AMAG Austria Metall AG started up production of a new aluminum cold rolling mill in Ranshofen, Austria, as part of a massive expansion plan aimed at making the integrated company Europe’s most state-of-the-art aluminum manufacturer. The official opening of the new mill, along with heat treating and passivation capacity, was held on June 22, 2017 (Figure 1), with around 700 guests in attendance. In addition to increasing capacity, the new facility enables the company to produce wider strip, strengthening its ability to supply specialty sheet for the automotive and aerospace industries.

“With the plant expansion, we are increasing our production capacity and at the same time our quality, flexibility, and productivity, as well as our competitiveness in the global market,” said Helmut Wieser, ceo of AMAG Austria Metall AG. “With the expanded product dimensions and 60 years of experience with aluminum, new sales potentials open up especially in the areas of automotive, aerospace, commercial vehicles, packaging, and engineering.”

Company History

AMAG Austria Metall was originally founded as a primary aluminum smelter in 1939 by Vereinigte Aluminiumwerke AG Berlin (VAW) and was later expanded in 1950 to include a rolling mill and extrusion plant, followed by a secondary casthouse for aluminum scrap recycling in 1979.

In 1989, AMAG acquired a 20% interest in the Aluminerie Alouette Inc. smelter in Sept Iles, Quebec, Canada (the remaining shares currently held by Rio Tinto, Hydro Aluminium, Marubeni Metals & Minerals, and Investissement Québec). The smelter officially started production in 1992, which corresponded with the closure of the primary aluminum smelter at AMAG’s Ranshofen facility. The Alouette smelter completed an expansion in 2005, bringing output up to 600,000 tpy.

AMAG was privatized in 1996, with Klaus Hammerer acquiring a 40% stake along with Constantia Packaging AG (40%) and an employee trust (20%). Hammerer later sold his stake to Constantia, with the extrusion business spun off to become HAI Hammerer Aluminium Industries GmbH.

AMAG is now the largest aluminum business in Austria and one of the largest rolling operations in Europe. At its integrated site in Ranshofen, the company recycles aluminum scrap, producing 86,000 tonnes of foundry alloys and 226,000 tonnes of wrought alloys, and manufacturers high quality aluminum rolled products in the form of sheet, strip, and plate, serving industries such as transport (aircraft, automotive, truck, trailer, bus, train, ship), packaging, architecture, renewable energy, and consumer electronics, among others. The core market for AMAG is Europe, representing 53% of sales, with the most important overseas market being North America with 27% of sales. The company shipped 405,900 tons of aluminum products in 2016, representing a 6.5% increase compared to 2015.

