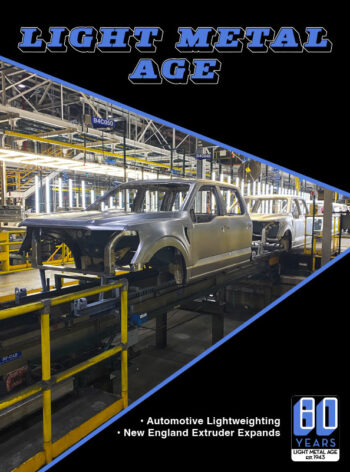

Cover Aluminum Ford F-150 crew cab being assembled at the Dearborn Truck Plant in Dearborn, MI. Switching to aluminum for the body of its best selling pickup truck saved weight, improved performance, and was able to hold up to the rugged workload of truck users. As Ford moves into the electric vehicle market with its […]