Researchers at the Pacific Northwest National Laboratory (PNNL) have developed and successfully tested a novel process — called friction stir dovetailing — that joins thick plates of aluminum to steel. The new process will be used to make lighter-weight military vehicles that are more agile and fuel efficient.

According to the U.S. Government Accountability Office, the military spends several billion dollars each year on fuel consumption, which could be reduced by lightening the weight of ships, aircraft, ground vehicles, and cargo. To lower fuel costs and increase operational effectiveness while still maintaining the safety of military personnel, the U.S. Army Tank Automotive Research Development and Engineering Center (TARDEC) launched a campaign in 2014 seeking ways to make combat systems — such as tanks, fighting vehicles, and personnel carriers — more lightweight. One approach they are investigating is the replacement of heavy steel components with thicker, yet lighter, aluminum. However, aluminum and steel cannot be welded together due to vastly different melting points and risk of galvanic corrosion, so they sought a new process to join these materials.

In order to address this challenge, TARDEC joined forces with PNNL (which had previously developed unique material joining techniques for the automotive industry) to develop the new process friction stir dovetailing. These previous techniques combined friction stir welding (for join similar metals of differing thickness) and friction stir scribe (which joins thin sheets of significantly different materials, like aluminum and steel). While friction stir scribe solved the challenge of joining thin sheets of aluminum with steel, that technique was found to not scale up to the thick plates of aluminum needed for robust military vehicles.

Friction Stir Dovetailing

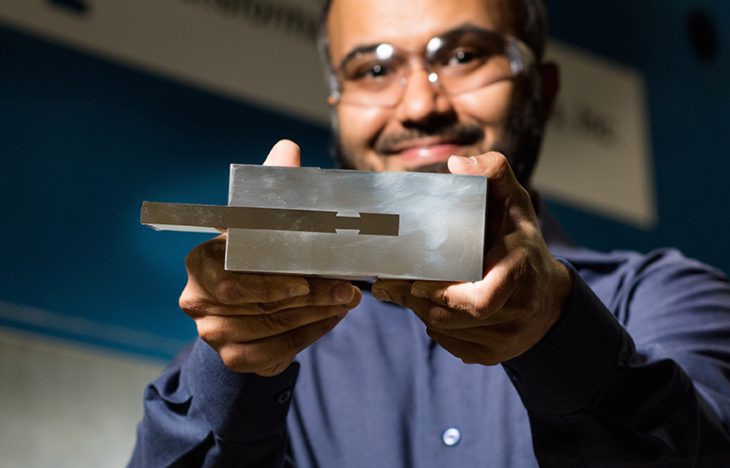

Friction stir dovetailing uses a similar approach to the dovetails and glue used to securely join pieces of wood together in woodworking. Using a specially designed tool, aluminum is deformed into a steel dovetail groove to form a mechanical interlock. At the same time, the tool rubs along the bottom of the dovetail to form a thin metallurgical bond — or intermetallic compound — which “glues” the metals together within the dovetail. “The combination of mechanical interlocking and metallurgical bonding formed during a single process is the innovation that produces joints of superior strength and ductility compared to joints created by the other friction stir methods,” said Scott Whalen, the PNNL engineer who led the research.

The research team discovered that using complex machine controls to precisely regulate temperature and pressure at the aluminum-steel interface inhibited growth of intermetallic compounds, which would grow thick and non-uniformly during the other friction stir techniques, causing joint brittleness and failure. However, growth of intermetallic compounds — iron aluminide or Fe3Al — during the friction stir dovetailing technique is beneficial to the joint because they are so thin, one thousand times thinner than a human hair, enabling a strong bond without causing embrittlement.

“Intermetallic compounds will form between aluminum and steel during all friction stir techniques as part of the heating process,” said Whalen. “We discovered that friction stir dovetailing inhibits intermetallic compound overgrowth because temperature and pressure are much lower than other friction stir approaches.”

Lab testing of joints made by friction stir dovetailing showed that when combining metallurgical bonding with the dovetail configuration, the joint strength is superior. In addition, the material can stretch to over a half centimeter before the joint break, illustrating five times more ductility than aluminum and steel joined with other friction stir techniques — an attractive feature for military combat vehicles.

“We are constantly looking for innovative multi-material joining methods to help us select the right material for the right purpose in the right location, and friction stir dovetailing offers us precisely such a state-of-the-art method,” said Jason Middleton, TARDEC associate director for Product Lifecycle Engineering.

The research team now plans to refine the technique and expand the process for other joint configurations. In addition to aluminum and steel, other material combinations such as aluminum to copper, aluminum to magnesium, and magnesium to steel can also be joined using friction stir dovetailing. In addition to helping to solve the fuel consumption challenge for TARDEC, it is available for licensing for other potential applications as well as collaborative research opportunities with PNNL.

More details about this process can be found in “Joining Thick Section Aluminum to Steel with Suppressed FeAl Intermetallic Formation via Friction Stir Dovetailing,” Scripta Materialia, Vol. 148, 2018, DOI: 10.1016/j.scriptamat.2018.01.026.