Trimet Aluminium SE commissioned a new casting machine for aluminum sows at its aluminum smelter in Voerde, Germany. Prior to this, the smelter delivered 99.9% pure aluminum in liquid form to its local customers and the Trimet foundry in Essen, Germany. Now, the site is able to produce its own block metal.

“The casting machine gives us greater flexibility, enabling us to better meet changing market requirements and customer needs,” siad Dr. Andreas Lützerath, member of the executive board at Trimet. “The high metal purity of the cast aluminum also satisfies a growing need within the processing industry.”

The new machine features a casting carousel capable of producing 20 aluminum sows per hour, each weighing 780 kg. In order to guarantee consistent product quality, the entire process is automated — from casting, skimming, and labeling of the aluminum sows to weighing and depositing them on a conveyor belt. The new machine also further improves occupational health and safety for the employees.

Additional Investments

Trimet is currently investing in the upgrade of the 188 electrolytic cells at Voerde. In the past year, work has begun on converting the busbar system within the cells to improve their energy efficiency and to cut carbon dioxide emissions.

“Energy efficiency is a key issue for us,” said Christian Krupp, site manager at the Voerde smelter, where he had been working for 23 years. “We are continuously working on making sure that the plants and work processes are as easy on resources as possible. This also includes digitally networking all production processes.”

Trimet is also taking advantage of opportunities to save energy beyond the area of metal production. In the future, the aluminum smelter will conduct hot air extracted from the electrolytic cells to the Rhine-Lippe Port in Wesel, Germany, where it will be used as energy to power a logistics center. The effective use of this waste heat will prevent the production of around 27,000 tons of carbon emissions annually.

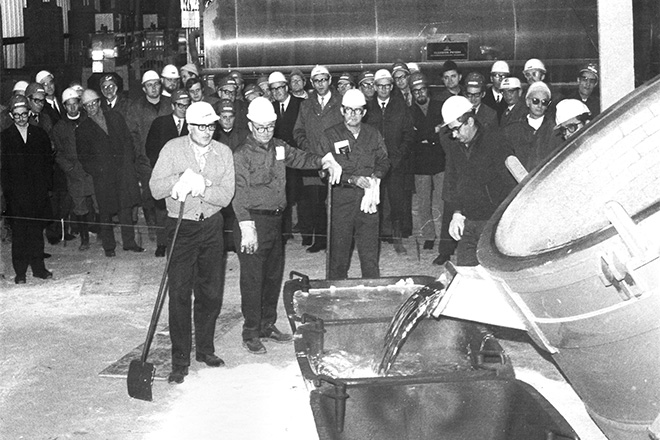

Celebrating 50 Years

Trimet is also celebrating the 50th anniversary of tis Voerde aluminum smelter and adjoining anode factory, which started operation on May 11, 1971. The smelter was planned and built by Kaiser-Preussag Aluminium GmbH, which had been founded by the U.S. aluminum manufacturer Kaiser Aluminum Corporation with the involvement of the German conglomerate Preussag AG. With its 188 electrolytic cells, the aluminum smelter had been designed for an annual capacity of 64,000 tons of aluminum, but achieved an output of 72,000 tons within only a few years.

Ownership of the aluminum plant has changed hands several times since the 1980s. Eventually, Trimet Aluminium SE acquired the site in May 2014, along with its 280 employees at the time. Following this acquisition, Trimet expanded Voerde’s production capacity and set the smelter on a growth course.

Today, the Voerde smelter produces around 95,000 tons of aluminum and 65,000 tons of carbon anodes here each year. Employing 320 personnel, the smelter is an integral part of the Trimet group, which has two other locations in Germany and meets the growing demand for aluminum in various sectors, such as vehicle manufacturing, the packaging industry, and the building sector.

“With its technical equipment and convenient geographical location, the aluminum smelter in Voerde is well positioned for the future,” said Lützerath. “Above all else, however, it is the experience, expertise, and commitment of the employees that play a key role in the location’s success, and they will continue to secure its future.”