By Michael Niedzinski, Constellium.

Aluminum armor solutions have been in existence for the past 60 years, almost since the start of the Aluminum Association circa 1954. These plate products were developed for armored personnel carriers, either wheeled or tracked. Armored vehicles serve an important function as reconnaissance, ambulance, scout, or infantry delivery vehicles. One of the first armored vehicles, which used aluminum armor, was the M113 armored personnel vehicle (Figure 1). The M113 introduced new aluminum armor that made the vehicle much lighter than earlier vehicles; it was thick enough to protect the crew and passengers against small arms fire, but light enough that the vehicle was air transportable.

The plate products used were developed during the Vietnam War era. Since then, many enhancements and improvements have been made and thousands of these vehicles are in service. Aluminum armor was developed and selected based on its lower density. Density of aluminum alloys is about 2.7 g/cm3 (0.1 lb/in3) and can vary ±7% from the nominal based on the level of alloying elements. Depending on the level of alloying elements, density of steel can vary between 7.75 and 8.05 g/cm3 (0.280 and 0.291 lb/in3). Lower density translates into lighter vehicles, thus improved mobility. Higher mobility results in higher speed and better acceleration and deceleration, which results in higher responsiveness on the battlefield and more maneuverability in urban warfare. Lighter weight also allows easier negotiation of steep slopes. All of these attributes result in lowering the vulnerability of the vehicle. Additionally, most of these vehicles are transferred to the war zone via air transport. More lightweight vehicles can be deployed using fewer aircraft. Lighter weight also reduces the need for refueling, providing a longer range.

