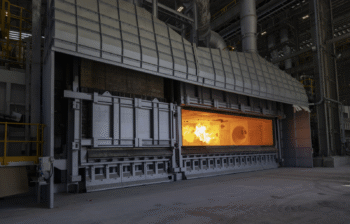

Emirates Global Aluminium (EGA) achieved a major milestone in the construction of its aluminum recycling plant under construction at Al Taweelah. The giant melting furnace at the plant has been charged with scrap metal for the first time. “Aluminum’s infinite recyclability is a key reason our metal is an essential material for the development of […]