Continuous Growth

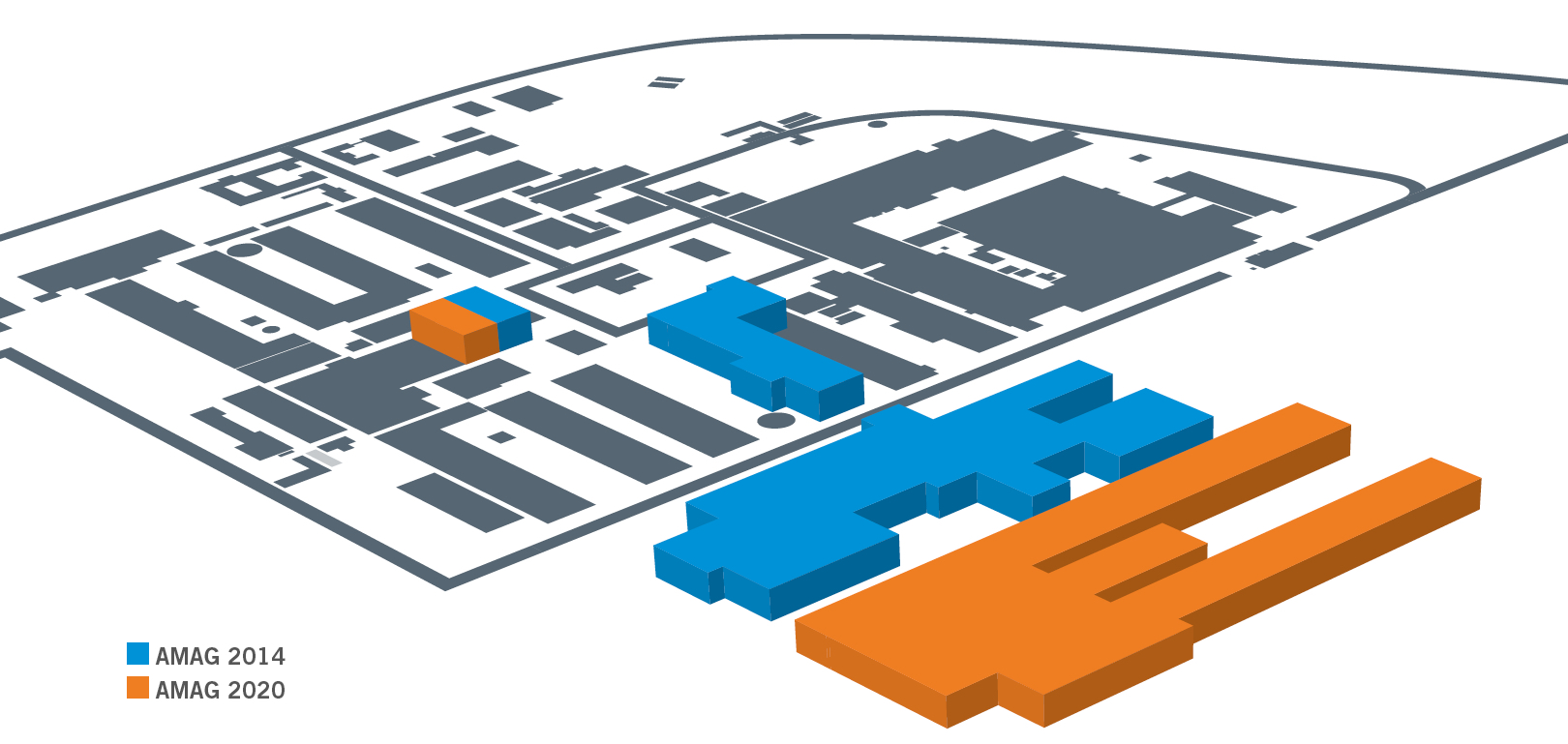

AMAG has been in a state of continuous growth for over ten years (2007-2017), investing €1 billion during that period—with €520 million being for two large projects at the Ranshofen site, AMAG 2014 and AMAG 2020 (Figure 2), with the aim of transforming the site into Europe’s most modern aluminum site.

“The decision to invest in the Ranshofen location was based on several strategic factors,” said Wieser. “Among these are its location in the core market of Europe (being geographically close to important customers), the excellent education and research facilities, the high level of training, as well as the many years of proven experience of our employees, in combination with the stable political and economic landscape, which also plays an important role.”

The AMAG 2014 project consisted of the construction of a new hot rolling mill, plate production center, logistics center, and slab casting capacity, which started up operation in November 2014. The twin coiler hot rolling mill, supplied by Danieli, increased capacity from 150,000 tpy to 225,000 tpy. Along side the hot mill, a new plate shear, slab preheating furnace, and bar mill (to remove the skin of the rolling slab) were installed. The new plate production center includes a Danieli 80 MN plate stretcher, along with plate sawing equipment, an artificial aging furnace, an ultrasonic inspection line, a horizontal heat treatment furnace, and a packaging line. With the new hot rolling mill and plate production, the company can produce plates with a maximum thickness of 152.4 mm and maximum width of 2,300 mm.