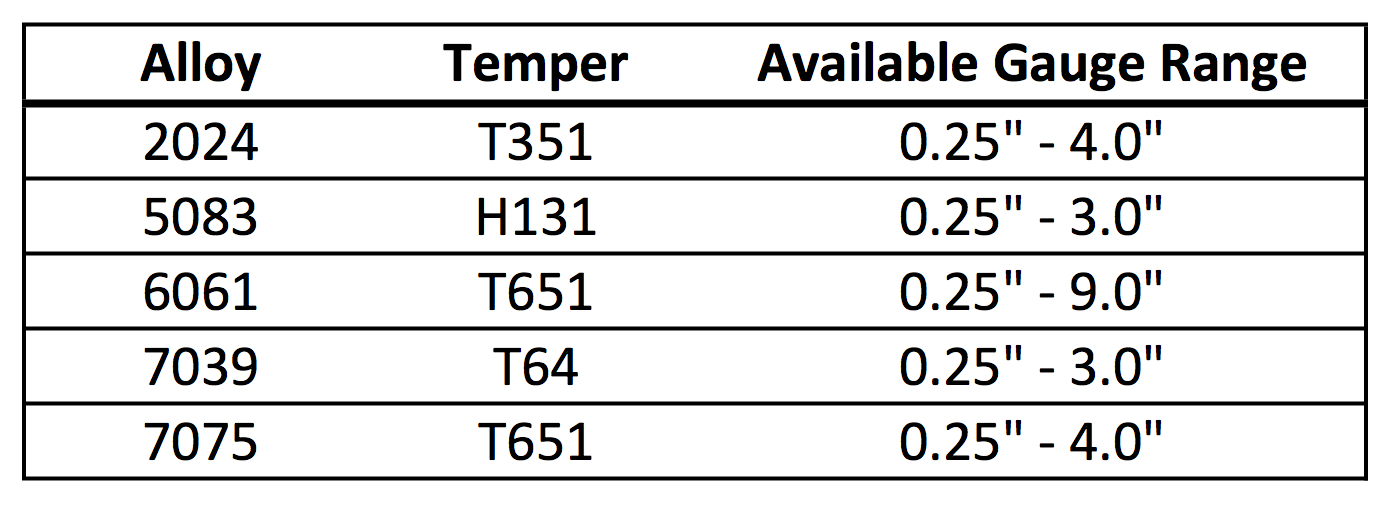

Based on their ballistic characteristics, alloys 5083-H131 and 7039-T64 have been the preferred alloys for armored vehicles. Alloy 5083 in H131 temper is a high strength temper developed through a high level of cold work (cold roll/stretch). Based on the high level of cold work, formability is reduced but the material is very weldable and exhibits good corrosion resistance. Conversely, alloy 7039 has superior protection against armor piercing and fragment threats, but it has substandard corrosion (especially stress corrosion) resistance. Alloy 7039 is more difficult to fusion weld and thus the only way to join individual components is by using mechanical fasteners. Other alloys have been employed (Table I), however their ballistic performance was not as effective as the two aforementioned products.

However, lower density does not necessarily mean lighter weight armor. The concept of areal density was developed to quantify the ability of armor to defeat particular or combinations of threats. Since armor is used to protect a particular area, its practical weight is best described by its areal density. Areal density is described as the ratio of weight of the armor system to area being protected. In the U.S., pounds per square foot are the typical units. Thus areal density is a physical characteristic of the armor and does not indicate if that armor is effective. The effectiveness of two armor systems can only be assessed by comparing their performance against the same threat. Based on multiple tests, a lower areal density was observed for aluminum armor when compared to steel, for the threats mentioned hereafter. Thus, for a given protection level, lower weight armor can be used, resulting in a lighter vehicle. Primary threats for the occupants of these vehicles are Armor Piercing (AP) rounds. Another threat was shrapnel from artillery rounds, such as Caliber .30 AP M2, Caliber .50 AP M2, Caliber .50 FSP, and 20 mm FSP.

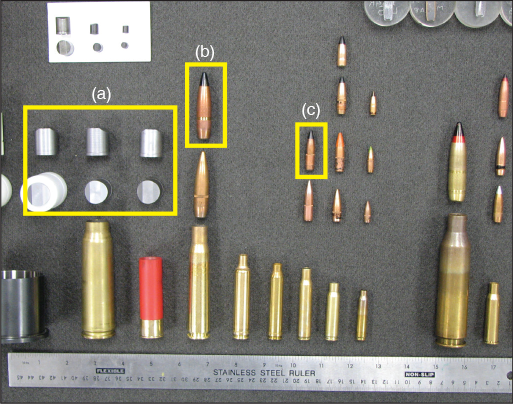

The Army Research Laboratory developed a series of tests to help evaluate and properly size armor plates used on the sides and front of the vehicles. Standardized AP rounds and projectiles, which simulate shrapnel, or fragment simulator projectiles (FSPs) are fired at a test plate from a specific distance to obtain the ballistic protection limit for a given thickness of aluminum or steel armor (Figure 2). Ballistic protection limit is a number based on multiple shots, which provide a balance between complete and partial penetration. Tables that list ballistic protection limit or V50 (limit protection curve corresponding to a complete perforation by a given projectile with a 50% probability) for each combination of threat and armor thickness are provided in MIL-DTL standards, which are public documents. Therefore, designers of armored vehicles have a ready reference to select a particular aluminum armor type and thickness to defeat a specific combination of threats.

(a), .50 caliber AP round (b), and .30 caliber M2AP round (c).

