By Andrew Halonen, Mayflower Consulting LLC.

The automotive business is rife with change as OEMs introduce new powertrains for hybrid and electric vehicles (EVs). Car companies are also spending billions in big bets on advanced driver assistance systems (ADAS), ride sharing, artificial intelligence (AI), and service businesses in an attempt to shift dollars from the aging population to the next generation of drivers, and everyone in-between.

Regardless of the big changes surrounding vehicle design, humans still need to drive and ride in those cars. Therefore, it is imperative that car manufacturers design the vehicle that keeps everyone safe. Crash management is the umbrella term for the science and engineering of passenger safety. This could include technologies such as the ADAS system (which may have as many as ten sensors to monitor the surroundings on all four sides of the vehicle)1 to structural systems that protect the passenger from impact during a collision. A variety of materials play an important role in structural crash management systems. Aluminum extrusions are a versatile structural form that continues to see a growing market share in automotive crash management.

Crash Management

When considering the purchase of a new vehicle, it is common to look into its safety record as determined by government-monitored crash tests. The National Highway Traffic Safety Administration (NHTSA) is the governing body in the U.S. In addition, the Insurance Institute for Highway Safety (IIHS) does extensive testing and implements a star rating system (up to five stars) to determine vehicle safety, due to the fact that accidents are covered by auto insurance.2 IIHS evaluates two aspects of vehicle safety—crashworthiness (how well a vehicle protects its occupants in a crash) and crash avoidance and mitigation (how well vehicle technology can prevent a crash or lessen its severity). In addition to its star rating system, the IIHS also presents an annual Top Safety Pick, based on vehicle segment.

To achieve a star rating from the IIHS, a vehicle is assessed through a series of tests addressing frontal crash, side crash, roof strength, head restraints and seats, and front crash prevention. Several of these tests directly examine the structural design of the vehicle. Three tests determine the crash management of a vehicle in the event of a frontal crash, including the moderate overlap test (the vehicle travels at 40 mph toward a barrier) and the driver-side small overlap and passenger-side small overlap tests, both of which are designed to replicate what happens when the front left or right corner of a vehicle collides with another vehicle or an object like a tree or utility pole. In the side crash test, a 3,300-lb SUV-like barrier hits the driver side of the vehicle at 31 mph, and in the roof strength test, the roof is crushed down 5 inches, with level of force (lbs) needed to perform the crush determining the strength of the roof.

In order to meet the safety standards of the NHTSA and IIHS, vehicle manufacturers design and test their models in a number of crash scenarios, including front, rear, and side impact, as well as roll over. The goal in designing the crash management systems of a car is not to prevent damage to the vehicle. Instead, the aim is to design the body structure to absorb or deflect energy as much as possible to protect the passenger compartment.

Figure 1 shows a Honda Pilot after a small overlap front crash test on the drive side. The Pilot model features a steel body construction, with an extruded aluminum bumper beam (the bright silver stripe at the front of the vehicle).2 As can clearly be seen, the crumple zone is significantly damaged. However, the driver compartment remained intact, keeping the passenger safe.

Within crash management, the vehicle is designed to ensure a load path that protects the passengers. Think of the force of a car hitting another vehicle from the side. In this case, the load path is designed so that the incoming vehicle first hits the rocker panel and the door in order to absorb and deflect energy around the body structure to prevent crushing the passenger compartment.

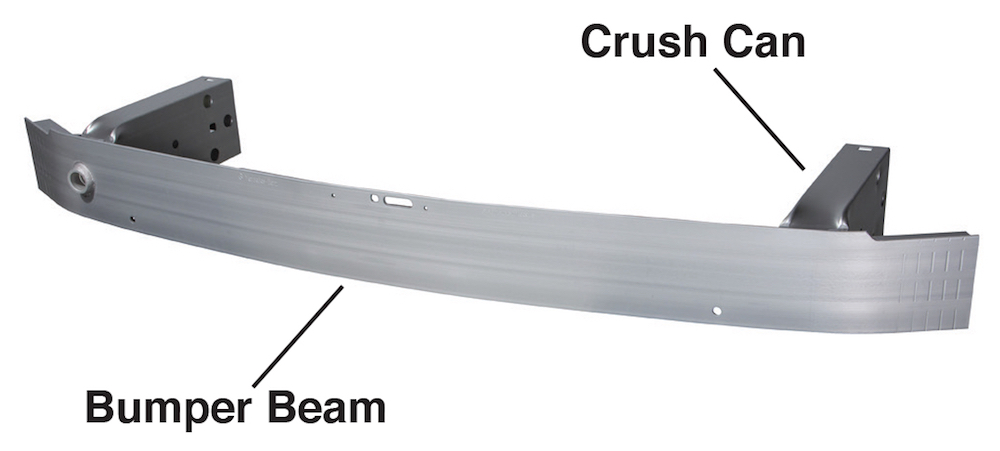

For the purposes of this article, the discussion will focus on front and rear crashes. The load path of a front or rear collision begins with contact at the fascia, which is an aesthetic plastic cover that offers little structural benefit. The energy absorption during a crash is handled by the bumper beam, and behind the beam, the crush cans (Figure 2). Beyond the crush cans, the crash energy is directed through the front rails, outside to the rocker, up the A-pillars, across the header, and then dissipates across the safety cage structure.

The bumper and crush cans are, therefore, the first line of defense to protect against impact from the front or rear of the vehicle. Since these components are positioned far from the center of gravity of the vehicle, it is advantageous to keep their weight as low as possible in order to ensure vehicle stability when driving and cornering.

