The U.S. Department of Energy (DOE) in partnership with Lawrence Livermore National Laboratory (LLNL) is providing nearly $1.2 million for four new projects to support American steel and aluminum manufacturers in improving energy efficiency, increasing productivity, and accelerating manufacturing innovation. Among the projects to be funded is Alcoa’s “Large Eddy Simulation to Improve Cell Design,” while the other three projects are focused on steel.

The funding announced will provide advanced computing capabilities to improve manufacturing processes and resolve key manufacturing challenges through the use of high performance computing. These projects were selected from the sixth solicitation for the High Performance Computing for Manufacturing (HPC4Mfg) program. The HPC4Mfg program, supported by DOE’s Advanced Manufacturing Office, facilitates technical support from national laboratories, including access to supercomputing capabilities, high-end modeling and simulation software, and subject matter experts.

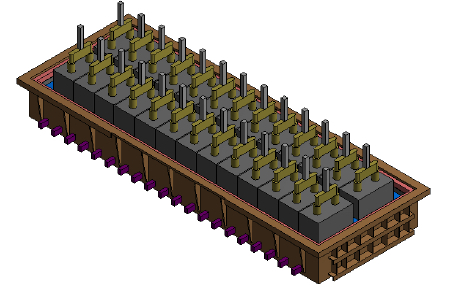

Large Eddy Simulation to Improve Cell Design

Alcoa in New Kensington, Pennsylvania, will receive $300,000 to support its project to develop a novel hybrid advanced smelting process to increase productivity and cell performance while minimizing emission of greenhouse gases. The design utilizes novel materials and a unique anode-cathode combination. Computational tools and pilot prototypes are being developed to address materials, process, and design for this technology. Alumina and the bath ratio in the process both must be maintained at the desired levels for the new smelting process, which is quite challenging due to the unique flow field and limited area of the narrow space between the anode and cathode pair. Sophisticated computational tools are required to understand the alumina dissolution and bath ratio distribution while optimizing the number of feed, feed rates, and feeder locations. This work proposes application of large eddy simulations (LESs) to understand alumina dissolution and bath ratio distribution in the proposed cell design. Optimized feeder operation is necessary to achieve the target 15% energy efficiency improvement over the conventional Hall-Héroult process.

The principle investigator on the project is Rajneesh Chaudhary, Alcoa USA Corp, with Prashant K. Jain from Oak Ridge National Laboratory acting as a national lab partner.