By Curt Wells and Paul O’Connor, The Aluminum Association.

Aluminum recycling provides significant societal environmental benefit in terms of landfilled waste reduction and the energy consumption/emissions avoided as compared to aluminum produced from virgin ore. However, aluminum recycling also generates waste products and these are referred to as secondary aluminum processing wastes, which are comprised of two components. By far the largest in terms of generation is saltcake, which is the slag generated during the recovery of aluminum scrap and dross in rotary furnaces. To maximize metal recovery, a salt flux is often added to aluminum scrap and dross in the recovery process, and the residue left after the metal has been recovered is referred to as saltcake or saltslag. Saltcake typically contains 3-10% metallic aluminum, 20-60% aluminum oxide, and 20-80% salt. A much smaller component is baghouse dust, which is the particulate matter captured in air pollution control equipment managing air emissions emanating from rotary furnace operation. For discussion purposes, these two components will be referred to by the acronym SC/BHD. In the spring of 2007, the aluminum industry faced a challenge when major landfill companies began expressing concern that secondary aluminum processing wastes such as saltcake and baghouse dust could be detrimental to the operation of landfills. In response to these concerns, the Aluminum Association formed a Saltcake Workgroup under the sponsorship of the Association’s Environmental Committee and Casting and Recycling Division to work with the Environmental Protection Agency (EPA), concerned state officials, and the solid waste landfill industry in assessing concerns about the landfilling of these materials. Specifically, the workgroup’s focus was on resolving the concerns through a thorough review of the safety of secondary aluminum processing waste landfilling toward ensuring that it would remain a viable option in support of the health of U.S. aluminum recycling. Since its formation and continuing to the present, the Association’s Saltcake Workgroup has supported a variety of deliverables toward the goals expressed. Upon its formation, the Association’s Saltcake Workgroup identified three key areas of focus:

- Research in collaboration with the U.S. EPA and the landfill industry on the characterization of SC/BHD and the potential risks that it presents in the landfill environment.

- An assessment of the regulatory status of SC/BHD in order to help inform compliant material management.

- Development of recommendations for landfill operators to utilize when accepting, considering acceptance, or actively managing SC/BHD materials.

Research

The Aluminum Association partnered with the EPA and the solid waste industry’s Environmental Research and Education Foundation (EREF) in multi-year joint research projects to better define and understand the behavior of SC/BHD in landfills. In particular, the explicit objectives of studying SC/BHD were to: characterize and identify the metal constituents in SC/BHD, investigate the leaching behavior of metals from SC/BHD resulting from its contact with water, identify the dominant crystalline mineral phases in SC/BHD, evaluate the factors that impact the reactivity of SC/BHD, and evaluate the effects resulting from SC/BHD interaction with water and ambient landfill materials, including temperature rise and gas generation.

A key point of all the investigations undertaken is that all research and reports referenced focus on the commingled disposal of SC/BHD with municipal solid waste (MSW) in landfills, although the practice of segregated monofill/monocell disposal of SC/BHD is more prevalent at this time.

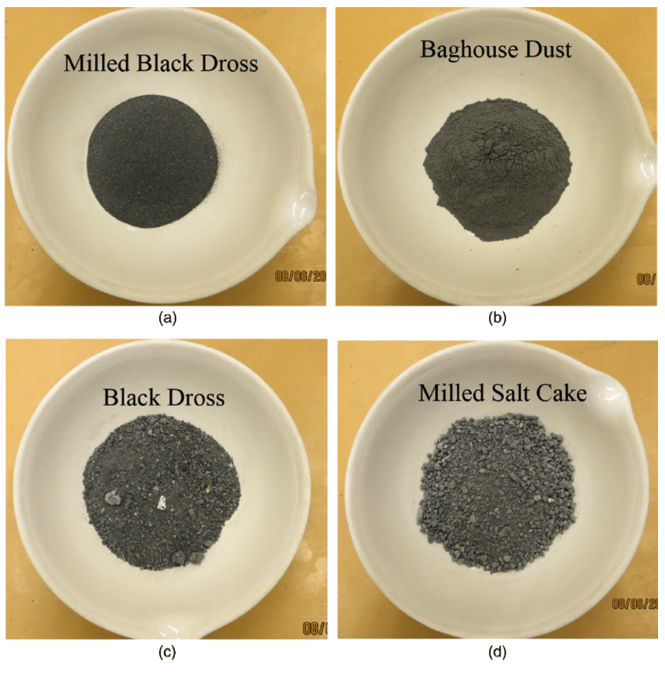

In order to support the EPA’s research activities, Aluminum Association member companies supplied SC/BHD samples (Figure 1) from an extensive range of secondary aluminum processes across the U.S. The EPA sample pool consisted of 39 saltcake samples from ten secondary aluminum facilities and 78 baghouse dust samples from 13 secondary aluminum facilities. As an outcome of their research using these samples, in 2015, the EPA published the research papers Secondary Aluminum Processing Waste: Saltcake Characterization and Reactivity (EPA/600/R-15/109)1 and Secondary Aluminum Process Waste: Baghouse Dust Characterization and Reactivity (EPA/600/R-15/203).2 These papers found the following:

- SC/BHD has aluminum and other metal compounds present that can react with water to generate heat and gases.

