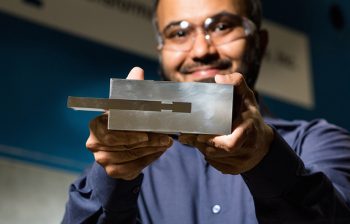

Atomic13, a startup launched by Eric Donsky, signed an exclusive agreement with the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) to commercialize the patented Shear Assisted Processing and Extrusion Process (ShAPE™) technology, which can transform 100% post-consumer scrap aluminum into high quality extrusions. The new company aims to create a range of custom […]