Following the completion of the hot rolling mill, the company launched its second large project, AMAG 2020. This project—completed in June 2017—includes the construction of a new cold rolling mill, continuous heat treatment furnace with a passivation line, batch annealing furnaces, shear, dry lubrication plant, and packaging line, as well as a further expansion of the existing slab casthouse.

The Cold Mill

Housed in a 55,000 sq m greenfield building at Ranshofen, the new cold rolling mill was completed in a record construction time of just 16 months with work performed by more than 40 equipment and service suppliers. The cold mill is integrated with the new hot mill through the on-site logistic system, enabling easy transfer of the hot rolled coil from the hot rolling mill to high bay storage in the cold rolling mill complex. The mill doubles production capacity at Ranshofen to more than 300,000 tonnes, as well as enabling the company to produce wider sheet and strip. This strengthens AMAG’s capabilities in the supply of special sheet for automotive body panels and structural parts and modern passenger aircraft components, as well as other strip products, such as aluminum packaging material.

The 6-Hi cold rolling mill (Figure 3) from SMS group was designed to provide a high degree of production flexibility for an extensive range of sheet and coil products using continuously variable crown (CVC®) plus technology. The mill enables AMAG to cold roll products up to a maximum width of 2,250 mm. Actuators and X-Pact® control systems installed on the mill ensure that the tight product tolerances required by the automotive and aerospace industries are met. An Airwash™ system provides efficient purification of the exhaust air from the rolling process, and an oil recovery system allows for rolling oil to be fed back into the process cycle.

SMS also installed a continuous heat treatment furnace with a connected passivation line (Figure 4) that features a compact layout and resource saving process technology. During heat treatment in the floatation furnace and subsequent water quenching, the sheet achieves the mechanical properties specified by the customer. The passivation line provides the final chemical coating process, optimally preparing the sheet and coil for further downstream processing steps—a process that is primarily requested by the automotive industry. AMAG can offer strip tempering in a thickness range of 0.3–8.0 mm.

A CNC shear for the slitting of strip for automotive and other aluminum alloys was supplied by Danieli Fröhling (Figure 5). The shear divides coils in a longitudinal direction and can slit up to four strips at a time with a maximum width of 2,450 mm. The design of the new shear allows for the processing of a wide range of strip thicknesses from 0.15 to 3.5 mm. Each of the ten knife heads can be individually adjusted both axially and vertically, thereby ensuring optimal gap and overlap for the selected cutting program.

For its automotive customers, AMAG installed a dry lubrication plant in order to facilitate the deep drawing of complex vehicle parts, rather than water-based lubricants that may impair the durability of adhesive bonds. “Dry lubrication refers to lubricants that are grip-dry at room temperature but become liquid when heated,” said Dr. Paul Oberhauser, AMAG rolling GmbH. “At AMAG, we use oil- and waxed-based dry lubes that are semi-solid at room temperature. The addition of wax means that forming forces can be transferred optimally from the tool to the part. With friction coefficients of less than 0.10, the lubrication effect is superior to that of conventional oils.”

Separate from the heat treatment unit previously described, the dry lubrication system uses up to five tanks with heated hoses, spray bars, and cabin to evenly apply the lubricant across the entire width of the strip (up to 2,300 mm wide). Two in-line UV lasers seamlessly monitor the coating thickness, which can be as thin as 0.3–2 g/m2, depending on requirements of the OEM. Additional monitoring and inspections are undertaken with infra-red handheld instruments and gravimetrically in the laboratory.

AMAG aluminum coils with dry lubrication are normally provided with an electro discharge texturing (EDT) surface, in which the roll surface is textured using spark erosion. EDT complements the dry lubrication process by creating lubricant pockets on the surface of the coil.

A coil handling system and semi-automatic packaging line were supplied by SMS Logistiksysteme. The handling system consists of a fully automatic high-bay warehouse with links to the rolling and processing lines. The warehouse technology includes an innovative cooling system that flexibly switches between air circulation and forced cooling in the various warehouse areas, depending on the material grades of the coils and the type of downstream processing. The packaging line weighs the finished coils and then securely ties, packs, and labels them for transport to customers all over the world. Coil finalization, packaging, and delivery port is fully integrated in the new cold mill complex.