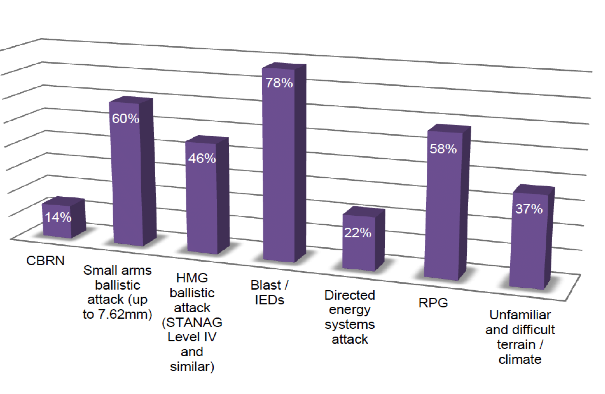

Over the past 15 years, new types of warfare have emerged. Soldiers are increasingly engaged in urban warfare with multiple threats. AP rounds are fired at close distance and rocket propelled grenades are a weapon of choice. Beyond this, a new threat has emerged affecting armored columns on the roadways and on city streets. The emergence of improvised explosive devices (IEDs), which detonate under a moving vehicle, forced the Army to seek new solutions that would improve the performance of aluminum armor alloys by adding blast protection while enhancing AP and FSP protection. Improved occupant safety and crew survivability from blast, fragmenting, and armor piercing threats for combat and tactical wheeled vehicles became a primary objective, as shown in a survey of major threats affecting combatants in current warfare (Figure 3).

Aluminum producers have responded by developing more advanced armor solutions. Constellium, which is a global producer for a broad scope of markets and applications, including the aerospace, defense, and transportation industries, has provided a number of new aluminum armor solutions under the KEIKOR™ brand (named after the armor of Samurai warriors, which was able to defeat many contemporary threats). Two alloys, which draw their heritage from aerospace applications, emerged as the preferred choice based on an excellent combination of strength, blast/ballistic protection, corrosion resistance, and high formability in intermediate tempers. These armor plate products are KEIKOR 2139™ and KEIKOR 7056™. This article will highlight alloy 2139, which has been standardized in MIL-DTL 32341A.