- SC/BHD should always be managed at landfills with synthetic liners and leachate collection systems in place, because the salt content can increase the permeability of clay liners over time.

- SC/BHD management commingled with MSW at landfills is feasible but concerns exist with this practice regarding elevated temperatures already present in MSW landfills and the potential for hydrogen and ammonia generation from SC/BHD, which is not normally found in MSW landfills.

In addition, an evaluation of the 117 MSW facilities further clarified the EPA’s understanding of SC/BHD characterization, however further research was needed to make a conscious decision regarding the future management of SC/BHD. In particular, the overall impact SC/BHD disposal has on the waste temperature distribution in MSW landfills led the EPA to conduct research to model potential thermal changes at MSW landfills resulting from SC/BHD management. Their final report published in 2016, Modeling Thermal Changes at Municipal Solid Waste Landfills: A Case Study of the Co-Disposal of Secondary Aluminum Processing Waste (EPA/600/R-16/174),3 utilized a finite element analysis approach in order to model MSW landfill temperature changes across a range of SC/BHD placement scenarios. The EPA concluded that:

- The heat generation rate of SC/BHD has the greatest single influence on overall waste temperature changes in the landfill.

- SC/BHD placement strategy in the landfill has a significant effect on the landfill temperature distribution, with the highest heat generation found when the SC/BHD was modeled as a discrete pocket placement and the lowest heat generation found when the SC/BHD was modeled as a diffuse uniform mixture within the larger body of MSW landfill.

Regulatory Assessment

Repeated questions arising about the waste regulatory status of SC/BHD led the Saltcake Workgroup to conduct a regulatory review of the materials. At the outset it was clear that, at minimum, SC/BHD is an industrial solid waste, however the review focused on other potential waste regulatory categories that could apply. Notably, saltcake is not found on the EPA’s F-List (non-specific source wastes), K-List (source specific wastes), or the U- and P-lists (discarded commercial products). It also does not meet any of the D-List characteristics for hazardous waste.4

In terms of the D-List characteristics, the EPA utilizes four identifications for listing hazardous waste: ignitability, corrosivity, reactivity, and toxicity.4 Solid waste in the U.S. is categorized as hazardous if it exhibits any of these hazardous characteristics or matches any listings found in the hazardous waste regulations. Based on testing of representative samples of SC and BHD, previous waste determinations were confirmed that these materials did not meet any criteria such that they would be considered a hazardous waste.

First, ignitability as defined by the EPA is a solid waste that “exhibits the characteristics of ignitability, if… it is not a liquid and is capable under standard temperature and pressure, of causing a fire through… absorption of moisture… and, when ignited, burns so vigorously and persistently that it creates a hazard.” SC/BHD fails to meet this standard established for quantifying ignitability. In terms of corrosivity, SC/BHD is a solid and the corrosivity characteristic requires a liquid be present, therefore that characteristic is not applicable. With respect to the definition of reactivity, the EPA states, “This definition was intended to identify wastes, which because of their extreme instability and tendency to react violently or explode, pose a problem at all stages of the waste management process.”5 However, there is no U.S. EPA specified testing method to determine reactivity and, although SC/BHD can react with water, it does not present extreme instability or react violently. In terms of the fourth characteristic, toxicity, extensive testing across multiple facilities and years of testing document that saltcake also did not exhibit this fourth and final D-List characteristic.

Consistent with this information, regulatory applicability determinations conducted on SC/BHD over the years have reached similar conclusions. A notable review was conducted by the Tennessee Department of Environmental Conservation (TDEC) in 2011 of a generating facility’s non-hazardous waste determination for saltcake. Its conclusion was that TDEC “could not identify any information that justified contesting the facility’s hazardous waste determinations or that warranted requesting any additional data or testing related to their hazardous waste determinations.”6

As relates to the U.S. Department of Transportation (DOT) hazardous materials regulations, SC/BHD are tested against the Division 4.3 (dangerous when wet material) standard, which contains a different criteria than the EPA’s reactivity and ignitability criteria. In particular, Division 4.3 states, “a material that, by contact with water, is liable to become spontaneously flammable or to give off flammable or toxic gas at a rate greater than 1 liter per kilogram of the material, per hour.”7 If aluminum remelting by-products such as SC/BHD are tested against this criteria and meet it, then a 4.3 characteristic material is present and it is classified as UN 3170 for transportation purposes. Considering that SC/BHD has a wide range of constituencies, generalizations are not easily made when determining if 4.3 characteristics are present or not and testing a representative sample of the material as generated is required. If a 4.3 characteristic material is present, for shipment, DOT special provision B115 permits the use of non-specification bulk containers that are sift-proof, prevent water from reaching the material, and are adequately ventilated.

