Rio Tinto began construction of a new commercial scale demonstration plant at its Rio Tinto Fer et Titane (RTFT) metallurgical complex in Sorel-Tracy, Quebec. When the plant begins operation, Rio Tinto will become the first producer of high-quality scandium oxide in North America. In addition, the new facility will enable the production of high quality aluminum-scandium alloys, for which the company has already received its first order. Both the high quality scandium oxide and aluminum-scandium master alloy will be commercialized under the business brand name Element North 21.

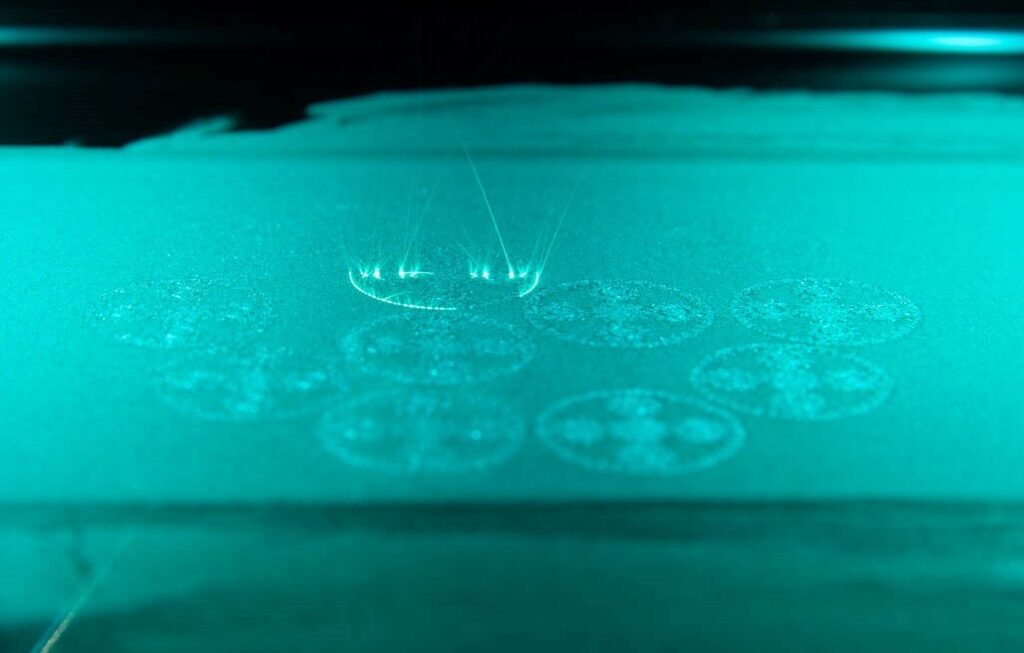

Scandium oxide is used to improve the performance of solid oxide fuel cells, which are used as a power source for data centers and hospitals, as well as in niche products such as lasers and lighting for stadiums or studios. It is also used to produce high-performance aluminum-scandium master alloys for the aerospace, defense, and 3D printing industries.

“We are proud to offer North America’s first reliable supply of scandium oxide using an innovative and sustainable process, with the construction of this new plant,” said Stéphane Leblanc, managing director of Rio Tinto Iron and Titanium. “With the support of Rio Tinto’s aluminum business, we are uniquely positioned to deliver aluminum-scandium master alloys and develop synergies with North America’s manufacturing supply chain.”

New Scandium Plant

Rio Tinto is investing US$6 million for the construction of the first module of the commercial scale demonstration plant, which will use an innovative process developed by RTFT. Proven at the pilot scale, the process is able to extract high purity scandium oxide from the waste streams of titanium dioxide production, without the need for any additional mining at its ilmenite mine in Havre-Saint-Pierre, Quebec.

The first module of the plant will have an initial capacity to produce three tonnes of scandium oxide per year, or approximately 20% of the current global market. It will also be able to produce aluminum-scandium alloys to meet customer’s needs. The new plant will have the ability to expand its operations through the addition of further modules in line with market demand.

“RTFT’s scandium oxide valorization project is a concrete example of how we can extract value from our mining wastes,” said Jonatan Julien, Quebec Minister of Energy and Natural Resources. “It demonstrates our ability to innovate and seize business opportunities in a growing market as we strive to ensure secure supplies of critical minerals. This business has the potential to become a major scandium supplier outside China.”

RTFT expects to begin commercial supply of scandium oxide in the second quarter of 2021.

First Order for 3D Printing Alloy

Rio Tinto signed an agreement with Amaero, a leader in metal additive manufacturing, for the supply of a first commercial batch of high-performance aluminum-scandium alloy. The alloy will be delivered from the company’s new demonstration plant under construction at its RFTF complex.

“As a global leader in aluminum and the first producer of high-quality scandium oxide in North America, Rio Tinto is uniquely positioned to provide a secure source of aluminum-scandium alloy to the market,” said Tolga Egrilmezer, vice president Sales and Marketing, Rio Tinto Aluminium. “Aluminum-scandium alloy is the material of choice where a lightweight, high-strength material with thermal resistance and good welding properties is needed, such as for defense and aerospace applications. This first sale demonstrates our ability to develop products that meet our customers’ needs, drawing on our technical expertise and world class assets.”

Under the agreement, Rio Tinto will deliver aluminum-scandium alloy billets, which will be processed by Amaero into powder for 3D printing and offered to the market for high temperature applications. The companies also plan to collaborate to develop the supply chain for Amaero’s high operating temperature aluminum alloy, Amaero HOT Al, and to commercialize this lightweight material for applications in the aerospace, defense, and other industries.

“We are very pleased to enter this agreement with Rio Tinto to purchase the first commercial batch of aluminum scandium alloy from a North American source,” said Barrie Finnin, chief executive officer of Amaero. “This is an important step in the commercialization of this high performance alloy that will be used in our breakthrough 3D metal printing technology. We look forward to working with Rio Tinto to progress the production of the alloy so we can commence the qualification process with key customers in the aerospace sector and other industries.”