprises a flexible ring-shaped body, being rounded in cross section, having a fiber cord core and an abrasion resistant flexible sheathing surrounding the core.

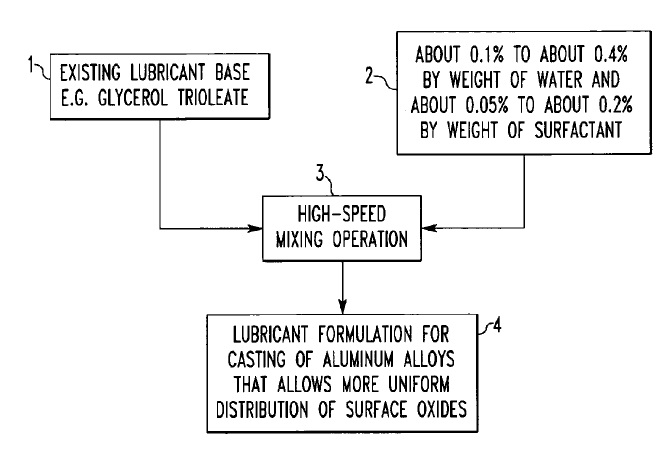

US7273086 — LUBRICANT FOR IMPROVED SURFACE QUALITY OF CAST ALUMINUM AND METHOD — Alcoa Inc. (USA) — In a lubricant composition suitable for use in the manufacture of aluminum alloys comprising lubricant base selected from the group consisting of solid lubricants, liquid lubricants, grease lubricants, emulsion lubricants, and dispersion lubricants, the improvement wherein the lubricant composition further comprises: an effective amount of water and surfactant. It is believed that mixing oil with water and surfactant provides a method for uniformly distributing the surface oxide at the meniscus for casting applications. Uniform distribution of the oxide at the meniscus reduces vertical fold formation that can lead to cracks in the aluminum ingot. In addition, the mixture promotes uniform heat transfer around the mold. Uniform heat transfer around the mold allows the solidifying aluminum alloy to stay in contact with the mold longer and form stronger ingot shells. A process for continuous or semi-continuous casting of aluminum alloys via the use of this lubricant composition is also disclosed.

US7143812 — LUBRICANT FOR IMPROVED SURFACE QUALITY OF CAST ALUMINUM AND METHOD — Alcoa Inc. (USA) — In a lubricant composition suitable for use in the manufacture of aluminum alloys comprising lubricant base selected from the group consisting of solid lubricants, liquid lubricants, grease lubricants, emulsion lubricants, and dispersion lubricants, the improvement wherein the lubricant composition further comprises: an effective amount of water and surfactant or water and a compound comprising phosphates, borates, fluorides, and silicates. It is believed that mixing oil with water and surfactant or one of these compounds provides a method for uniformly distributing the surface oxide at the meniscus for casting applications, thereby reducing vertical fold formation that lead to cracks in aluminum ingots. In addition, the mixture promotes uniform heat transfer around the mold allowing the solidifying aluminum alloy to stay in contact with the mold longer and form stronger ingot shells. A process for continuous or semi-continuous casting of aluminum alloys via the use of this lubricant composition is also disclosed.

US7000676 — CONTROLLED FLUID FLOW MOLD AND MOLTEN METAL CASTING METHOD FOR IMPROVED SURFACE — Alcoa Inc. (USA) — A DC casting mold for casting molten metal alloy comprising a cooled tubular body that has a thermally insulated insert attached to its top surface. The thermally insulated insert has a bottom portion with a beveled sidewall, which forms an angle with the horizontal melt surface layer of the molten metal and creates an eddy. The eddy causes a substantial number of oxides that are formed during the casting process to remain in the bottom sidewall portion of the thermally insulated insert of the mold, thereby substantially reducing the number of ingot surface imperfections that promote ingot cracking. In addition, the eddy promotes break-up of the oxides into smaller pieces as the oxides flow toward the cooled inner walls of the cooled tubular body, thereby having limited surface area for growth of oxide folds. A method of casting molten metal alloys with improved surface quality is also disclosed.