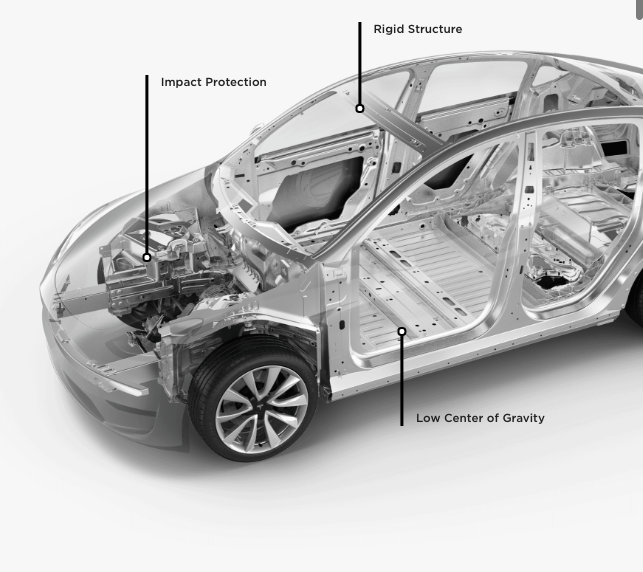

Tesla is developing its latest electric vehicle, the Model Y, a fully electric compact utility vehicle (CUV) that will have the longest range of any electric CUV or sports utility vehicle (SUV), lasting for 300 miles before needing to be recharged. Of this, 168 miles worth can be charged in 15 minutes at ‘supercharger’ locations around the world. With a five star safety rating the CUV is designed to be the safest vehicle in its class according to Tesla, “low center of gravity, rigid body structure and large crumple zones provide unparalleled protection.”

Built on the Model 3

Model Y shares 76% of its parts with the Model 3 — with a similar hybrid aluminum and steel body (a departure from previous Models S and X, which used all-aluminum construction). Lightweight aluminum will be used in areas of the body structure that are less likely to be damaged in case of accidental impact, such as the trunk floor and wheel wells. The likely reason for this is due to repair concerns. Although aluminum has excellent crash performance, when a crash does occurs, the entire aluminum component must be replaced compared to steel components that can be reworked back into shape. The use of aluminum reduces the overall weight of the vehicle, helping to extend battery range.

The battery tray is also comprised of aluminum and steel, with the materials bonded together using friction stir welding, adhesives, and mechanical fasteners.

Japanese company UACJ produces aluminum automotive parts for the Tesla Model 3. In 2017, the company invested $26 million into its subsidiary UACJ Automotive Whitehall Industries, Inc. in Michigan (acquired in 2017) in order to support production for Tesla in the U.S. Based on this recent investment, it is likely that UACJ will also be manufacturing the parts for Model Y, though this has not been officially announced.

In the Motor

Aluminum is also used in the cabling connecting the electric motor with the onboard battery pack in the Model 3. Traction cabling allows electric current to flow between the motor and battery, much like fuel supply lines allow gasoline to flow in an internal combustion vehicle. A shielded aluminum with silicone cable provides this essential function for the Model 3 Tesla. The aluminum cabling is lighter and less expensive than traditional materials used in cabling. Tesla reportedly ordered 3,000 km (1,864 miles) of these shielded aluminum cables as part of this $5.4 million deal with an Austrian cable company.

Vehicle of the Future

Steering the pulse of society towards technological advancement, the Model Y will have full self-driving capabilities, which will enable automatic driving on streets and highways, if future regulations permit. Depending on one’s perspective, Tesla is either heralding the futuristic age of high-tech vehicles, or a harbinger of a new science-fiction-like reality as the car will also have the ability to “come find you anywhere in a parking lot.”

The Model Y is already available for order, however interested customers will have to be patient as standard range production for the Y is expected to begin in 2021.