Constellium Plate Alloy for Armor

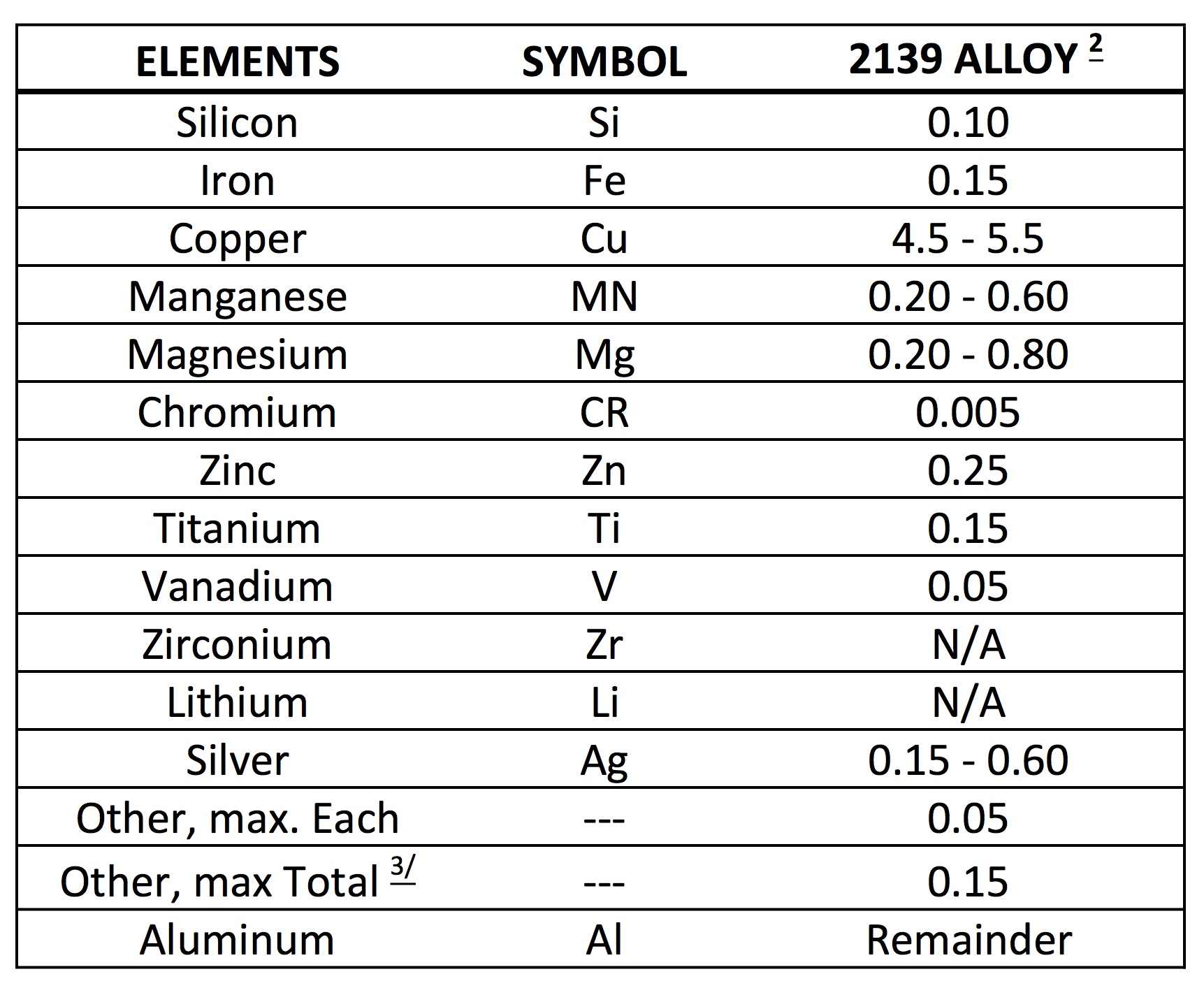

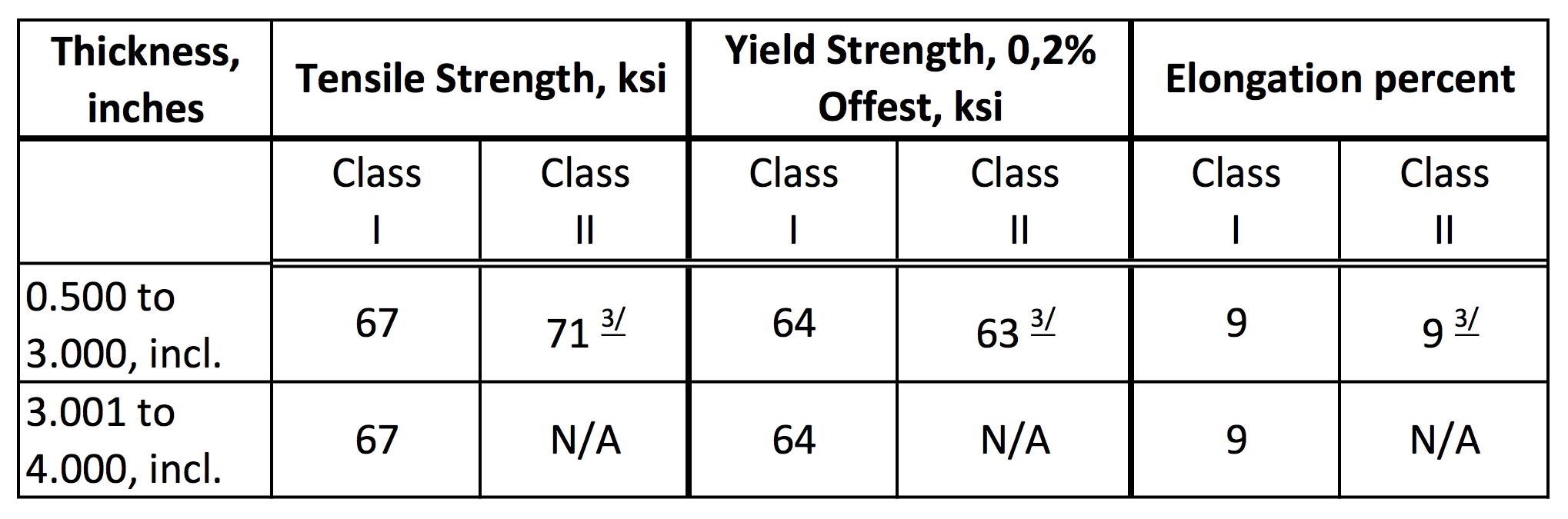

Keikor 2139 was developed for armor applications in the 0.500-4.000 inch thickness range. Originally, this alloy was developed for aircraft wing applications under AMS 4468, but its high strength and toughness balance prompted examination as an armor alloy. Standardized ballistic testing, described earlier, was used to develop a ballistic table for the four types of threats in the AP and FSP categories. Alloy 2139 is a high strength/toughness copper-magnesium-manganese-silver alloy with superior corrosion resistance and ability to resist softening at elevated temperatures. Corrosion resistance, specifically stress corrosion cracking (SCC), is a very important aspect because these vehicles are used in various environments, including marine. The early precursors in the 2xxx armor plate