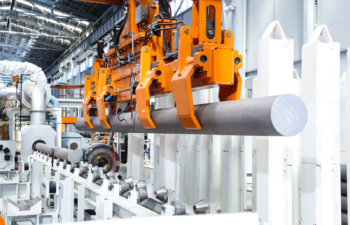

Shape Corp., a global tier-one automotive supplier, recently held a groundbreaking ceremony for its new Aluminum Center of Excellence to be located in Trenton, OH (Figure 1). The 322,000 sq ft facility will allow the company to expand its manufacturing capacity for the production of tight tolerance aluminum extrusions and assemblies, while also providing research […]