Cover

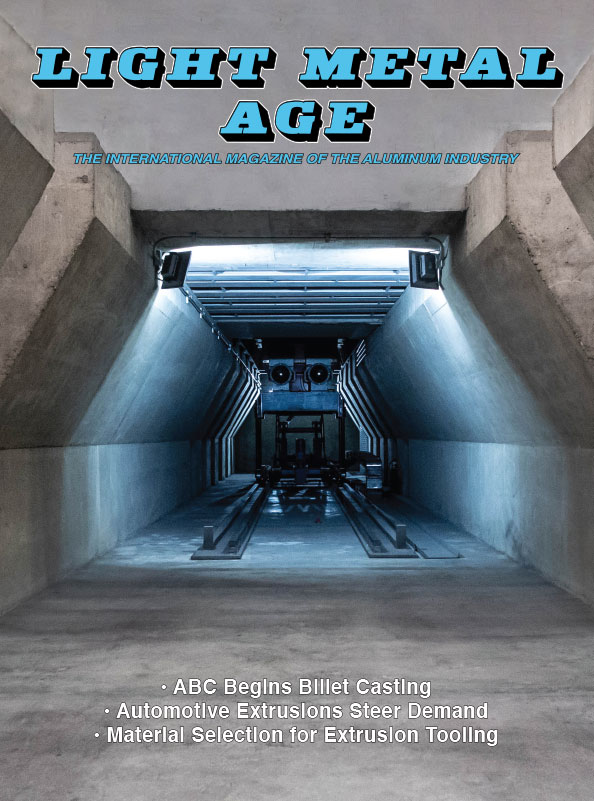

A magnetic stirring system installed within the double-chamber melting furnace at ABC Aluminum Solutions in Tijuana, Mexico. The company recently started operation of its new remelt and casting operation, which provides safe and environmentally friendly recycling of various scrap grades for the production of high quality billet. This billet is supplied to its nearby extrusion facility. See story on page 6.

Articles

ABC Reshapes Its Manufacturing Landscape with New Billet Casting Capabilities

By Andrea Svendsen

Page 6

Aluminum Extrusions Prove Superior in Bumper Systems

By Andrew Halonen

Page 14

Development of Extruded Battery Enclosures for Ultra-Low Emission Vehicles

By Z. Li, et al.

Page 18

Addressing Aluminum Melt Quality – Part I: Methods of Analyzing Alloy Composition and Inclusions

By John Grandfield and Corleen Chesonis

Page 20

The Effect of Die Design on Billet Skin Contamination

By Tommaso Pinter

Page 26

Material Selection for Extrusion Tooling: Maximum Longevity, Improved Productivity, and Lower Cost

By Yahya Mahmoodkhani and Paul Robbins

Page 30

Common Surface Defects on Anodized Aluminum and How to Avoid Them

By Dr. Anne Deacon Juhl

Page 34

Aluminum Steers Automakers in the Right Direction

Page 38

Preventing Amputations in Aluminum Manufacturing

By Alex Lowery

Page 42

Auto Supplier Installs Closed-Die Forging Line

Page 43

Press Maintenance Manual Becomes a Living Document in Online Format

Page 44