“AMAG was already a member of the exclusive circle of aluminum manufacturers that supply special sheet both for automotive bodies and modern passenger aircraft,” said Wieser. “The new plant contributes to further expanding our position as a leader in this technology.”

Casthouse Improvements

As part of the AMAG 2020 project, the company also completed a second expansion of its rolling slab casthouse in 2017, which is able to supply slab in more than 100 different alloy variants. As part of the expansion, the company installed a new tiltable melting/casting furnace from Hertwich Engineering, along with a charging machine. The furnace has a holding capacity of over 110 tonnes and annual capacity of 55,000 tonnes. Two pairs of regenerative burners are installed inside the furnace, with gas consumption of up to 500 kWh/tonne, which satisfies economic and environmental requirements. The rail-guided, pusher type charging machine has a capacity of 25 tonnes.

The upgraded casthouse also includes an electromagnetic caster (EMC) supplied by GAP Engineering (Figure 6). The EMC caster uses a semi-continuous, vertical casting process for the production of aluminum slab, in which metal feeding takes place via a melt distribution system consisting of a nozzle, a plug valve, and a glass cloth filter sack. The EMC process is contact-free and enables the production of rolling slabs with a very smooth surface and a homogeneous microstructure.

A total of five new batch homogenizing furnaces from Hertwich have been installed since 2014, with the fifth completed in 2017. Each of the homogenizing furnaces has a capacity of 200 tonnes, with a fully automated system that identifies each slab with its batch and rolling slab number.

In addition, recycling is considered a core capability for AMAG. Ranshofen is considered to be one of Europe’s largest single-site recyclers, with 330,000 tonnes of scrap processed in 2016. “Our Ranshofen site stands out from the rest of the industry thanks to its uniquely high recycling ratio,” said Wieser. “We use 75-80% aluminum scrap on average for the production of our high-quality foundry alloys and rolling slabs. Thanks to the various processing technologies used in both our casthouses and the extensive recycling expertise of our personnel, almost all types of scrap in various states and compositions can be processed at the site.”

In order to further improve its recycling capabilities, AMAG commissioned an automatic scrap sorting plant from TOMRA in 2016 (Figure 7). “The latest technology has been installed in both the Ranshofen recycling center and in the rolling ingot foundry,” said Wieser. “This will enable us to maintain our scrap metal use of over 75% as production quantities increase throughout the facility, ensuring that products from Ranshofen are produced sustainably.”

Conclusion

AMAG’s continuous expansion through the AMAG 2014 and AMAG 2020 projects has not only provided increased capacity, but enables it to process larger plate, sheet, and coil. These projects provide the Ranshofen site with two independent production streams—each with a hot and cold rolling mill along with corresponding casthouse—thus optimizing product delivery flexibility and reliability. Combined with the high degree of automation provided by the new hot and cold rolling facilities, this has enabled AMAG to strengthen its competitiveness in the global rolled aluminum products market.

According to AMAG, the global rolled aluminum market is seeing strong growth of over 6% per year worldwide, most notably in the transportation sector (particularly automotive and aircraft), which is expected to see an 11% annual growth rate.

“With this expansion project, AMAG is sending a clear signal in the market for rolled aluminum products,” said Wieser. “We remain the only company to process all aluminum alloys from 1xxx to 8xxx at a single integrated site, and so we can create our own rolling slabs and flat rolled products from these alloys. For these reasons, I can say that we have a unique concentration of expertise at the Ranshofen site. The future will be exciting, as we can now combine this expertise with the most modern facilities.”

Editor’s Note: This article first appeared in the December 2017 issue of Light Metal Age. To read more articles from this issue, please subscribe.