family, specifically armor 2519-T87, has improved ballistic performance when compared to legacy armor but has very poor SCC resistance due to its high copper level. Thus, 2519 is not suitable for multiuse environments. Chemical analysis and minimum tensile properties of 2139 are shown in Tables II and III.

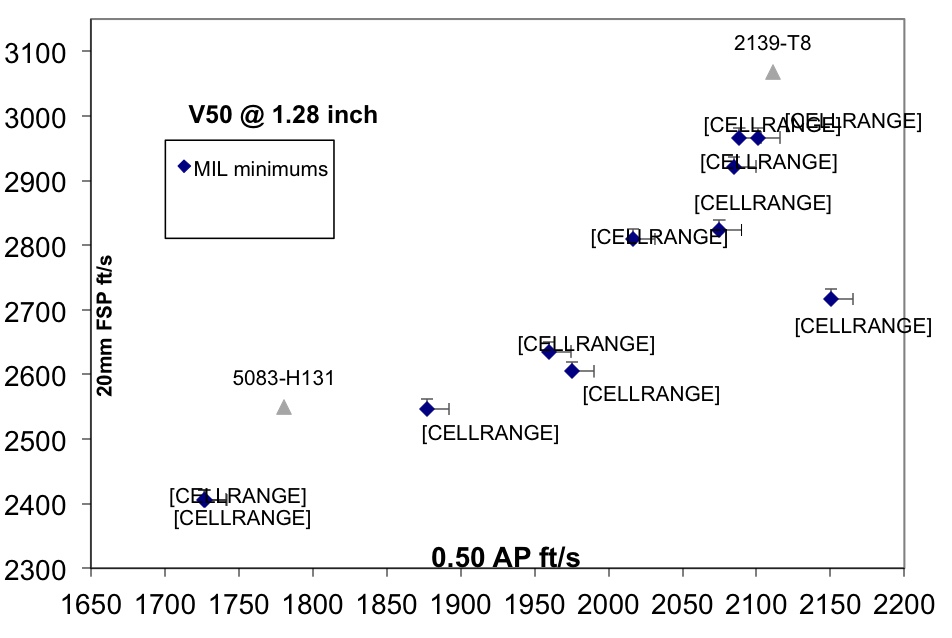

Keikor 2139 is produced in two discrete tempers, an AP/FSP resistant temper (T8) and a blast resistant temper (T84). Alloy 2139 T8 (AP/FSP resistant) is produced using a proprietary level of cold work and followed by artificial aging treatment to attain balanced properties. It is typically used for the applique or side and top armor. Ballistic testing indicated superior performance when compared to the two legacy armor solutions, i.e., 5083-H131 and 7039-T64. A relative comparison of the V50 velocity for two threats — 20 mm FSP and .50 caliber AP — is shown in Figure 4. This chart also includes Constellium’s Keikor 7056 produced in two discrete tempers, AP resistant and blast resilient (which are not discussed in this article but may be covered in the future). The chart indicates that, for 1.28 inch thick armor plate, V50 for the 20 mm FSP threat is about 2,550 and 2,650 ft/sec for 5083-H131 and 7039-T64, respectively. Alloy 2139-T9 exhibits V50 of about 3,050 ft/sec. In practical terms it means that, for a given armor thickness, alloy 2139 offers 400-500 ft/sec extra margin of safety. Similarly, in the .50 Cal AP area alloy 5083-H131 and 7039-T64 offer V50 of 1,780 and 1,910 ft/sec, respectively. Alloy 2139 exhibits V50 of 2,110 ft/sec. Margin of safety ranges from 200 to 330 ft/sec. Thus, manufacturers of armored vehicles can either provide extra survivability or consider a down gauge of the design yielding equivalent protection with lighter, more maneuverable construction.

