Hydro is investing US$20 million in Verdox, a spin-off of the Massachusetts Institute of Technology (MIT), which is commercializing an all-electric carbon capture technology. The new technology will be applicable for capturing emissions from both aluminum production and directly from the air. It will be utilized at Hydro’s aluminum smelters to reduce their overall carbon footprint.

Aluminum is a crucial material in the green transition, and demand is expected to grow by about 70% by 2050, according to the International Aluminium Institute (IAI). At the same time, the primary aluminum industry is challenged to reduce its carbon footprint in order to align with customers that are becoming more sustainability conscious. Therefore, capturing the CO2 emissions from hard-to abate industrial sectors, including aluminum, is crucial to reach international goals, such as the Paris agreement 1.5 degree target.

“Hydro’s roadmap to zero-carbon aluminum production includes solutions both for existing and new aluminum capacity,” noted Eivind Kallevik, executive vice President of Aluminium Metal in Hydro.. “Carbon capture such as the Verdox technology will ensure the continued competitiveness of our existing smelters, whereas our groundbreaking new process technology, HalZero, will be developed for new capacity. In this way, we increase our chances of delivering on our climate ambitions and taking the lead in the aluminum industry.”

The Carbon Capture Technology

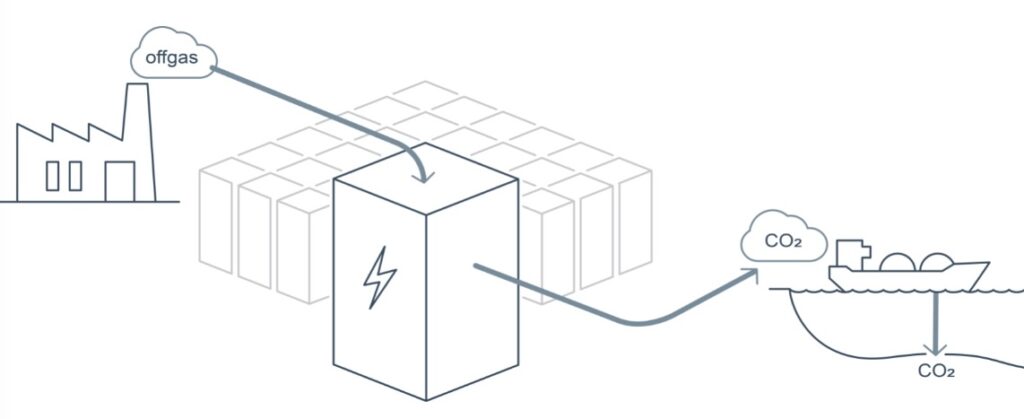

After developing the new carbon capture technology in 2019, a group of engineers at MIT decided to set up Verdox as a separate company in order to commercialize the process. The technology is able to capture carbon emissions both from industrial off-gas and directly from air.

Most carbon capture technologies have been developed for capturing the off-gas from fossil power production and industries with higher concentrations of CO2, typically above 4%. The off-gas in aluminum smelters has a relatively low concentration of CO2 at around 1%.

Hydro’s studies have shown that capturing CO2 directly from the off-gas can eliminate most of the direct emissions from the aluminum smelting process. The remaining emissions can be removed through a direct air capture system connected to the plant.

“Hydro has assessed more than 50 carbon-capture technologies and found very few that we expect will be applicable for aluminum production,” said Kallevik. “Verdox’s technology has the advantage of being able to capture CO2 at very low concentrations both from industrial off-gas and directly from air.”

Hydro entered into a collaboration with Verdox in early 2021. Since then, the carbon capture technology has been tested to assess its applicability to capturing the CO2 in the off-gas from Hydro’s primary aluminum smelters. Early results have been very promising.

Under their cooperation, the Verdox carbon capture technology will be used to capture the CO2 in industrial off-gas from Hydro’s aluminum smelters via electro swing adsorption, making the CO2 available for storage. Where other carbon capture solutions rely on thermal, pressure, or heating and cooling of liquid substances, Verdox’s technology is fully electric, enabling the system to run entirely on renewable energy and avoid further emissions.

The next phase of collaboration includes testing and piloting of the technology at Hydro’s aluminum smelters with the goal of reaching industrial scale by 2030. Following the investment, Hydro will be a minority owner of Verdox.