Materials and Design

Extruded aluminum bumper systems are found on more than 50% of vehicles—from the older and economical Chevy Cruz to the newly designed 2021 Ford Mustang Mach-E electric car (Figure 3). Though the general shape varies from vehicle to vehicle, aluminum extruded bumper beams generally feature multiple hollows inside, a rectangular cross-section, and a curved shape from side to side (Figure 4). The versatility and value of extruded bumper beams is further recognized by their usage in vehicles across powertrains—both internal combustion engines (ICEs) and EVs—and in both steel and aluminum-intensive body structures. On a unit weight basis, aluminum alloys show higher energy absorption than steels of equivalent yield strength. Energy absorption can be further improved by increasing the gauge thickness. However, since that will also result in increasing the weight, a better approach is to select a material with a higher yield strength.4

Perhaps EVs are the most impressive bumper beam application in this regard, because the battery pack is large and crash sensitive, leaving less room to absorb energy. EVs also have a higher gross vehicle weight (around 450 kg more than a comparable ICE model), which means it can take longer for the car to slow during a collision. For example, the 2021 Ford Mustang Mach-E body is more than 90% steel. It is 36% heavier than the baseline Mustang and also has 10% less space in the crumple zone. With this in mind, Ford decided that the best solution for the front bumper system was extruded aluminum.5 This is a great sign of the future growth for aluminum extruded bumper beams, because even though Ford utilized high strength steels elsewhere in the vehicle, the OEM still chose aluminum extruded bumpers, proving that aluminum is effective for crash management despite the increased vehicle weight and reduced crush zone. In addition, the aluminum extruded bumper on the Mach-E was extended on both ends so that the car would achieve better IIHS ratings on the small overlap reinforced barrier (SORB) test.

A number of other steel-intensive vehicles have also selected aluminum extruded bumpers. In the body structure material listing on the Honda Pilot, the only aluminum listed is the bumper beam assembly.6 The same applies for the Acura RDX, which uses aluminum for its front and rear bumpers, as does the new Acura TLX sedan.

The Mach-E uses 6000 series aluminum for the front and rear bumper beams. The 6000 series alloys dominate most extruded applications because they bring a robust offering of performance, value, ease of processing, and competitive pricing across a large suite of manufacturers. Although 7000 series aluminum offers more weight reduction, the alloys are more difficult to manufacture and more expensive, with fewer suppliers. Most bumper beams are produced with 6061, 6082, and 6110 aluminum and have two to three hollows within their profile.

Behind the bumper beam, the crush cans are often welded or bolted to the beam. Proper alloy design in the crush can typically involves achieving a high yield strength along with reducing its cracking tendency.7 Upon impact, the crush can is deformed in a crumple effect, without cracking, and absorbs the crash energy so that the impact doesn’t go into the passenger’s body. The crumple effect is carefully engineered through the alloy design, grain structure, can shape, and by using crush-initiators, which are features, such as indents or holes, that initiate the accordion-like deformed shape (Figure 5). The 6063 aluminum alloy is by far the most popular, as it has a long history of success in crush cans. It is difficult for car companies to pivot from a working solution like this in exchange for a few grams of weight reduction that a stronger alloy may offer.

Market Opportunity

Aluminum extruded bumper beams and crush cans are popular in both ICE and EV models and have a bright future. Many vehicles from companies such as Honda, Toyota, Tesla, Kia, Hyundai, Chevy, and Stellantis (Jeep) use extruded bumper beams. Though EVs today have just 2% of the global market share, many industry experts predict they will continue to take over the ICE market share year-over-year.

Looking at the popular EVs in North America today, Tesla is by far the leader. The combined sales of the Model 3 and Model Y was just shy of 183,000 cars for the first quarter of 2021.8 Using this as a base rate, the combined Tesla sales for this year will likely be around 732,000 vehicles. At an estimated 2.8 kg per rear bumper beam, implementation of extruded bumpers on the Tesla models alone would represent around 2,000 tonnes of extruded aluminum. Even the smaller scale and more affordable Chevy Equinox, with annual sales exceeding only 270,000 vehicles per year, will keep extrusion plants buzzing all year with its use of an extruded bumper.

It is clear that extruded aluminum bumper beams and crush cans are proving to be the superior material of choice across the automotive sector—from mainstream to electric vehicles and from steel-intensive to mixed-material models. The future is bright for the extrusion business.

References

- “ADAS Advanced Driver Assistance Systems – Definition AUTO Connected Car,” Auto Connected Car News.

- “2019 Top Safety Pick: 2020 Honda Pilot,” IIHS.

- “Vehicle Ratings,” IIHS.

- “Crumple Zone,” Lightweight Composite Structures in Transport (Science Direct), 2016.

- Huetter, John, “Ford describes reworking crash protection to accommodate 2021 Mustang Mach-E battery,” Repairer Driven News, July 5, 2021.

- “2016 Honda Pilot Body Structure,” Boron Extrication, July 28, 2015.

- Parsons, N., J-F. Beland, and J. Fourmann, “Aluminum Extrusions for Automotive Crash Applications,” WCX™ 17: SAE World Congress Experience, Detroit, MI, April 2017.

- Dean, Grace, “Elon Musk predicts Tesla’s Model Y will ‘quite likely’ be the world’s best-selling car in 2022,” Business Insider, April 27, 2021.

Andrew Halonen is president of Mayflower Consulting, LLC, a lightweighting consultancy that provides strategic marketing, market research, and business development for high tech clients. Halonen works with castings, extrusions, brakes, and new material development programs. Contact him at: www.lightweighting.co.

Andrew Halonen is president of Mayflower Consulting, LLC, a lightweighting consultancy that provides strategic marketing, market research, and business development for high tech clients. Halonen works with castings, extrusions, brakes, and new material development programs. Contact him at: www.lightweighting.co.

Editor’s Note: This article first appeared in the October 2021 issue of Light Metal Age. To receive the current issue, please subscribe.