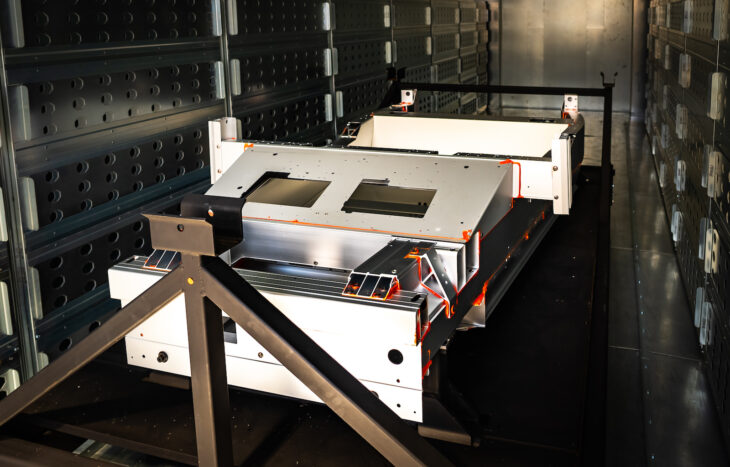

Lotus Group marked the beginning of a new manufacturing era with the first extruded and bonded aluminum chassis being built at its new facility in Hurricane Way, Norwich.

The unit, a chassis for the legendary Lotus Elise, was built for the validation and quality checking of the company’s new manufacturing process. This aluminum chassis is not destined for a particular vehicle, but will remain at the factory for standard testing. As chassis manufacturing volumes grow steadily over the next few months, this will help the OEM ensure that their processes adhere to the globally recognized quality standards expected from Lotus.

The new 12,300 m2 facility has the capacity to build several thousand aluminum chassis per year. It will produce around 1,500 units for the Lotus Elise, Exige and Evora during 2021. Set to employ 125 highly skilled operators, technicians and engineers, the site also houses the welding and fabrication of sub-frames, suspension components, and other key parts for Lotus cars.

This investment from Lotus, whose headquarters and sports car manufacturing are located 10 miles away in Hethel, Norfolk, further demonstrates its commitment to the region. Lotus announced in July 2020 that it had outgrown existing facilities in Worcester and Norwich, and would therefore bring together both production capacities into one new combined location at Hurricane Way in the north of Norwich. Tooling has already been upgraded to be ready for a new range of Lotus sports cars to be launched in the coming years.

“The production of this first lightweight chassis is a significant landmark for the new Hurricane Way facility,” said David Hewitt, executive director of Operations, Lotus Cars. “I would like to thank everyone who has worked extremely hard to ensure that, despite challenging circumstances, it is up and running and on schedule. In parallel, we are close to finishing our new assembly facility at our Hethel HQ. By the end of the year, the whole of Lotus’ sports car manufacturing facilities and processes will be either new or vastly improved. This will give us solid foundations to maintain our leadership in the rapidly changing low volume automotive assembly industry.”

The Lotus Final Edition Models

Lotus has been producing the Elise model in various iterations for 25 years. In honor of the Elise, and its sister, the Exige, Lotus has announced a range of five new Final Edition cars, which have higher power, greater standard specification, and – in true Lotus style – light weight.

These cars are the ultimate versions of the Elise and Exige and mark the pinnacle of technical development to showcase more than two decades of engineering. The performance cars are set to be built in limited numbers, and Lotus is anticipating high demand from global market as customers rush to acquire this slice of history. They are available with unique paint colors and new exterior decals, wheel finishes, and trim, as well as Final Edition badging.

The improvements continue under the skin, a fact reflected in new names that reveal their higher power outputs on three of the five — the Elise Sport 240, Elise Cup 250, Exige Sport 390, Exige Sport 420, and Exige Cup 430.

The Elise and Exige Final Edition cars are on sale now at official Lotus Cars importers.