Aluminum is vital to the society in which we live. Our homes, workplaces, vehicles, digital devices, packaging, and buildings that provide shelter and security – to name just a few examples – rely heavily on aluminum. Furthermore, the lightweight metal is integral to global emissions reduction efforts, with solar panels, wind turbines, and electric vehicles all depending on it.

Ensuring aluminum’s place in society — now and in the future — requires a consideration of not only how aluminum is used, but how it is manufactured. Therefore, aluminum industry organizations are working to put forth plans to ensure the long term environmental and societal sustainability of aluminum.

GHG Reduction Pathways

The International Aluminium Institute (IAI) has published “Aluminium Sector Greenhouse Gas Pathways to 2050,” a new report highlighting comprehensive greenhouse gas (GHG) emissions reduction pathways for the aluminum sector over the next three decades.

While the industry works to reduce its emissions by about 80%, demand for aluminum products is also predicted to grow. Over the coming decades, global demand for primary aluminum will increase by up to 40% and recycled aluminum from post-consumer scrap will more than triple through to 2050, as economies grow, urbanize, and build up their infrastructure.

Simultaneously reducing emissions while meeting increasing demand will require huge investments in production technologies, along with commitment from all along the value chain.

“Emissions reduction is a challenge for every sector,” said said Miles Prosser, the IAI’s secretary general. “It is, however, a challenge that the aluminum sector is poised to address. Over the last two years, a Greenhouse Gas Pathways Working Group made up of IAI member companies and regional associations have been working to articulate credible ways to achieve global climate goals. This collaboration is what has resulted in the industry’s most comprehensive pathways, which we have published today.”

The pathways are based on the IAI’s unrivaled data and leading analysis of the global aluminum industry.

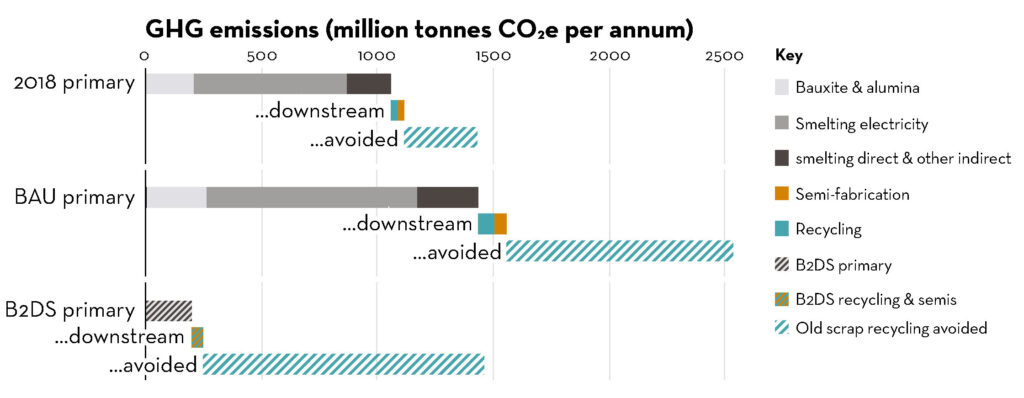

Using its comprehensive data and analysis of the global aluminum industry, the IAI is now publishing 15 years of emissions data by their source, covering all production processes from cradle to gate. This includes all the emissions generated during smelting, secondary production, and semis manufacturing operations, as well as those embedded in raw and secondary materials and the energy that the sector consumes.

“This is the most comprehensive, detailed and up-to-date dataset that exists not just for aluminum but also any material today,” explained Prosser. “This greenhouse gas data and the material flow analysis modeling, which is used to produce robust scenarios for primary and recycled aluminum, underpins the pathways we have unveiled today, which will play a vital role in helping aluminum industry stakeholders choose the necessary actions to achieve global climate goals.