regards to V50 velocity for two threats—20 mm FSP and .50 Cal AP.

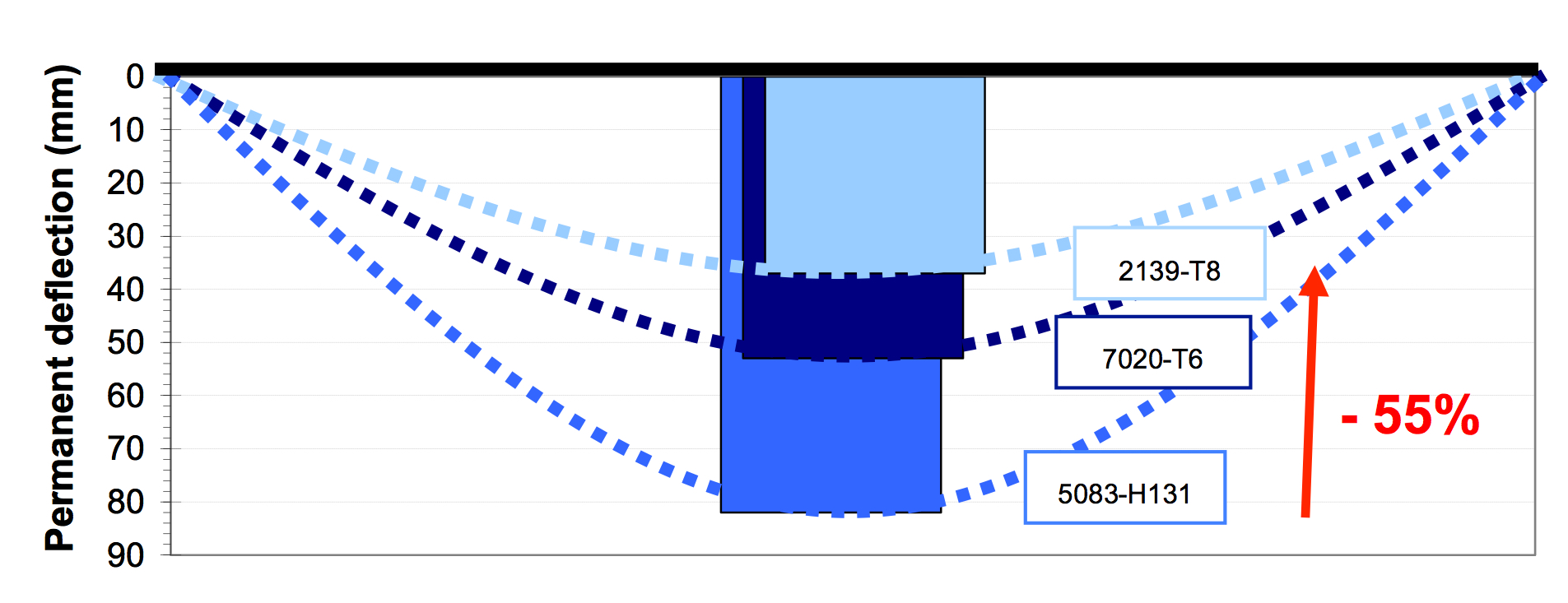

Keikor 2139’s minimum ballistic properties compare favorably with the legacy armor offering. More significant are the blast characteristics of the second temper, 2139-T84. Due to its higher strength and toughness, 2139-T84 experiences lower plastic deformation under a standardized blast test when compared to legacy 5083 armor. In a standardized test, a sample plate is exposed to a blast of equivalent weight of TNT with constant standoff distance. The amount of buckling of permanent plastic deformation is measured after the blast. Figure 5 indicates that, under standardized test conditions, 2139-T84 exhibits plastic deformation about 50% lower than equivalent thickness of 5083-H131 armor. Occupants of the vehicle experience significantly lower impulse/impact during the explosive event. This reduces the potential for injuries.

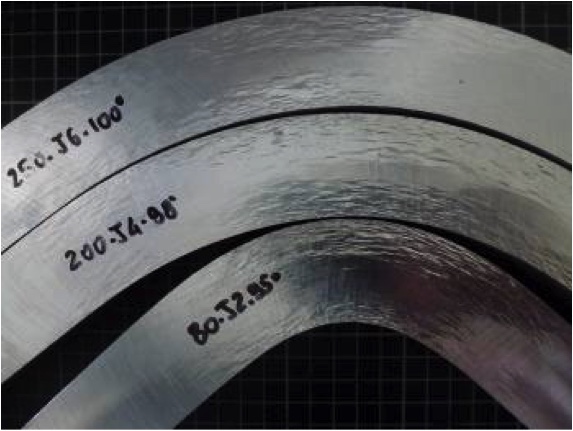

T84 (blast resistant) temper is generally used for the underbelly of the armored vehicle and is obtained by the end user through aging Keikor T34 at an elevated temperature using a thermal treatment recipe supplied by Constellium. Plate for the complex, heavily formed bottom of the vehicle is supplied in T34 or an intermediate temper produced by solution heat treat (SHT) and proprietary cold work of the plate. This results in a product with high formability and low flow stresses needed for the bending and forming processes. Formability of alloy 2139 is illustrated in Figure 6. Constellium is in partnerships with metal machine forming facilities to optimize the fabrication needed to produce the required shapes. Older constructions utilized welded structures or bolted constructions. Welds and bolt holes introduce weak areas or stress raisers during a blast event, which may cause perforation of the underside of the vehicle with resultant intrusion of lethal fragments into the crew compartment. Conversely, a monolithic formed underside provides a much stronger structure, which may plastically deform but will survive a blast event without fracturing. This also minimizes and limits welding activity to the less vulnerable sections of the vehicle. Constellium developed welding techniques using commonly available filler wires in the 2xxx and 4xxx weld wire family. Weldability of alloy 2139 provides an extra manufacturing flexibility not readily attainable with 7xxx series alloys.

Several vehicles have been designed and fielded by taking advantage of the ballistic and blast superiority of 2139. Specifics of the design of these vehicles are classified for security reasons. One example of a vehicle, which was built using Keikor 2139 was the Concept for Advanced Military Explosion-Mitigating Land (CAMEL) program vehicle. The vehicle (Figure 7) was built by Detroit, MI, based Pratt & Miller and was successfully tested under various threat scenarios at the Army’s Tank Automotive Research Development and Engineering Center (TARDEC). This work was done in support of the Combat Vehicle Prototype (CVP) platform.

In September 2016, it was announced that Constellium will supply Keikor 2139 for TARDEC’s entire CVP integrated hull capsule. Constellium’s manufacturing plant in Ravenswood, WV, will supply the 2139 plate. Erik Polsen, TARDEC’s chief engineer for CVP survivability, said Constellium’s 2139 aluminum alloy “met the necessary performance properties and characterized manufacturing process for the performance and packaging requirements that we were looking for in our hull structure.”

Editor’s Note: This article first appeared in the December 2016 issue of Light Metal Age. To read more articles from this issue, please subscribe.