Emirates Global Aluminium (EGA) signed an agreement with Gulf Extrusions and the Mohammed Bin Rashid Space Centre (MBRSC) to send CelestiAL aluminum produced from solar power into space. The metal will be used to produce extruded components for MBRSC’s MBZ-SAT, the region’s most advanced commercial satellite in the field of high-resolution satellite imagery.

“At EGA, we have been making [aluminum] in the Emirates since 1979. We are proud to now provide CelestiAL solar aluminium, together with Gulf Extrusions, to another UAE champion which will use it to reach beyond the sky on behalf of our nation. Aluminium is an essential material for modern life, including space travel, and the UAE’s production through EGA is a global contribution to human progress.”

Since the first satellite launch in 1957, aluminum has been the leading material in space exploration due to its lightweight, strength and resistance to corrosion. EGA has developed its own aluminum smelting technology in the UAE for more than 30 years. EGA’s latest technology, DX+ Ultra, is amongst the most efficient in the global aluminum industry. The company has used its own technology in all its smelter expansions since the 1990s has retrofitted all its older production lines and was the first UAE industrial company to license its core process technology internationally.

In 2021, EGA became the first company in the world to produce aluminum commercially using solar power through a partnership with Dubai Electricity and Water Authority, which operates the Mohammed bin Rashid Al Maktoum Solar Park in the desert outside Dubai. Electricity generation accounts for around 60% of the global aluminum industry’s greenhouse gas emissions. The use of solar power significantly reduces these emissions.

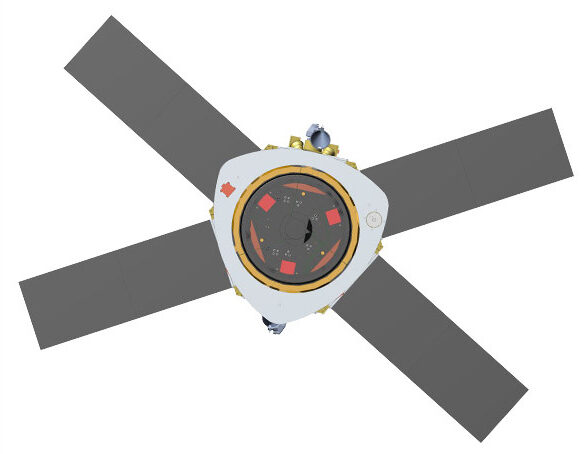

Gulf Extrusions will manufacture the solar-produced aluminum into extruded components for the MBZ-SAT commercial satellite. A subsidiary of Al Ghurair Group, the extruder makes components for everything from car parts to window frames for the local market and global export.

“Our parts, made in the UAE with EGA’s aluminum, are already found in everything from cars to skyscrapers around the world,” said Omar Shegem, chief executive officer of Gulf Extrusions. “We are now honored that our work will leave the Earth’s atmosphere for the first time as part of MBZ-SAT. Together we are making it in the Emirates for the world and beyond.”

MBRSC is dedicated to the advancement of space science, technology, and exploration, playing a pivotal role in the UAE’s space ambitions. The center’s main activities encompass the UAE Satellite program, the UAE Astronaut program, the Emirates Mars Mission, and the Mars 2117 program, which includes the Emirates Lunar Mission and Space Ventures, among others. Recognizing the importance of collaboration, MBRSC actively engages in partnerships with private entities, fostering innovation and driving the growth of the space sector.

“At MBRSC, our mission is not only to explore the vast potential of space but also to drive the diversification of the UAE’s economy,”said His Excellency Salem Humaid AlMarri, director general of the Mohammed Bin Rashid Space Centre. “We recognize the immense value of joining forces with diverse partners to leverage their unique expertise and capabilities. By forging strategic partnerships with innovative entities such as Emirates Global Aluminium and Gulf Extrusions, we are able to expand the horizons of the UAE’s space sector. Together, we are committed to pushing the boundaries of innovation and fuelling the growth of this vital industry.”

The partnership is a space sector milestone for Make it in the Emirates, supporting the UAE’s Operation 300bn ambition to more than double the size of the industrial sector by 2031, and for the UAE’s goal of being a leader in space exploration.

The first fully UAE-made aluminum parts have already been delivered to the MBRSC at Al Khawaneej in Dubai. The MBZ-SAT commercial satellite due to be launched in 2024.