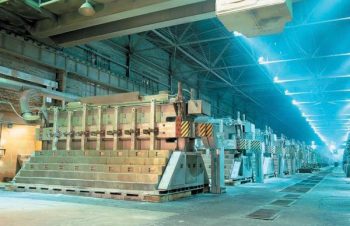

Partnering with world class experts in the aluminum industry, the Minerals, Metals and Materials Society (TMS) develops aluminum courses that provide the latest tools and techniques for solving current problems and anticipating future challenges. The courses feature networking events, plant tours, and individualized instructor attention to provide unmatched opportunities to connect and learn from colleagues and […]