Landfill Management Recommendations

From real world experience and the results of the research conducted jointly with the EPA, the Saltcake Workgroup developed recommendations and considerations for management of SC/BHD at landfills to ensure that the materials are managed safely and in an environmentally protective manner. Most of this information is focused on the prevention/minimization of contact between SC/BHD and water due to the presence of aluminum nitride and fine elemental aluminum in SC/BHD, as these materials are most likely to cause ammonia generation and temperature rise in contact with water. The following advice and considerations are recommended:

- Manage SC/BHD in as dry a state as possible. This includes taking actions such as placing SC/BHD in closed/tarped containers prior to landfilling, not landfilling during periods of sustained precipitation, and utilizing daily or more frequent immediate compaction and cover practices.

- Protect workers at the landfill working face from ammonia exposure, if moisture contact with the material exists.

- Do not damage the integrity of baghouse dust bags. Trenching the bags into the working face and then providing immediate cover is recommended.

- Only manage SC/BHD in landfills that do not recirculate leachate as leachate recirculation can exacerbate the chemical reactions that cause temperature rise and gas evolution.

- Publicly Owned Treatment Works (POTW) acceptance of leachate can be affected by its ammonia and salinity concentrations, which SC/BHD management in the landfill can contribute to.

- Ammonia and hydrogen gas evolution can damage landfill gas collection equipment and contaminate collected methane.

Conclusion

Although most of the deliverables from the Saltcake Workgroup are now completed, the Aluminum Association will continue to monitor future developments in the management of SC/BHD to ensure that it is being performed in a safe and protective manner. This is vital because SC/BHD management continues to be a highly visible and potentially disruptive issue for the ongoing viability of U.S. secondary aluminum production. However, research has shown that without further processing, SC/BHD can be safely transported and disposed in non-hazardous landfills when proper care is taken and material handling guidelines are met.

References

- Secondary Aluminum Processing Waste: Saltcake Characterization and Reactivity (EPA/600/ R-15/109), U.S. Environmental Protection Agency, Office of Research and Development, National Risk Management Research Laboratory, Land Remediation and Pollution Control Division, Waste Management Branch, Last updated – September 19, 2017.

- Secondary Aluminum Process Waste: Baghouse Dust Characterization and Reactivity (EPA/600/R-15/203), Office of Research and Development, National Risk Management Research Laboratory, Land Remediation and Pollution Control Division, Waste Management Branch, April 2015.

- Tolaymat, T., A. El-Badawy, J. Smith, M. Barlaz, P. Jain, S. Luettich, and X. Huang, Modeling Thermal Changes at Municipal Solid Waste Landfills: A Case Study of the Co-Disposal of Secondary Aluminum Processing Waste, U.S. Environmental Protection Agency, Washington, DC, EPA/600/R-16/174, 2016.

- Subtitle C of RCRA has been codified in the U.S. Code as the Solid Waste Disposal Act (SDWA), Subchapter III (Hazardous Waste Management), 42 U.S.C. §§ 6921 through 6939e.

- Federal Register, Hazardous Waste and Consolidated Permit Regulations, May 19, 1980.

- Review of Waste Determinations – Tennessee Aluminum Processors (TAP) and Smelter Services Corporation (SSC), State of Tennessee, Department of Environment and Conservation, Division of Solid Waste Management, March 3, 2011.

- “49 CFR 173.124 – Class 4, Divisions 4.1, 4.2 and 4.3 – Definitions,” LII / Legal Information Institute, www.law.cornell.edu/cfr/text/49/173.124.

Curt Wells is senior director of Regulatory Affairs for the Aluminum Association. In that capacity, he focuses on environmental regulatory interaction with the U.S. EPA on a wide range of issues. He also manages the Association’s health and safety programs, including the Casthouse Safety Workshop, the molten metal incident reporting program, and regulatory interaction on health and safety issues. Prior to joining the Association in 2014, Wells was a regulatory compliance specialist with StrataG and worked in a variety of leadership roles within the corporate environmental, health, and safety operations for Alcoa and Reynolds Metals Company.

Paul O’Connor is an intern in the Policy Department of the Aluminum Association, focusing on supporting environmental, regulatory, and international trade policy initiatives. He is enrolled at Michigan State University, where he is pursuing a major in International Environmental Policy.

Editor’s Note: This article first appeared in the October 2018 issue of Light Metal Age. To receive the current issue, please subscribe.