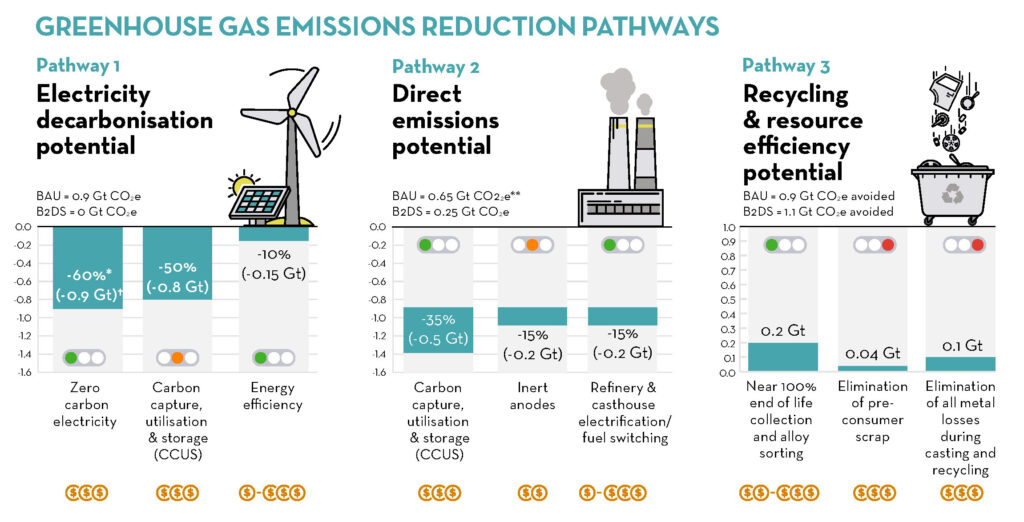

Based on this detailed data collection and research, the IAI developed its new report, setting out three credible and realistic approaches to emission reductions for the aluminum industry, in line with the International Energy Agency’s Beyond 2 Degree Scenario. These pathways are as follows:

- Electricity Decarbonization – More than sixty percent of the aluminum sector’s 1.1 billion tonnes of CO2e emissions (2018) are from the production of electricity consumed during the smelting process. Decarbonized power generation and the deployment of carbon capture utilization and storage (CCUS) offer the most significant opportunity to reduce emissions to near zero by 2050.

- Direct Emissions – Emissions from fuel combustion make up 15% of the industry’s emissions. Here, electrification, fuel switching to green hydrogen, and CCUS offer the most credible pathways. Process emissions make up a further 15% and require new technologies, such as inert anodes. These emissions and those in transport and raw materials will need to be reduced by 50-60% from a Business as Usual (BAU) baseline scenario by 2050.

- Recycling and Resource Efficiency – Increasing collection rates to near 100% as well as other resource efficiency progress by 2050 would reduce the need for primary aluminum by 20% compared to BAU, which in turn will cut the sector’s emissions by an additional 300 million tonnes of CO2e per year – a figure second in magnitude only to the first pathway, electricity decarbonization.

Beverage Can Recycling Roadmap

In Europe, the recycling rate for aluminum beverage cans stood at 76.1% in 2018, according to European Aluminium. The momentum created by the recently adopted ambitious EU 2025 and 2030 recycling targets for aluminum packaging, as well as the new EU methodology for the calculation of these targets, presents an opportunity for the European aluminum industry to set out ambitious recycling targets.

Therefore, European Aluminium and Metal Packaging Europe launched an ambitious joint roadmap towards achieving 100% aluminum beverage can recycling by 2030. “Aluminium Beverage Can Recycling Roadmap” reflects the conviction among aluminum producers of can sheet, manufacturers of aluminum beverage cans, and recyclers of used aluminum beverage cans that the full potential of the aluminum beverage can as a front-runner in a truly circular economy can be achieved within the next ten years.

“While we are confident that we can achieve this ambitious target, it will require the participation and support of the entire value chain,” said Andy Doran, chairman of the European Aluminium Packaging Group. “We therefore call on our partners, including brand owners, retailers, consumers, packaging recovery organizations, recyclers, and others, to work with us to further improve the collection of cans, as part of a joint mission to fully close the loop and move from the current recycling rate of 76.1% to a real recycling rate of 100% in 2030.”

The “Aluminium Beverage Can Recycling Roadmap” can be viewed online or downloaded as a pdf summary.